Black Oxide Coating: How It Works, Benefits, And Pitfalls

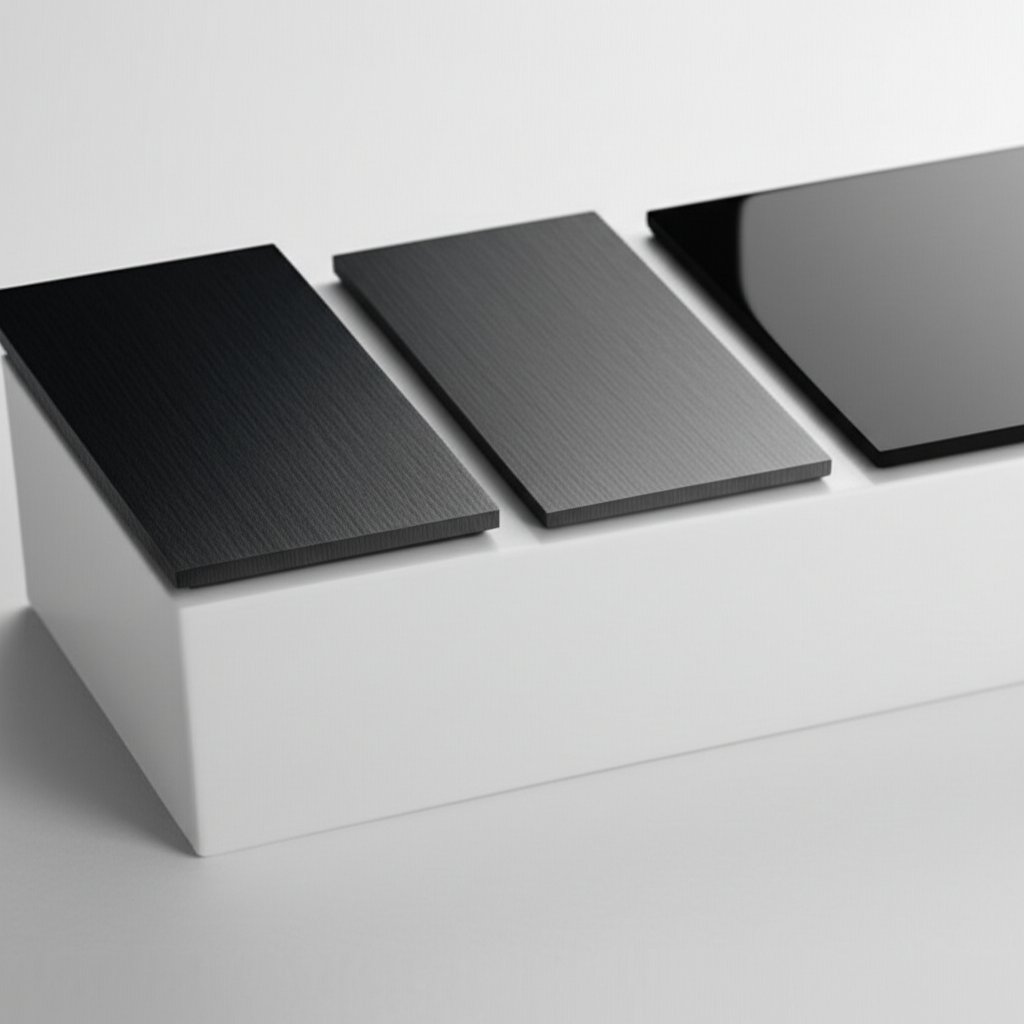

Black Oxide Coating

Ever wondered how those sleek, matte-black machine parts or tools get their distinctive look without sacrificing precision? Or why some blackened steel components resist glare and wear, yet fit with perfect accuracy? If you’ve heard terms like black oxide coating, blackening coating, or metal blackening used interchangeably, you’re not alone. Let’s break down exactly what is black oxide coating, where it fits among metal finishes, and why it’s a go-to choice for engineers and fabricators.

What Is Black Oxide Coating?

Black oxide coating is a chemical conversion process that transforms the surface of ferrous metals into a thin, black magnetite layer, enhancing appearance and providing mild corrosion and wear resistance without adding significant thickness to the part.

Unlike paint or plating, which add material on top of a part, black oxide is a conversion coating. This means the metal’s surface itself is chemically altered into a new, durable oxide layer, typically only 1–2 micrometers thick. This subtlety is critical for high-precision applications—think gears, fasteners, or surgical tools—where even a slight dimensional change can affect fit or function.

For those searching for what is black oxide or what is blackened steel, the answer lies in this unique, almost-invisible transformation that produces a smooth, black, and non-reflective finish on steel and other ferrous alloys.

Why Engineers Choose a Black Metal Finish

Imagine you’re designing a part that must slide smoothly, fit tightly, and look sharp—all while resisting rust and glare. Here’s why black oxide coating is often the answer:

- Dimensional stability: The conversion process adds virtually no measurable thickness, preserving tight tolerances and precision fits.

- Glare reduction: The matte or satin black finish minimizes reflections, making it ideal for optical, surgical, or tactical components.

- Mild corrosion resistance: When sealed with oil or wax, the black oxide layer helps protect against moisture and oxidation in low- to moderate-risk environments.

- Improved lubricity: The surface is smoother and less prone to galling, facilitating break-in and wear resistance for moving parts.

- Aesthetic uniformity: Produces a consistent, attractive blackened steel appearance that is both professional and functional.

Engineers and machinists often select black oxide when they need a cost-effective finish that won’t compromise part geometry or assembly, especially in automotive, aerospace, and tooling applications.

Limits of Black Oxide You Should Know

Sounds perfect? Not quite. Here are some misconceptions and limitations to keep in mind:

- It is not a thick protective layer: Unlike plating or paint, black oxide’s protection is surface-deep and relies heavily on post-treatment oil or wax for real corrosion resistance.

- Not for harsh environments: Black oxide is best for indoor, low-moisture, or regularly maintained parts. For marine or high-salt settings, tougher coatings may be needed.

- Not easily repairable: Once damaged, the coating is difficult to touch up compared to paint or powder coat.

- Corrosion resistance depends on sealant: The oil or wax applied after blackening is what really keeps rust at bay.

In summary, black oxide coating stands apart from other finishes thanks to its minimal impact on part dimensions, its ability to create a uniform, blackened steel look, and the way it leverages chemical conversion rather than material buildup. It’s not a cure-all, but when used in the right context, it’s a powerful tool in the metal finishing toolbox.

How Black Oxide Process Transforms Metal

Ever wondered what actually happens during the black oxide process, or why some parts get a rich, deep black while others look patchy? Understanding how to blacken metal is key to choosing the right method for your parts—whether you’re running a precision production line or just need a quick touch-up in the shop. Let’s demystify the science and workflow behind hot and cold blackening, so you can make the best choice for your application.

Hot Blackening for Robust Production Lines

Imagine you’re producing hundreds—or thousands—of steel components that need a consistent, durable black finish. Hot blackening is the industry’s workhorse for this scenario. The process involves immersing ferrous metals in a heated alkaline salt bath, typically around 141°C (286°F), which chemically converts the surface into a thin layer of magnetite (Fe3O4). This black oxide layer is just 1–2 micrometers thick, so it won’t throw off tight tolerances or fits.

Hot blackening is prized for:

- Fast cycle times—parts can be finished in 10 to 15 minutes

- Consistent, deep black appearance for large batches

- Compatibility with automated handling and racking

It’s ideal for high-throughput environments like automotive or aerospace, but requires careful temperature control and safety measures due to the risk of caustic fumes and steam.

Room Temperature Blackening for Onsite Touch Ups

Need to know how do you blacken steel or repair a finish without industrial equipment? Cold blackening (or room temperature blackening) is a practical solution. Instead of forming a true magnetite layer, this method deposits a black copper selenide compound at room temperature (20–30°C, 68–86°F). It’s commonly used for small batches, maintenance, or DIY applications, where hot baths aren’t practical.

Pros of cold blackening include:

- Simple setup—no need for heated tanks

- Safer handling for small-scale or onsite work

- Useful for touch-ups and low-heat scenarios

However, the resulting layer is thinner and less durable than hot blackening, making it more sensitive to surface prep and finish quality. Sealing with oil or wax is a must for any corrosion resistance.

Process Flow Overview: From Clean to Seal

Regardless of the method, the black oxide process follows a series of carefully controlled steps. Here’s a universal workflow you’ll encounter in both industrial and small-batch settings:

- Clean and deoxidize: Remove all oils, dirt, rust, or scale. Surface prep is critical for uniform blackening.

- Rinse thoroughly: Any residue from cleaners or acids can cause patchy results.

- Convert in black oxide bath: Immerse parts in the appropriate hot or cold solution for a time specified by the supplier. For how to blacken stainless steel, specialized chemistries and activation steps are required—more on this in the next section.

- Rinse again: Essential for removing chemical residues that could affect the finish or cause corrosion later.

- Post-treat with oil or wax: This step seals the porous oxide layer, boosting corrosion resistance and determining gloss or matte appearance.

- Dry and inspect: Ensure the coating is uniform and free of defects before moving to assembly or packaging.

Choosing the Right Method: Quick Comparison Table

| Method | Typical Use Cases | Throughput | Part Complexity Handling | Typical Appearance |

|---|---|---|---|---|

| Hot Blackening | High-volume production, automotive, aerospace, tools | Very high (minutes per batch) | Excellent for racks of small/complex parts | Deep, uniform black (matte or glossy with sealant) |

| Room Temperature Blackening | Touch-ups, maintenance, small-batch, DIY | Low (longer dwell times, manual) | Best for simple shapes, limited for deep recesses | Black to dark grey, may be less uniform |

Critical Control Points for a Quality Finish

- Surface Preparation: Any contamination or unevenness leads to patchy color—always degrease and remove rust or scale.

- Bath Condition: Regularly check and maintain temperature, chemical concentration, and bath cleanliness to ensure repeatable results.

- Immersion Time: Follow supplier recommendations for dwell times; over- or under-processing can affect color depth and adhesion.

- Thorough Rinsing: Prevents streaks, stains, or later corrosion.

- Sealant Choice: Oil for gloss and maximum corrosion resistance, wax for a matte look—both are essential for the final performance.

Special note: For stainless steel and copper alloys, the black oxide process requires dedicated chemistries and sometimes activation steps to break through the natural oxide film. If you’re wondering specifically how to blacken stainless steel, you’ll want to consult your supplier for compatible solutions and follow their prep instructions closely.

By understanding the strengths and limitations of hot blackening versus room temperature blackening, and by following a disciplined process flow, you’ll achieve a consistent, attractive, and functional black oxide finish—whether you’re coating hundreds of fasteners or just refreshing a single tool. Up next, we’ll dive into which metals are most compatible with black oxide, and the prep steps that make all the difference.

Which Metals Take Black Oxide Best?

Ever wondered why some parts come out with a flawless, deep black finish, while others turn patchy or fail to blacken at all? The answer often lies in the base material and the prep work before blackening. Whether you’re aiming for a crisp blackened steel sheet or a subtle stainless black look, understanding material compatibility is key to getting repeatable, high-quality results.

Steel and Alloy Steel Suitability Notes

For most engineers and fabricators, carbon steels and alloy steels are the gold standard for black oxide coating. These ferrous metals react reliably to the conversion process, forming a robust magnetite (Fe3O4) layer. The result? Classic blackened steel plate or fastener finishes that are uniform, non-reflective, and dimensionally stable. Tool steels and cast irons also respond well, provided the surface is thoroughly cleaned and free of scale or rust.

Black Oxide on Stainless Steel: Keys to Success

Wondering if black oxide stainless steel is possible? Absolutely—but it’s a bit trickier. Stainless steels (including 200, 300, and 400 series) require specialized chemistries and activation steps to break through their passive oxide layer. When done correctly, you’ll see a deep grey to true blackened stainless steel finish, often used for medical instruments and optics to eliminate glare. Surface prep is crucial: any residual oil or unevenness can cause streaks or patchy color. The final appearance and corrosion resistance will also depend heavily on the grade and initial surface condition.

Non-Ferrous Metals and Alternatives

What about copper, brass, or aluminum? While not traditional candidates, these materials can be blackened using adapted processes:

- Copper and brass: Blackening options (like Ebonol C) exist, producing a dark grey to brown-black finish. These are popular for decorative or electrical applications, but require different solutions from ferrous black oxide.

- Aluminum: Conventional black oxide aluminum is rare—aluminum doesn’t form magnetite. Instead, black anodizing or powder coating is usually recommended for a durable black look.

Practical Compatibility Matrix

| Material Class | Suitability | Special Preparation | Expected Appearance | Cautions |

|---|---|---|---|---|

| Low Carbon Steel | Excellent | Standard cleaning, degreasing | Deep black, matte or glossy | Seal with oil/wax for corrosion resistance |

| Alloy Steel / Tool Steel | Excellent | Remove scale/rust, uniform prep | Consistent black, smooth finish | Surface pitting may show through |

| Cast Iron | Very Good | Thorough cleaning, avoid porosity | Dark black, slight texture | Porosity may trap solution, rinse well |

| Stainless Steel (200/300/400 series) | Good (with proper chemistry) | Activation step, specialized solution | Dark grey to black, non-reflective | Surface prep critical, some grades less uniform |

| Copper / Brass | Possible (with adapted process) | Use Ebonol C or similar, clean surface | Grey-black to brown-black | Different chemistry; not as durable as steel |

| Aluminum | Not typical | Consider anodizing or powder coat instead | Black oxide not recommended | Black oxide aluminum is not true conversion |

- Always degrease thoroughly—residual oils can ruin a blackened steel sheet or part.

- Remove all rust, scale, or old coatings before blackening.

- Mask areas that must remain uncoated.

- Rack or hang parts to allow for full drainage and even coverage.

Remember: the initial surface—whether polished, shot-blasted, or mill-finished—will strongly influence the final color and uniformity. A rougher surface may appear more matte; polished parts will look glossier after sealing. If you’re aiming for high-end coating for stainless steel or a flawless blackened stainless steel finish, meticulous prep and the right chemistry are non-negotiable.

