Join Shaoyi Metal Technology at EQUIP AUTO 2025: Discover the Future of Automotive Precision

It's Official: Shaoyi Technology at EQUIP AUTO 2025 in Paris!

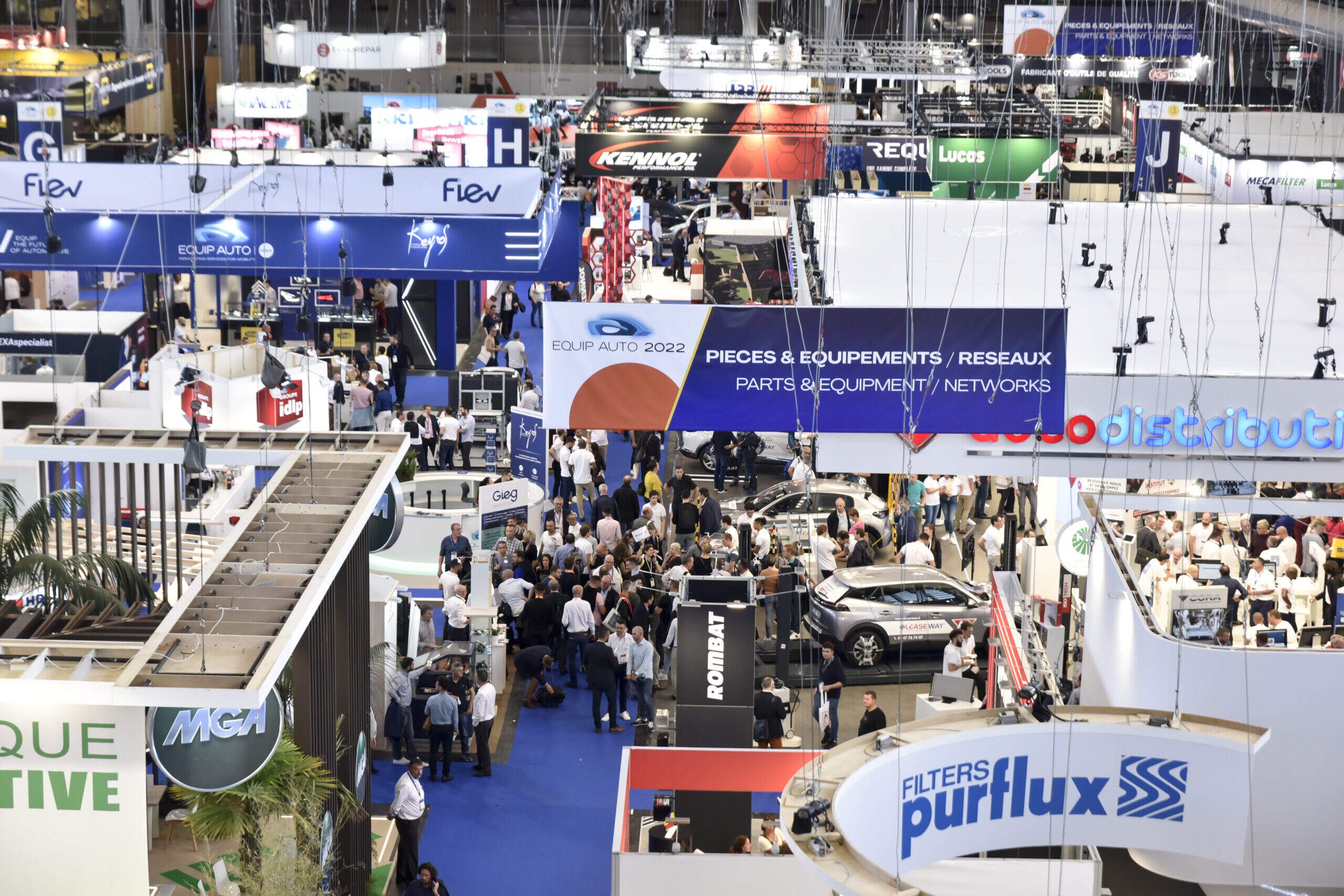

Have you ever wondered where the future of automotive precision is headed? If you’re following the latest trends in the industry, you’ll know that EQUIP AUTO Paris 2025 is the place where global innovation and expertise converge. This year, Shaoyi (Ningbo) Metal Technology Co., Ltd. is proud to announce our participation in this landmark event—a key moment for anyone invested in the next generation of automotive technology.

As a technology-driven precision automotive components manufacturer, Shaoyi Technology is set to join more than 1,400 exhibitors from across the world at the Paris automotive parts trade show. EQUIP AUTO 2025 isn’t just another exhibition. It’s a dynamic crossroads where suppliers, distributors, and automotive professionals gather to explore new solutions, exchange insights, and shape the future of mobility together. With over 100,000 square meters of exhibition space and representation from every segment of the automotive value chain, this event is recognized as a must-attend for industry leaders and innovators alike (EQUIP AUTO Paris 2025).

Why is this such a pivotal moment for Shaoyi Technology? Imagine a single supplier capable of delivering everything from high-precision, lightweight chassis parts to fully integrated solutions for new energy vehicles (NEVs). At EQUIP AUTO 2025, we will showcase our latest advancements in machining, stamping, and assembly—demonstrating how our expertise supports the evolving demands of global automakers and aftermarket specialists.

- Comprehensive Capabilities: From initial design to mass production, Shaoyi Technology leverages advanced machining and stamping technologies to supply critical automotive components with tight tolerances and consistent quality (Shaoyi Metal Technology).

- Innovation for NEVs: As the industry pivots toward electrification and lightweighting, our portfolio includes specialized new energy vehicle part solutions—think battery enclosures, powertrain structures, and custom aluminum extrusions engineered for performance and sustainability.

- Trusted by Top Brands: Our end-to-end approach and commitment to quality have earned us a reputation as a reliable partner for leading automotive brands worldwide.

Attending EQUIP AUTO 2025 gives you the unique opportunity to see firsthand how Shaoyi Technology is pushing the boundaries of precision manufacturing. Whether you’re interested in advanced chassis components, innovative NEV solutions, or integrated manufacturing services, our team will be ready to share our latest breakthroughs and insights.

Stay tuned for more details on our booth location, featured technologies, and how you can connect with our engineering experts during the event. EQUIP AUTO 2025 is your chance to experience the next level of automotive precision—don’t miss it!

Highlight #1: Get a First Look at Our Core Product Lines

When you step onto the show floor at EQUIP AUTO 2025, what kind of innovations will truly stand out? Imagine discovering components that not only push the boundaries of performance but also set new standards for reliability and precision. At Shaoyi Technology’s booth, you’ll notice a carefully curated display of our most advanced automotive metal solutions—each engineered for the next generation of vehicles and trusted by leading automakers worldwide.

Stamped Parts for Automotive Chassis: Precision and Reliability

At first glance, stamping may look simple—but in reality, it’s a highly engineered process that defines the strength, safety, and efficiency of modern vehicles. Automotive chassis systems today must balance durability, lightweighting, and cost-effectiveness, especially under the pressure of electrification and stringent safety regulations. Shaoyi’s stamped chassis parts are produced using advanced tooling, progressive dies, and high-strength sheet metals. This ensures every component meets exacting performance requirements while keeping vehicles lighter and more efficient. Our stamping expertise delivers:

-

High repeatability and accuracy across large production volumes

-

Excellent formability to achieve complex geometries with reduced waste

-

Tight dimensional tolerances for smooth assembly and interchangeability

-

Material flexibility to support OEM-specific requirements in steel and aluminum

These stamped parts are already supporting global automotive brands in building safer, lighter, and more sustainable vehicles.

Aluminum Die-Cast Parts for Automotive Chassis: Lightweight Strength at Scale

In today’s automotive industry, reducing vehicle weight without compromising safety is a top priority—especially with the rapid growth of electric and hybrid vehicles. Aluminum die-cast parts play a crucial role in this shift. By combining lightweight properties with excellent mechanical strength, die casting enables the production of complex chassis components that meet both performance and efficiency demands.

Shaoyi’s aluminum die-cast parts are engineered with advanced tooling and precise process control, ensuring:

-

High dimensional accuracy for seamless assembly into critical chassis systems

-

Excellent strength-to-weight ratio, reducing overall vehicle mass while maintaining durability

-

Complex geometry capability, making it possible to design integrated multi-functional parts

-

Superior consistency across large production volumes, meeting global OEM quality standards

These components are already helping automakers worldwide build safer, lighter, and more energy-efficient vehicles.

Lightweight Aluminum Extrusions for EVs and NEVs

As the market for new energy vehicles (NEVs) surges—driven by stricter emissions rules and consumer demand for efficiency—the need for lightweight, high-strength components has never been greater. Shaoyi’s lightweight aluminum extrusions for EVs are engineered to meet these exacting demands. Used in powertrain frames, battery enclosures, and control system housings, these extrusions offer:

- Superior strength-to-weight ratio, improving vehicle range and performance

- Corrosion resistance for long-term reliability

- Precision tolerances for integration with advanced sensor and electronics systems

Our aluminum extrusion capabilities are backed by over a decade of experience and a commitment to quality that aligns with the world’s most demanding automotive brands (Shaoyi Automotive Aluminum Extrusions).

High-Precision Stamping Dies and Custom Metal Bushings

Ever wondered how automakers achieve such tight fits and flawless finishes in their vehicles? The answer lies in high-precision automotive stamping dies and custom automotive metal bushings. Shaoyi’s dies are designed and manufactured in-house, using advanced CAE simulation to optimize every feature before production begins. This approach minimizes tooling errors and maximizes part consistency, supporting everything from prototype runs to high-volume mass production.

Our custom metal bushings are another highlight, engineered to deliver low-friction, high-durability solutions for suspension, steering, and powertrain systems. Each bushing is tailored to the specific needs of our clients, ensuring optimal fit and function in even the most challenging applications.

Meeting the Standards of Leading Global OEMs

What sets these product lines apart? It’s our relentless focus on quality and our proven track record with global leaders like VW, GM, BYD, and NIO. Every part is manufactured under a stringent IATF 16949-certified quality management system, ensuring that each component not only meets but exceeds industry standards for performance and reliability.

By integrating forging, extrusion, stamping, and machining under one roof, Shaoyi provides a one-stop solution for automotive manufacturers seeking efficiency, innovation, and peace of mind. In the next section, we’ll explore how our advanced manufacturing technologies further elevate these products—so you can see why Shaoyi is a partner of choice for the future of mobility.

Highlight #2: A Deep Dive into Our Smart Manufacturing Power

What Makes an IATF 16949 Certified Auto Parts Manufacturer Stand Out?

When you think about the backbone of modern automotive manufacturing, what comes to mind? Is it cutting-edge machinery, digital management, or relentless quality control? At Shaoyi Technology, it’s all three—woven into a seamless system that ensures every part meets the highest industry standards and customer expectations.

- Smart Digital Management: Imagine tracking every stage of production in real time. Shaoyi’s robust ERP (Enterprise Resource Planning) and PLM (Product Lifecycle Management) systems do just that. These digital tools enable precise scheduling, resource allocation, and traceability from the first engineering drawing to the final product shipment. This level of transparency not only streamlines workflows but also minimizes errors, ensuring on-time delivery for every order.

- Automated Automotive Production Lines: Picture a factory floor where automation and robotics handle everything from machining to inspection. Shaoyi’s fully automated production lines are designed for efficiency, consistency, and scalability. Automated cells reduce human error and deliver repeatable results, whether producing a single prototype or thousands of components for global OEMs. This commitment to automation means faster turnaround, higher throughput, and lower costs for our partners.

- Precision Machining Technology: Precision isn’t just a buzzword—it’s a promise. With over 12 years of experience in mechanical processing, Shaoyi has mastered the art of tight tolerances and flawless finishes. Advanced CNC machining centers and in-house mold development ensure that every part matches the exact specifications required by today’s automotive leaders. Consistency in quality and process is our hallmark (Shaoyi Automotive Industry News).

Advanced Welding and Comprehensive Non-Destructive Testing

Sounds complex? It’s essential for safety-critical assemblies. Shaoyi’s welding technology covers gas-shielded welding, arc welding, and laser welding, all integrated with automatic assembly lines. But how do we make sure every weld is safe and reliable? The answer is rigorous non-destructive testing (NDT):

- Ultrasonic Testing (UT) for internal flaw detection

- Radiographic Testing (RT) using advanced digital X-ray and CT for safety-critical parts

- Magnetic Particle Testing (MT) and Penetrant Testing (PT) for surface crack detection

- Eddy Current Testing (ET) for hardness and surface defect checks

- Pull-off Force Testing to verify weld strength

These methods are not just about compliance—they drive sustainability by reducing waste, lowering costs, and enabling rapid, accurate inspections at every stage of production (Waygate Technologies).

Quality Management: The Value of IATF 16949 Certification

Why does IATF 16949 certification matter? For automotive procurement managers and engineers, it’s a global benchmark of quality, reliability, and process control. This certification proves that Shaoyi’s systems are independently verified, recognized throughout the automotive supply chain, and trusted by top brands. It also means you benefit from:

| Benefit | Impact |

|---|---|

| Consistent quality approach | Every part meets rigorous, repeatable standards |

| Reduced operating costs | Efficiencies and automation cut waste and save money |

| Faster time-to-market | Digital management and rapid prototyping accelerate delivery |

| Global recognition | Certification opens doors with leading automotive OEMs |

Want to see how this all comes together? At EQUIP AUTO 2025, you’ll get a firsthand look at our CAE analysis and mold development process. Our engineers use advanced simulation tools to validate designs before production, minimizing risk and ensuring a smooth transition from concept to reality. This proactive approach is what sets Shaoyi apart as a partner who does more than just make parts—we deliver strategic, risk-mitigating solutions for the world’s most demanding automotive projects.

Curious how our engineering expertise can support your next project? In the following section, we’ll show you how to connect directly with our R&D team for personalized technical consultations and rapid-response services—so you’re always a step ahead in the race for automotive innovation.

Highlight #3: Connect One-on-One with Our Engineering Experts

Your Direct Line to Automotive Innovation: Meet Our R&D and Engineering Team

Ever wished you could sit down with the minds behind the world’s most precise automotive components? At EQUIP AUTO 2025, that’s exactly what you’ll get. Shaoyi Technology’s booth isn’t just a product showcase—it’s a live hub for technical exchange, where you can engage directly with our expert team in automotive component project management, CAE analysis, and mold development. Imagine bringing your toughest engineering challenge or next-gen concept and leaving with actionable insights and a clear path to production.

- Automotive Structural Design Consulting: Our specialists are ready to discuss your design—whether it’s a new chassis, battery enclosure, or custom bushing. Using advanced CAE tools, we simulate metal flow, stress, and potential defects before any steel is cut, helping you optimize for manufacturability, cost, and reliability (Shaoyi CAE & Die Design Process).

- Project Management from Concept to Mass Production: With 17 years of experience in PLM-based workflows, our project managers guide you through every stage—from initial DFM (Design for Manufacturability) feedback to final delivery. You’ll benefit from transparent timelines, proactive risk mitigation, and seamless communication at every milestone.

- End-to-End Mold and Tooling Expertise: Need a rapid turnaround? Our in-house mold development team leverages simulation, precision machining, and iterative prototyping to ensure your tooling is right the first time—reducing costly rework and speeding up your launch.

Rapid Prototyping and 24-Hour Quotes: Speed Meets Precision

When you’re racing against the clock, every day counts. That’s why Shaoyi offers rapid prototyping services for auto parts, delivering functional samples in as little as a few days. Whether you need a handful of parts for testing or a small batch for market validation, our flexible approach covers:

- CNC Machining: Ideal for high-fidelity, functional prototypes that match production-grade materials and tolerances.

- Vacuum Casting & 3D Printing: Perfect for complex geometries, quick design iterations, and low-volume production runs.

- Rapid Tooling: Accelerates the transition from prototype to mass production by delivering soft tooling in record time.

But speed is nothing without clarity. Need to get a 24-hour manufacturing quote? Our proprietary digital quoting system ensures you receive a detailed, accurate estimate fast—so you can plan, budget, and move forward with confidence.

Why Personal Consultation Matters at EQUIP AUTO

Sounds like a lot? It’s actually simple: direct access to Shaoyi’s engineering experts means you’re not just another client—you’re a partner. Here’s what you can expect during your visit:

| Consultation Topic | Benefit |

|---|---|

| Design Feasibility & Optimization | Identify risks and opportunities early, saving time and cost |

| Process Simulation & CAE Analysis | Validate manufacturability before investing in tooling |

| Prototype Review & Iteration | Accelerate development cycles with rapid feedback |

| Production Planning | Get clear timelines and supply chain transparency |

Whether you’re an OEM engineer, procurement manager, or startup innovator, this one-on-one access empowers you to make smarter, faster decisions. And if you’re ready to move from concept to reality, our rapid-response team ensures you never lose momentum.

Curious how to take the next step? In the final section, we’ll share all the details you need to plan your visit to EQUIP AUTO 2025 and connect with Shaoyi’s team for a personalized consultation—so you can experience the future of automotive precision firsthand.

Find Us at EQUIP AUTO Paris 2025 Hall 2.2 | Stand D1

Wondering how to make the most out of your trip to one of the world’s leading automotive trade shows? Planning ahead is key—especially when EQUIP AUTO Paris 2025 promises a packed agenda, cutting-edge exhibits, and countless networking opportunities. Here’s your essential guide to joining Shaoyi Technology at this milestone event.

Key Details at a Glance

- Event Name: EQUIP AUTO Paris 2025

- Dates: October 14–18, 2025

- Location: Paris Expo Porte de Versailles, 1 place de la Porte de Versailles, 75015 Paris, France

- Booth: Hall 2.2 | Stand D1 (Look for Shaoyi Technology in the main exhibition area)

With more than 1,400 exhibitors and 100,000 professionals expected, this 50th anniversary edition is set to be EQUIP AUTO’s largest and most international yet (EQUIP AUTO Paris 2025 Press Kit). The show covers 100,000 square meters across five pavilions, featuring 14 sectors of activity and eight theme villages—from Tech and Energy to Circular Economy and Talent. Whether you’re seeking the latest in digital transformation, sustainable mobility, or next-generation vehicle components, you’ll find it all under one roof.

How to Book a Meeting at EQUIP AUTO

Ready to discuss your automotive project or explore Shaoyi’s capabilities in detail? Here’s how you can connect with our team for a personalized, one-on-one consultation at EQUIP AUTO Paris 2025 Hall 2.2 | Stand D1 :

- Pre-book Your Meeting: Secure a dedicated time slot by emailing us directly. This ensures you receive focused attention and tailored technical advice—no waiting in line or missed opportunities. (For Shaoyi Technology contact information and inquiry forms, visit our official contact page.)

- Request a Quote for Automotive Parts: If you have specific requirements or want to compare solutions, submit your project details in advance. Our rapid-response team can provide a 24-hour quote, so you arrive at the show with clear options in hand.

Pro tip: Early booking helps us prepare relevant samples, technical documentation, and the right specialists for your consultation—making your visit both productive and efficient.

Stay Connected for Live Updates and Insights

Want to keep up with the latest announcements, live demos, and behind-the-scenes moments during the show? Follow Shaoyi Technology on our official social media channels for real-time updates, interviews, and highlights from EQUIP AUTO Paris 2025. You’ll get a front-row seat to new product launches, expert talks, and industry trends as they unfold.

- Follow us on LinkedIn, Twitter, and WeChat for live event coverage and exclusive content.

- Use the hashtag #equipauto to join the conversation and network with other attendees.

Checklist: Before You Arrive

| Action | Benefit |

|---|---|

| Book meeting at EQUIP AUTO | Guarantee time with our experts and avoid queues |

| Request a quote for automotive parts | Receive tailored solutions and pricing before the show |

| Download event map and schedule | Plan your visit efficiently and maximize your experience |

| Connect on social media | Stay informed and engage with the EQUIP AUTO community |

By planning your visit and connecting with Shaoyi Technology at EQUIP AUTO Paris 2025 Hall 2.2 | Stand D1, you’ll unlock direct access to engineering expertise, innovative solutions, and the future of automotive precision. Don’t leave your agenda to chance—reach out today to reserve your spot and make the most of this landmark industry event.

Frequently Asked Questions about Shaoyi at EQUIP AUTO 2025

1. What products will Shaoyi Technology showcase at EQUIP AUTO 2025?

Shaoyi Technology will showcase advanced automotive metal solutions, including high-precision stamped chassis parts, durable stamping brackets, welded assemblies for vehicle structures, aluminum extrusion bushings for vibration damping, and lightweight aluminum die-cast components for chassis systems. Every product is engineered to meet the rigorous standards of leading global automakers.

2. How does Shaoyi ensure the quality of its automotive components?

Shaoyi operates under IATF 16949-certified quality management, employs smart digital management systems like ERP and PLM, and utilizes automated production and rigorous non-destructive testing to guarantee reliability and performance for every component.

3. Can visitors consult directly with Shaoyi’s engineering experts at EQUIP AUTO 2025?

Yes, visitors can meet Shaoyi’s R&D and engineering teams for in-depth technical consultations, including structural design, CAE analysis, and project management. Rapid prototyping and 24-hour quoting services are also available for prospective clients.

4. How can I book a meeting with Shaoyi Technology during EQUIP AUTO Paris 2025?

To secure a dedicated consultation at Hall 2.2 | Stand D1, visitors can pre-book a meeting by contacting Shaoyi via their official website or email. Early booking ensures personalized attention and tailored technical support during the show.

5. What makes Shaoyi a preferred partner for automotive manufacturers?

Shaoyi offers a one-stop manufacturing solution with in-house capabilities for die-cast, stamping, machining, and assembly. Their CAE-driven approach, certified quality, and track record with global OEMs help clients reduce costs, accelerate timelines, and minimize risk.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —