The True ROI of Custom Extrusion Dies for Mass Production

The True ROI of Custom Extrusion Dies for Mass Production

TL;DR

The return on investment (ROI) of custom extrusion dies for high-volume production is exceptionally strong due to a modest initial tooling cost that is amortized over a large number of parts. With die costs often ranging from $300 to over $2,000, the per-unit expense becomes minimal at scale. This makes custom extrusion a highly economical manufacturing method for creating complex, precise profiles compared to processes with more expensive tooling, like die casting.

Deconstructing the Initial Investment: A Breakdown of Custom Extrusion Die Costs

Before calculating the long-term return, it is essential to understand the initial investment in tooling. Unlike other manufacturing processes where tooling can be a significant financial barrier, the cost of custom aluminum extrusion dies is relatively low. This affordability is a primary driver of their favorable ROI, especially in high-volume scenarios. The initial outlay for a die is a one-time charge that, when spread across thousands or millions of units, has a negligible impact on the final part price.

The cost of an extrusion die is not a single figure but varies based on several key design and manufacturing factors. According to an analysis by Ya Ji Aluminum, costs can be broken down by complexity. A simple solid die might cost between $300 and $800, while a more intricate hollow profile die could range from $800 to $2,000. For highly complex, multi-void profiles or very large sections, the investment can exceed $2,000. These figures are significantly lower than the tooling for alternatives like die casting, which can cost upwards of $25,000, as noted by American Douglas Metals.

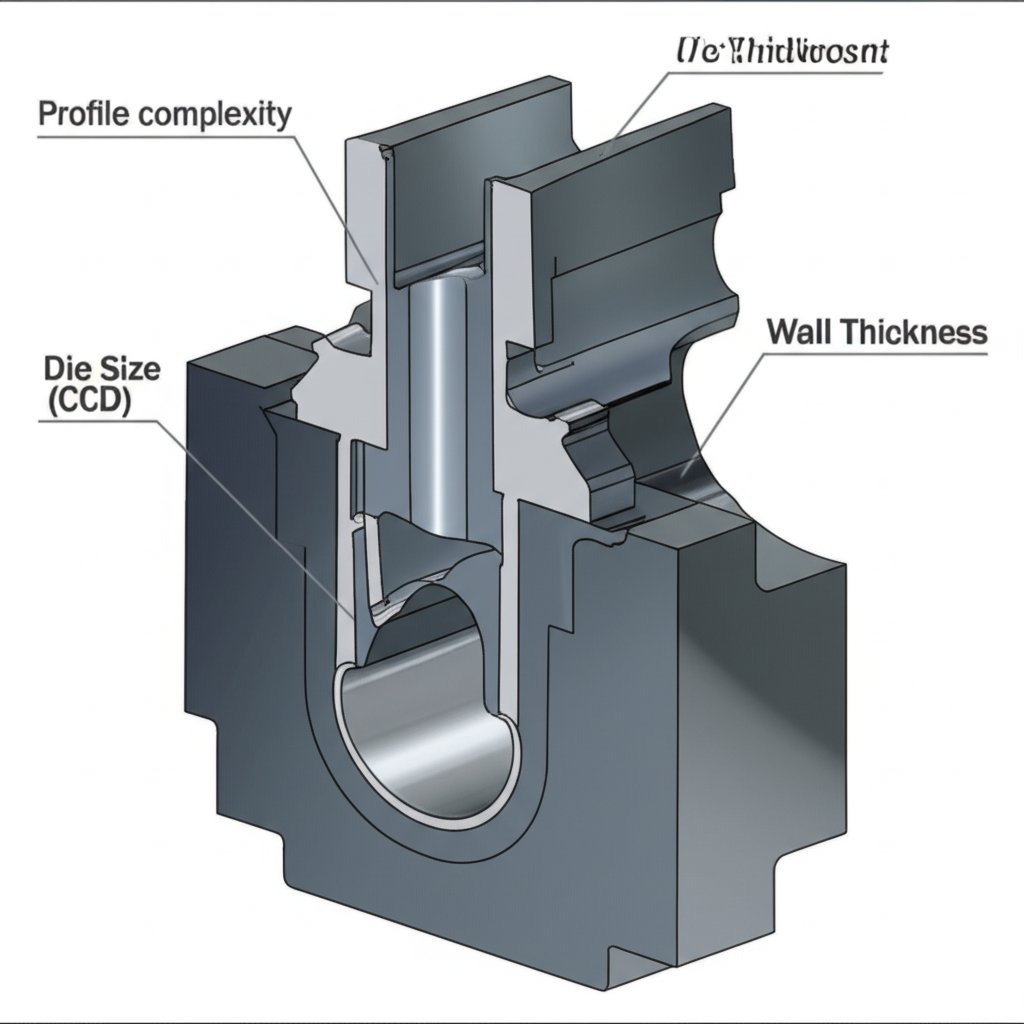

Several critical factors directly influence this initial cost. The primary driver is profile complexity. A simple, symmetrical shape is easier to machine and requires less steel than a complex, asymmetrical profile with internal voids. Other key variables include:

- Die Size: Measured by the Circumscribing Circle Diameter (CCD), which is the smallest circle the profile's cross-section can fit inside. A larger CCD requires a larger, more expensive die block.

- Tolerances: Tighter dimensional tolerances demand more precise machining and extensive quality checks, which increases the cost.

- Die Material: Most dies are made from H13 tool steel, but high-wear applications may require premium materials or coatings, adding to the price.

- Number of Cavities: For small profiles produced in very high volumes, a multi-cavity die can extrude several parts at once. While the upfront cost is higher, it dramatically reduces the per-part production cost.

The Payoff: How Custom Dies Drive ROI in High-Volume Production

The core of the ROI calculation lies in amortization. The initial tooling cost, while important, is a fixed expense. In high-volume production, this cost is divided across the entire production run. For example, a $1,500 die used to produce 100,000 feet of a profile adds only $0.015 per foot to the cost. As the production volume increases, this per-unit tooling cost approaches zero, making the raw material and extrusion time the dominant expenses. This principle is what makes custom extrusion a powerhouse for mass production.

Beyond simple cost amortization, custom dies generate ROI through significant engineering and operational efficiencies. The extrusion process allows for the creation of incredibly complex cross-sections that can integrate multiple functions into a single component. This capability can eliminate the need for secondary machining, welding, or assembly operations. For instance, features like screw bosses, heat sink fins, and snap-fit joints can be built directly into the profile, reducing both labor costs and the number of parts in a final assembly.

Furthermore, custom extrusions contribute to ROI by optimizing material usage. Engineers can design profiles that place metal only where it is structurally needed, creating lightweight yet strong components. This is a distinct advantage over subtractive manufacturing methods that start with a solid block of material and generate significant scrap. The efficiency of the extrusion process itself, often measured by its "yield"—the amount of finished product relative to raw material used—is inherently high, minimizing waste and maximizing the value extracted from the raw aluminum billet.

Strategic Design and Planning: Actionable Tips to Maximize ROI

Achieving the maximum possible ROI from custom extrusion dies is not automatic; it requires thoughtful design and strategic planning. Engineers and designers can take several concrete steps to optimize their profiles for both cost-effectiveness and performance. By focusing on design for manufacturability (DFM), teams can reduce initial tooling costs and improve production speeds, further enhancing the financial return.

One of the most effective strategies is to maintain uniform wall thickness throughout the profile. Drastic variations in thickness can cause uneven cooling and material flow issues, leading to dimensional instability. As a design guide from Gabrian highlights, symmetrical shapes are easier and cheaper to extrude because they allow for balanced pressure on the die. Where thickness changes are necessary, they should be gradual, using smooth transitions and rounded corners instead of sharp angles, which can create stress points in both the part and the die.

Another key tip is to avoid unnecessarily tight tolerances. Specifying tolerances that are stricter than the application requires can significantly increase die complexity and cost. Designers should also consider breaking an overly complex profile into two or more simpler, interlocking parts. While this may seem counterintuitive, two simple dies are often cheaper and faster to produce than one extremely intricate die. For projects with demanding requirements, such as those in the automotive sector, partnering with a specialist can be invaluable. For automotive projects demanding precision-engineered components, consider custom aluminum extrusions from a trusted partner. Shaoyi Metal Technology offers a comprehensive one-stop service, from rapid prototyping to full-scale production under a strict IATF 16949 certified quality system, helping to streamline manufacturing and ensure specifications are met efficiently.

Making the Business Case for Custom Extrusions

Ultimately, the business case for investing in custom extrusion dies for high-volume production is compelling. The combination of a low initial tooling investment, dramatic per-unit cost reduction through amortization, and significant opportunities for part consolidation and weight reduction creates a powerful return on investment. By embracing strategic design principles and collaborating with experienced suppliers, manufacturers can leverage this versatile process to gain a significant competitive advantage, reducing total product cost while improving performance and quality.

Frequently Asked Questions

1. How much does a custom extrusion die cost?

The cost of a custom aluminum extrusion die typically ranges from $300 to over $5,000. A simple, solid profile die may cost between $300 and $800. A hollow profile die generally falls in the $800 to $2,000 range. Highly complex, large, or multi-void dies can cost $2,000 or more. The final price depends on the profile's complexity, size (CCD), tolerances, and the number of cavities.

2. What is the yield of extrusion?

In the context of extrusion, "yield" refers to the amount of finished, usable product obtained from a certain amount of raw material. It is a measure of process efficiency. A high yield indicates that very little material was wasted as scrap during production, which is a key factor in keeping costs down, especially in high-volume runs.

3. What is the price of 4040 aluminum extrusion?

The price of a standard profile like 4040 aluminum extrusion is not directly related to custom die costs, as the tooling for these common shapes has long been amortized. The price for standard profiles is primarily based on the current market price of aluminum per kilogram or pound, plus the extruder's processing and finishing costs. Prices vary between suppliers and fluctuate with the global aluminum market.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —