Custom Aluminum Extrusions for Vehicle Roof Racks Explained

Custom Aluminum Extrusions for Vehicle Roof Racks Explained

TL;DR

Custom aluminum extrusions provide a superior solution for vehicle roof racks, offering a combination of lightweight strength, exceptional durability, and a perfect fit tailored to your specific vehicle and needs. Through a collaborative process with specialized manufacturers, you can design and produce a high-performance rack system that standard off-the-shelf products cannot match. This process involves precise engineering, from alloy selection to final finishing, ensuring optimal performance and aesthetics.

Understanding the Core Benefits of Custom Aluminum Extrusions

When sourcing a roof rack, opting for one built from custom aluminum extrusions provides significant advantages over generic, mass-produced alternatives. The extrusion process allows for the creation of complex cross-sections that are optimized for strength, weight, and functionality. This level of customization translates directly into better performance, longevity, and a seamless integration with your vehicle. These benefits make it the preferred choice for commercial, recreational, and heavy-duty applications.

The primary advantages are rooted in the material properties of aluminum and the precision of the manufacturing process. Key benefits include:

- Lightweight Strength: Aluminum alloys, particularly those in the 6000 series like 6061 and 6063, offer an excellent strength-to-weight ratio. This means you can have a robust rack capable of carrying heavy loads without adding significant weight to your vehicle, which helps maintain fuel efficiency and handling characteristics.

- Superior Corrosion Resistance: Aluminum naturally forms a protective oxide layer that prevents rust. This resistance can be dramatically enhanced through surface treatments like anodizing or powder coating, ensuring the rack withstands harsh weather conditions for decades. This is a clear advantage over steel, which is susceptible to rust if its coating is compromised.

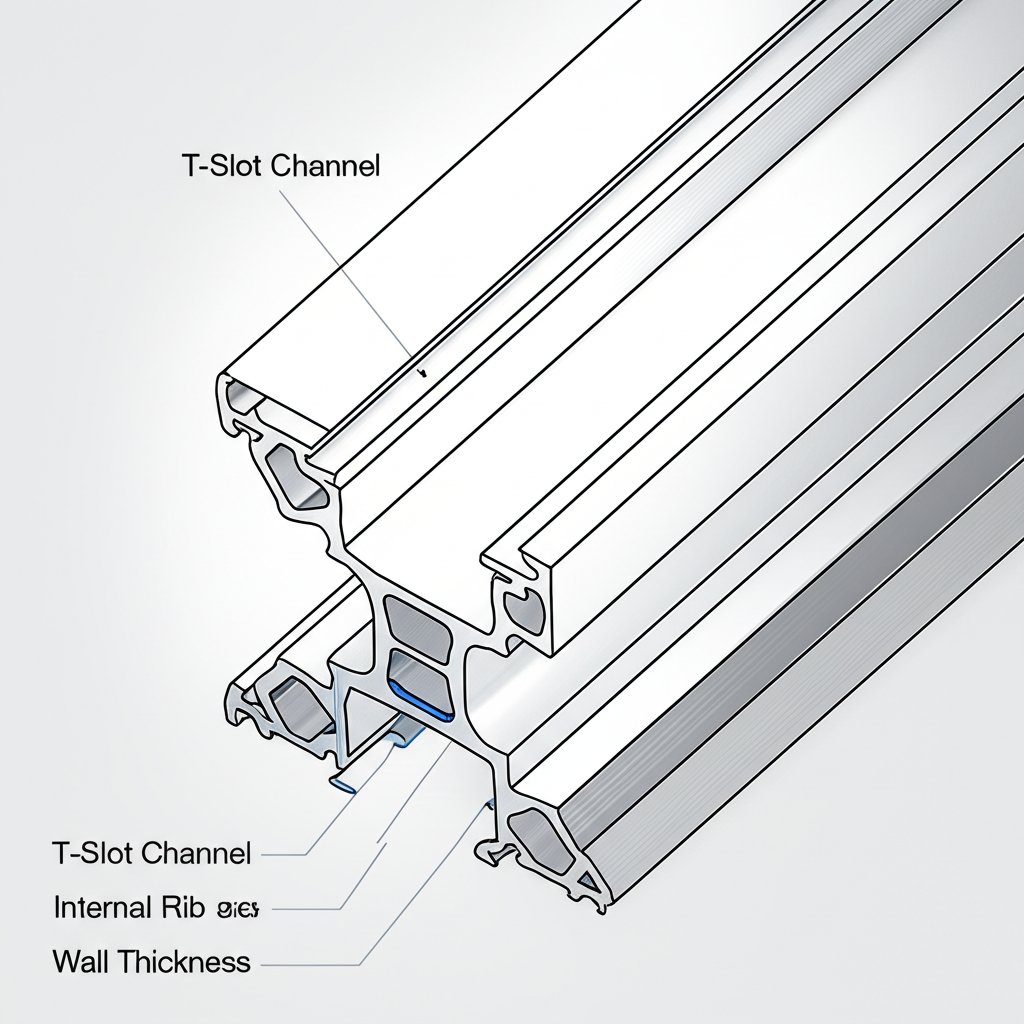

- Complete Design Freedom: The core benefit of custom extrusion is the ability to design a profile that meets your exact needs. This includes creating integrated T-slots or M8-compatible fastener channels for easy accessory mounting, as detailed by suppliers like Rugged Bound Supply Co. This allows for a clean, modular system without bulky, add-on clamps.

- Aerodynamic Efficiency: A custom-designed rack can be shaped to minimize wind noise and drag. Unlike bulky universal-fit racks, an extruded profile can be made sleek and low-profile, complementing the vehicle's lines and improving its aerodynamic performance on the road.

The Customization Process: From Concept to Final Product

Creating a custom aluminum roof rack is a structured engineering process that transforms a design concept into a finished, high-performance product. This journey involves close collaboration with a manufacturer to ensure every technical requirement is met. Leading suppliers like Wellste and HTS-ALU outline a clear, multi-stage workflow that provides control and precision from start to finish. Understanding these steps demystifies the process and helps manage expectations for quality and lead times.

The typical development path follows these key stages:

- Initial Consultation and Design: The process begins with a detailed consultation where you provide your specifications, drawings (CAD or STEP files are often preferred), or concepts to the manufacturer's engineering team. They provide feedback on feasibility, suggest design optimizations for strength and manufacturability, and finalize the profile design.

- Material and Alloy Selection: Based on the application's demands, the ideal aluminum alloy and temper are chosen. For instance, 6061-T6 is often selected for its high strength in structural applications, while 6063-T5 is prized for its excellent surface finish, making it ideal for parts where aesthetics are paramount.

- Mold (Die) Development: Once the design is approved, a custom steel die is precision-machined. This die is the negative of the desired profile through which heated aluminum will be pushed. This step is critical to the final product's dimensional accuracy and can typically take two to four weeks to complete.

- Extrusion and Fabrication: A billet of the selected aluminum alloy is heated and forced through the die, emerging as a long, continuous profile. After cooling, the extrusions are stretched to relieve stress and ensure straightness. They are then cut to the required lengths and can undergo secondary fabrication processes like CNC machining, drilling, or welding to create the final components.

- Finishing and Assembly: The final step is applying a surface treatment. The components are then ready for assembly, often using specialized hardware designed to fit the integrated channels. For automotive projects requiring this level of precision, working with a partner that offers a complete service is key. For example, some manufacturers specialize in delivering strong, lightweight, and customized parts under strict quality systems.

Key Technical Specifications and Options

Making informed decisions during the design phase is crucial for achieving the desired performance and durability of your custom roof rack. The primary technical choices revolve around the aluminum alloy, the type of surface finish, and the method of hardware integration. Each of these elements directly impacts the rack's strength, resistance to the elements, and modularity. Gaining a clear understanding of these options empowers you to specify a product that is truly fit for purpose.

Aluminum Alloy Types

The choice of alloy is fundamental. The 6000 series is most common for these applications, with 6061 and 6063 being the top contenders. While similar, they have key differences that make them suitable for different needs.

| Alloy | Primary Characteristics | Best For |

|---|---|---|

| 6061 | Higher strength, excellent mechanical properties, good weldability. | Structural components, heavy-duty racks, off-road applications requiring maximum durability. |

| 6063 | Excellent corrosion resistance, exceptionally smooth surface finish, good extrudability for complex shapes. | Applications where aesthetics are critical, intricate profiles, and standard-duty cargo carrying. |

Finishing Options

The surface finish protects the aluminum and defines its final appearance. The two most popular choices for vehicle roof racks are powder coating and anodizing.

- Powder Coating: This process involves electrostatically applying a dry powder to the aluminum and then curing it under heat. It creates a thick, durable, and uniform finish that is highly resistant to chipping, scratching, and fading. It also offers a vast range of color options, with black being a popular choice for a sleek, OEM look.

- Anodizing: An electrochemical process that thickens the natural oxide layer on the aluminum's surface. This creates an incredibly hard, corrosion-resistant, and wear-resistant layer that is integral to the metal itself, meaning it cannot chip or peel. Common finishes include clear (natural silver) and black.

Hardware Integration

A major advantage of custom extrusions is the ability to build in mounting solutions directly into the profile. This eliminates the need for drilling or external clamps, resulting in a stronger and cleaner design. Look for extrusions with channels designed for T-nuts or standard fasteners, such as the M8-compatible channels mentioned in the SERP. Companies like Sherpa Equipment Co. offer a wide range of compatible components, including drop-in T-nuts, mounting feet, and stainless steel bolts, allowing for a fully modular and customizable system.

Applications and Vehicle Compatibility

The true value of custom aluminum extrusions lies in their universal adaptability. Because each component is designed and manufactured for a specific purpose, these roof racks are not limited to a narrow range of vehicles or applications. The process allows for complete freedom in terms of length, width, shape, and mounting style, ensuring a perfect fit on virtually any vehicle, from a commercial work van to a rugged off-road SUV or a passenger car.

This versatility allows for the creation of various roof rack styles, each tailored to a specific use case. Platform racks offer a large, flat surface ideal for rooftop tents, oversized gear, or construction materials. Basket racks, with their raised sides, are perfect for securing luggage and irregularly shaped items. Crossbar systems provide a minimalist base for mounting specialized carriers for bikes, skis, or kayaks. By customizing the extrusion profile itself, these different styles can be optimized for strength and utility.

The compatibility extends across a wide array of vehicle types and brands. Manufacturers often showcase solutions for popular platforms like the Mercedes Sprinter, Toyota 4Runner, and various trucks and SUVs. The ability to create custom mounting feet and extrusions cut to precise lengths means that even unique vehicles or trailers can be outfitted with a perfectly integrated and highly functional roof rack system. This ensures a secure, stable platform for carrying cargo, no matter the adventure or job.

Frequently Asked Questions

1. Why choose aluminum over steel for a roof rack?

Aluminum is the preferred material primarily due to its excellent strength-to-weight ratio and natural corrosion resistance. An aluminum rack is significantly lighter than a steel one of comparable strength, which improves fuel economy and makes installation easier. Unlike steel, aluminum will not rust, and this durability is further enhanced with finishes like anodizing or powder coating.

2. How much weight can a custom aluminum roof rack hold?

The load capacity of a custom aluminum roof rack is not a single standard number; it is determined by its design. Factors include the specific alloy and temper used (e.g., 6061-T6 is stronger than 6063-T5), the thickness and shape of the extrusion profiles, the number of crossbars, and the vehicle's own roof load limit. A properly engineered system is designed to meet specific load requirements safely.

3. What are the most common aluminum alloys used for roof racks?

The most common alloys are from the 6000 series, specifically 6061 and 6063. 6061 is chosen for applications demanding higher structural strength and rigidity, making it ideal for heavy-duty and off-road use. 6063 is selected when a high-quality surface finish and more intricate profile shapes are a priority, without sacrificing good overall strength.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —