Slash Aluminum Extrusion Costs With 5 Essential DFM Tips

Slash Aluminum Extrusion Costs With 5 Essential DFM Tips

TL;DR

To effectively reduce aluminum extrusion costs, apply Design for Manufacturability (DFM) principles from the very beginning. The most impactful strategies involve simplifying the part's cross-sectional profile, maintaining uniform wall thickness, and selecting the most appropriate aluminum alloy for the application. Specifying standard tolerances and minimizing complex, non-functional features will further decrease both tooling and production expenses, leading to significant savings.

The Foundation: Key DFM Principles for Cost-Effective Extrusion

Design for Manufacturability (DFM) is a proactive engineering approach focused on designing products to optimize all facets of the manufacturing process. When applied to aluminum extrusion, DFM bridges the gap between a design's intent and the physical realities of production. The core goal is to eliminate potential problems, reduce complexity, and lower costs before the first piece of metal is ever pushed through a die. By considering the manufacturing process during the design phase, you can prevent costly revisions, reduce material waste, and shorten lead times.

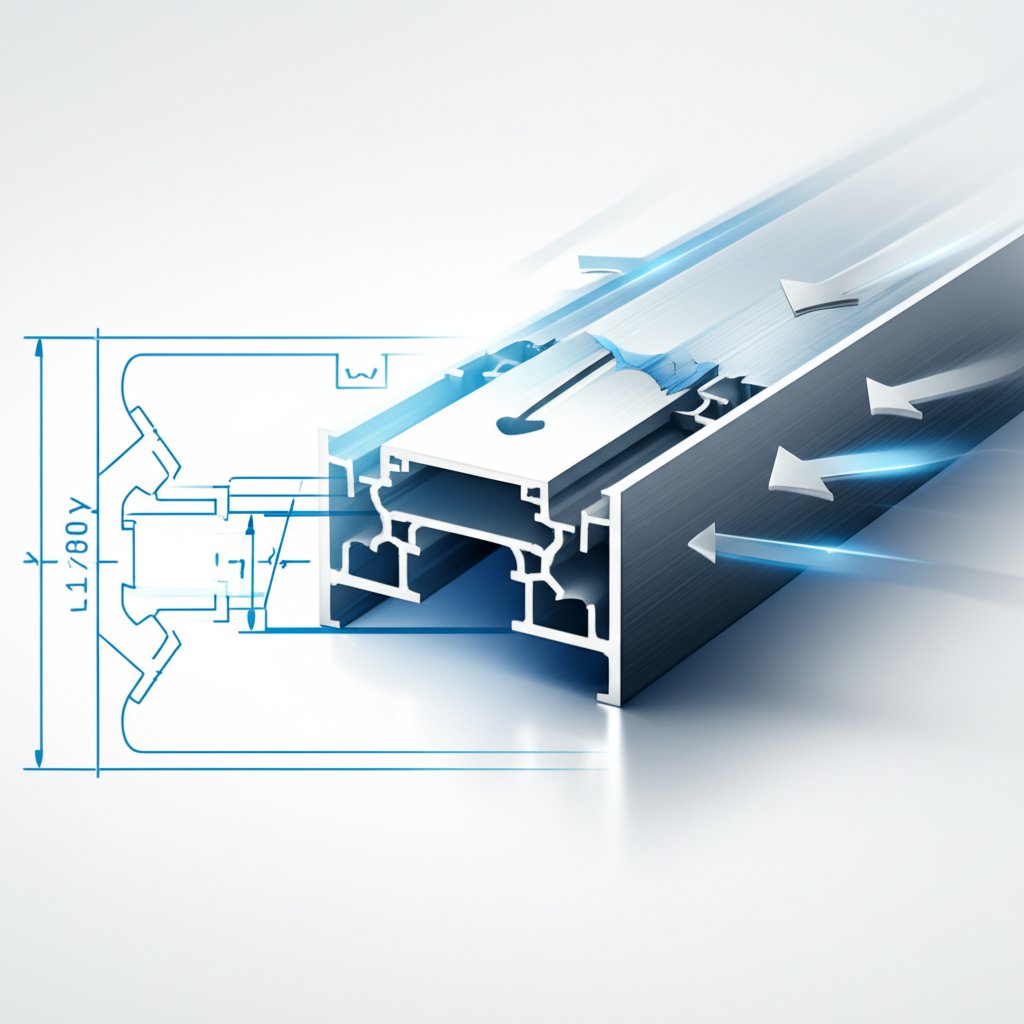

A fundamental principle of DFM for extrusion is the pursuit of simplicity and symmetry. Complex, asymmetrical profiles can cause uneven material flow and cooling, leading to warping, twisting, and dimensional inaccuracies. Symmetrical designs, in contrast, promote balanced pressure and consistent flow, resulting in a more stable process and a higher-quality final product. As explained in a guide from Jiga, simplifying the cross-section not only reduces the complexity and cost of the extrusion die but also enhances the operational reliability of the entire production run.

Another critical DFM concept is optimizing material usage and flow. Since aluminum is often priced by weight, any reduction in a profile's cross-sectional area directly translates to cost savings. DFM encourages designing with the minimum material necessary to meet structural requirements. This involves more than just making walls thinner; it includes using features like rounded corners instead of sharp ones. Rounded corners facilitate smoother metal flow, reduce stress concentrations, and minimize die wear, all of which contribute to a more efficient and affordable manufacturing process.

Strategic Profile Design: How Shape and Wall Thickness Drive Cost

The geometry of the extrusion profile is the single most significant factor influencing cost. Every decision about the shape, from its overall complexity to the thickness of its walls, has a direct impact on tooling expenses, production speed, and material consumption. The primary goal should be to create the simplest, most streamlined profile that still meets all functional requirements. This means eliminating any features that do not serve a critical purpose.

Maintaining a uniform wall thickness is paramount for cost-effective extrusion. Significant variations in thickness create an unbalanced die, forcing the aluminum to flow at different speeds through different parts of the profile. This can lead to a host of problems, including warping, twisting, and an inability to hold tight tolerances. To avoid these issues, which slow down production and increase scrap rates, designers should aim for consistent walls. When thickness variations are unavoidable, the transitions should be gradual and smooth. A common guideline is to keep wall thickness above 1 mm to prevent distortion during machining and handling.

Beyond wall thickness, the overall complexity of the shape plays a major role. Features like deep, narrow channels or sharp internal corners are difficult to extrude and can dramatically increase tooling costs and wear. Here are some actionable tips for simplifying your profile design:

- Do use simple, rounded hollows instead of complex, multi-void shapes whenever possible.

- Do design with generous radii on all internal corners to improve metal flow and reduce stress.

- Don't specify features that require undercuts, as these often necessitate expensive secondary machining operations.

- Don't create profiles with a high extrusion ratio (the ratio of the circumscribing circle's area to the profile's area), as these are more difficult and slower to produce.

Material and Tooling: Upfront Choices with Downstream Savings

The choices you make regarding the aluminum alloy and the extrusion die design are foundational investments that dictate a large portion of the total project cost. These upfront decisions have significant downstream consequences on everything from production speed to the need for secondary finishing operations.

First, selecting the right aluminum alloy is a balance of performance, cost, and manufacturability. While a high-strength alloy like 7075 may be necessary for demanding aerospace applications, it is more expensive and harder to extrude than more common alloys. The two most widely used alloys for custom extrusions are 6061 and 6063. 6061 aluminum is known for its superior strength and is excellent for structural applications. In contrast, 6063 aluminum is slightly softer, making it easier to extrude into complex shapes and providing a better surface finish, which is ideal for parts that will be anodized or used in architectural applications. Choosing the most cost-effective alloy that meets your project's functional needs is a key DFM strategy.

Second, the extrusion die itself is a major cost driver. The complexity of your profile directly determines the cost of the tooling. As detailed by experts at Profile Precision Extrusions, a simple solid die might cost around $1,250, whereas a more complex hollow die can cost $1,950 or more. Hollow profiles require a much more intricate and robust two-part die, increasing both the initial cost and the setup time. By simplifying a design from a hollow to a solid shape, you can achieve significant savings. For specialized applications, particularly in sectors like automotive where precision is paramount, partnering with an experienced supplier can be invaluable. For instance, companies like Shaoyi Metal Technology offer comprehensive services from prototyping to production under strict quality systems, helping to navigate these complex decisions.

Finishing Touches: Optimizing Tolerances and Finishes to Cut Final Costs

The final details of a design—specifically, dimensional tolerances and surface finishes—are often overlooked but can substantially inflate the final part cost. Applying DFM principles to these finishing touches is crucial for preventing unnecessary expenses at the end of the production cycle.

Specifying unnecessarily tight tolerances is one of the most common ways projects go over budget. While high precision is critical for some features, such as mating surfaces, applying it across an entire part is wasteful. Tighter tolerances require slower extrusion speeds, more rigorous quality control checks (often with expensive CMM equipment), and can lead to higher rejection rates. This all adds time and money. The most practical approach is to specify standard commercial tolerances for all non-critical dimensions and reserve tight tolerances only for the features that absolutely require them for functionality or assembly.

Similarly, decorative features and surface finishes should be evaluated based on function rather than aesthetics alone. Every intricate detail, such as an engraved logo or a textured pattern, adds machining time and complexity. According to DFM guidelines, it is often more cost-effective to achieve a desired look through secondary finishing processes. Consider these points:

- Limit Machined Details: Instead of milling complex patterns, consider post-extrusion finishes like anodizing or powder coating to add color and improve appearance.

- Specify Finishes Only When Needed: A standard mill finish is the most economical option. Specify cosmetic finishes like brushing or polishing only for surfaces where appearance is a primary functional requirement.

- Design for Finishing: If a part is to be anodized, choosing an alloy like 6063 will yield a better, more consistent result, potentially lowering finishing costs and improving quality.

A Blueprint for Cost-Effective Extrusion

Reducing the cost of aluminum extrusions is not about cutting corners on quality; it's about making smarter, more informed decisions throughout the design process. By embracing Design for Manufacturability, you shift from a reactive to a proactive approach, solving problems before they can impact your budget or timeline. The key is to think like a manufacturer from the moment you begin your design.

The core takeaways are clear and actionable. Prioritize simplicity and symmetry in your profile geometry. Insist on uniform wall thickness to ensure a stable and efficient extrusion process. Select the least expensive aluminum alloy that meets all performance criteria, and design your part to use the simplest possible tooling. Finally, be judicious with tolerances and finishes, specifying them based on functional necessity rather than arbitrary standards.

By integrating these DFM tips into your workflow, you can create parts that are not only high-performing and reliable but also significantly more economical to produce. This strategic approach transforms the design process from a simple act of creation into a powerful tool for cost control and manufacturing excellence.

Frequently Asked Questions

1. What is the biggest factor in aluminum extrusion tooling cost?

The single biggest factor is profile complexity. Specifically, the difference between a solid and a hollow profile has the most significant impact. Hollow profiles require a more complex, multi-part die that is more expensive to manufacture and has a longer lead time. Other elements like very thin walls, sharp corners, and asymmetrical features also increase die complexity and cost.

2. Which aluminum alloy is cheapest to extrude?

In general, softer alloys are easier and faster to extrude, which can lower production costs. 6063 aluminum is typically considered one of the most extrudable alloys due to its lower strength and excellent formability. While the raw material cost difference between alloys like 6063 and the stronger 6061 may be minimal, the ease of processing 6063 can lead to lower overall costs, especially for complex profiles.

3. How does wall thickness affect extrusion cost?

Wall thickness affects cost in two main ways. First, non-uniform walls cause unbalanced material flow, which can slow down the extrusion process and lead to defects like warping, increasing scrap rates. Second, extremely thin walls (typically under 1mm) are fragile, prone to distortion, and require slower extrusion speeds to produce successfully. Both scenarios increase production time and drive up the final part cost.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —