Beyond Price: The Real Value of Automotive Stamping Dies

The Foundation of Automotive Manufacturing

What Are Automotive Stamping Dies?

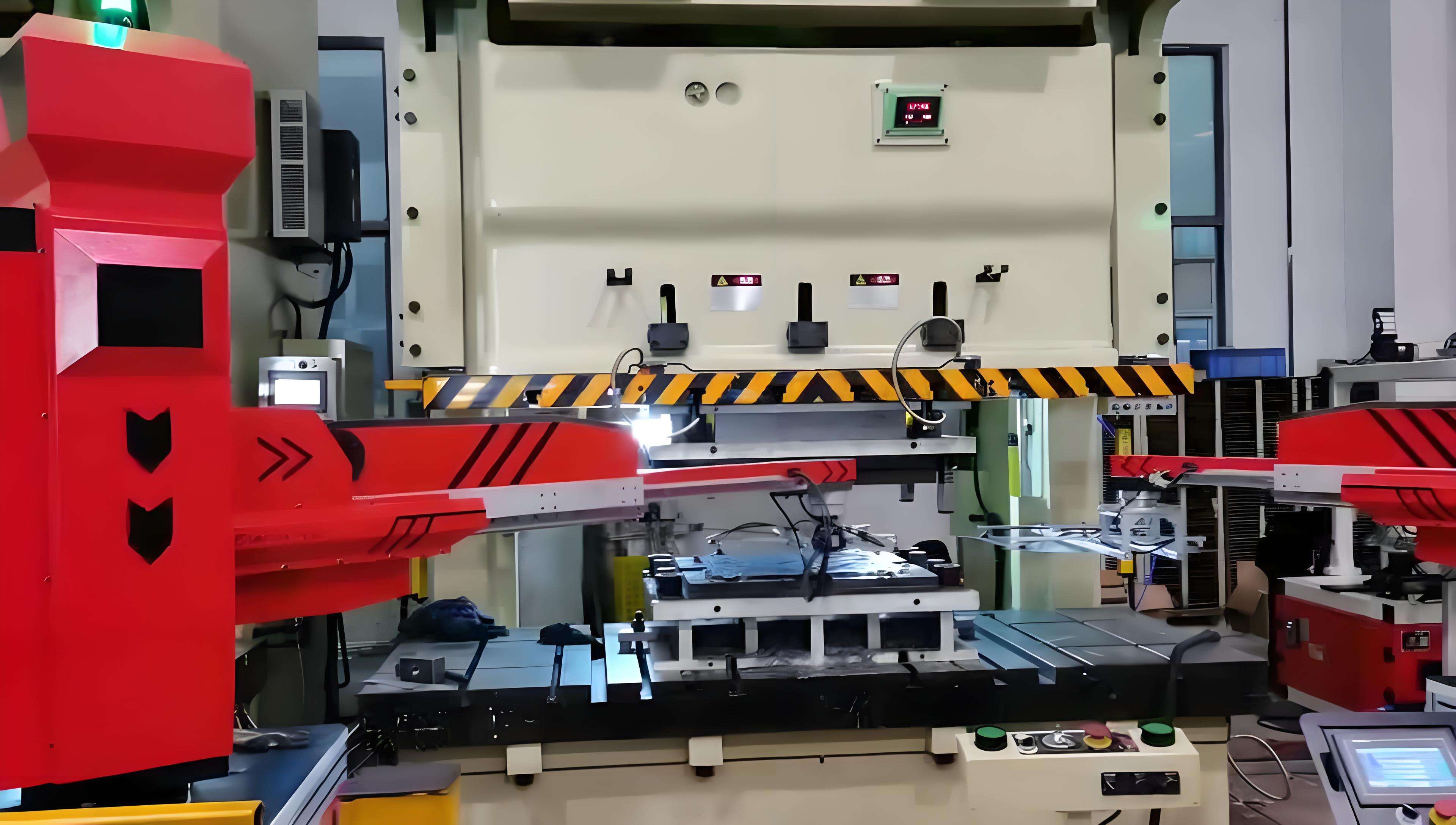

When you look at a modern vehicle, have you ever wondered how those sleek body panels or intricate support brackets are made? The answer lies in the heart of the manufacturing process: automotive stamping dies. These are specialized tooling dies designed to cut, form, and shape sheet metal into the essential components that make up a car’s structure and appearance. So, what is a die in manufacturing? Simply put, a die is a precision tool—usually crafted from hardened steel or other wear-resistant materials—used to impart a specific shape to a material, most commonly metal. In the automotive industry, these dies are engineered with incredible accuracy to ensure every part fits perfectly, from the smallest bracket to the largest door panel.

The Backbone of Modern Car Manufacturing

Imagine the complexity of building a car: thousands of parts must align with exact tolerances for the vehicle to function safely and efficiently. That’s where automotive stamping dies step in. They enable manufacturers to mass-produce components such as:

- Body panels (doors, hoods, roofs)

- Structural brackets and reinforcements

- Chassis components

- Interior and exterior trim parts

Each automotive die is designed for a specific function—cutting, forming, or both—ensuring every stamped part meets strict quality and safety standards. The process of what is a stamping involves placing flat sheet metal into the die and applying force, transforming it into a finished part with remarkable speed and consistency.

Precision in stamping die design is not just a technical requirement—it's the difference between a vehicle that meets today’s safety standards and one that falls short. In modern automotive manufacturing, even a fraction of a millimeter matters.

Without these advanced tooling dies, the scale and consistency required in automotive production would be impossible to achieve. They are truly the unsung heroes of the supply chain, supporting everything from initial concept to final assembly and ensuring that every vehicle on the road is built to last.

As we explore further, you’ll see how these dies are engineered, the materials that make them durable, and the innovations shaping the future of automotive manufacturing.

Key Types of Automotive Stamping Dies

Progressive Die Stamping Explained

When you see a car roll off the assembly line, have you ever wondered how so many identical metal parts are made so quickly? The answer lies in the types of stamping dies used in the process. Among these, the progressive die is a true workhorse. In progressive die metal stamping, a long strip of sheet metal feeds through a series of stations within a single die. At each station, a different operation—such as cutting, bending, or punching—takes place. By the time the strip reaches the end, a finished part drops out, ready for assembly. This method is ideal for high-volume production of parts like brackets, clips, and other repetitive components where speed and consistency are crucial.

Transfer vs. Compound Dies

Not all automotive components are simple, and that’s where other types of dies come into play. Transfer dies are used for larger or more complex parts that can’t be formed in a single pass. Imagine a sheet metal die that moves the part from station to station, performing a unique operation at each stop. This method is like an assembly line for stamping, offering flexibility for intricate or deep-drawn shapes—think structural supports or chassis reinforcements. Transfer dies are especially valuable when a part requires multiple, distinct forming steps that can’t be combined in one die set.

On the other hand, the compound die is engineered for efficiency in producing flat, precise parts. In a single press stroke, it performs several operations—such as cutting and punching—simultaneously. This makes compound dies a favorite for medium-volume runs of flat parts where dimensional accuracy is critical, such as washers or electrical connectors. However, they’re less suited for complex 3D shapes.

| Die Type | Process Description | Best For | Common Automotive Applications |

|---|---|---|---|

| Progressive Die | Sheet metal passes through multiple stations in a single die; each station performs a different operation until the part is complete. | High-volume, consistent parts; cost-effective for large runs | Brackets, clips, small body reinforcements |

| Transfer Die | Part is transferred from one station to the next, with each die performing a unique operation. Allows for complex or deep-drawn shapes. | Large, complex parts; flexibility for intricate shapes | Chassis components, structural supports, deep-drawn panels |

| Compound Die | Multiple operations (cutting, punching) performed in a single press stroke, producing flat parts with high precision. | Medium-volume, flat parts; high dimensional accuracy | Washers, gaskets, electrical connectors |

Choosing the Right Die for the Job

So, how do manufacturers decide which stamping die to use? It comes down to part complexity, production volume, and material type. For high-speed production of simple shapes, progressive dies are the go-to choice. If you need a flat, precision part in moderate quantities, a compound die offers efficiency and accuracy. For larger or more intricate components that require multiple forming steps, transfer dies provide the necessary flexibility—even if the setup is more complex and time-consuming.

- Progressive dies: Best for high-volume, simple components

- Transfer dies: Ideal for complex, multi-step, or deep-drawn parts

- Compound dies: Suited for flat, high-precision parts in moderate volumes

Understanding the strengths and limitations of each die type allows automotive engineers to balance speed, cost, and quality. As you move into the next stage of automotive stamping dies, you’ll see how the choice of die material can further impact performance, longevity, and part quality.

Die Materials

Tool Steel vs. Carbide in Die Making

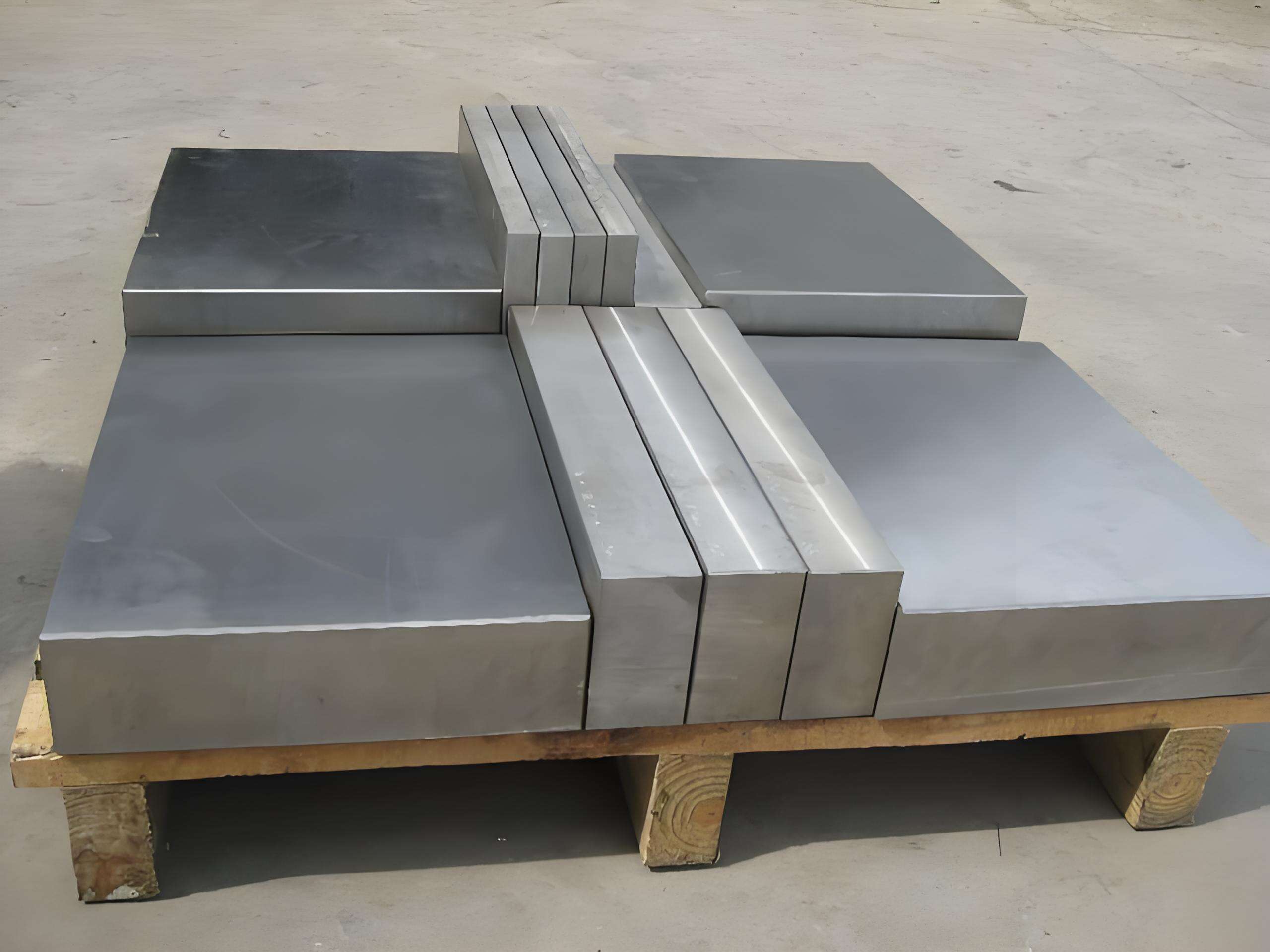

When you see a flawless car hood or a perfectly shaped fender, have you ever wondered what makes those automotive metal parts so precise and consistent? The answer often lies in the choice of die material. The materials used for metal die construction are the backbone of both performance and longevity in automotive stamping dies. But what makes one die last for millions of cycles while another wears out too soon? Let’s break down the key players—tool steels, carbide inserts, and advanced alloys—and see how they shape the world of steel stamping dies and aluminum stamping dies.

Material Selection for High-Strength Steel and Aluminum Stamping

Modern vehicles demand more than just strength; they require lightweighting, corrosion resistance, and the ability to form complex shapes. That’s why die material selection is so critical. For automotive metal stampings—especially those involving Advanced High-Strength Steels (AHSS) or aluminum alloys—the die must withstand extreme forces, high temperatures, and abrasive wear from sheet metal pressings. Here’s how the most common die materials stack up:

- D2 Tool Steel: A high-carbon, high-chromium steel prized for its exceptional wear resistance and dimensional stability. It’s a favorite for intricate die designs—think detailed body panels or precision brackets—where maintaining tight tolerances is a must. However, D2 can be more challenging to repair and isn’t always the best fit for the highest production volumes or the most abrasive environments.

- Tungsten Carbide Inserts: When you need unmatched wear resistance, carbide is the go-to. Carbide inserts in dies are ideal for high-volume runs of abrasive materials, including some AHSS grades. They maintain dimensional accuracy over millions of cycles but are brittle and difficult to machine or repair. That’s why they’re often used only in the most critical wear areas of a die.

- Advanced Tool Steels (e.g., H13, QRO90): These steels are engineered for a balance of hardness, toughness, and thermal conductivity. In hot stamping—especially for aluminum stamping dies—advanced tool steels like QRO90 offer high wear resistance and allow for efficient heat transfer, which is vital for controlling part properties and die life [source].

- Pearlitic Cast Iron: For prototypes or short-run production, cast iron can be a cost-effective die material. While it doesn’t match tool steel for toughness or wear resistance, it can be suitable for forming less abrasive materials, especially in sheet metal pressings where die life is less critical.

Impact of Die Material on Part Quality

Choosing the right die material directly impacts the quality and consistency of automotive metal stampings. Here’s a quick look at the pros and cons of each option:

-

D2 Tool Steel

- Pros: Excellent wear resistance; holds sharp edges; good for detailed, high-precision parts.

- Cons: Can be brittle; not ideal for high-impact or extremely high-volume applications; more difficult to repair.

-

Tungsten Carbide Inserts

- Pros: Superior wear resistance; maintains accuracy over long runs; ideal for abrasive or high-strength sheet metals.

- Cons: High cost; brittle and challenging to machine or modify; limited to specific die areas.

-

Advanced Tool Steels (e.g., H13, QRO90)

- Pros: Good balance of toughness, hardness, and thermal conductivity; suitable for both AHSS and aluminum; reduces risk of galling and thermal fatigue.

- Cons: Higher material cost; may require special heat treatment or coatings for optimal performance.

-

Pearlitic Cast Iron

- Pros: Cost-effective for prototypes or low-volume runs; easy to machine.

- Cons: Lower wear resistance and toughness; not suitable for demanding, high-volume automotive metal applications.

In summary, the choice of die material isn’t just about cost—it’s about matching the right material to the demands of your automotive stamping dies project. As vehicle designs evolve with new steels and lightweight alloys, the science of die material selection becomes even more crucial. Next, we’ll walk through how these materials are transformed into the precision tools that shape every modern vehicle.

The Die Manufacturing Process Step by Step

From Digital Design to Physical Tool

Ever wonder how a flat metal sheet transforms into a perfectly shaped car door or fender? It all starts long before any metal is pressed. The journey of die manufacturing for automotive stamping dies is a meticulous, multi-stage process that blends digital precision with skilled craftsmanship. If you’ve ever asked, what is die manufacturing or how a Class A die is created, you’re about to see the step-by-step journey that goes into every high-quality automotive component.

-

Design & Simulation (CAD/CAE)

The first step in any stamping die design is a deep dive into the requirements of the final part. Using advanced Computer-Aided Design (CAD) software, engineers create a detailed 3D model of the die, factoring in the shape, tolerances, and material properties of the target automotive part. But design doesn’t stop at modeling. Modern die processing leverages Computer-Aided Engineering (CAE) and simulation tools like Finite Element Analysis (FEA) to predict how the sheet metal will behave during stamping. These simulations are crucial—they reveal potential issues like wrinkling, tearing, or springback before a single piece of steel is cut. By running digital tryouts, engineers can adjust the die design and optimize material flow, saving both time and costly mistakes down the line. -

Precision Machining (CNC, EDM)

Once the digital design is perfected, it’s time to turn virtual plans into real-world tools. This phase of machining dies starts with rough machining, where large blocks of tool steel are milled down to basic shapes. Next, CNC (Computer Numerical Control) machines take over, carving out intricate details with incredible accuracy—often to within fractions of a millimeter. For the most complex features, such as sharp internal corners or deep cavities, Electrical Discharge Machining (EDM) is used. EDM employs electrical sparks to erode metal, allowing for shapes that traditional cutting tools simply can’t achieve. This combination of CNC and EDM ensures every detail matches the original digital design, supporting the high standards required for automotive dies production. -

Heat Treatment

After machining, the die components undergo heat treatment. This step is all about durability. By heating the steel to precise temperatures and cooling it under controlled conditions, the die achieves the hardness and toughness needed to withstand the immense pressures of mass production. Proper heat treatment is essential for extending die life and ensuring consistent part quality throughout the die process. -

Surface Finishing & Coating

Even the best-machined die needs a flawless surface. Surface finishing—such as grinding and polishing—removes microscopic imperfections, ensuring the sheet metal flows smoothly during stamping. Depending on the application, special coatings (like nitriding or PVD) may be applied to further boost wear resistance, reduce friction, and prevent galling. These finishing touches are critical for producing defect-free automotive parts and minimizing downtime for maintenance. -

Assembly & Tryout

All the carefully crafted components come together in the assembly phase. Here, die makers fit punches, cavities, guide pins, and plates with meticulous precision. But the job isn’t finished until the die is tested. In a tryout press, the assembled die stamps test parts, allowing for real-world validation. Engineers inspect these parts for dimensional accuracy, surface quality, and any defects. If adjustments are needed, minor tweaks are made—such as grinding or shimming—until the die consistently produces parts that meet Class A standards. Only then is the die approved for full-scale production.

The Role of EDM in Complex Die Features

Why is EDM so important in modern die processing? Imagine trying to create a tiny, perfectly square corner or a deep, narrow slot in hardened steel—tasks that traditional machining struggles with. EDM (Electrical Discharge Machining) uses controlled sparks to shape metal with extreme precision, making it indispensable for the most intricate aspects of stamping die design. This technology ensures that even the most complex automotive components can be formed with consistency and repeatability, supporting the ever-evolving demands of the industry.

What Defines a Class A Die?

Not all dies are created equal. A Class A die is the gold standard in dies production for automotive applications. These dies are engineered to produce visible parts—like exterior body panels—where flawless surface finish and exacting tolerances are non-negotiable. Creating a Class A die requires not just advanced technology and materials, but also a relentless commitment to quality at every step of the die process. From simulation and machining to finishing and tryout, every detail is scrutinized to ensure the final product meets the highest standards of the automotive industry.

As you can see, what is die manufacturing goes far beyond simple metal shaping. It’s a blend of digital engineering, skilled craftsmanship, and rigorous quality control—ensuring that every stamped automotive part is as precise and reliable as the last. Next, we’ll tackle the real-world challenges that arise during stamping and how industry experts solve them to keep production running smoothly.

Overcoming Common Stamping Challenges

When you watch a flawless car panel glide down the assembly line, it’s easy to overlook the technical hurdles behind the scenes. The metal stamping process for automotive components is anything but simple. Every step—from forming to final inspection—can introduce challenges that threaten quality and efficiency. So, what is a die used for in stamping manufacturing? It’s not just about shaping metal; it’s about solving real-world problems that arise during production. Let’s break down the most common stamping forming issues and explore proven solutions that keep production on track.

Solving Material Springback in AHSS

Have you ever wondered why high-strength steel parts sometimes don’t hold their intended shape? That’s due to springback—the tendency of metal to return toward its original shape after forming pressure is released. This is especially problematic with Advanced High-Strength Steels (AHSS), which are now common in automotive design for their strength-to-weight advantages.

- Root Cause: Springback occurs because AHSS and aluminum alloys store significant elastic energy during stamping. When the die opens, this energy is released, causing the part to distort or deviate from design specs.

-

Actionable Solutions:

- Over-bending: Intentionally bending the part beyond its final shape compensates for expected springback.

- Springback compensation in die design: Using CAE simulation, engineers can predict and adjust the die profile before production begins.

- Material selection and process optimization: Choosing materials with lower yield strength or optimizing forming speeds can also help minimize springback.

- Incremental forming: Breaking the process into multiple steps reduces stress and helps control final geometry.

Implementing these strategies early in the stamping manufacturing process ensures parts meet tight tolerances without costly rework.

Preventing Galling and Premature Tool Wear

Imagine your dies producing thousands of parts per day. Over time, you’ll notice surface scratches, burrs, or even cracks—classic signs of tool wear and galling. But how does stamping work to prevent these issues?

- Root Cause: Galling happens when friction between the die and workpiece causes material to transfer and stick, while abrasive wear results from hard particles scraping the die surface. Both lead to defects and downtime.

-

Actionable Solutions:

- Surface polishing and coatings: Polishing die surfaces and applying advanced coatings (like nitriding or PVD) reduce friction and resist galling.

- Lubrication: Using high-performance lubricants—especially those with extreme-pressure additives—minimizes direct metal-to-metal contact.

- Material upgrades: Reinforcing critical die areas with carbide inserts or using advanced tool steels improves resistance to wear.

- Regular maintenance: Scheduled grinding and inspection help catch wear before it leads to defects.

These preventive measures extend die life and ensure consistent quality, supporting precision die stamping for even the most demanding automotive applications [source].

Strategies for Tight Tolerance Control

Ever noticed how even a tiny error in a stamped part can cause assembly problems down the line? Maintaining tight tolerances is critical for automotive safety and performance, but it’s also one of the toughest challenges in the metal stamping process.

- Root Cause: Tolerance issues often stem from die wear, inconsistent material thickness, or improper press setup. Material springback and residual stresses can also cause parts to deviate from specs.

-

Actionable Solutions:

- Precision die design: Incorporate guide posts, precision positioning pins, and springback compensation directly into the die design.

- Process control: Use real-time monitoring and statistical process control (SPC) to catch deviations early.

- First-piece inspection: Conduct thorough inspections using 3D scanning or CMM (Coordinate Measuring Machine) to verify part geometry at the start of each run.

- Material management: Strictly inspect incoming material for thickness and mechanical properties to ensure consistency.

By combining robust die design with process discipline, manufacturers can achieve the high level of precision required for today’s complex automotive assemblies.

Turning Challenges into Opportunities

Every automotive stamping operation faces hurdles, but with the right approach, each challenge becomes an opportunity for improvement. Whether you’re dealing with springback, tool wear, or tight tolerances, understanding how does stamping work and applying proven solutions can make all the difference. As you move forward, the next step is ensuring these solutions are backed by rigorous quality control and industry standards—guaranteeing every stamped part meets the demands of modern automotive manufacturing.

Quality Assurance and Standards in Automotive Stamping

When you think about the sheer number of parts in a car, you might wonder—how do manufacturers ensure every piece is safe, reliable, and fits perfectly? The answer lies in rigorous quality control and strict adherence to industry standards throughout the automotive stamping process. Without these safeguards, even the most advanced die for manufacturing could yield inconsistent results, risking performance and safety. Let’s break down why quality assurance is so vital, and how top-tier inspection methods and certifications keep the industry on track.

The Role of IATF 16949 in Stamping

Imagine trying to coordinate a stamped mechanical part assembly made up of thousands of components from different suppliers. How do you ensure every part meets the same high standards? This is where the IATF 16949 quality management system comes in. As the world’s leading automotive quality standard, IATF 16949 is built on the foundation of ISO 9001 but is tailored for the automotive sector’s unique demands. It’s not just a certificate—it’s a comprehensive system that:

- Promotes customer satisfaction by focusing on meeting end-user requirements

- Creates a culture of continuous improvement using the Plan-Do-Check-Act cycle

- Identifies and manages risk through evidence-based decision-making

- Ensures every supplier in the chain follows best practices for design, manufacturing, and servicing of automotive metal stamped parts

For any company involved in metal stampings for automotive components, IATF 16949 certification is often a minimum requirement to participate in the global automotive supply chain. It’s a clear signal to customers and partners that your processes are robust, repeatable, and globally recognized [source].

Advanced Inspection with CMM and 3D Laser Scanning

Sounds complex? It is—but that’s where advanced inspection technologies come in. Even the best process controls need verification, especially when dealing with intricate automotive metal stamped parts. Two of the most powerful inspection methods in use today are:

- Coordinate Measuring Machines (CMM): These machines use a precise probe to measure key dimensions and geometries, ensuring that every stamped part aligns with the original design. CMMs are highly accurate but require a controlled environment and are best for detailed spot checks or critical features.

- 3D Laser Scanning: Need to inspect complex shapes or hard-to-reach areas? 3D laser scanners capture millions of data points across the entire surface of a part, creating a full-field digital twin. This allows for rapid comparison against CAD models, enabling quick identification of defects, springback, or trimming line issues. It’s especially valuable for high-mix, high-volume production where speed and flexibility are key.

By combining these methods, manufacturers can catch deviations early, optimize production, and ensure that every die for manufacturing delivers consistent, high-quality results.

Ensuring Traceability and Compliance

When you buy a car, you expect every part to be traceable and compliant with safety regulations. But what is dies in manufacturing if not a guarantee of repeatability and accountability? Quality control isn’t just about catching defects—it’s about documenting every step, from raw material to final assembly. This traceability is essential for:

- Meeting regulatory requirements and industry standards

- Quickly identifying and isolating issues in the event of a recall

- Building trust with customers and partners through transparent processes

According to industry leaders, strict quality control reduces errors, prevents waste, and optimizes production—delivering safer, more reliable vehicles to the market [source].

In summary, quality assurance and adherence to standards like IATF 16949 and ISO 9001 are not just checkboxes—they’re the backbone of the automotive stamping industry. With advanced inspection tools and robust documentation, every stamped part is a testament to precision, safety, and reliability. As you explore the future of automotive stamping, you’ll see how these principles drive innovation and shape the next generation of vehicles.

The Future of Automotive Stamping Technology

The Rise of Smart Dies and IoT Integration

When you hear about automotive metal stamping today, it’s no longer just about force and metal—it’s about intelligence. Imagine a stamping die that can “talk” to your factory floor, alerting you to wear, misalignment, or temperature spikes in real time. That’s the promise of smart dies equipped with embedded sensors and Internet of Things (IoT) connectivity. These advanced tools collect data on every stamping and pressing cycle, enabling predictive maintenance and minimizing unplanned downtime. With real-time analytics, manufacturers can spot trends, optimize progressive die design, and ensure consistent quality across every run. As Industry 4.0 transforms stamping technology, smart dies are becoming the backbone of a more efficient, data-driven production ecosystem.

Lightweighting and Its Impact on Die Design

Ever wondered how automakers are making vehicles lighter without sacrificing safety or performance? The answer lies in the growing use of aluminum, high-strength steels, and advanced composites. This lightweighting trend is reshaping auto stamping in profound ways. Stamping dies must now handle a wider variety of materials, each with unique forming characteristics and demands on die durability. For example, forming ultra-high-strength steel or aluminum panels requires dies with enhanced wear resistance and precise thermal management. As a result, engineers are rethinking die construction, incorporating new coatings and cooling strategies to support the next generation of lightweight vehicles [source]. The shift toward lighter materials also means more complex shapes and tighter tolerances—pushing progressive die design to new levels of sophistication.

Additive Manufacturing in Tool and Die Making

Picture this: a stamping die with intricate internal cooling channels, lattice structures for weight reduction, or custom geometry that would be impossible to machine using traditional methods. That’s what additive manufacturing (AM), or 3D printing, is bringing to the table. By building dies layer by layer, AM enables unprecedented design freedom—allowing for rapid prototyping, faster iteration, and even the integration of conformal cooling channels that dramatically improve cycle times and part quality. Recent research shows that dies produced with AM can achieve up to 17% higher cooling rates and 11.5% material savings compared to conventional dies, all while maintaining or improving structural integrity [source]. This technology is especially valuable for hot stamping applications and for producing dies tailored to the demands of lightweight, high-strength materials.

- Smart dies: Enable real-time monitoring and predictive maintenance

- Lightweighting: Drives new die materials and advanced cooling strategies

- Additive manufacturing: Unlocks complex, efficient die designs and faster development cycles

As the automotive industry races toward electric, autonomous, and more sustainable vehicles, stamping technology will continue to evolve. Embracing these innovations isn’t just about staying competitive—it’s about shaping the future of auto stamping for a smarter, lighter, and more adaptable world. Next, we’ll explore how choosing the right manufacturing partner ensures you leverage all these advancements for your next project.

Achieving Excellence with an Expert Partner

Choosing the Right Manufacturing Partner

When you’re sourcing metal stamping dies for the automotive industry, have you ever asked yourself—what separates a flawless component from one that causes headaches down the line? The answer is rarely just price. It’s the depth of expertise in die design, materials science, and rigorous quality control that truly makes the difference. Imagine trying to launch a new vehicle model with tight timelines—would you trust just any stamping dies manufacturer to deliver on precision, reliability, and speed?

In today’s market, automotive stamping companies must offer more than just tools; they need to be strategic partners who understand the full spectrum of challenges, from rapid prototyping to mass production. The best providers combine advanced simulation, robust process controls, and a proven track record with global aftermarket car manufacturers and OEMs. That’s why companies like Shaoyi Metal Technology Co., Ltd. are trusted by industry leaders—they deliver custom metal stamping dies and die stamp set solutions that meet the highest international standards, including IATF 16949 certification.

Key Considerations for Your Next Project

So, who offers the best quality in automotive aftermarket and OEM supply? The answer lies in a partner who can integrate every stage of the process, from digital design and material selection to inspection and traceability. Here are the key takeaways to guide your decision:

- Holistic Expertise: Success in metal stamping car parts requires mastery of die design, material science, and process engineering.

- Quality Assurance: Only work with stamping dies manufacturers committed to international standards and advanced inspection methods.

- Integrated Solutions: Choose a partner with in-house capabilities for prototyping, production, and assembly—minimizing risk and accelerating timelines.

- Proven Track Record: Look for automotive stamping companies trusted by top global brands and aftermarket car manufacturers.

- Future-Ready Technology: Ensure your provider is investing in smart dies, digital process control, and additive manufacturing for next-generation performance.

For organizations seeking reliable, high-precision components, the right partner is a catalyst for success. If you’re ready to elevate your next project, explore how Shaoyi Metal Technology Co., Ltd. can deliver the expertise, technology, and confidence you need in custom metal stamping dies and more. Excellence in automotive stamping starts with the right collaboration—make it count.

Frequently Asked Questions about Automotive Stamping Dies

1. What is an automotive stamping die and why is it important?

An automotive stamping die is a precision tool used to shape sheet metal into car parts like body panels and brackets. Its importance lies in enabling manufacturers to produce high-quality, consistent, and safe automotive components at scale, ensuring that each part meets strict industry standards and fits perfectly during vehicle assembly.

2. How do progressive, transfer, and compound dies differ in automotive manufacturing?

Progressive dies perform multiple operations in sequence for high-volume, simple parts. Transfer dies move parts between stations for complex shapes and deep draws. Compound dies complete several actions in a single press stroke, making them ideal for flat, precise components. The choice depends on part complexity, volume, and required accuracy.

3. What materials are used to make automotive stamping dies?

Automotive stamping dies are commonly made from tool steels like D2, advanced alloys, and sometimes carbide inserts for high-wear areas. The material choice affects the die's durability, resistance to wear, and ability to handle advanced materials like high-strength steel or aluminum, which are increasingly used in modern vehicles.

4. How do manufacturers ensure quality and consistency in stamped car parts?

Quality is maintained through rigorous inspection methods like Coordinate Measuring Machines (CMM) and 3D laser scanning. Industry certifications such as IATF 16949 and ISO 9001 ensure process control, traceability, and compliance, reducing errors and guaranteeing that every stamped part meets automotive safety and performance standards.

5. What new technologies are shaping the future of automotive stamping dies?

Emerging trends include smart dies with real-time monitoring sensors, the use of additive manufacturing for complex die features, and a focus on lightweighting with advanced materials. These innovations help automotive stamping companies improve efficiency, reduce costs, and produce more precise, reliable car parts.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —