Why Most Auto Parts Stamping Fails & How to Succeed

The Core of Automotive Manufacturing

What is Auto Parts Stamping?

Ever wondered how a car’s body panels, brackets, or engine mounts are made with such precision and consistency? The answer lies in a process called auto parts stamping. To define stamping in this context, it’s a manufacturing method that transforms flat sheets of metal into the complex shapes and structures that make up a modern vehicle. This is done using powerful stamping presses and carefully engineered dies, ensuring that each part meets strict requirements for size, strength, and fit.

When you look at the sheer scale of the automotive industry manufacturing process, it’s clear why stamping is so essential. Imagine trying to produce thousands—or even millions—of identical, high-quality parts by hand. Sounds impossible, right? That’s where stamping manufacturing comes in, allowing automakers to meet high-volume demands with speed and accuracy.

It’s estimated that over half of all metal components in a typical vehicle are produced through metal stamping processes, making it a cornerstone of automotive manufacturing.

The Backbone of Modern Vehicle Manufacturing

So, what is stamping in the bigger picture? In essence, automotive metal stamping is the process that shapes much of what you see (and don’t see) in a car—from outer body panels to intricate internal brackets. This technique is not just about forming metal; it’s about ensuring that every part is durable, consistent, and cost-effective. By automating the stamping manufacturing process, automakers can deliver vehicles that meet strict safety, performance, and aesthetic standards, all while keeping production costs under control.

- High-volume production: Stamping allows for the rapid creation of thousands of identical parts.

- Precision and consistency: Each stamped part meets tight tolerances, which is critical for safety and performance.

- Durability: The process creates parts that can withstand the harsh environments of daily driving.

In short, auto parts stamping is the silent force driving the efficiency and reliability of today’s vehicles. Without it, the modern automotive industry manufacturing process would be far less efficient, and vehicles wouldn’t meet the high standards drivers expect. As we dive deeper, you’ll see why mastering this process is key to automotive success.

Exploring Key Automotive Stamping Processes

Key Stamping Techniques Explained

When you see a perfectly shaped car fender or a complex engine bracket, have you ever wondered how such precision is possible on a massive scale? The answer lies in the stamping process in manufacturing—a set of highly specialized methods that transform flat metal sheets into the intricate components essential for car parts manufacturing. Let’s break down the three most important techniques: progressive die stamping, transfer die stamping, and deep drawing.

- Progressive Die Stamping: Imagine an industrial metal stamping machine working like an assembly line for metal. In this process, a strip of metal moves through a series of stations, each performing a specific operation—such as cutting, bending, or punching—until the final part is complete. The magic of automotive components progressive stamping is its speed and efficiency, making it ideal for producing large volumes of smaller, detailed parts with tight tolerances.

- Transfer Die Stamping: Now, picture parts moving independently from station to station. Here, mechanical arms transfer the part from one die to the next, allowing for more flexibility and the ability to remove excess material at different stages. Transfer die stamping shines when creating larger or more complex shapes that need multiple operations but not necessarily at the same breakneck speed as progressive dies.

- Deep Drawing: Ever wondered how fuel tanks or engine housings are made with seamless, deep cavities? Deep drawing is a specialized stamping manufacturing process where a metal sheet is drawn into a die, forming parts whose depth exceeds their diameter. This technique is perfect for producing strong, hollow components that require both durability and lightweight design.

Comparing Progressive, Transfer, and Deep Drawing

Choosing the right stamping method depends on the part’s shape, size, and production volume. Here’s a side-by-side look at how these three processes stack up:

| Stamping Process | Best For | Production Speed | Tooling Complexity | Typical Parts |

|---|---|---|---|---|

| Progressive Die Stamping | High-volume, small to medium-sized, detailed parts | Very High | High (multi-stage) | Brackets, connectors, clips |

| Transfer Die Stamping | Large, complex shapes or lower-volume runs | Moderate | Moderate (individual dies) | Chassis components, cross-members, large brackets |

| Deep Drawing | Parts with significant depth (depth > diameter) | Moderate | High (precision dies and control) | Fuel tanks, engine housings, body panels |

Why Process Selection Matters in Automotive Manufacturing

The automotive stamping process is not one-size-fits-all. For example, if a manufacturer needs thousands of identical clips, progressive die stamping—often integrated with automatic stamping feeders—delivers speed and consistency. But for a car’s structural cross-member, transfer die stamping offers the flexibility to handle larger, more intricate forms. And when it comes to deep, seamless parts like fuel tanks, deep drawing is the go-to solution, though it requires careful control of material properties and tooling precision.

Each stamping process in manufacturing brings its own set of challenges and advantages. Progressive dies excel at efficiency but require precise alignment and maintenance. Transfer dies allow for more customization but can be slower. Deep drawing demands exact control over metal flow to prevent defects, but it’s unmatched for creating strong, lightweight, and complex hollow forms.

As you move forward in understanding how materials and tooling choices impact these processes, you’ll see why mastering the art of auto parts stamping is essential for high-quality, reliable car parts manufacturing.

Essential Materials for Stamped Auto Parts

Material Selection in Stamping

When you look at a car’s crisp body lines or feel the strength of its frame, have you ever wondered what materials make up these automotive metal parts? The answer isn’t as simple as just “metal”—it’s a careful blend of science, engineering, and economics. Selecting the right material for stamp sheet metal is a critical decision that directly impacts a vehicle’s weight, safety, performance, and even its final cost.

Let’s break it down. The most common materials used in automotive sheet metal parts are steel and aluminum alloys, but the choice often depends on the specific function of each component. For example, a structural bracket might require the toughness of high-strength steel, while a lightweight hood could benefit from aluminum’s lower density. Other specialized metals, such as stainless steel or copper alloys, also play roles in specific electrical or corrosion-sensitive applications.

Steel: The Classic Choice for Strength and Versatility

Steel sheet stamping remains the backbone of most automotive metal parts. Why? Steel offers a powerful combination of high strength, durability, and cost-effectiveness. It’s especially favored for chassis components, safety-critical frames, and body-in-white structures that demand impact resistance and rigidity. Advanced High-Strength Steels (AHSS) and High-Strength Low-Alloy (HSLA) steels are now widely used, helping to reduce weight while maintaining safety standards. These steels are engineered for specific mechanical properties, making them ideal for parts that need to absorb energy in a crash or support heavy loads.

However, steel does have its downsides. Its density means it adds more weight to the vehicle, which can impact fuel efficiency. And unless it’s coated or made from stainless steel, it can be prone to corrosion over time (Global Gauge).

Aluminum: Lightweight Innovation for Modern Cars

Aluminium auto parts are becoming increasingly popular as carmakers strive for better fuel efficiency and lower emissions. Aluminum’s greatest strength is its high strength-to-weight ratio—it can match the strength of steel in many applications while significantly reducing the part’s weight. This makes it a go-to choice for body panels, wheels, suspension arms, and even some engine components. Aluminum also naturally resists corrosion, which is a bonus for longevity and appearance.

But aluminum isn’t perfect for every job. It’s generally more expensive than steel and, while strong, may not be suitable for the most demanding structural applications. That’s why manufacturers often use a mix of both metals, optimizing for each component’s needs.

Steel vs. Aluminum in Modern Cars: Pros and Cons

- Steel Pros: High strength, excellent durability, cost-effective, versatile for many automotive sheet metal parts.

- Steel Cons: Heavier (increases vehicle weight), can corrode if not properly treated.

- Aluminum Pros: Lightweight (improves fuel efficiency), strong for its weight, naturally corrosion-resistant, recyclable.

- Aluminum Cons: Generally more expensive, not as strong as steel for some structural applications, can be more challenging to form in certain stamp sheet metal processes.

Other Metals in Automotive Stamping

While steel and aluminum dominate, other metals sometimes play a role in auto parts stamping. Stainless steel is used for its corrosion resistance in exhaust systems and trim. Copper alloys are essential for electrical connectors and wiring components, thanks to their high conductivity. Each material is chosen based on the unique demands of the part—whether it’s strength, conductivity, or resistance to the elements.

Ultimately, the right material selection in automotive metal stamping is a balancing act. It’s about matching the properties of each metal to the needs of the vehicle—ensuring that every stamped part, from a crash-resistant frame to a lightweight hood, delivers safety, performance, and value. In the next section, you’ll see how the science of tooling and die design brings these material choices to life, shaping every detail of the final product.

The Critical Role of Tooling and Die Design

The Science of Tool and Die Design

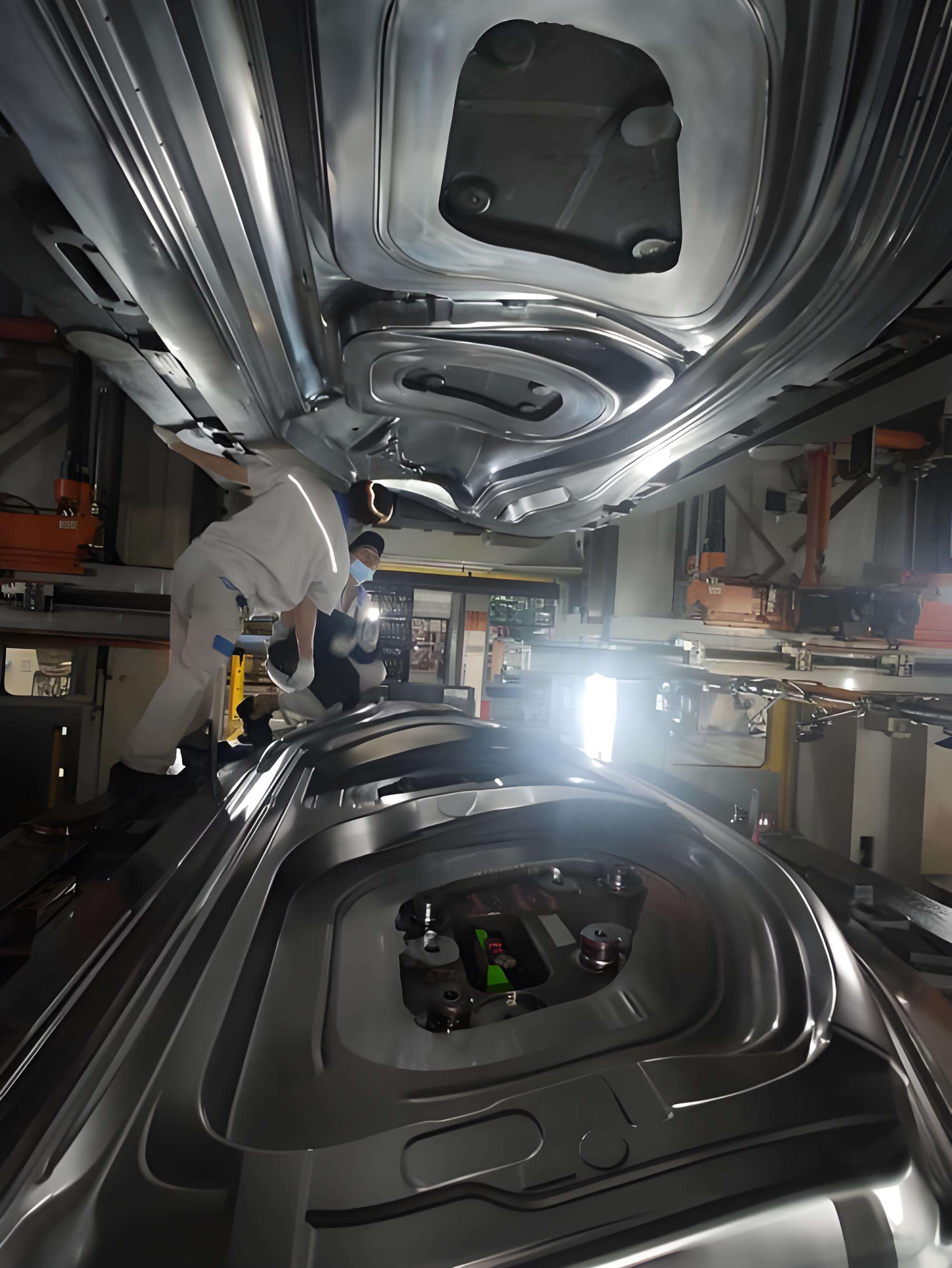

Ever wondered why some stamped auto parts fit perfectly, while others struggle with quality issues or early wear? The difference often lies in the design and engineering of the automotive stamping dies that shape every piece of metal. Imagine the die as a custom mold—its precision determines whether a car’s fender, bracket, or panel meets the tight tolerances required for modern vehicles.

So, what makes a great automotive stamping die? It starts with engineering expertise. Dies are designed using advanced CAD software, with every curve, edge, and feature tailored to the specific part. The goal is to ensure the metal flows smoothly, forms accurately, and releases easily—without cracks, wrinkles, or distortion. Even a minor flaw in die design can lead to costly defects or production delays.

Material Choices: Why Die Materials Matter

Sounds complex? That’s because it is. The choice of material for an automotive die directly impacts its performance and lifespan. Most automotive stamping dies are crafted from specialized tool steels—such as D2 or A2—chosen for their exceptional hardness, wear resistance, and toughness. These alloys often include chromium, vanadium, and molybdenum to enhance durability and resist cracking. For larger die bodies, cast iron (either gray or ductile) is commonly used for its stability and cost-effectiveness, while carbide inserts may reinforce critical cutting edges.

- Tool Steels (D2, A2): High hardness and wear resistance for long production runs.

- Cast Iron: Excellent vibration damping and machinability for large die structures.

- Carbide Inserts: Extreme edge durability for high-volume or abrasive applications.

The right combination ensures that dies can withstand the enormous forces of stamping—cycle after cycle—without losing shape or precision.

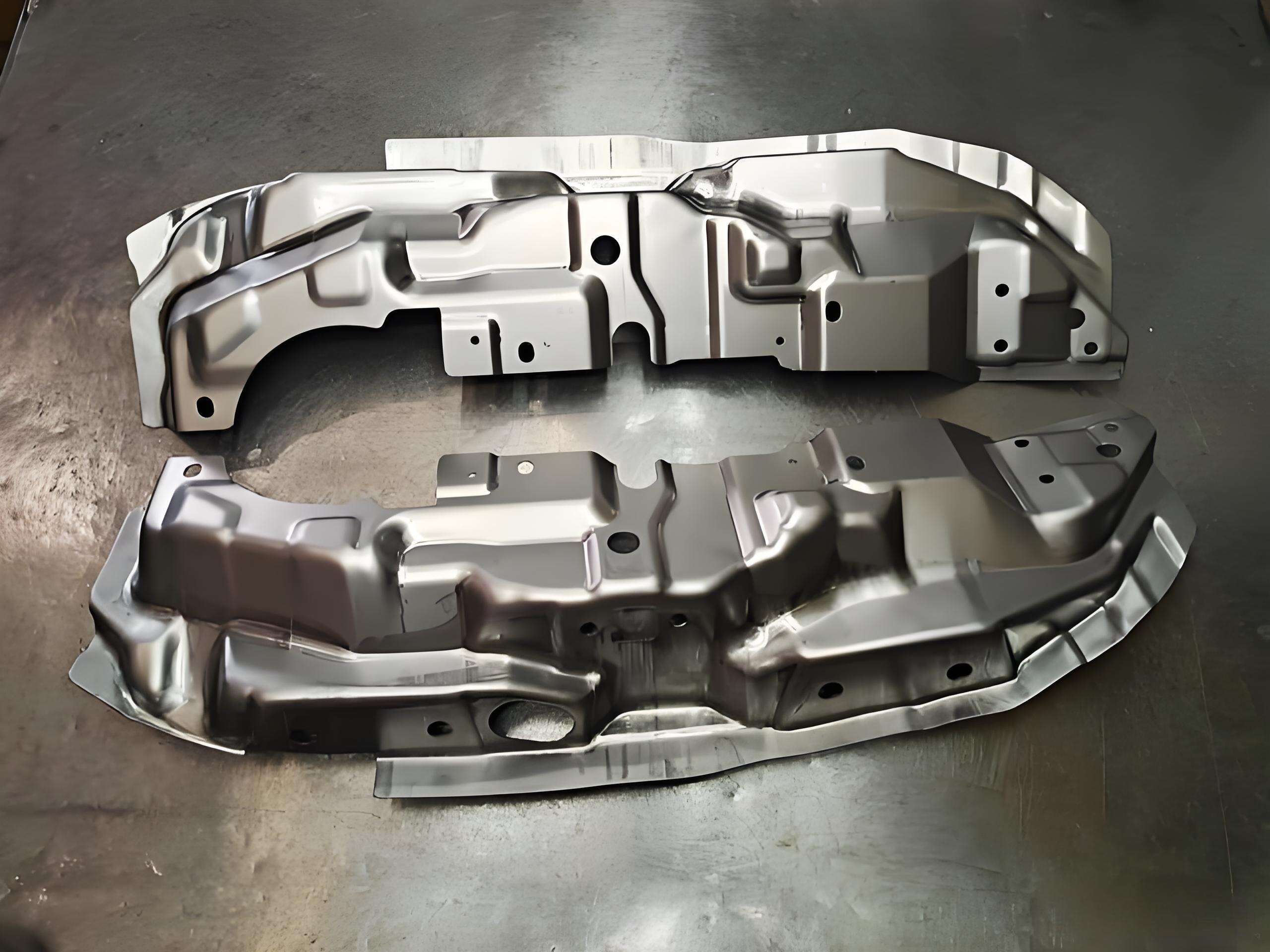

From Prototype Stampings to Mass Production

Before a die ever sees full-scale production, manufacturers often rely on prototype stampings to validate designs and catch issues early. Prototype tooling—sometimes called soft tooling—enables quick, cost-effective production of small batches for testing and design tweaks. This phase is crucial: it allows engineers to refine the die, adjust tolerances, and ensure the final automotive stamping die delivers consistent, high-quality results in mass production.

- Prototype stampings help identify potential problems before investing in expensive hard tooling.

- They bridge the gap between concept and production, shortening time-to-market for new models.

Once the design is proven, hard tooling is built for high-volume runs, ensuring every stamped part meets exacting standards.

Maintenance and Wear Management: Protecting Your Investment

Imagine investing in a precision automotive die—only to see its performance decline after a few thousand cycles. That’s why ongoing maintenance and wear management are non-negotiable. Regular inspections, cleaning, and timely repairs extend the life of both prototype and production dies, preventing defects and costly downtime. Wear-resistant materials and surface treatments (like nitriding or hard chrome plating) further enhance longevity, ensuring that each stamped part remains consistent—cycle after cycle.

In summary, the success of auto parts stamping hinges on the art and science of tool and die design. From material selection to prototyping and maintenance, every detail shapes the quality, efficiency, and reliability of the final product. Next, let’s explore how rigorous quality control standards ensure that every stamped part lives up to industry expectations.

Quality Control and Precision Standards

Ensuring Quality in Every Part

When you consider the sheer number of stamped mechanical part assemblies in a single vehicle, you might wonder: how do manufacturers ensure every component meets exacting standards? The answer lies in a rigorous quality control framework—one that separates good aftermarket car parts from those that fall short. In the world of auto parts stamping, quality isn’t just a buzzword; it’s a non-negotiable requirement that defines safety, performance, and long-term reliability.

At the heart of this framework is the concept of tight tolerances. Imagine a stamped bracket or chassis component that’s just a fraction of a millimeter off. Even such a small deviation can lead to assembly issues, rattles, or, in worst cases, safety risks. That’s why every step in the stamping process is closely monitored, from the first die strike to the final inspection. Manufacturers aiming for performance stamping must deliver parts that fit perfectly, function flawlessly, and withstand real-world stresses.

Navigating Automotive Quality Standards

So, what does it take to consistently achieve this level of precision? The industry relies on globally recognized standards and certifications, the most significant being IATF 16949. This standard, developed by the International Automotive Task Force, is tailored specifically for automotive suppliers and builds on the foundation of ISO 9001. It requires companies to implement robust quality management systems, focusing on defect prevention, process control, and continuous improvement.

Certification to IATF 16949 is more than a badge—it’s proof that a manufacturer can consistently deliver stamped mechanical part assemblies that meet the highest automotive expectations. It also signals to customers and automakers that the supplier is committed to quality, risk mitigation, and ongoing improvement (PPAP Manager).

Another cornerstone of quality assurance is the Production Part Approval Process (PPAP). Think of PPAP as a comprehensive checklist that ensures every new or modified part is fully validated before mass production begins. It covers everything from design records and material certifications to process capability studies and sample inspections. By following PPAP, manufacturers can catch potential issues early, guaranteeing that only parts meeting all requirements reach the assembly line.

- Incoming Material Inspection: Verifying that raw materials meet required specifications before stamping begins.

- In-Process Checks: Monitoring critical dimensions and features during each stage of stamping, ensuring tight tolerances are maintained.

- First Article Inspection: Detailed inspection and documentation of the first part off a new die or production run.

- Final Quality Audit: Comprehensive review of finished parts for surface finish, fit, and functional performance.

- PPAP Submission: Providing full documentation and sample parts to the customer for approval before full-scale production.

- Ongoing Process Audits: Regular reviews to ensure process consistency, equipment calibration, and operator training remain up to standard.

Why Quality Matters for Aftermarket and OEM Parts

Ever shopped for good aftermarket car parts and wondered why some brands consistently outperform others? It often comes down to their commitment to these quality standards. The best suppliers—those who offer the best quality in automotive aftermarket—invest in advanced testing, certifications, and continuous improvement. They understand that a single defective bracket or poorly stamped panel can undermine an entire vehicle’s performance and reputation.

In performance stamping, this attention to detail is even more critical. High-stress applications—like suspension mounts or drivetrain brackets—demand parts that can handle extreme loads and harsh environments. That’s why industry leaders go beyond basic requirements, using real-world testing, advanced materials, and robust process controls to deliver stamped mechanical part assemblies that stand up to the toughest conditions.

As you can see, quality control is the backbone of reliable auto parts stamping. From global certifications to hands-on inspections, every step is designed to ensure that each part—OEM or aftermarket—meets the highest standards. Next, let’s see how these quality-driven stamped parts find their place throughout the modern vehicle, supporting everything from body panels to powertrain systems.

Applications of Stamped Parts in Modern Vehicles

Stamped Parts from Bumper to Bumper

When you look at a modern car, nearly every system relies on metal stampings for automotive components. But where exactly do these stamped parts show up, and why do auto parts manufacturers rely on them so heavily? Let’s break down the vehicle section by section so you can see just how essential automotive metal stamped parts are to both structure and function.

-

Body-in-White (BIW) Panels

- Doors, hoods, fenders, roofs, trunk lids, and quarter panels

- These large panels give the car its shape and provide the first line of defense in a collision.

-

Chassis and Structural Components

- Brackets, cross-members, frame rails, subframes, and bumper reinforcement bars

- These stamping parts are critical for stability, crash energy absorption, and mounting other systems.

-

Powertrain and Engine Bay

- Engine mounts, transmission housings, oil pans, fuel injection shields, and battery cable connectors

- Here, automotive metal stampings must withstand heat, vibration, and mechanical stress.

-

Suspension and Steering

- Control arms, linkages, hangers, and steering wheel sensor terminals

- These metal stamping parts help ensure smooth handling and precise steering response.

-

Interior and Safety Features

- Seat rails, seat belt buckles/latches, instrument panel frames, and center consoles

- Stamped parts here combine safety, comfort, and style—think of the sturdy seat belt hardware or sleek dashboard supports.

-

Electrical and Connectivity

- ECU housings, battery terminals, bus bars, and electrical connectors

- Precision-stamped connectors ensure reliable power and signal flow throughout the car.

Common Applications in Vehicle Systems

Why do automotive parts manufacturers choose metal stamping for so many applications? It’s all about consistency, cost, and flexibility. Automotive stamping parts can be produced in high volumes with minimal waste, while maintaining tight tolerances for fit and function. Whether you’re looking at the robust frame beneath the car or the detailed trim inside the cabin, automotive metal stamped parts are everywhere.

Imagine assembling a car without stamped brackets, body panels, or connectors—it would be nearly impossible to achieve the same quality or efficiency. That’s why leading auto parts manufacturers and automotive stamping parts suppliers invest in advanced stamping processes to meet the evolving demands of modern vehicles. As the industry shifts toward lighter, more complex designs, the importance of metal stampings for automotive components will only continue to grow.

Next, let’s look at how these stamped parts are adapting to new trends—like electrification and lightweighting—to shape the future of automotive manufacturing.

Future Trends in Automotive Stamping for 2025

Stamping for the Next Generation of Cars

Ever wondered how the shift to electric vehicles (EVs) and the push for lighter, more efficient cars are changing the world of auto parts stamping? When you walk around a dealership or scroll through the latest vehicle launches, you’ll notice that modern cars look and perform differently than models from just a few years ago. This transformation is no accident—it’s driven by new demands for fuel efficiency, sustainability, and advanced technology, all of which are reshaping the automotive stamped component market (Data Insights Market).

Lightweighting is one of the hottest aftermarket trends in automotive engineering. Automakers and aftermarket car manufacturers alike are searching for ways to reduce vehicle weight without sacrificing strength or safety. Why? Lighter vehicles use less energy, which means better fuel economy for gasoline cars and longer range for EVs. Auto parts stamping is at the heart of this shift, as manufacturers increasingly turn to advanced materials and innovative stamping methods to produce thinner, stronger parts.

- Advanced high-strength steel and aluminum: These materials are now staples in automotive metal pressings, offering the strength needed for crash safety with a fraction of the weight.

- Complex geometries: Modern stamping presses can form intricate shapes that were once impossible, enabling lighter yet more robust structural components.

The Impact of EVs and Lightweighting

Imagine the inside of an electric vehicle. Instead of a large engine, you’ll find battery enclosures, electric motor housings, and specialized cooling systems—all requiring precision-stamped metal parts. The rise of EVs is driving a surge in demand for custom automotive metal pressings designed to fit these new applications. But it’s not just about new shapes; it’s about meeting strict requirements for strength, thermal management, and electrical insulation.

Manufacturers are adapting their stamping processes to handle these challenges. High-tonnage servo presses, for example, provide the control and force needed to form thick, multi-layer battery covers or intricate motor components with tight tolerances. Automation and AI-driven quality systems are also becoming standard, ensuring that every stamped part meets the exacting standards of the EV market.

- Battery enclosures: Require strong, lightweight, and precisely sealed metal stampings to protect sensitive cells and manage heat.

- Motor housings: Demand complex shapes and high accuracy to ensure quiet, efficient operation.

- Lightweight structures: Every gram saved in chassis, suspension, and body panels contributes to greater efficiency and performance.

What’s Next for the Automotive Stamped Component Market?

Looking ahead, the automotive stamped component market is set for continued growth as OEMs and aftermarket car manufacturers race to meet evolving consumer and regulatory demands. Expect to see even more investment in automation, robotics, and digital quality control as automotive aftermarket trends push for smarter, safer, and more sustainable vehicles (Spherical Insights).

In summary, the future of auto parts stamping is all about adaptability. Whether it’s meeting the challenges of electrification, lightweighting, or new safety standards, manufacturers who embrace innovation in materials, equipment, and process control will lead the way. As we move forward, choosing the right stamping partner will be more critical than ever—a topic we’ll tackle next as you consider how to select a supplier who can keep pace with these rapid changes.

Selecting Your Precision Stamping Partner

How to Choose the Right Stamping Partner

When you’re tasked with sourcing stamped components for your next automotive project, the stakes are high. A single misstep in supplier selection can lead to missed deadlines, quality issues, or costly recalls. So, how do you ensure your partner for auto parts stamping delivers both reliability and innovation? Imagine you’re comparing a shortlist of car parts manufacturers—the right questions can make all the difference.

Key Factors for Supplier Selection

Sounds complex? It doesn’t have to be. Leading automotive stamping companies share several critical attributes that set them apart in a crowded field. Here’s a practical checklist to guide your decision-making process:

- IATF 16949 Certification: This globally recognized standard is non-negotiable for automotive suppliers. It proves that a company’s quality management system meets the industry’s strictest requirements—reducing your risk and ensuring consistent part quality.

- In-House Tooling Capabilities: Look for auto part manufacturers who design and build their own dies and tools. In-house capabilities mean faster turnaround, better process control, and the flexibility to adapt quickly to design changes or production challenges.

- Material Expertise: Can your supplier work confidently with both advanced high-strength steel (AHSS) and aluminum? Material know-how is essential for modern vehicles, especially as lightweighting and electrification drive demand for custom automotive metal stamping solutions.

- Proven Track Record: Ask about past projects, client references, and experience with complex assemblies. The best aftermarket car parts manufacturers have a history of meeting demanding specifications for global automotive brands.

- Integrated Manufacturing Services: A full-service partner can simplify your supply chain—combining stamping, CNC machining, welding, and assembly under one roof. This integration often leads to better coordination, shorter lead times, and fewer quality escapes.

Why These Criteria Matter

Choosing among automotive metal stamping companies isn’t just about price—it’s about minimizing risk and future-proofing your project. For example, a partner with in-house tooling can quickly address design tweaks, while deep material expertise means your parts will perform as intended, whether they’re made of lightweight aluminum or ultra-tough AHSS. Companies that invest in quality certifications and digital production systems are also more likely to deliver consistent results, meeting the high standards of both OEMs and those who are high-quality aftermarket part suppliers.

Shaoyi Metal Technology Co., Ltd.: A Model Partner

If you’re searching for a supplier that checks every box, Shaoyi Metal Technology Co., Ltd. stands out among custom automotive metal stamping providers. As a leading integrated precision auto metal parts solutions company in China, Shaoyi combines IATF 16949 certification, in-house tooling and engineering, and proven expertise with aluminum, steel, and specialty alloys. Their end-to-end approach—from design for manufacturability (DFM) analysis to mass production—has earned the trust of global automotive brands.

What sets Shaoyi apart from other automotive stamping companies is their commitment to digital efficiency and quality. With modern MES systems for transparent production, rapid prototyping for design validation, and a robust track record with OEMs and aftermarket leaders, they exemplify what best aftermarket car parts manufacturers should offer: reliability, flexibility, and technical depth.

"Selecting a stamping partner isn’t just about meeting today’s needs—it’s about building a foundation for future innovation and growth."

As you evaluate potential partners, use this checklist to compare capabilities and credentials. The right choice will not only help you avoid common pitfalls in auto parts stamping but will also position your business for success as the automotive industry evolves.

Frequently Asked Questions About Auto Parts Stamping

1. What is auto parts stamping and why is it important in car manufacturing?

Auto parts stamping is a process that shapes flat metal sheets into precise automotive components using powerful presses and dies. It's essential because it enables high-volume, consistent, and durable production of parts like body panels, brackets, and engine mounts, forming the backbone of modern vehicle manufacturing.

2. What materials are commonly used in automotive metal stamping?

The most common materials are various grades of steel, including advanced high-strength steel (AHSS), and aluminum alloys. Steel offers strength and cost-effectiveness for structural parts, while aluminum provides lightweight benefits for fuel efficiency. Manufacturers may also use stainless steel or copper alloys for specialized needs.

3. How do manufacturers ensure the quality of stamped automotive parts?

Quality is maintained through strict standards like IATF 16949 certification, PPAP validation, and rigorous inspections at every stage. Top suppliers use advanced testing, in-process checks, and ongoing audits to guarantee that each stamped part meets precise tolerances and performance requirements.

4. What are the main stamping processes used for automotive components?

Automotive manufacturers use progressive die stamping for high-volume small parts, transfer die stamping for larger or complex shapes, and deep drawing for parts with significant depth. Each process is selected based on part geometry, volume, and application needs.

5. How do I choose the right auto parts stamping partner?

Look for a supplier with IATF 16949 certification, in-house tooling, proven expertise with multiple materials, and a strong track record with global brands. Companies like Shaoyi Metal Technology Co., Ltd. offer integrated services, digital efficiency, and robust quality systems, reducing risk and ensuring reliable, high-quality parts.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —