For over 15 years, Shaoyi has been helping automakers and suppliers bring ideas to life.

Get a QuoteUpload your drawings or share your custom requirements, and receive a personalized quote tailored just for you!

High-precision stamping for chassis and structural parts, ensuring consistent dimensions in high-volume production.

Complex components machined to ±0.01mm tolerance, meeting strict automotive standards.

Lightweight, high-strength aluminum parts with excellent surface finish, ideal for chassis and structural applications.

Precision welding assemblies that guarantee strength and alignment for chassis and structural components.

Custom automotive stamping dies built with rigorous quality control and expert craftsmanship, optimized for reliable, high-volume production.

High-strength cold-formed parts with precise dimensions, perfect for suspension and structural applications.

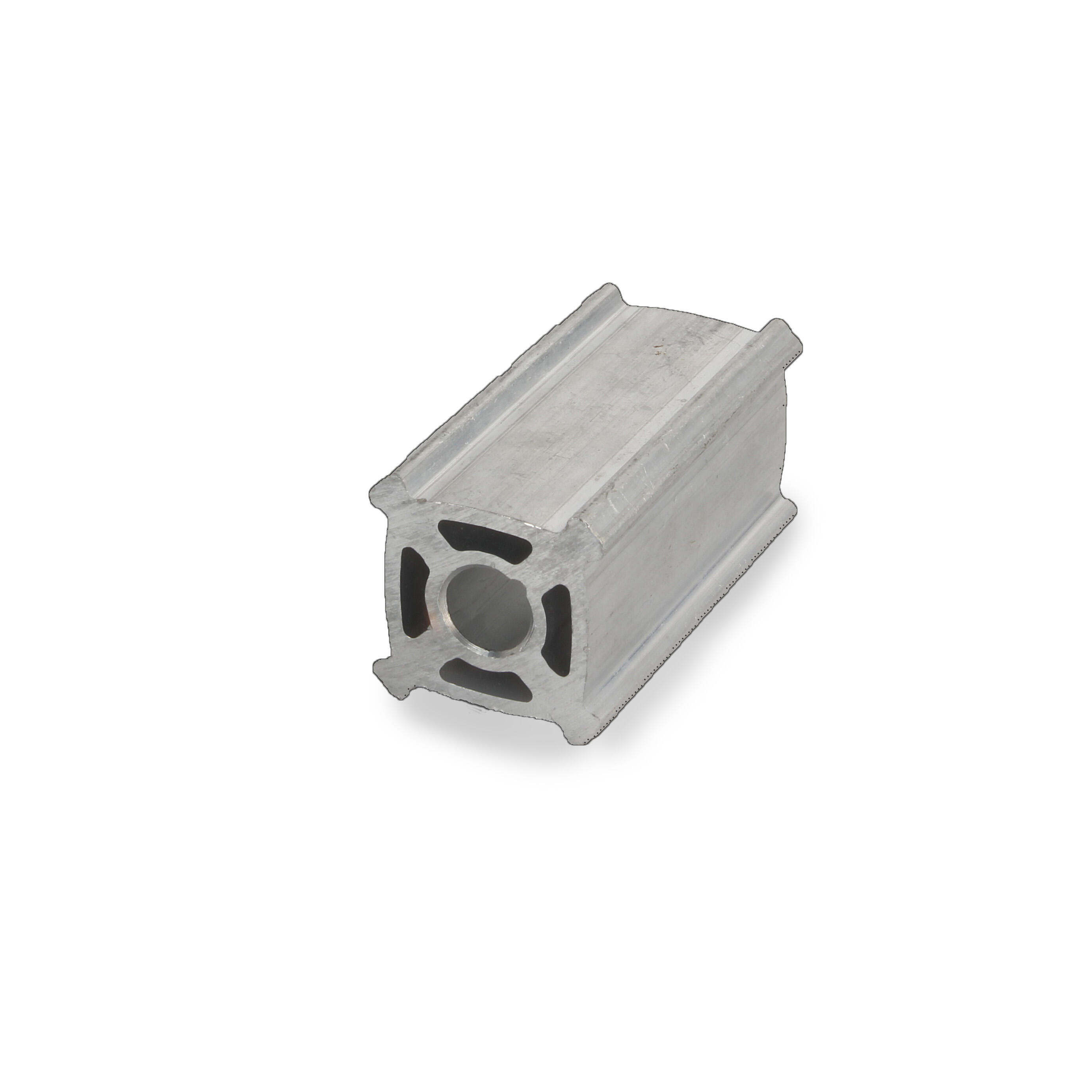

Custom aluminum profiles designed for strength, lightweight, and high-stress automotive structures.

Durable metal bushings engineered for chassis and suspension systems, enhancing wear resistance and longevity.

We provide end-to-end automotive metal part solutions – from custom stamping, CNC machining, surface finishing, to welding and assembly – delivering high precision, consistent quality, and fast turnaround for OEMs and Tier 1 suppliers

Different product usage scenarios have different surface requirements, such as rust prevention, aesthetics, and roughness requirements, etc.

Provides enhanced corrosion resistance and better paint adhesion for durable performance.

This finish enhances mild corrosion resistance and reduces light reflection, making it ideal for automotive parts that require a matte, anti-glare finish.

Delivers excellent coating adhesion with stable, consistent quality.

This finish creates a smooth, even surface with excellent bonding strength, making it widely applied to metal housings, frames, and automotive parts.

This coating improves surface hardness and enhances color durability, making it ideal for decorative and protective applications on automotive components.

Commonly used for automotive fasteners, brackets, and chassis parts, this process produces a consistent, protective zinc layer across all components.

Enhances conductivity and acts as an underlayer for other coatings.

Improves hardness, corrosion resistance, and wear performance.

This finish provides stable, eco-friendly protection with high consistency and is commonly used for automotive chassis, fasteners, and brake systems.

An electrochemical process that forms a controlled oxide film on aluminum, providing excellent corrosion resistance, electrical insulation, and decorative finishes in diverse colors.

No matter where you are, simply send your design or idea—we’ll handle the rest.

Get a Quote

All bushing core products will undergo 100% dimensional inspection

Using a variety of processing techniques, it is used in automobile air conditioning metal brackets

Made by precision stamping to achieve the strength and accuracy required for suspension safety

Heavy-duty stamping process with 9mm steel plate, delivering durability and load-bearing capacity.

Machined with CNC for precise weight control, ensuring smooth vehicle balance.

Manufactured with robotic welding and multiple processes, offering consistency and reliability in high-volume production.

Produced by turning to ensure accurate threading and perfect fit with mating components.

Assembled with automated press-fit technology, combining multiple steps into one efficient process.

Stamped and then coated with electrophoresis, giving it excellent rust protection and long service life.

Produced through multi-stage stamping with CAE validation to guarantee structural stability for passenger cars.

A robust welded assembly tailored for medium-sized buses, supporting air conditioning compressors with durability.

A combination of CNC machining and welding, providing both strength and dimensional accuracy.

We implement rigorous quality control protocols to ensure that every Forging parts consistently meets the exacting size and performance specifications demanded by our clients.

Our unwavering commitment to quality, bolstered by IATF 16949 certification, underpins our stringent quality control at every stage of production. This meticulous approach enables us to deliver superior forging automobile parts—from initial design to final delivery—ensuring exceptional performance, reliability, and long-term durability.

Leveraging state-of-the-art production and inspection equipment for hot forging, we ensure that every forging automobile part is produced with unmatched precision and consistency. Our advanced machinery, combined with automated quality checks, maintains strict tolerances and optimizes performance throughout the manufacturing process, resulting in components that deliver exceptional durability and reliability.

Our team of seasoned experts brings decades of experience in hot forging, specializing in forging parts of automobile. Their deep technical knowledge and commitment to innovation ensure that every component is engineered to meet the highest industry standards. By integrating advanced technology with proven expertise, our team consistently delivers high-quality, reliable parts that drive automotive performance and safety.

Yes, we provide fully customized solutions and are equipped to handle both prototyping and small to large batch production. Every project is tailored to meet your specific requirements.

Our quality management system is IATF 16949 certified. We perform in-process inspections, CAE simulations, and final quality checks to ensure every part meets strict automotive industry standards.

Lead time depends on the part complexity and required processes. Our rapid prototyping service can deliver samples within 7 days, while standard production schedules are planned to meet your project timeline efficiently.

We assign a dedicated project manager to each client. You will receive regular updates on production status, quality checks, and shipment schedules, ensuring full transparency and accurate timelines.

We can prioritize urgent projects by optimizing scheduling and production workflow. Our one-stop service allows faster prototyping and mass production while maintaining high precision and quality.

Yes, we offer rapid prototyping services using stamping, CNC machining, and die-casting, allowing you to test and validate designs before full-scale production.

Our engineers evaluate your requirements and recommend the most suitable metals and alloys, considering strength, weight, corrosion resistance, and cost efficiency.

We use advanced quality control tools, in-process inspections, and CAE simulations to maintain uniformity and ensure every part meets strict automotive standards.

Yes, we coordinate packaging, labeling, and shipping to North America, Europe, the Middle East, and Southeast Asia, ensuring safe and timely delivery worldwide.

After years of development, the company's welding technology mainly includes gas shielded welding, arc welding, laser welding and kinds of welding technologies, combined with automatic assemble lines, through Ultrasonic Testing (UT), Radiographic Testing(RT), Magnetic particle Testing(MT) Penetrant Testing(PT), Eddy Current Testing(ET), Pull-off force of testing, to achieve high capacity, high quality and safer welding assemblies, we could supply CAE, MOLDING and 24-hour quick quotation to provide customers with better service for chassis stamping parts and machining parts.