Повече от 15 години Шаои помага на производители на автомобили и доставчици да превърнат идеите си в реалност.

ПОЛУЧИ ОФЕРТАКачете чертежите си или споделете вашите индивидуални изисквания и получете персонализирана оферта, създадена специално за вас!

Високоточно штамповане за шасита и конструкционни части, осигуряващо постоянни размери при производство в големи серии.

Сложни компоненти, обработени с точност ±0,01 мм, отговарящи на строгите стандарти в автомобилната промишленост.

Леки, високопрочни алуминиеви части с отлична повърхностна обработка, идеални за шасита и конструкционни приложения.

Прецизни заваръчни сглобки, които гарантират здравина и правилно подравняване на шасита и конструкционни компоненти.

Персонализирани штамповъчни матрици, изработени със строг контрол на качеството и професионално майсторство, оптимизирани за надеждно производство в големи обеми.

Високопрочни студено формовани части с прецизни размери, перфектни за употреба в окачвания и конструкции.

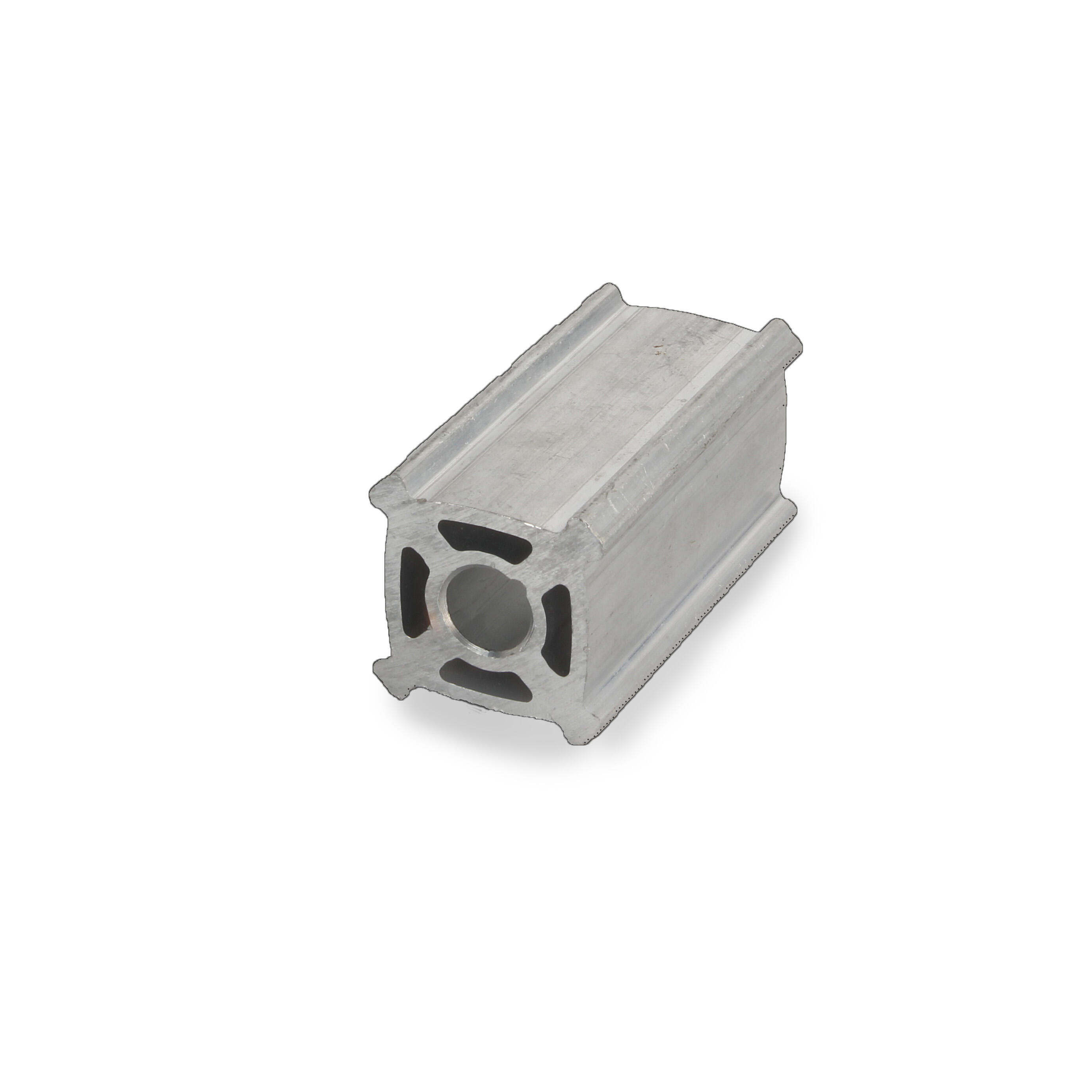

Персонализирани алуминиеви профили, проектирани за здравина, лекота и високонапрегнати автомобилни конструкции.

Издръжливи метални бушинги, проектирани за шасита и окачвания, които подобряват устойчивостта на износване и увеличават живота.

Ние предлагаме комплексни решения за метални части за автомобили – от индивидуално штамповане, CNC обработка, финиширане на повърхности, до заваряване и монтаж – осигурявайки висока прецизност, постоянство на качеството и бързо изпълнение за OEM производители и доставчици от първо ниво

Различните сценарии на употреба изискват различни повърхностни свойства, като например защита от ръжда, естетика и изисквания за грапавост и др.

Осигурява подобрена устойчивост към корозия и по-добра адхезия на боята за продължителна експлоатация.

Тази повърхност подобрява умерената устойчивост към корозия и намалява отразяването на светлината, което я прави идеална за автомобилни части, нуждаещи се от матова, антибликаща повърхност.

Осигурява отлична адхезия на покритието със стабилно и последователно качество.

Тази повърхност създава гладък, равномерен слой с отлична якост на сцепване, поради което широко се прилага при метални корпуси, рами и автомобилни части.

Това покритие подобрява твърдостта на повърхността и усилва издръжливостта на цвета, което го прави идеално за декоративни и защитни приложения върху автомобилни компоненти.

Често използван за автомобилни фиксатори, скоби и шасийни части, този процес създава равномерен, защитен цинков слой върху всички компоненти.

Подобрява проводимостта и действа като подслой за други покрития.

Подобрява твърдостта, корозионната устойчивост и износоустойчивостта.

Това финиширане осигурява стабилна, екологично чиста защита с висока последователност и често се използва за автомобилни шасита, фиксатори и спирачни системи.

Електрохимичен процес, при който се образува контролиран оксиден филм върху алуминия, осигуряващ отлична устойчивост на корозия, електрическа изолация и декоративни повърхности в различни цветове.

Независимо къде се намирате, просто изпратете своя дизайн или идея – ние ще се погрижим за останалото.

ПОЛУЧИ ОФЕРТА

Всички продукти от ядрото на бушингите ще преминат през 100% размерен контрол

Използване на различни технологични процеси, прилага се за метални държачи на климатици в автомобили

Изработена чрез прецизно штамповане за постигане на необходимата якост и точност за безопасността на окачването

Тежък штампов процес със стоманен лист от 9 мм, осигуряващ издръжливост и носеща способност.

Обработен с CNC за прецизен контрол на теглото, осигуряващ гладко балансиране на возилото.

Произведен с роботизирано заваряване и множество процеси, осигуряващ последователност и надеждност при серийно производство.

Произведена чрез обработка на токарен стан за осигуряване на точни резби и перфектно сглобяване със съответстващите компоненти.

Сглобен с автоматизирана технология за пресоване, комбинираща няколко етапа в един ефективен процес.

Изработен чрез штамповане и последващо покритие с електрофореза, осигуряващо отлична защита от ръжда и дълъг срок на служба.

Произведен чрез многостепенно штамповане с валидация по метода на крайните елементи (CAE), за да се гарантира структурната стабилност при леки автомобили.

Издръжливо заварено сглобяване, адаптирано за средни автобуси, което поддържа компресорите на климатиците с висока устойчивост.

Комбинация от обработка с CNC и заваряване, осигуряваща както якост, така и точност на размерите.

Прилагаме строги протоколи за контрол на качеството, за да се гарантира, че всяка кована част постоянно отговаря на точните размерни и спецификации за производителност, изисквани от нашите клиенти.

Нашата непоколебима ангажираност към качеството, подкрепена от сертификат IATF 16949, задържда нашата строга проверка на качеството на всеки етап от производството. Този внимателен подход ни позволява да доставяме превъзходни ковани автопartenuri – от първоначалния дизайн до крайната доставка – гарантирайки изключителна производителност, надеждност и продължителна тревогодност.

Използвайки най-съвременни производствени и инспекционни устройства за горещо коване, гарантираме, че всяка кована автомобилна част се произвежда с безпрецедентна прецизност и последователност. Нашата напреднала машинария, комбинирана с автоматизирани проверки на качество, запазва строги толеранции и оптимизира производителността през целия процес на производство, което води до компоненти, които предлагат изключителна устойчивост и надеждност.

Нашата екип от изкуствени експерти привлича десетилетия опит в горещото формене, специализирайки се върху формене на части за автомобили. Тяхната дълбока техническа знание и ангажимент към иновациите гарантират, че всяка компонента е проектирана да отговаря на най-високите стандартни за индустрията. Чрез интеграция на напреднали технологии с доказано зnanie, нашият екип постоянно предлагат висококачествени, надеждни части, които подпомагат производителността и безопасността на автомобилите.

Да, ние предлагаме напълно персонализирани решения и разполагаме с възможности за изработване както на прототипи, така и на малки до големи серийни партиди. Всеки проект се адаптира според вашите конкретни изисквания.

Нашата система за управление на качеството е сертифицирана по IATF 16949. Изпълняваме проверки по време на производствения процес, CAE симулации и окончателни проверки на качеството, за да гарантираме, че всеки компонент отговаря на строгите стандарти на автомобилната индустрия.

Времето за изпълнение зависи от сложността на детайла и изискваните процеси. Нашата услуга за бързо прототипиране може да достави пробни образци в рамките на 7 дни , докато графикът за стандартно производство се планира така, че ефективно да отговаря на сроковете на вашия проект.

Към всеки клиент се назначава отделен мениджър по проекта. Ще получавате редовни актуализации относно статуса на производството, проверките на качеството и графиките на пратките , което осигурява пълна прозрачност и точни срокове.

Можем да приоритизираме спешни проекти чрез оптимизиране на графика и производствения поток. Нашата комплексна услуга позволява по-бързо прототипиране и масово производство, като същевременно се запазва висока прецизност и качество.

Да, ние предлагаме услуги за бързо прототипиране чрез штамповане, CNC обработка и леене под налягане, което ви позволява да тествате и валидирате дизайна преди пълномащабно производство.

Нашият инженерен екип оценява вашите изисквания и препоръчва най-подходящите метали и сплави, като взема предвид якост, тегло, устойчивост на корозия и икономическа ефективност.

Използваме напреднали инструменти за контрол на качеството, проверки по време на процеса и CAE симулации, за да осигурим еднородност и да гарантираме, че всеки компонент отговаря на строгите автомобилни стандарти.

Да, ние координираме опаковката, етикетирането и пратката до Северна Америка, Европа, Близкия изток и Югоизточна Азия , осигурявайки безопасна и навременна доставка по целия свят.

След години от разработка, технологията за сваряване на компанията включва главно газозащитно сварване, изкравчено сварване, лазерно сварване и различни видове сварвателни технологии, комбинирани с автоматизирани линии за монтаж. Чрез Ултразвуково Тестване (UT), Рентгенско Тестване (RT), Магнитно Частично Тестване (MT), Инфилтрационно Тестване (PT), Течностружково Тестване (ET) и тестване на отривна сила, достигаме висока производителност, високо качество и по-безопасни сварени конструкции. Можем да предлагаме CAE, MOLDING и 24-часово бързо офертиране, за да предоставяме по-добри услуги за шасийни чекмеджета и обработени части.