With a clear understanding of which materials respond best to black oxide and the critical prep steps involved, you’ll avoid costly trial-and-error and achieve the consistent, professional results your application demands. Next, we’ll compare black oxide to other popular finishes so you can make the right choice for your project’s needs.

Choosing the Right Finish

When you’re weighing options for finishing metal parts, it’s easy to assume all black coatings offer similar protection and appearance. But if you’re deciding between black oxide vs zinc plated, black phosphate finish, or other alternatives, the differences can have a big impact on function, cost, and long-term performance. Let’s break down the real tradeoffs so you can choose the right finish for your project, whether you’re prioritizing dimensional stability, corrosion resistance, or aesthetics.

When To Choose Black Oxide Versus Phosphate Or Zinc

| Finish Type | Dimensional Impact | Appearance | Typical Post Seal | Corrosion Behavior | Lubricity | Reworkability | Conductivity | Common Applications |

|---|---|---|---|---|---|---|---|---|

| Black Oxide | Minimal (0.5–2.5 μm) | Matte or satin black, uniform | Oil, wax, or polymer | Mild (relies on sealant) | High (excellent for break-in, moving parts) | Easy (can be stripped and reapplied) | Slightly conductive (reduced with oil/wax) | Tools, fasteners, firearms, optics, decorative |

| Black Phosphate | Low to moderate (2–10 μm) | Dark grey to black, less uniform | Oil, wax, chromate | Moderate (better than black oxide alone) | Good (holds oil well) | Easy (strip and recoat possible) | Non-conductive | Automotive, bearings, gears, paint base |

| Zinc Plating (Black Zinc) | Moderate (5–25 μm) | Glossy to semi-matte black | Chromate, topcoat | High (sacrificial protection, 96–200+ hrs salt spray) | Moderate (can be waxed for more slip) | Limited (removal requires abrasion or acid) | Non-conductive (chromate layer) | Fasteners, brackets, outdoor hardware |

| Organic/PVD (e.g., Paint, Powder, PVD Black) | Variable (10–100 μm typical) | Wide range, deep black to colored | None or clear coat | High (depends on thickness, chemistry) | Variable (depends on resin) | Limited (can chip, harder to repair) | Non-conductive | Decorative, electronics, high-wear surfaces |

Appearance and Functional Tradeoffs

Imagine you’re specifying a finish for a set of precision fasteners. With black oxide coating, you’ll notice almost no change in thread fit or part dimensions. The finish is smooth, non-reflective, and ideal for parts that must slide or mate closely. But, if you need outdoor corrosion resistance, black zinc vs black oxide is a key consideration. Black zinc plating adds a sacrificial zinc layer, offering much higher rust protection—especially with a chromate seal—but it does add measurable thickness and can affect tight tolerances.

Black phosphate finish sits between the two: it’s a conversion coating like black oxide, but usually results in a darker grey and holds oil very well for added lubricity. It’s often used on gears or bearings where break-in and oil retention are critical. Organic or PVD black finishes, such as paint or powder coat, provide the most color options and corrosion protection, but at the cost of significant thickness and the risk of chipping or flaking under impact.

The real-world corrosion resistance of black oxide depends almost entirely on the quality and maintenance of the oil or wax sealant applied after blackening.

Scenario Based Recommendations

- Need maximum dimensional accuracy and glare reduction? Choose black oxide coating for tight-tolerance parts, optics, or tools where a thin, uniform, non-glare finish is essential.

- Looking for break-in and lubricity on moving parts? Both black oxide and black phosphate finishes excel, but phosphate holds more oil for extended lubricity in gears and bearings.

- Fasteners or hardware exposed to weather or salt? Black zinc plating is superior for corrosion resistance—think automotive, marine, or outdoor applications. Compare zinc plating vs black oxide for these cases.

- Decorative deep black on stainless or aluminum? Consider organic or PVD black for maximum color depth and versatility, or specialized black oxide for stainless (with the right chemistry).

- High abrasion or industrial environments? Phosphate and PVD finishes offer better wear resistance, but always check if re-coating is feasible for your part.

- High-salt or chemical exposure? Black zinc plating, with a robust chromate or topcoat, is usually the best fit.

Remember, there’s no one-size-fits-all answer in the black oxide vs black phosphate or black zinc plating vs black oxide debate. Your best choice depends on balancing appearance, function, cost, and downstream requirements—always confirm against your customer specs and industry standards before finalizing a finish. Next, we’ll cover how to verify your finish quality and ensure it meets real-world performance needs.

How to Evaluate a Quality Black Oxide Finish

Wondering how to tell if your black oxide finish on steel is truly up to standard? Or maybe you’re facing questions like, "does black oxide rust?" and want to back up your answers with real tests. Whether you’re in a lab or on the shop floor, having clear, practical methods to verify your finish gives you—and your customers—confidence in every batch.

How To Verify Finish Quality and Uniformity

Imagine inspecting a batch of fasteners or tools fresh from the blackening line. What should you check to ensure a quality black oxide result?

- Visual Uniformity: Inspect parts under consistent lighting. The finish should be even, with no streaks, blotches, or color variation. Pre-existing scratches or pits will still show but should be blackened, not bare metal.

- Water Break-Free Test: After cleaning and before sealing, apply water to the surface. It should sheet evenly without beading, indicating a contaminant-free surface ready for sealing.

- Oil Absorption/Retention: After sealing, check that the oil or wax is evenly absorbed—no dry spots or puddling. This is crucial for corrosion resistance and smooth operation.

- Rub or Smut Test: Before applying oil/wax, gently rub the surface. Minimal black residue should come off. Excessive smut suggests incomplete conversion or poor cleaning.

- Simple Abrasion Check: Lightly rub with a cloth or wood stick to ensure the finish does not easily wear away. A properly applied black oxide steel layer should be durable, not powdery.

Corrosion and Environmental Exposure Testing

It’s natural to ask, is black oxide corrosion resistant? The answer depends heavily on the post-treatment. The blackened layer alone offers limited protection; it’s the oil or wax sealant that keeps moisture out and slows rust.

- Humidity Cabinet Test: Expose sealed parts to 100% relative humidity (ASTM D 2247). Check for rust, pitting, or discoloration after the specified period.

- Salt Spray (Fog) Test: Common but often misunderstood. This test exposes parts to a salt-laden mist to simulate aggressive environments. However, real-world performance depends more on sealant quality and maintenance than on salt spray hours alone.

Salt spray results are not a direct predictor of real-world life, since oil and wax sealants—and their upkeep—dominate actual corrosion resistance for black oxide steel.

To maximize protection, always specify the length and type of sealant, storage conditions, and expected maintenance intervals. If you’re ever asked, "will black oxide rust?"—the honest answer is: only if the sealant is neglected or worn away.

Adhesion and Wear Checks for Service Readiness

How do you know your finish will hold up in the field? Here’s what to look for:

- Adhesion Test: Try a simple tape pull or scratch test—there should be no flaking or peeling. Black oxide is a conversion coating, so it shouldn’t chip like paint.

- Wear/Abrasion Test: For moving parts, cycle or rub the finished area to check for premature wear. Small marks may appear, but the finish should not rub off easily.

Document the part’s surface condition before blackening (e.g., roughness, scale, or previous coatings). This helps explain any color variation and sets realistic expectations for your black oxide finish on steel.

Reference Standards and Best Practices

- ASTM D 2247 – Water resistance in humidity cabinet

- AMS2485, MIL-DTL-13924 – Black oxide on steel (specifies appearance, adhesion, and corrosion test methods)

- ISO/IEC equivalents for international compliance

Always verify acceptance criteria against customer drawings and referenced standards—don’t assume generic thresholds fit every application. For quality black oxide work, detailed documentation and regular maintenance of sealants are just as important as the initial finish.

Next, we’ll walk through standard operating procedures and safety tips to ensure every batch is finished right from start to finish.

SOPs and Safety for Reliable Shop Execution

Setting up a repeatable, safe, and high-quality black oxide process doesn’t have to be intimidating—whether you’re using a full-scale production line or a compact black oxide coating kit for small-batch work. Imagine walking onto your shop floor and knowing every operator can follow a clear, step-by-step procedure, with built-in checks for quality and safety. Here’s how you can achieve that, drawing on proven industry practices and adaptable SOPs that fit both hot and room temperature blackening scenarios.

Shop Floor SOP for Hot Blackening

- Receipt and Identification of Parts: Log incoming parts, verify material type, and assign batch/serial numbers for traceability.

- Cleaning/Degreasing: Remove all oils, grease, and contaminants with an approved cleaner. Surface must be free of visible residue (reference).

- Oxide/Scale Removal: Use acid pickling or abrasive methods if allowed by spec. Ensure no rust, mill scale, or old coatings remain.

- Rinse Discipline: Rinse parts thoroughly in clean water to remove all cleaning chemicals.

- Conversion (Blackening): Immerse parts in the hot black oxide solution for the supplier-recommended time. Monitor temperature and agitation.

- Post Rinse: Remove all chemical residues with a series of rinses (warm, then cold, then hot water if specified).

- Oil/Wax Seal: Immerse parts in the selected oil or wax to seal the porous oxide layer and enhance corrosion resistance.

- Dry: Air dry or use warm air. Ensure no water or oil pooling remains.

- Inspection: Check for uniform color, absence of defects, and correct oil absorption.

- Documentation: Record batch numbers, operator signoff, inspection results, and any deviations.

Room Temperature Blackening Quick Start

- Receipt and Identification: As above—track all parts and lots.

- Surface Prep: Clean and degrease meticulously. Room temperature processes are highly sensitive to surface contaminants.

- Rinse: Use distilled or deionized water for best results.

- Conversion (Cold Black Oxide Solution): Submerge parts in the metal blackening solution or cold black oxide solution as directed by your supplier's instructions. Follow precise dwell times—overexposure can dull the finish.

- Rinse Again: Thoroughly wash away all residues.

- Seal: Apply oil or wax immediately to lock in the finish and provide corrosion resistance.

- Dry and Inspect: As above—look for even color and complete coverage.

- Documentation: Record all process steps, including any adjustments or issues.

If you’re using a commercial blackening kit, you’ll often find these steps outlined in the included manual—just remember to adapt dwell times and rinsing steps to your specific part geometry and production needs.

Critical Controls and Quality Evidence Table

| Step | Critical Control | What To Check | Evidence To Record |

|---|---|---|---|

| Cleaning | Cleaner concentration, time, temperature | No visible oil, water break-free | Log of solution checks, operator initials |

| Oxide/Scale Removal | Acid strength, exposure time | Surface is bright, no rust/scale | Visual inspection, batch notes |

| Blackening | Bath temp, dwell time, agitation | Uniform black color, no streaks | Bath log, time-in/out |

| Rinsing | Fresh water, agitation | No chemical residue, clear water | Rinse tank checks |

| Sealing | Sealant type, immersion time | Even oil/wax coverage, no dry spots | Sealant log, inspection pass/fail |

| Final Inspection | Lighting, trained inspector | No defects, meets appearance spec | Inspection sheet, operator signoff |

Safety and Environmental Controls

- Personal Protective Equipment (PPE): Always wear chemical-resistant gloves, goggles or face shields, and aprons when handling solutions.

- Ventilation: Ensure adequate exhaust or fume extraction, especially with hot baths or concentrated chemicals.

- Chemical Handling: Store all concentrates and cleaners per SDS guidelines. Label all tanks and containers clearly.

- Spill Response: Keep neutralizing agents and absorbents on hand. Train staff in emergency spill procedures.

- Waste Management: Collect and dispose of rinse waters and spent solutions according to local environmental regulations. Many steel blackening solution suppliers offer recycling or purification options.

Maintain easy access to Safety Data Sheets (SDS) for every chemical used, and post emergency contacts and first-aid instructions near the work area.

Best Practices for Consistency and Traceability

- Standardize racking and fixturing to ensure even exposure and drainage.

- Train all operators on bath maintenance, titration, and changeover procedures.

- Document every batch with serial numbers, operator initials, and inspection outcomes for full traceability.

- Review and update SOPs regularly based on process audits and supplier updates.

By following these structured SOPs—whether you’re running a high-volume line or experimenting with a black oxide coating kit—you’ll ensure safe, repeatable, and high-quality results. Up next, we’ll tackle troubleshooting common black oxide issues, so you can resolve defects and keep your process running smoothly.

Troubleshooting Black Oxide Like a Pro

Ever pulled a batch of parts from the tank, only to find streaks, patchy spots, or a finish that rubs off too easily? Or maybe you’ve noticed a dull brown instead of that rich, blackened colour you expected? These issues aren’t just cosmetic—they can signal deeper process problems that affect part performance, especially on precision jobs like cold rolled steel blackened or a high-visibility black iron finish. Let’s break down the most common black oxide coating defects, what causes them, and how to fix and prevent them for a reliable, repeatable blackened steel finish.

| Symptom | Likely Causes | Corrective Actions | Preventive Actions |

|---|---|---|---|

| Color variation, streaks, or uneven blackening | Inadequate cleaning, mixed alloys, bath contamination, poor agitation, heat treat scale | Reclean and repickle parts; segregate alloys; replace or filter bath; increase agitation; ensure uniform surface prep | Standardize cleaning steps; batch parts by alloy; schedule regular bath maintenance; train operators on surface prep |

| Patchy or brownish finish (not true blackened colour) | Incorrect bath temperature, expired chemicals, over-immersion, excessive colloidal iron | Check and adjust bath temperature; refresh chemicals; monitor immersion time; filter bath | Install temperature controls; log chemical changes; follow supplier dwell time guidance |

| Flash rust or poor corrosion resistance after sealing | Insufficient rinsing, incomplete drying, poor oil/wax coverage, contaminated sealant | Repeat rinse and dry steps; reapply or replace sealant; use clean, uncontaminated oil/wax | Train staff on rinse discipline; specify sealant dwell times; store sealed parts properly |

| Smut or rub-off (residue on handling) | Incomplete conversion, poor rinsing, over-concentration of bath, inadequate post-seal cure | Repeat blackening and rinsing; dilute bath if needed; adjust sealant application and curing | Regularly test bath concentration; monitor post-seal times; verify conversion before sealing |

| Edge effects, stains, or trapped chemistry | Poor racking, inadequate agitation, insufficient drainage/rinsing | Reorient parts for better drainage; increase agitation during rinses; double-check blind holes and recesses | Standardize racking setups; implement agitation protocols; inspect for pooling after rinses |

| Adhesion issues or flaking (rare in conversion coatings) | Surface not properly activated, incompatible substrate (e.g., trying to blacken stainless steel without correct chemistry) | Use correct activation steps; switch to proper chemistry for blackening stainless steel; verify substrate compatibility | Document substrate types; update SOPs for special alloys; train on activation for stainless |

Inspection Checkpoints Before Release

- Uniform appearance and consistent blackened colour across all parts

- No visible residue, oil puddles, or dry spots

- Masking lines crisp and free of bleed-through

- No handling marks, smears, or rub-off on the finished surface

Sounds complex? It’s easier with a checklist and a disciplined process. For example, if your cold rolled steel blackened parts show patchy color, start by auditing your cleaning and racking steps before adjusting chemistry. If you’re aiming for a flawless blacken stainless steel result, always verify you’re using the right activation and chemistry for that alloy—otherwise, you’ll risk adhesion issues or a weak finish [reference].

Don’t forget: every process fix should be documented, and your SOP or operator training updated to prevent repeat issues. This disciplined approach ensures every blackened steel finish—from everyday tools to specialty black iron finish components—meets your standards and customer specs. Next, we’ll cover how to qualify suppliers and set up robust procurement processes for black oxide at production scale.

Procurement and Vendor Selection for Production Black Oxide Coating

When you’re gearing up for production—especially in automotive or high-reliability sectors—finding the right partner for black oxide coating is about much more than searching for “black oxide coating near me.” Imagine you’ve designed a critical assembly using black oxide screws or specified a stainless steel coating for corrosion resistance and appearance. How do you ensure your supplier can deliver not only a consistent finish, but also the documentation, traceability, and process control your customers demand?

Vendor Qualification and Audit Readiness

Sounds complex? It doesn’t have to be. Picture yourself walking into a supplier’s facility or evaluating their proposal—what questions should you ask to filter out the best from the rest? Here’s a practical checklist you can use for qualifying any black oxide vendor, whether local or global:

- What certifications do you hold? (e.g., IATF 16949, ISO 9001)

- Can you provide documented process controls for black oxide and related finishes?

- How do you ensure traceability for each lot or batch?

- Are you capable of supporting PPAP or other automotive documentation requirements?

- What post-treatment sealing options do you offer (oil, wax, polymer)?

- How do you handle masking and special requirements for coating stainless steel?

- Do you routinely process black oxide screws and black oxide stainless screws for critical assemblies?

- Can you provide sample parts or pilot runs for validation?

- What is your policy for rework or handling nonconforming parts?

- How do you update your processes to meet changing industry standards?

For those seeking an integrated solution—combining machining, stamping, and downstream assembly—partners like Shaoyi can streamline the entire workflow. Their IATF 16949-certified processes are designed for automotive PPAP, and their end-to-end traceability means fewer handoffs and faster launches. When building your RFQ, consider asking about integrated capabilities to reduce risk and speed up your project.

Incoming Inspection and Documentation

Once your parts arrive, how do you verify the finish meets your requirements? Here’s a table mapping common inspection criteria to the documents you should expect from any qualified black oxide supplier:

| Inspection Criteria | Required Documentation | Purpose |

|---|---|---|

| Visual appearance (color, uniformity) | Sample part photos, inspection sheet | Confirms finish meets specification |

| Coating thickness (if specified) | Process control logs, supplier statement | Verifies dimensional stability |

| Corrosion resistance (per spec) | Salt spray or humidity test report | Documents performance against requirements |

| Traceability (lot/batch) | Lot traceability record, C of C | Links parts to production run |

| Process control | Bath maintenance logs, calibration records | Ensures consistent processing |

| Material compatibility | Material certs, finish spec confirmation | Prevents mix-ups (e.g., correct stainless steel coating) |

Train your incoming inspection team to check these documents and sample a percentage of each batch—typically at least 10% or a minimum of three parts per lot. If you spot any issues, document them with photos and communicate promptly with your vendor to resolve them. This approach helps you avoid surprises, whether you’re sourcing black oxide near me or managing a global supply chain.

RFI and RFQ Checklist for Production Black Oxide

Ready to send out a request for information (RFI) or quote (RFQ)? Make sure your package includes these essentials:

- Clear finish specification (e.g., "black oxide per MIL-DTL-13924, Class 1, oil-sealed")

- Material and part drawing with all masking, thread, and surface requirements

- Expected volume, lot size, and delivery cadence

- Required documentation: C of C, process logs, test reports

- PPAP or other regulatory compliance needs

- Sample part requirements for validation

- Special notes for coating stainless steel or unique alloys

- Questions about end-to-end process capability (machining, coating, assembly)

Before issuing an RFQ, always align your finish specification, drawing notes, and test methods with your supplier. This prevents costly misunderstandings and ensures your parts meet every expectation.

With these tools and checklists, you’ll be fully equipped to qualify, audit, and manage vendors for any black oxide project—whether it’s a run of black oxide screws for automotive, black oxide stainless screws for electronics, or precision stainless steel coating for medical devices. Next, we’ll wrap up with a simple action plan to lock in your finish and move confidently toward production release.

Action Plan for a Reliable Blackened Metal Finish

Ready to move from research to results? Whether you’re finalizing a new product, specifying a black oxide treatment for critical fasteners, or evaluating a diy black oxide coating for prototypes, a clear action plan helps you avoid costly missteps and ensures your finish performs in the real world. Here’s how to lock in a consistent, high-quality black oxide finishing process, step by step.

Your Three Step Action Plan

- Choose the Right Finish and Sealant: Review your application’s needs using the comparison tables and scenario recommendations above. Factor in dimensional requirements, corrosion risks, and the desired appearance—whether you want a classic blackened metal finish or a functional, low-glare coating black. Select the sealing method (oil, wax, or lacquer) that matches your service conditions and maintenance plan.

- Validate Samples and Acceptance Criteria: Request sample parts or run a pilot batch. Inspect for uniform color, thickness, and surface quality. Use the checklists for documentation and compare against your customer’s drawing notes or referenced standards. This is the time to adjust process parameters or clarify requirements for black oxide plating before scaling up.

- Lock SOPs, Training, and Vendor Agreements: Finalize your standard operating procedures based on proven steps for cleaning, blackening, sealing, and inspection. Train your team or vendor on these SOPs, and ensure all agreements specify traceability, documentation, and rework policies. For those seeking seamless upstream and downstream integration, consider a partner like Shaoyi—their end-to-end support, from prototyping to black oxide coating and assembly, can help reduce lead time and risk, especially when dimensional control is critical.

What to Document Before Release

- Material and finish specification, including sealing method

- Sample validation results and acceptance criteria

- Finalized SOPs and operator training records

- Vendor agreements covering traceability and documentation

- Maintenance plan for sealant and periodic inspections

For best results, always align your material, black oxide finish, and sealing method with the actual service environment—don’t just rely on lab tests or datasheets.

By following this action plan, you’ll set up your black oxide treatment for long-term success—whether you’re managing an in-house line, outsourcing to a specialist, or exploring diy black oxide coating for short runs. If you already have a trusted supplier, use these checklists and SOPs to drive consistency and quality. If you need integrated support for high-precision or fast-turnaround projects, a partner like Shaoyi can provide the technical depth and end-to-end capability to keep your launch on track.

Black Oxide Coating FAQs

1. What are the disadvantages of black oxide coating?

Black oxide coating offers minimal corrosion resistance on its own and relies on post-treatment with oil or wax for protection. It is less durable than thicker finishes like zinc plating, may wear off in high-friction or outdoor environments, and is not suitable for harsh or marine conditions. The finish can also be difficult to repair if damaged and is best used for parts requiring dimensional stability and a non-reflective appearance.

2. Does black oxide wear off?

Yes, black oxide can wear off over time, especially on parts that experience frequent use or abrasion, such as tools and fasteners. However, the finish can be reapplied without significant surface preparation. Regular maintenance of the oil or wax sealant helps extend the life of the coating.

3. Does black oxide coated steel rust?

Black oxide coated steel can resist rust if properly sealed with oil or wax, but the base oxide layer alone provides limited protection. If the sealant wears off or is not maintained, the underlying steel may rust, especially in humid or corrosive environments. Regular inspections and reapplication of sealant are recommended for long-term performance.

4. How does black oxide coating compare to zinc plating and phosphate finishes?

Black oxide coating is thinner and maintains tight tolerances, making it ideal for precision parts. Zinc plating provides superior corrosion resistance but adds more thickness, which can affect fit. Phosphate finishes offer moderate protection and are often used for their oil retention and lubricity. The best choice depends on your application’s need for durability, appearance, and dimensional accuracy.

5. What should I look for when choosing a black oxide coating supplier?

Look for suppliers with certifications like IATF 16949 or ISO 9001, documented process controls, traceability, and experience with your specific part materials. Ask about their ability to handle post-treatment sealing, provide sample validation, and support documentation requirements such as PPAP for automotive applications. Integrated partners, such as Shaoyi, can streamline production by combining upstream machining, black oxide finishing, and downstream assembly.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —