Strengthening Warehouse Excellence Through Staff Skill Assessments: A Closer Look at Our June 4 Examination

Introduction: Precision in Warehouse Management as a Competitive Edge

In today’s fiercely competitive market, a company's true strength lies not only in the quality of its products and services, but also in the precision and standardization of its internal operations. Warehouse management, as a core part of business operations, has a direct impact on production efficiency, cost control, and customer satisfaction.

On June 4, our company held a significant employee skill assessment, serving not only as a test of individual abilities but also as a thorough exercise in reinforcing our warehouse operation protocols. This initiative exemplifies our commitment to professional discipline and internal excellence—a value we proudly share with our clients.

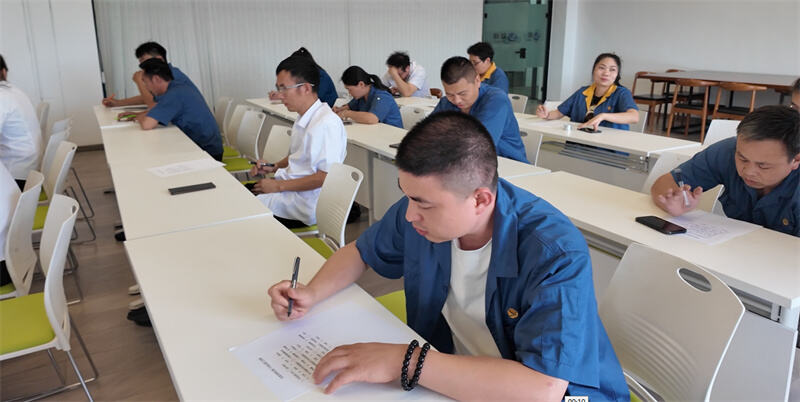

Examination site

1. Why We Conducted This Warehouse Operations Exam

As our business expands, warehouse operations have become increasingly complex and crucial. To ensure accuracy, efficiency, and safety in our supply chain, we have implemented a comprehensive set of protocols covering:

·Barcode-based outbound shipments

·Inventory reconciliation and delivery

·3rd-party warehouse operations

·Daily supply inventory and request management

·Outsourced order processing

·Defective product reporting workflows

The goal of the exam was to evaluate our team’s understanding of these procedures through both theoretical questions and hands-on practical assessments. By reinforcing operational norms, we aim to ensure every team member can execute their tasks with precision, supporting our long-term goal of providing customers with stable, high-quality products and services.

2. Key Exam Topics: Deep Integration with Standardized Warehouse Procedures

A. Barcode Outbound Process

Barcode scanning is a crucial step for accuracy and traceability. During the exam, employees were expected to confirm shipment warehouses based on outbound notifications, especially when using third-party fulfillment centers. Real-time scanning not only ensures error-free dispatch but also improves transparency and inventory traceability for customers.

Warehouse scanning code into the warehouse

B. 3rd-Party Warehouse Fulfillment

Maintaining synchronization between our internal system and third-party warehouses is essential for timely delivery. The exam evaluated knowledge on daily sales order processing and reconciliation procedures. Employees demonstrated their ability to identify discrepancies and align records efficiently—a process that protects both customer interests and financial integrity.

C. Daily Supplies Inbound & Issuance

Although simple on the surface, daily supply management requires precise handling. The test covered the entire workflow from request to dispatch, including form submissions, item identification, and barcode-based release. Standardizing this process minimizes waste, controls stock levels, and supports cost tracking.

D. Outsourcing and Defect Reporting Processes

Employees demonstrated their understanding of post-outsourcing inspections using colored card systems (yellow for pending, green for approved), mobile QA reporting, and proper documentation. For defect reporting, candidates had to log quantities, categorize defects, issue rework requests, and reconcile materials used versus order demand. Accurate recordkeeping and swift handling here are crucial for quality control and process optimization.

3. What This Means for Our Customers

The impact of standardizing warehouse procedures extends far beyond internal operations. For our customers, it means:

·Fewer shipping errors and delays

·Improved order fulfillment visibility

·Stable product quality through better material handling

·Higher trust in our logistics and supply chain transparency

By embedding rigorous training and testing into our operations, we safeguard our ability to meet customer expectations reliably and efficiently.

4. Our Vision: Continuous Improvement and Smart Warehousing

Though this exam was a success, we view it as one step in our journey. Moving forward, we will:

·Increase the frequency of internal training and assessments

·Upgrade warehouse systems with smart automation

·Explore advanced warehouse management software

·Gather client feedback to tailor process improvements

By doing so, we aim to set new benchmarks in warehouse efficiency and customer service.

Let’s Build Excellence Together

We deeply appreciate the support and trust of our customers. Every improvement we make in our internal processes is designed to bring greater value to you. We invite you to follow our journey and grow with us.

For inquiries about our warehouse operations or to learn more about our supply chain capabilities, please contact us.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —