What Is Powder Coating Rims: Price Breakdown, Timing, And Warranty

Understanding Powder Coating Rims in Plain Terms

Ever wondered why some wheels seem to shrug off chips, corrosion, and road grime while others lose their shine after just a few seasons? The secret often lies in the finish. So, what is powder coating rims—and why is it becoming the go-to choice for drivers who want both style and substance?

What Powder Coating Rims Actually Means

Powder coating rims is a modern finishing process that uses a dry, pigment-rich powder instead of traditional liquid paint. Here’s how it works: after the wheels are thoroughly cleaned and prepped, the powder is applied using an electrostatic charge. This charge helps the powder cling to every curve and crevice of the rim—even intricate designs that are tough to reach with a spray can or brush. Once coated, the wheels are heated in a curing oven. The result? The powder melts, flows, and fuses into a single, uniform layer that’s both attractive and exceptionally tough.

Why Powder Beats Traditional Paint on Rims

Imagine driving through a construction zone or down a salted winter road. With powder coating, your wheels are protected by a thick, non-porous shield that resists chipping, flaking, and corrosion far better than most liquid paints. The difference between paint and powder coat comes down to both the materials and the process: powder contains no solvents and forms a thicker, more resilient film when baked. This makes powder coating rims vs painting a clear win for those seeking longer-lasting results and fewer touch-ups.

- Durability: Powder coat wheels can last up to three times longer than painted wheels, resisting chips and scratches from daily driving.

- Corrosion Resistance: The non-porous finish acts as a shield against road salts, debris, and moisture.

- Finish Consistency: Electrostatic application ensures even coverage—even on complex wheel designs—leading to a smooth, high-end look.

- Eco-Friendliness: Powder coating emits no volatile organic compounds (VOCs), making it a cleaner, safer process for both operators and the environment.

Powder coating rims creates a cohesive, cured film that resists chips and corrosion better than most aerosol paints when properly prepped and baked.

Common Myths About Powder Coated Wheels

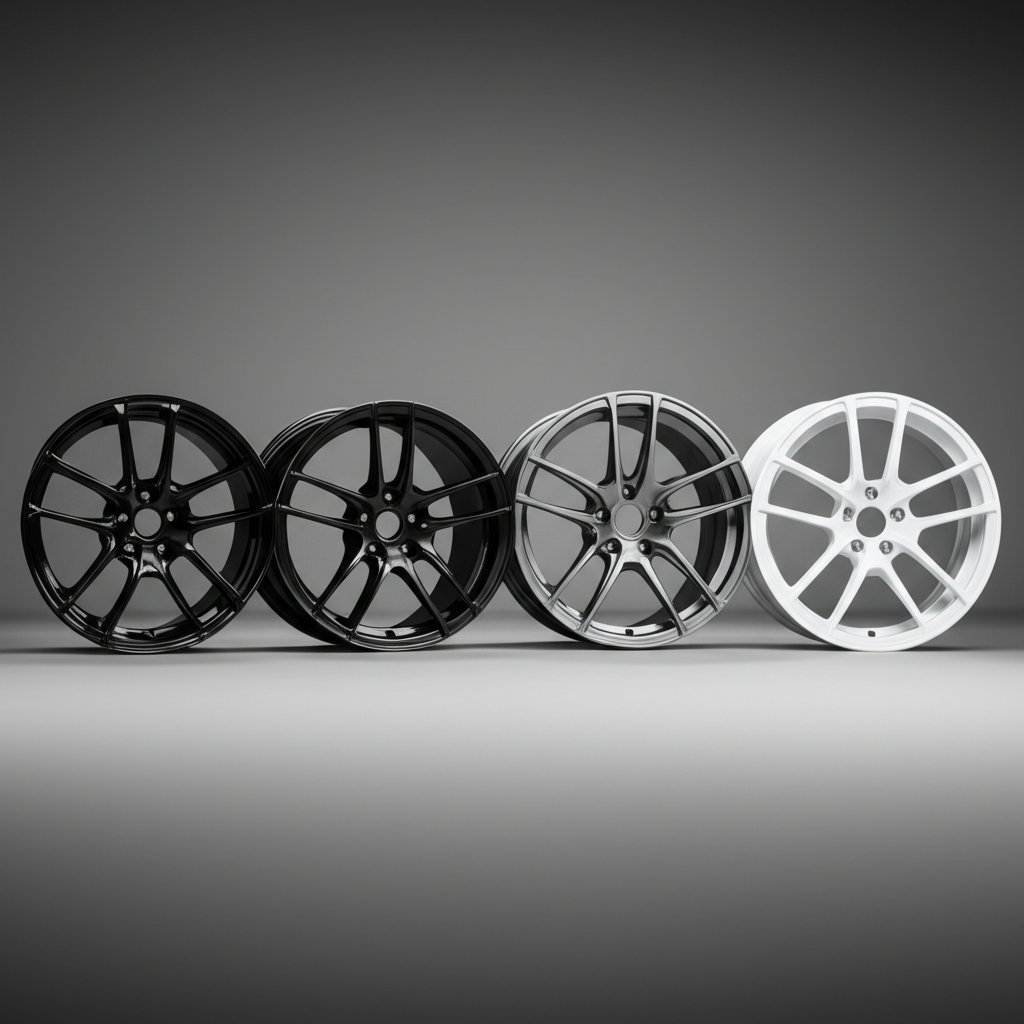

Some drivers worry that powder coating wheels limits their color choices or makes repairs difficult. In reality, while custom color matching is easier with paint, powder coating offers a wide range of vibrant, standard finishes—from gloss black and matte black to metallics and even white. And when it comes to maintenance, powder-coated rims are easier to clean and keep looking new, provided you follow basic care guidelines.

In short, if you’re looking for a finish that stands up to the demands of daily driving and delivers a premium, uniform appearance, powder coating rims is a smart investment. For those still weighing powder coating rims vs painting, consider the superior durability, environmental benefits, and low maintenance needs that set powder coating apart. Always refer to powder manufacturer technical data sheets for validated application and curing specifications to ensure the best results.

How the Rim Powder Coating Process Works

Ever wondered what really goes on behind the scenes when you drop off your wheels for powder coating? The transformation from a scuffed, faded rim to a flawless, durable finish is all about precision and process. Let’s break down the step-by-step workflow for powder coating wheels, so you know exactly what to expect—and why every stage matters for lasting results.

Preparation Essentials Before Coating

-

Stripping and Cleaning

- All old paint, clear coats, and contaminants must be removed. This is often done with chemical strippers or mechanical means.

- Thorough cleaning ensures that no grease, brake dust, or residues remain, which could cause adhesion problems later.

-

Media Blasting

- Wheels are sandblasted (or blasted with aluminum oxide or glass bead, depending on the wheel alloy and desired finish) to create a rough profile for powder adhesion.

For powder coating aluminum wheels, extra care is taken to remove all oxidation and ensure a uniform surface. - Every nook and cranny is addressed—any missed spot can lead to uneven coating or future flaking.

- Wheels are sandblasted (or blasted with aluminum oxide or glass bead, depending on the wheel alloy and desired finish) to create a rough profile for powder adhesion.

-

Degassing (When Required)

- Some wheels, especially cast aluminum or chrome, are pre-baked in an oven to release trapped gases. This helps prevent bubbles or pinholes in the final finish.

-

Masking Critical Areas

- Hub bores, lug nut seats, and threaded holes are masked to prevent powder buildup. This step is crucial for proper wheel fitment and safe torqueing.

Masking, Application, and Curing Sequence

-

Electrostatic Powder Application

- The wheel is hung in a powder coating booth and grounded. The powder is sprayed using an electrostatic gun, ensuring the particles cling evenly to the surface.

- Consistent coverage is achieved even on intricate spokes and designs, a key advantage of the powder coating wheel process.

- Before spraying, the wheel should be solvent-wiped and handled only with clean gloves to prevent contamination.

- Verify a solid ground path for an even electrostatic wrap—this helps avoid thin spots or uneven texture.

-

Curing in an Oven

- After coating, the wheel is placed in a preheated oven. The temperature and time must match the powder manufacturer’s technical data sheet—typically around 400°F (204°C) for 15-20 minutes, but always check your specific powder’s requirements(Good Car).

- The heat causes the powder to melt, flow, and chemically bond into a tough, seamless layer.

- For multi-stage finishes (like clear coats on powder coating chrome wheels), additional bake cycles are required.

Post-Cure Checks That Prevent Early Failure

-

Cooling and Inspection

- Allow the wheel to cool completely before handling. Premature handling can mar the finish.

- Inspect for uniform coverage, gloss, and any surface defects such as pinholes, orange peel, or fisheyes.

- If defects are found, they are addressed before the wheel leaves the shop.

-

Final Quality Assurance

- Some shops perform adhesion tests or wipe the finish with a solvent to verify proper curing—if the coating rubs off, it needs to be recoated and cured again.

- Remove all masking, reinstall hardware, and prep the wheel for return or tire mounting.

Practical Tips for a Flawless Powder Coat Rim

- Always wear proper personal protective equipment (PPE), including gloves, respirators, and eye protection, when handling powders and blasting media.

- Maintain good ventilation and dust control in the spray booth to avoid fume and particulate buildup.

- Handle hot parts with suitable tools and allow full cooling before inspection.

- For the most consistent finish, control booth humidity, gun-to-part distance, and spray settings according to the powder manufacturer’s guidance.

Understanding each stage of how to powder coat wheels or how to powder coat rims helps you appreciate why a professional result takes more than just a can of paint. These steps ensure your powder coating rim investment delivers the durability, style, and low-maintenance benefits that set powder coating apart. Next, we’ll explore whether DIY or professional powder coating is the right fit for your project.

DIY Versus Professional Powder Coating Realities

Thinking about tackling powder coating rims at home? Or maybe you’re wondering if it’s worth handing your wheels over to the pros. Let’s break down what’s truly involved in both approaches—so you can decide which path fits your project, budget, and expectations.

What a DIY Setup Really Requires

So, how do you powder coat rims yourself? At minimum, you’ll need:

- Electrostatic spray gun—for even powder application

- Air compressor—to power the gun, ideally with a filter to keep air dry and oil-free

- Dedicated oven—large enough for wheels (never use your kitchen oven!)

- Well-ventilated spray booth or enclosure—to contain powder and ensure safety

- Proper grounding—to prevent static build-up and ensure even coating

- Personal protective equipment (PPE)—including respirators and gloves

DIY powder coating is best for cosmetic touch-ups on structurally sound wheels with simple masking needs. It’s a rewarding process if you enjoy hands-on work and don’t mind a learning curve. However, even with the right tools, achieving a flawless finish takes patience and practice. Common issues like orange peel or uneven coverage often trace back to surface contamination, humidity, or improper cure times.

When a Professional Shop Is the Smarter Choice

Professional powder coating shops bring industrial-grade equipment and years of experience to the table. Their process includes advanced surface prep (like sandblasting), precise masking, and controlled curing ovens. Pros can handle complex projects, such as wheels needing corrosion repair, intricate masking, or multi-stage finishes. If you want a finish that rivals OEM quality—or if your wheels have sentimental or monetary value—professional service is often the best route.

Side-by-Side Comparison: DIY vs Professional

| Aspect | DIY Powder Coating | Professional Powder Coating |

|---|---|---|

| Equipment | Basic spray gun, home oven, air compressor, PPE | Industrial spray systems, large curing ovens, sandblasting tools |

| Space & Utilities | Garage or workshop with ventilation; dedicated oven | Purpose-built facility with dust/fume control and precise temp/humidity |

| Quality Control | Manual checks; risk of uneven finish or adhesion issues | Professional inspection, adhesion testing, multi-stage finishing possible |

| Risk | Higher risk of defects (orange peel, flaking); safety hazards if not careful | Lower risk; expertise ensures durability and appearance |

Safety Practices Hobbyists Often Overlook

- Never use a kitchen oven for curing wheels—powder residue can contaminate food.

- Always ground your workpiece to prevent static discharge.

- Wear a respirator and gloves to avoid inhaling or touching powder particles.

- Keep your workspace clean and dust-free—powder is highly flammable before baking.

- Handle hot parts with tongs or heat-resistant gloves.

Whether you’re considering wheel painting vs powder coat or trying to decide if you should paint or powder coat wheels, remember: DIY is great for learning and small projects, but complex or high-value wheels are safest in professional hands. If you’re after a finish that lasts for years and stands up to the elements, investing in professional powder coating is often the better bet. Next, let’s break down the costs and what drives the price of a quality powder coat job.

Cost Factors and Price Breakdown for Coated Rims

Ever found yourself asking, “How much to powder coat rims?” or “Is it worth the investment compared to painting or buying new wheels?” Understanding what goes into the powder coating rims price gives you the clarity to budget smartly and avoid surprises.

What Drives the Cost of Wheel Powder Coating?

The price you pay for powder coating wheels isn’t just about spraying on some color. Each step in the process adds value—and cost. Here’s what typically factors into rim powder coating prices:

| Cost Component | Per Wheel | Per Set (4 Wheels) |

|---|---|---|

| Stripping/Chemical Removal | Included in most quotes | Included in most quotes |

| Media Blasting | Included or additional if heavy corrosion | Often discounted for full set |

| Masking & Prep Labor | Varies by complexity (simple vs. intricate design) | Lower per wheel if all are similar |

| Powder Material | Standard color included; specialty colors extra | Bulk savings may apply |

| Number of Coats | Single coat standard; clear or candy topcoat adds cost | Multicoat finishes raise total |

| Curing Cycle(s) | Included in base price | Included in base price |

| Inspection & Reassembly | Included; new valve stems/weights may be extra | Included; ask about bundle pricing |

| Repairs (Curb Rash, Welds) | Hourly or flat rate (often $60/hr for repairs) | Separate line item |

According to recent market data, the average cost to powder coat a single wheel is $100–$250, and a full set of four typically runs $400–$1,000, depending on size, finish, and location(Kipardo Racing). Larger or more complex wheels (like deep dish or beadlock designs) can push the price higher, sometimes up to $300 per wheel. Specialty finishes—such as metallics, candy, or clear coats—also increase the cost to powder coat rims due to the extra labor and material involved.

Single Color Versus Multi-Coat Finishes

Choosing a basic, single-stage color is the most economical option. If you want a two-stage finish (such as a candy color or a protective clear topcoat), expect an extra charge—often 50% more per wheel for the added process. Shops may also charge a minimum fee per job or per color change, so bundling all four wheels in one order usually gives you the best value.

Hidden Costs to Plan For

- Wheel repairs: Fixing curb rash or welding cracks is usually not included in the base quote and is billed separately—often at an hourly rate.

- Valve stems and balancing: Some shops offer reassembly with new valve stems or wheel weights for an added fee.

- Rush service: Need your wheels back quickly? Expedited turnaround may come with a premium.

- Specialty prep: Heavily corroded or previously chrome-plated wheels require extra prep, which can increase the price.

To keep the powder coating wheels cost manageable, consider these tips:

- Deliver wheels clean and tire-free to reduce prep time.

- Opt for a standard color and single-stage finish for the best pricing.

- Bundle all four wheels for potential discounts.

Always ask for a written estimate that spells out surface prep, masking, number of coats, and cure method—so you can compare rim powder coating prices accurately.

By understanding the full breakdown behind how much does it cost to powder coat rims, you’ll be better equipped to choose the right shop and finish for your needs. Next, we’ll cover how to select a provider and what quality standards to look for to protect your investment.

Choosing a Provider and Understanding Quality Standards

Searching for “wheel powder coating near me” or “powder coating rims near me” can return dozens of shops, but how do you know which provider will truly protect your investment? The difference between a flawless, long-lasting finish and a disappointing result often comes down to process discipline, quality controls, and certifications. Let’s break down what to look for—and how to compare your options.

How to Evaluate a Powder Coating Provider

Imagine you’ve just refinished your wheels with a fresh coat—only to discover bubbling, uneven color, or poor fitment. Sounds frustrating, right? Avoid these headaches by choosing a provider with:

- Documented process control—Consistent, repeatable procedures for each stage of alloy wheel powder coating or wheel rim powder coating.

- Clean prep and blast rooms—Dedicated, dust-free environments for stripping and blasting help ensure strong adhesion and prevent surface defects.

- Calibrated curing ovens—Accurate temperature control is essential for proper curing and long-term durability.

- Masking expertise—Critical areas like hub bores and mating faces must be masked precisely to avoid fitment issues.

- Automotive quality systems—Providers with ISO 9001, IATF 16949, or PCI certification demonstrate commitment to traceability and quality assurance.

Don’t hesitate to ask about their experience with auto wheel powder coating, their QA documentation, and whether they have insurance and liability coverage for your project.

Quality Controls That Protect Your Wheels

What sets a top-tier shop apart? Look for these quality control steps:

- Surface prep verification—Are wheels checked for oil, grease, and old coatings before blasting?

- Blast media standards—Do they use the correct media for your wheel’s alloy?

- Masking and inspection—Is masking double-checked before powder application?

- Powder brand and batch traceability—Can they provide details on the powder used?

- Post-cure inspection—Are finished wheels inspected for coverage, gloss, and adhesion?

Shops that invest in training, continuous improvement, and third-party certifications (like PCI or AAMA) are more likely to deliver consistent, high-quality finishes that last.

Certification and Traceability Indicators

Certifications aren’t just acronyms—they’re your assurance of process control and industry best practices. For example, Shaoyi stands out as an automotive-qualified partner for advanced surface treatments and assemblies, with IATF 16949 certification and a proven track record supporting automakers and Tier 1 suppliers. Their end-to-end capabilities and traceable quality systems make them a benchmark for rigorous QA in projects where precision matters most. Learn more about their services at Shaoyi.

| Provider Type | Surface Prep & Media | Masking Precision | QA Documentation | Turnaround |

|---|---|---|---|---|

| Shaoyi (Tier Supplier Partner) | Automotive-grade, documented; tailored for complex alloys and parts | Robotic or expert manual masking; traceable process logs | IATF 16949, full traceability, batch records | Fast, scalable for OEM/Tier 1 schedules |

| Automotive-Focused Shop | Industry-standard; may offer alloy-specific options | Experienced staff; visual checks | ISO 9001 or PCI, basic batch tracking | 1–2 weeks typical |

| General Job Shop | Standard blasting; basic prep for multiple part types | Manual masking; variable consistency | Limited documentation | Varies, often longer for custom jobs |

When you search for “powder coating wheels near me” or “powder coat rims near me,” remember: not all providers are created equal. Prioritize those who can demonstrate rigorous process control, industry certifications, and a track record of consistent results—especially for high-value rims powder coating near me projects. Next, we’ll help you plan your timeline and understand what to expect from drop-off to pick-up.

Timeline and Project Planning for Smooth Turnarounds

When you’re ready to upgrade your wheels, one of the first questions you’ll likely have is: how long does it take to powder coat rims? The answer isn’t as simple as a single number. Imagine dropping off your wheels, then waiting anxiously to get your car back—knowing what happens at each stage helps you plan, avoid frustration, and minimize downtime.

What Happens Between Drop-Off and Pick-Up?

-

Intake Inspection

Wheels are checked for damage, corrosion, and old coatings. Any repairs or special instructions are noted before work begins. -

Stripping and Cleaning

Old finishes, dirt, and contaminants are removed using chemical strippers or mechanical methods. This step is crucial for adhesion and can take extra time if the wheels have heavy corrosion or thick layers of paint. -

Blasting and Surface Prep

Wheels are sandblasted to bare metal, creating the ideal texture for powder coating. Complex designs or stubborn finishes may require additional attention. -

Masking Critical Areas

Areas like hub bores and bolt holes are carefully masked to ensure proper fitment later. Intricate masking adds time but protects your wheels and vehicle. -

Powder Application

The powder is electrostatically sprayed for even coverage. Most wheels receive a single color, but multi-coat or specialty finishes (like candy or clear coats) require additional steps. -

Curing in the Oven

Wheels are baked in a curing oven, allowing the powder to melt and bond into a durable finish. Oven cycles are dictated by the powder manufacturer’s specs and wheel thickness. -

Cool-Down

After curing, wheels must cool completely before handling. Rushing this step can damage the finish. Shops typically allow 45–60 minutes for cooling, depending on wheel size and ambient conditions. -

Final Inspection

Each wheel is checked for coverage, gloss, and defects. If any issues are found, touch-ups or rework may be required, adding to the timeline. -

Reassembly and Pick-Up

Masking is removed, and wheels are prepared for tire mounting and balancing. Some shops offer full reassembly, including new valve stems and weights, while others return wheels ready for your tire shop.

Lead time is driven by shop capacity and batch scheduling; multi-coat specialty finishes and corrosion remediation add steps that extend turnaround.

How Shops Batch Wheels to Optimize Turnaround

Curious why your wheels aren’t always ready the same day? Many shops batch similar jobs together to maximize oven cycles and efficiency. If you’re getting a standard color, your wheels might be grouped with others for a quicker turnaround. However, custom colors, multi-stage finishes, or wheels with significant corrosion typically require more time. According to industry experience, a standard set of four wheels usually takes 6–8 hours from start to finish, but heavy prep or specialty requests can extend this to a full day or longer.

When to Schedule Tire Services

- Remove tires and TPMS sensors before drop-off—This saves time and reduces the risk of damage during the process.

- Ask if the shop handles tire mounting and balancing—Some do everything in-house; others may require you to visit a tire shop after pickup.

- Confirm masking of mating surfaces—Request details to ensure proper fitment when reinstalling wheels.

- Plan for seasonal rushes—Shops are busiest before winter or show season, so book early if you need a fast turnaround.

- For shipped wheels—Package carefully to protect machined faces and freshly cured finishes during transit.

So, how long does it take to powder coat wheels? For most standard jobs, plan for a working day—longer if your wheels need extra prep or you’ve chosen a custom finish. By understanding the full process and communicating with your shop, you’ll avoid surprises and keep your project on track. Up next, we’ll explore how to choose the best color and finish to match your driving style and environment.

Choosing Colors and Finishes That Fit Your Use Case

Ever stared at a wall of color samples and wondered which finish will truly work for your daily drive—or help your car stand out at a show? With so many powder coat wheel colors and finishes available, the best choice really comes down to how (and where) you use your vehicle, your maintenance habits, and the look you want to achieve. Let’s break it down so you can confidently pick the right finish for your needs.

Match Finish to How You Drive

- Daily Commute: If you want wheels that hide minor scuffs and are easy to keep clean, gloss black rims are a smart pick. Black powder coated wheels are popular for their durability, but they tend to show brake dust, though they can show swirl marks over time.

- Track or Performance Use: Matte black wheels or satin finishes are trending for performance cars. These finishes reduce glare and look aggressive, but they can be more prone to marking and may require gentle cleaners to avoid discoloration(Detailed Image)

- Winter Roads: If you drive in harsh climates, robust prep and a clear coat for rims add an extra layer of protection against road salt and chemicals. A clear topcoat helps maintain the integrity of the finish—especially on lighter colors or metallics.

- Show Car or Custom Builds: Want your wheels to be the star of the show? Explore metallics, candy colors, or even powder coated white wheels for a bold, modern look. These finishes can create a bold, modern look.

Popular Color and Sheen Options for Wheels

- Black Powder Coated Rims: Timeless, versatile, and suits nearly any vehicle style. Black hides most imperfections but, as with all high-gloss finishes, will eventually show swirls from regular washing. The upside? Swirls are easy to polish out, and the finish is straightforward to refresh.

- Gloss Black Rims: Reflective and dramatic, these are a go-to for a premium, uniform appearance. They’re especially good at hiding minor surface imperfections but do show brake dust more readily.

- Matte Black Wheels: Understated and modern, matte finishes are less reflective and ideal for a stealthy look. However, they can be more susceptible to visible marks and require gentle, pH-neutral cleaners.

- Metallics and Candy Colors: These offer depth and a unique shimmer, making your wheels pop under sunlight. They usually require a clear coat for added protection and visual depth.

- Powder Coated White Wheels: Clean and striking, white finishes make a statement and can brighten the overall look of a car.

- Gunmetal, Bronze, and Custom Colors: These options let you personalize your ride. Gunmetal gray is especially popular for a subtle, high-end look without the upkeep of gloss black.

When to Add a Clear Topcoat

Wondering if a clear coat is worth the extra step? Adding a clear coat for rims is highly recommended for metallics, candies, or any finish that will face tough road conditions. A clear topcoat not only boosts chemical and abrasion resistance but also gives your wheels an extra layer of depth and gloss. For daily drivers, it can mean easier cleaning and longer-lasting shine. For show cars, it helps preserve the brilliance of bold or multi-stage colors.

Ultimately, the secret to long-lasting powder coated wheels isn’t just the color—it’s the quality of the prep and application. No matter which finish you choose, proper surface prep and professional application will ensure your wheels look sharp for years to come. Next, let’s explore how to keep your new finish looking its best with smart maintenance and care strategies.

Maintenance and Care to Protect Your Powder Finish

Safe Cleaning Methods for Powder Coated Wheels

When you invest in powder coated wheels, you want that deep, flawless finish to last as long as possible. But how do you keep them looking fresh year after year? Imagine pulling up to a car meet and your powder coated rims still have that "just finished" gloss—maintenance is the secret. The good news: caring for powder coated rims is very similar to looking after painted wheels, but with a few extra best practices for maximum lifespan.

-

Do:

- Wash wheels frequently, especially after driving through brake dust or road salts.

- Use pH-neutral wheel cleaners and a soft brush or microfiber mitt to prevent scratching the finish.

- Rinse your wheels when they are cool to the touch, never hot, to avoid water spots or thermal shock.

- Apply a wheel-safe sealant or coating compatible with powder finishes for added protection and easier cleaning.

- Dry thoroughly after washing to prevent water spots and mineral deposits on your powder coated rims.

-

Don't:

- Avoid harsh acid-based or highly alkaline cleaners—they can discolor or degrade the finish, especially on matte or satin wheels.

- Never use abrasive pads or steel wool, which can scratch and dull the surface.

- Don’t let brake dust, road salt, or tar sit for long periods—these contaminants can slowly etch into the coating.

- Don’t use aggressive compounds or polishes on matte or satin finishes; stick to gentle cleaners and soft towels.

Most premature failures trace to contamination, aggressive chemicals, or neglected chips—small, fast interventions prevent bigger repairs.

Touch-Up and Minor Defect Care

Even with careful maintenance, minor chips or scratches can happen. For small edge chips, a touch-up with compatible paint can help hide the blemish, but remember: this won’t match the durability or uniformity of a baked-on powder coat. For widespread damage or deep gouges, plan for a professional recoat to restore full protection. If you have polished wheels or machined faces sealed with a wheel clear coat or clear coat for aluminum wheels, treat them as you would delicate automotive clear—avoid harsh compounds, and always spot test any cleaner or polish on an inconspicuous area first.

Seasonal Tips for Long-Term Protection

- In winter or salty environments, rinse wheels often to remove corrosive buildup and reapply sealant as needed.

- Inspect wheels regularly for chips, especially after harsh weather or gravel roads, and address defects quickly to prevent underfilm corrosion.

- Store a record of your powder brand and color code—this makes future touch-ups or full recoats much easier to match.

- Consider adding a ceramic coating on top of your powder finish for even more resistance to contaminants and easier cleaning.

So, how long does powder coat last on rims? With professional application and regular maintenance, powder coated wheels can easily look their best for 3–5 years, and with careful care, up to 7–10 years or more. Proper cleaning and quick attention to minor defects are key factors in extending the lifespan of your powder coated rims.

By staying proactive with cleaning and protection, you’ll enjoy vibrant, durable wheels season after season. Next, we’ll dive into troubleshooting common defects—so you know exactly what to do if issues ever arise with your powder finish.

Troubleshooting Defects with Practical Fixes

Identify Common Powder Coating Defects on Wheels

Even when you follow every step in the powder coating process, issues can still pop up. Ever noticed bubbling, rough spots, or dull patches on freshly finished rims? These symptoms can be frustrating, but with a little know-how, you can quickly diagnose and resolve most problems—saving time, money, and your powder-coated aluminum wheels.

Root Causes and Immediate Checks

Sounds complex? It doesn’t have to be. Most powder coating defects trace back to a handful of root causes: improper surface prep, contamination, poor masking, or incorrect curing. Whether you’re working with powder coating aluminum or powder coating steel wheels, the first step is always a careful inspection. Let’s look at the most common issues and what you can do about them.

| Symptom | Likely Cause | Immediate Checks | Corrective Action |

|---|---|---|---|

| Poor Adhesion (Peeling, Flaking) | Inadequate surface prep, oil/grease residue, insufficient profile |

|

|

| Fisheyes (Small Craters or Dots) | Silicone or oil contamination from rags, air lines, or hands |

|

|

| Orange Peel (Textured, Uneven Surface) | Excessive powder, incorrect gun distance, or improper cure |

|

|

| Pinholing/Blistering | Trapped gases in cast alloys, moisture, or underbaked powder |

|

|

| Contamination (Blemishes, Discoloration) | Dirt, brake dust, or old balancing weights left on rim |

|

|

| Under-cure (Soft, Easily Marked Finish) | Insufficient oven temperature or time |

|

|

Corrective Actions That Actually Work

Imagine you’ve just finished a set of powder-coated aluminum wheels, only to spot bubbles or rough spots. Don’t panic—most issues can be traced to simple causes, like skipping a cleaning step or not masking properly. For pinholing on cast wheels, always pre-bake to outgas trapped air. For orange peel, focus on even powder application and correct oven settings. These fixes apply whether you’re working on powder coating steel wheels or alloy rims.

For persistent or mysterious defects, document everything: powder lot number, gun settings, booth humidity, and cure times. This makes troubleshooting much easier if you need to consult with your powder supplier or a professional shop.

Systematic troubleshooting and careful documentation are your best tools for flawless powder coating on wheels—don’t skip the basics!

By staying methodical and addressing problems as they arise, you’ll ensure your powder-coated aluminum or steel wheels look their best and last for years. Next, we’ll wrap up with a checklist of key takeaways and questions to ask your supplier for total confidence in your powder coating project.

Key Takeaways and a Supplier Checklist for Confidence

What Matters Most for Long-Lasting Results

When you step back and look at a set of flawless, durable rims, what’s really behind that finish? It’s not just the color you picked or the latest trend—it’s the foundation: proper prep, precise masking, and a cure process that follows the powder supplier’s technical data sheet. If you’re still asking yourself, what are powder coated rims and how do they stand out, remember this: the best results come from attention to detail at every stage, not just a pretty topcoat.

Quality powder coating car wheels is all about surface prep, masking precision, and validated curing—not just color choice or brand.

Supplier Checklist You Can Use Today

Ready to choose a provider or compare shops for your rim powder coating project? Here’s a practical checklist of questions to ask—whether you’re searching for where can I get my rims powder coated locally or evaluating an OEM partner for high-volume runs:

- How is surface preparation handled? (Ask about blasting, chemical stripping, and how they prevent recontamination before coating.)

- What masking procedures are in place? (Request details on how they protect hub bores, lug seats, and threaded areas.)

- Which powder brands and types are used? (Can they provide technical data sheets and batch traceability for each powder?)

- How is curing validated? (Do they use calibrated ovens, and do they follow the cure schedule from the powder manufacturer?)

- What post-cure QA checks are performed? (Look for adhesion tests, visual inspections, and documentation.)

- Are certifications or quality systems in place? (Ask about IATF 16949, ISO 9001, or PCI certification for added confidence.)

- How are repairs or defects handled? (Do they offer a written warranty or clear process for addressing issues?)

Next Steps to Move Your Project Forward

Imagine you’re ready to move ahead—what separates a smooth experience from a frustrating one? It’s all about working with a provider who values transparency, proven process, and clear communication. For those in the OEM or Tier 1 space, Shaoyi stands out as a prime example: their IATF 16949-certified systems, end-to-end process control, and rapid turnaround make them a reliable partner for automotive-grade surface treatments and assemblies. Learn more about their capabilities at Shaoyi.

For most car owners, choosing a vetted local shop with documented experience in rim powder coating is key. Always review their prep and QA practices, ask for references, and compare written estimates side by side. If your needs extend beyond wheels—perhaps into broader metal finishing or assembly—consider partners with a track record in automotive quality and process discipline.

Still deciding where to get my rims powder coated? Use the checklist above to interview providers, and don’t hesitate to walk away if answers are vague. In the end, understanding what is a powder coating and why process matters will set you up for a finish that turns heads and stands the test of time. With the right questions and the right partner, your powder coating car wheels project will deliver both style and substance for years to come.

Frequently Asked Questions

1. Is powder coating rims a good idea?

Powder coating rims is a popular choice for those seeking a durable, chip-resistant finish that stands up to road debris and corrosion. It offers superior weather and UV resistance compared to traditional paint, making it ideal for drivers who want their wheels to look great and last longer with less maintenance.

2. How much does powder coating cost?

Powder coating rims typically costs $100–$250 per wheel or $400–$1,000 for a set of four, depending on wheel size, finish complexity, and local labor rates. Specialty colors, multi-stage finishes, or repairs like curb rash may increase the price. Always request a detailed estimate from your provider.

3. What are the benefits of powder coating wheels compared to painting?

Powder coating creates a thicker, more durable layer than traditional paint, offering better resistance to chips, scratches, and corrosion. The process is eco-friendly, with no VOC emissions, and delivers a uniform finish even on complex wheel designs. This makes powder coating rims vs painting a clear win for long-term protection and style.

4. How long does powder coat last on rims?

With professional application and regular care, powder coated rims can maintain their finish for 3–5 years, and in many cases up to 7–10 years. Longevity depends on quality prep, proper curing, and routine cleaning to prevent buildup of brake dust or road salt.

5. What should I look for in a powder coating provider?

Choose a provider with documented process controls, clean prep and blast facilities, calibrated curing ovens, and certifications like IATF 16949 or ISO 9001. For demanding automotive applications, consider partners like Shaoyi, who offer full traceability, rapid turnaround, and rigorous QA for critical components.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —