Moreover, made from robust materials such as steel, these tend to be resistant against heavy wear on rough roads so you do not have the worry of ruining it. Plastic can also be given a shiny surface to make it resemble gold or chrome so the car looks pretty, too.

These plastic parts are often used for door handles and make it easy to open or close the doors. Bumpers, the parts that shield the car in the event of a fender-bender are also made of these tough plastic materials. These parts provide function to the vehicle, while also providing outside aesthetics of the vehicle as well.

These are also plastic parts that play a big role in the construction of electric cars. As people increasingly become aware of the environment and desire to drive more environmentally friendly cars.

One of the biggest ways injection molding had changed automotive production is by how well it could improve aesthetics and functionality.

Such technology has enabled the automobile manufacturers to design vehicles faster and more economically. It means more people in the world than ever can buy, and thus enjoy the freedom, of cars.

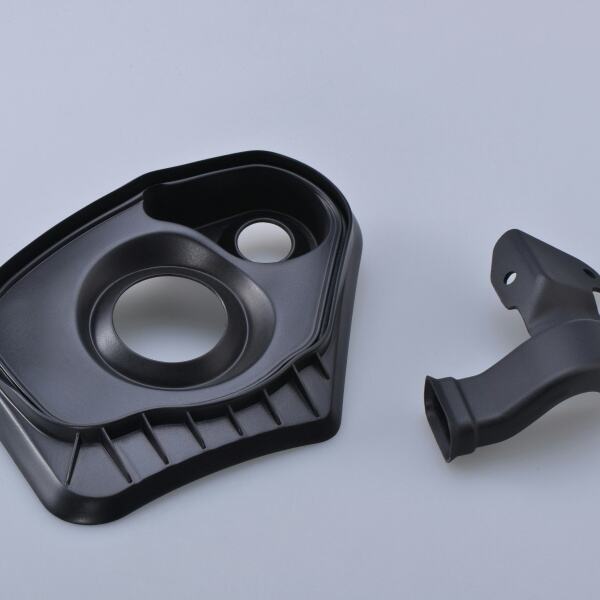

With more than 15 years of expertise in the automotive sector, our firm covers an area over 10,000 square meters and specialize in the manufacturing of metal parts for over 30 automotive brands. We utilize advanced processing techniques which include stamping, CNC machine machining, mold making, and aluminum die-casting to ensure that every product is of the highest quality standards. Our stringent quality control procedures ensure that our products are constant in terms of dimensions shape, form and performance. This creates confidence and trust with our customers.

We are very proud of our committed R&D department, where every engineer has over 10 years of automotive experience. This expertise enables us to understand the unique nature and characteristics of the various materials, allowing us to offer customized solutions to our clients. We offer expert CAE analyses in product development, technical support as well as comprehensive DFM report to ensure that every aspect of the design is optimised for manufacturing. We're committed to advancing technology and provide top-quality metal products that are designed to meet the needs of our clients.

Over 90% of the products we manufacture are intended for the automotive industry. We offer high-quality parts that are suitable for a broad range of vehicles, including passenger automobiles golf carts, commercial vehicles as well as motorcycles, trucks and tractor. Our wide range of products is a testament to our ability to satisfy all the requirements of the market for automobiles. We're also privileged to be the leading supplier of suspension systems to Volkswagen in China that demonstrates our capacity to offer reliable and revolutionary solutions to the top automotive brands. Our long-standing industrial knowledge allows our products not only meet but exceed customer expectations regarding the performance and quality.

Our company takes pride in possessing the IATF Certification 16949, which is as a proof of our commitment to excellence in quality management within the automotive industry. Our quality department has mastered five crucial quality tools including Statistical Process Control (SPC), Measurement Systems Analysis (MSA), Failure Mode and Effects Analysis(FMEA), Advanced Product Quality Planning and Production Part Approval Process. Furthermore, our quality staff has completed intensive Six Sigma training, ensuring that we are adhering to the most stringent standards in product quality standards. This thorough system of quality management makes sure that each product we offer not only meets but often exceeds expectations of the industry, but also provides our customers with confidence and satisfaction over our services.