5S Daily Inspections in Shaoyi’s CNC and Stamping Workshop

Introduction: Why 5S Matters in Automotive Metal Parts Manufacturing

In the fast-paced world of automotive metal parts manufacturing, maintaining a highly organized, efficient, and safe workshop environment is not just a best practice—it's a competitive necessity. At Shaoyi Metal Technology, we implement daily 5S inspections across our stamping workshop and CNC machining workshop to ensure every process is clean, controlled, and client-ready.

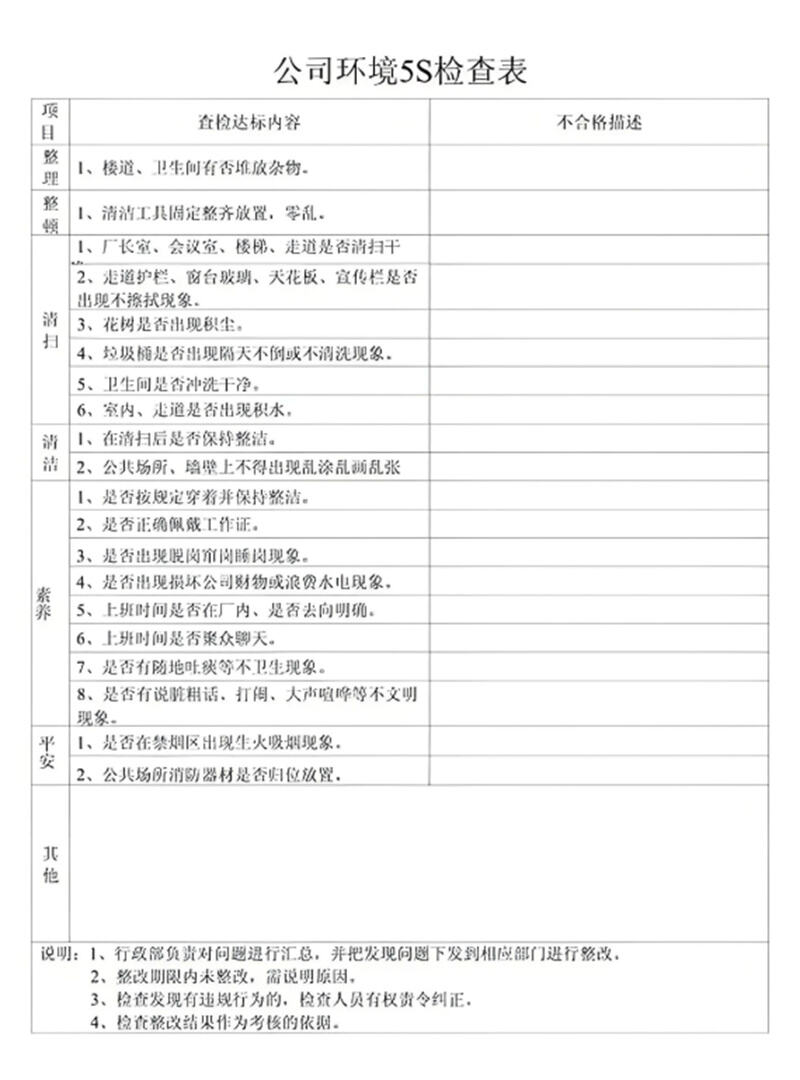

The 5S methodology—originally developed in Japan—encompasses:

1.Seiri (Sort) – Removing unnecessary items from the workspace.

2.Seiton (Set in Order) – Organizing necessary tools and materials for easy access.

3.Seiso (Shine) – Cleaning the work environment to maintain hygiene and safety.

4.Seiketsu (Standardize) – Establishing uniform procedures and practices.

5.Shitsuke (Sustain) – Instilling discipline to maintain and improve standards.

By embedding the 5S system into our daily routines, we not only streamline production of our automotive aluminum and metal stamping parts but also significantly enhance product quality, safety, and reliability.

CNC workshop

How 5S Strengthens CNC and Stamping Operations

1. Enhanced Productivity and Precision

In the CNC machining workshop, daily 5S checks ensure that machines are well-maintained, cutting tools are in top condition, and scrap or debris is immediately removed. This reduces tool wear, minimizes downtime, and guarantees that every automotive aluminum part we manufacture meets exact specifications.

In our metal stamping workshop, 5S practices keep dies and fixtures in organized storage, ensuring fast changeovers and consistent output during high-volume production runs. The result? Greater efficiency and fewer dimensional errors.

2. Accident Prevention and Operator Safety

A tidy workshop is a safe workshop. Through daily 5S audits, we proactively eliminate tripping hazards, oil spills, loose wires, and misplaced tools—common causes of workplace injuries. This disciplined approach minimizes accidents and improves morale among our operators and technicians.

Moreover, regular equipment cleaning and maintenance under Seiso and Seiketsu help detect early signs of wear or malfunction, allowing us to take preventive action before breakdowns occur.

What 5S Prevents – And Why It Matters for Our Clients

Our daily 5S inspections help prevent:

Production errors caused by misplacement of tools or improper materials.

Delays due to unplanned downtime or poor workflow.

Contamination in aluminum machining or stamping areas.

Unaccounted quality deviations in automotive parts that could compromise safety.

These small daily habits culminate in massive gains for our customers:

Reliable lead times thanks to consistent workflow and equipment readiness.

Fewer defects and reworks, resulting in more stable, high-performance automotive components.

Clear traceability and documentation from a clean, standardized production process.

Our clients, especially in the automotive industry, value stability and precision. 5S practices provide the foundation for both.

A Culture of Continuous Improvement

At Shaoyi, we go beyond ticking checklists. Every department has clear 5S responsibility zones, from the aluminum die casting area to CNC and stamping sections. Supervisors lead daily walkthroughs, while team members are encouraged to suggest improvements.

These internal improvements directly impact our automotive aluminum, metal stamping, and custom precision parts. Better workplace layout and tool organization mean tighter tolerances, fewer errors, and faster delivery times.

Conclusion: 5S as a Foundation for Excellence

By practicing 5S every day, we reinforce our dedication to quality, efficiency, and customer satisfaction. Our stamping and CNC workshops are not just clean—they are controlled, consistent, and continuously improving.

As the global demand for automotive lightweight solutions and precision aluminum components increases, we believe strong workplace habits are the hidden backbone of reliable manufacturing.

At Shaoyi, we invite you to experience the difference a clean, professional, and well-organized production floor can make.

�� Want to learn more about our metal part manufacturing?

�� Visit our CNC and stamping services page

�� Need custom aluminum or stamped parts? Contact us today

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —