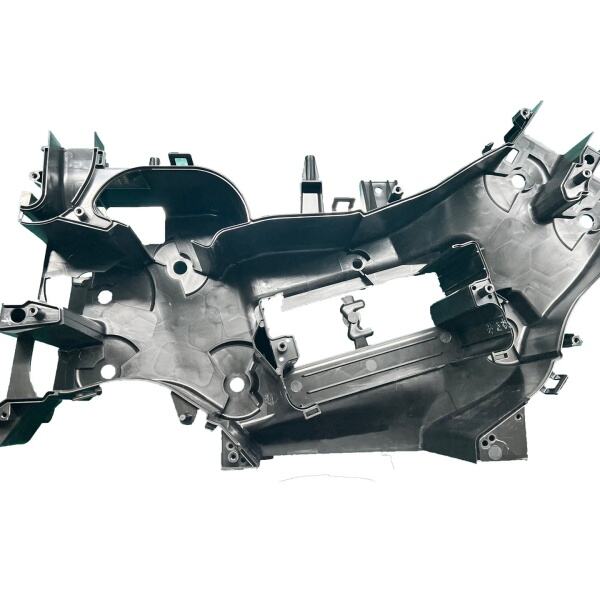

Plastic is in a lot of things we use on a daily basis. It's in our playthings, its packaging for our food and even in parts of a car! A method used to manufacture auto parts in which we excel is known as plastic injection molding. This method involves melting down the plastic and then forcing it into a mold that shapes it into the right shape. This is how we produce many of the components that make their way into cars. Now, we will explain how plastic injection molding style works and why it is a crucial component for car part creation.

The manufacture of car parts plastic injection molding is a very important process. Carmakers such as Shanghai-based Shaoyi use the technique to make custom-fit parts for their cars. We keep that process making sure each part is done the same every time. Shaoyi automotive plastic mould is important because it makes sure that cars are safe and functions perfectly. When every piece is in sync, the parts can operate well to create a functioning car and avoid headaches.

Injection molding has other advantages such as strong and direct fitting car parts that are manufactured by companies like Shaoyi. This implies that once the parts are assembled in a car, they complement each other and do not fracture easily. This process involves using a very resilient and durable plastic that results in testing conditions. These components will put up with anything from hot climate to chilly or hunks of asphalt. That longevity matters quite a bit because it keeps the car going strong longer.

Auto components that are light-weight and inexpensive to manufacture can also be moulded using Shaoyi automotive plastic injection moulding. It means cars can perform better when car parts are lightweight. This allows them not only to go faster, but also with lower fuel consumption. To sum it up, less fuel consumption = savings for drivers in the long run. Moreover, this molding process provides an intuitive assembly of car parts for car makers. Essentially, this saves time and money on each car produced, which makes the process more efficient as a whole.

Injection molded parts have dramatically changed the way cars are built. This will enable Shaoyi and other companies in particular to make parts with greater complexity and sophistication than they've been able to before. This gives car makers a whole new canvass to do all sorts of things with. Which allows them to make cars that are not only pretty but also have new features that directly contribute to enjoyment (in a way, safety) when on the road. That talk of creativity in car design is also nifty for the manufacturer and driver alike.

Adding safety is among the highest things car makers should consider. Shaoyi injection molded plastic auto parts allows car manufacturers to keeps the vehicles within a high safety standards. What this ultimately translates to, is that they've designed the cars to create a safe environment for when people are behind the wheel. Injection molding is very strong and accurate, meaning there are fewer chances of failure. It sure adds to the overall trust and security a driver would want in a vehicle.

The majority of products we produce are used in the automobile industry. We provide high-quality components that are suitable for a broad range of vehicles, including passenger cars commercial vehicles, golf carts motorbikes, trucks and tractors. Our extensive product range shows our flexibility and dedication to meet the diverse needs of the automotive market. We also are proud to be the leading supplier of suspension systems to Volkswagen in China. This proves the ability of our company to provide innovative and reliable solutions to the top auto brands. Our extensive industrial experience allows our products not only meet but exceed customer expectations for the performance and quality.

Our company, which covers more than 10,000 square meters and specializes in the manufacture of parts made of metal for over 30 automobile brands, boasts more than 15 years of experience in the field. We employ cutting-edge processing techniques, including stamping, CNC machining mold production, and aluminum die-casting, to ensure that each product is of the highest quality standards. Our strict quality control measures ensure that our products remain uniform in terms of dimension as well as performance. This increases confidence and trust with our clients.

We are incredibly proud to hold the IATF certification 16949, which is a testament to our quality management excellence that we strive to achieve within the auto industry. Our quality department has mastery over five crucial quality tools which include Statistical Process Control (SPC), Measurement Systems Analysis (MSA), Failure Mode and Effects Analysis(FMEA), Advanced Product Quality Planning and the Production Part Approval Process. Furthermore, our quality staff has completed extensive Six Sigma training, ensuring that we are adhering to the most stringent standards for quality of products. This comprehensive method of quality control ensures that every product we provide not only meets but often exceeds expectations of the industry, but also provides our clients with confidence and satisfaction over our services.

We are very proud of our dedicated R&D department, in which each engineer has more than 10 years of experience in automotive. This knowledge allows us to understand the unique characteristics and processes of different materials, which allows us to offer customized solutions to our clients. We offer professional CAE analysis as well as product development and technical assistance as well as a complete DFM report to make sure that every aspect of the design has been developed to meet the demands of production. We are committed to innovation and provide top-quality metal products which meet the exact requirements of our customers.