Elevating Automotive Manufacturing Standards: Recap Shaoyi’s Quality Training Day

Introduction: Quality Is the Cornerstone of Automotive Manufacturing

At Shaoyi Metal Technology, we believe that quality is not just an outcome—it's a mindset. In the competitive and high-precision world of automotive component manufacturing, especially in automotive stamping and CNC machining, excellence in quality is non-negotiable.

On Tuesday, June 4th, our team gathered an internal quality training session, emphasizing our continued commitment to operational excellence, customer satisfaction, and technical leadership. This training wasn't just a routine—it was part of our continuous improvement journey to reinforce high standards across the workworkshop floor.

Why Quality Matters in the Automotive Industry

For companies like Shaoyi, serving global automotive OEMs and Tier 1 suppliers, product quality directly impacts vehicle safety, performance, and regulatory compliance. A single defect can affect an entire supply chain.

That's why our approach to quality is built on:

Prevention rather than correction

Deep technical understanding of materials and processes

Rigorous standards aligned with IATF 16949 certification

By investing in regular training, we aim to build a culture where quality is everyone's responsibility—from the stamping press to final inspection.

Training Focus: Real-World Issues, Root Cause Thinking

Led by our senior quality expert Mr. Xu Xungui, the training focused on product performance knowledge, especially for aluminum tubing used in chassis and structural parts.

Key sections included:

1. Understanding Quality at Its Source

"Product quality is created during design and manufacturing, not by inspection. "

Employees were reminded that knowing the customer's technical requirements, assembly fitment needs, and special product characteristics is essential before production starts.

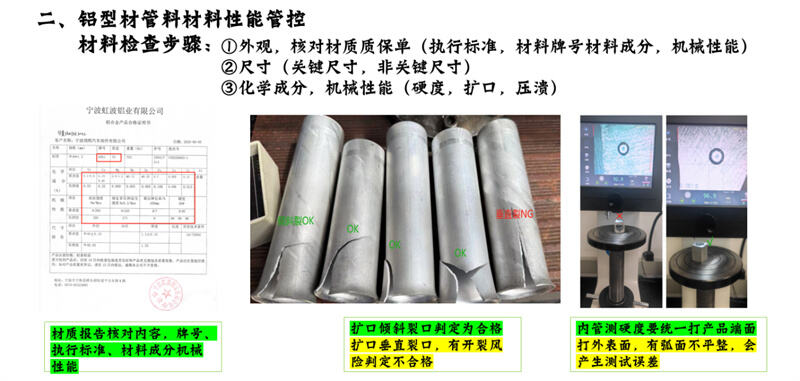

2. Material Quality Control

Participants learned how to verify aluminum alloy materials by checking:

`Certificates of conformity (chemical composition, mechanical properties)

`Critical dimensions

`Expansion and crushing behavior

`Hardness testing techniques (only on flat ends to avoid measurement errors)

Visual Aids Tip: Include a diagram of acceptable vs. unacceptable aluminum tube expansion samples.

3. Defect Identification in Aluminum Tubes

Real examples of typical defects were reviewed, such as:

`Inner and outer surface scratches due to unmaintained dies

`Bubbling from gas or contamination in billets

`Misalignment and eccentricity caused by uneven aluminum flow

These insights help operators and technicians detect issues early and contribute to defect prevention rather than after-the-fact corrections.

Tackling Electroplating Surface Issues

Shaoyi also addressed frequent challenges in surface finishing, including:

`Yellow spots from poor cleaning

`Sealant residue from improper application

`Uneven color or corrosion from inconsistent chemical parameters

Our team learned how minor errors during pre-treatment can lead to significant cosmetic and functional issues. Understanding these problems empowers employees to take preventive action on the workshop floor.

Reinforcing a Culture of Accountability

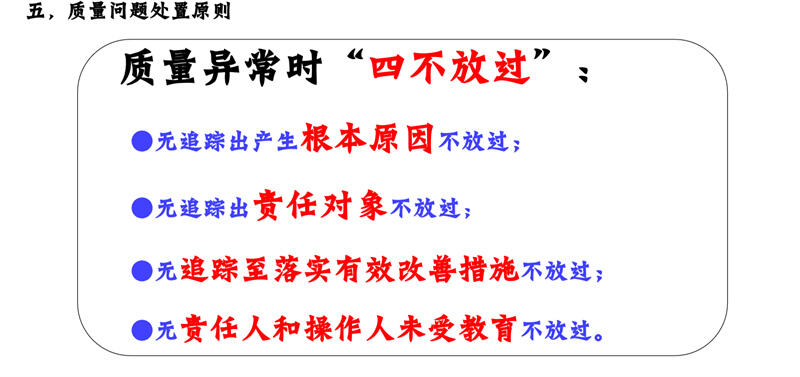

Our quality culture emphasizes the "Four No-Pass Rules":

If the root cause is unknown, the issue is not closed.

If the responsible party is unclear, the issue is not closed.

If no effective corrective action is in place, the issue is not closed.

If no training has been provided to those involved, the issue is not closed.

By applying these principles, we're not only resolving issues—we're building long-term capability.

Interactive Engagement: Learning Through Participation

To enhance engagement, the training included interactive Q&A sessions. Staff were presented with real scenarios and asked how they would respond or diagnose the issue. This practical, solution-oriented discussion helped reinforce theoretical learning with real-world applications.

What This Means for Our Customers

For our clients in the automotive sector, this training translates into:

`Fewer defects and rework

`More consistent lead times

`Reliable, on-spec parts that meet safety and performance standards

When our team is educated, proactive, and aligned, we create stronger partnerships and better results.

Our Promise: Continuous Improvement ,Never Stops

This training is one of many steps in our journey toward zero-defect manufacturing. Moving forward, we plan to:

`Increase training frequency

`Launch quality certification programs for operators

`Implement digital tracking of defect root causes

At Shaoyi, we know that manufacturing excellence starts with people, knowledge, and discipline.

Let's Build Quality Together

Thank you to every team member who participated with dedication and curiosity. Your effort drives our promise to deliver quality—every part, every time.

Do you want to learn more about our automotive metal parts manufacturing services? Contact us right now to explore how our services can meet your automotive manufacturing needs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —