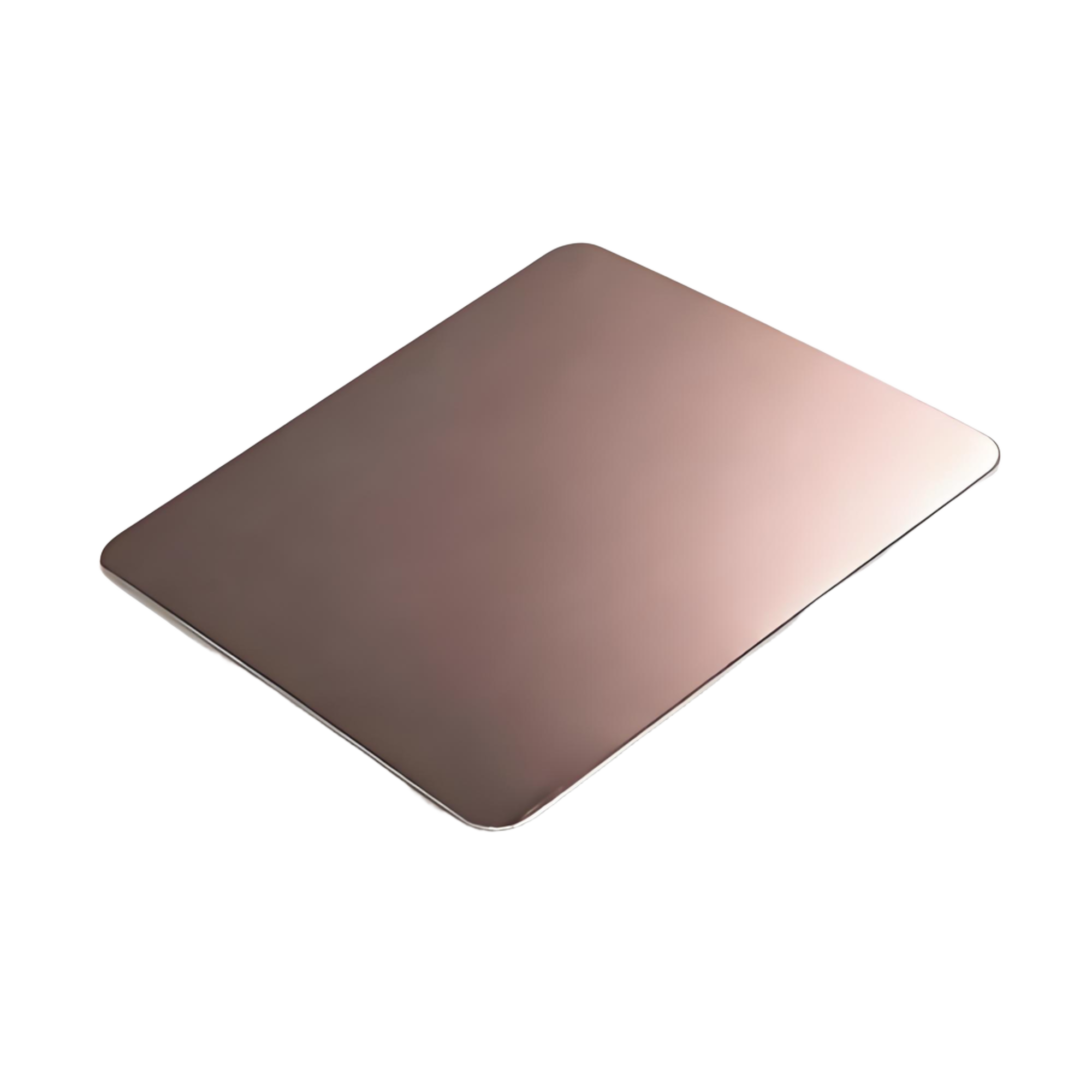

What Is Copper Plating? Key Base Coating in Automotive Metal Finishing

Copper Plating Defined And Why It Matters

When you design an automotive finish, the base coat often determines whether the rest of the stack succeeds. What is copper plating? It is an electrochemical method that deposits a thin copper coating on a conductive part using an electrolyte bath and current, producing a controlled copper deposition you can build on. This base layer improves adhesion, helps level minor defects with additives, raises electrical and thermal conductivity, and sets the surface up for nickel or chrome that follow. It can provide protection, but on bare steel alone copper may not prevent rust long term, so it is typically combined with other metals in a stack.

What Copper Plating Does In Automotive Finishes

Sounds complex? Think of copper as the bridge between the raw metal and the decorative or functional topcoats. In practice you will see electroplating examples like copper plated steel components used for solderability and aluminum parts treated with zincate before copper to enable nickel or chrome later. Because copper is soft and malleable, the layer conforms to stampings and cast features while supporting later polishing or buffing.

- Adhesion promotion between the substrate and subsequent layers

- Leveling of minor surface defects through bath additives such as levelers

- Improved electrical and thermal conductivity and better solderability

- Prepares the surface for nickel or chrome in multi metal systems

Why Copper Is Used Before Nickel And Chrome

On aluminum, a zincate pretreatment creates a zinc layer so copper can adhere, and that copper then prepares the surface for further plating with nickel or chrome. On steel, thorough cleaning and activation come first, after which copper enhances conductivity and solderability, with additional coatings added for corrosion performance. Copper and nickel have strong chemical affinity, so copper bonds to nickel and often serves as a base for additional coatings.

Key Advantages For Complex Geometries And Stampings

When parts have deep recesses or non conductive areas that need a seed layer, electroless copper can deposit uniformly without electricity. For high volume hardware, racks and barrels enable efficient electrolytic runs, and many shops offer quick turnarounds on high volume barrel plating lines.

Copper is the enabling base layer that makes multi metal automotive finishes stick, smooth, and perform.

In the chapters ahead, we will unpack the cell setup and chemistries, compare electroless and electrolytic approaches, outline rack and barrel workflows, review equipment and bath care, map a practical QA plan, troubleshoot defects, and help you evaluate capable suppliers.

How Copper Electroplating Works In Practice

How Copper Electroplating Works In Practice

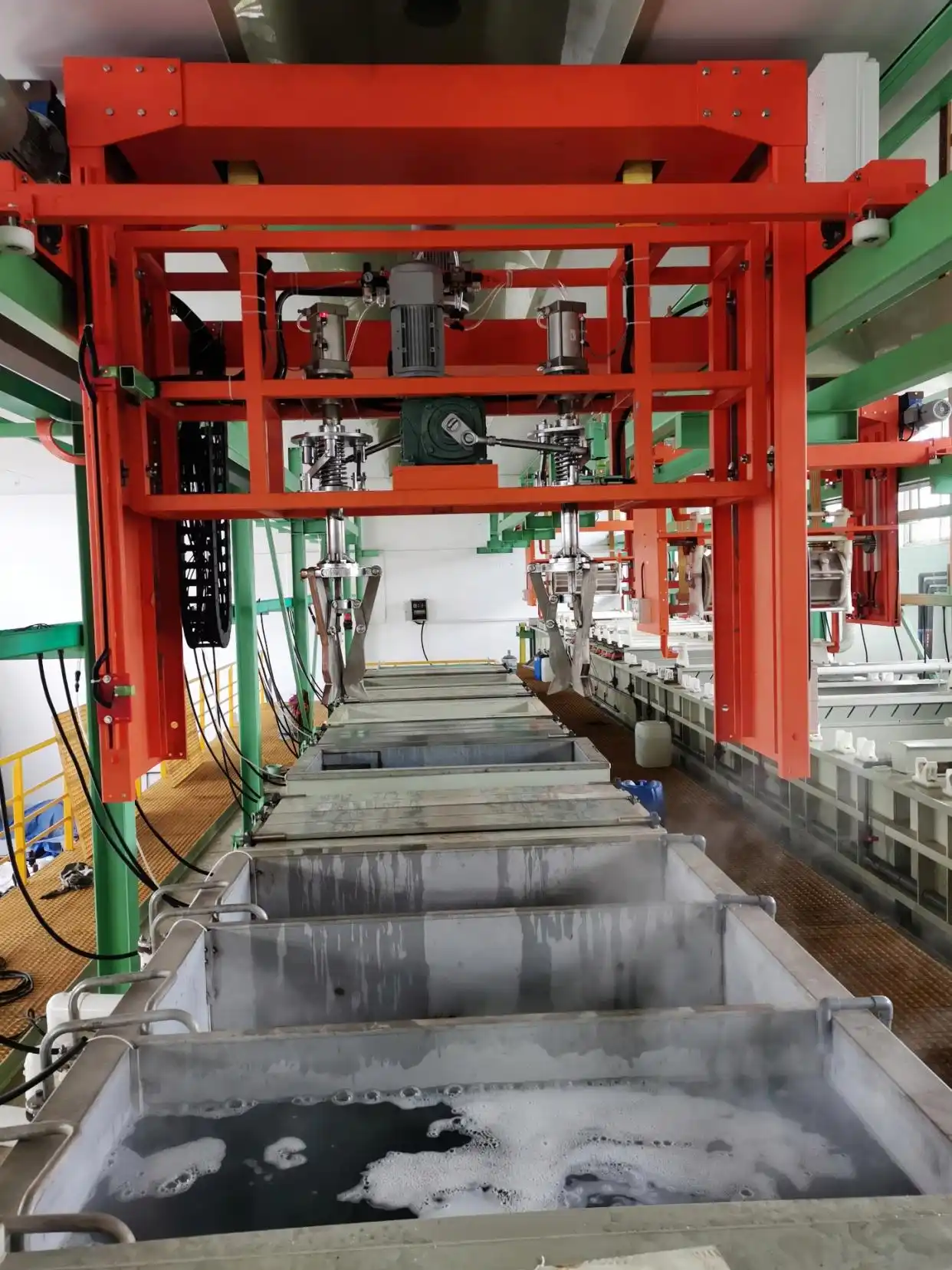

Sounds complex? Start with a simple picture of the electrolytic plating process. Electricity moves copper ions through a liquid and turns them into a tight metal layer on your part.

From Ion To Metal How Copper Deposits

Imagine your part clipped to the negative lead. It is the cathode and receives electrons. A copper bar on the positive lead is the anode. When current flows, positively charged copper ions travel through the bath to the cathode, gain electrons, and become solid copper, while the anode dissolves to replenish ions. A classic electroplating process diagram shows the anode, the workpiece as the cathode, and a bath made from copper sulfate, sulfuric acid, and chloride ions, which together enable even plating Formlabs, Electroplating overview.

Uniform current distribution and controlled chemistry drive deposit quality.

Inside The Cell Anode Cathode And Current Flow

In practice, a DC power supply pushes electrons to the cathode. The copper anode provides metal to the bath and helps keep copper ions available for deposition. Agitation keeps fresh ions moving to the surface and minimizes local depletion. Filtration removes particles and helps prevent pits or roughness. If mixing is inconsistent or air is pulled in through the filter pump, thickness can vary and defects can appear, so shops monitor solution movement and clarity as part of routine control.

Bath Chemistries You Will Encounter

There is not a single copper plating solution. Engineers electroplating copper choose chemistries to fit coverage and finishing goals. Common acid systems use a copper sulfate solution for electroplating with added sulfuric acid. Alkaline routes include cyanide and non-cyanide formulations, as well as mildly alkaline pyrophosphate, which is often favored for ductility and throwing power. Acid fluoborate baths exist for higher-speed work but demand careful handling. Electroless copper is different altogether. It relies on a chemical reduction reaction without external current, which can produce very uniform coverage and can begin on nonconductive substrates after a catalytic prep.

- Copper salts such as copper sulfate

- Acid, commonly sulfuric acid

- Chloride ions for bath function

- Additives, for example brighteners, levelers, accelerators, or suppressors

- Deionized water and maintenance chemicals to balance the copper plating solution

If you keep this mental model in mind, the next step is to see how copper functions as the base layer in a nickel chrome stack and what changes when the substrate is steel versus aluminum.

Copper As The Base Coat In Automotive Stacks

Wondering where copper actually fits in the stack you specify? As a plated copper base, it bridges the substrate and the topcoats, improving adhesion, leveling tool marks, and buffering the layers that follow.

How Copper Fits In A Nickel Chrome Stack

In automotive finishing, electroplated copper typically precedes nickel, and nickel plating copper then supports a chrome topcoat for appearance and wear. This plated copper layer contributes ductility and leveling, and it is especially valuable on zinc die cast alloys to avoid nickel diffusion and to bond difficult alloys such as leaded materials. These roles are reflected in common stack options like copper + nickel + chrome offered by finishing providers Eco Finishing, Electrolytic Copper Nickel Chrome.

- Clean and rinse to remove soils QA checkpoint

- Activate or etch to expose a fresh surface matched to the substrate QA checkpoint

- Optional copper strike to ensure adhesion and protect sensitive alloys QA checkpoint

- Copper build to create a smooth, conductive base

- Rinse sequence to prevent chemistry carryover

- Nickel deposit for corrosion and wear performance

- Chrome topcoat where required for appearance and hardness

- Final rinse and dry QA release check

Substrate Notes Steel Versus Aluminum

For copper plating steel stampings and fasteners, thorough cleaning and activation help the copper base adhere and fill minor tooling marks before downstream nickel and chrome. For copper plating aluminum castings or machined parts, a zincate pretreatment is commonly used first, and many lines apply a copper strike over the zincated surface to replace oxides, limit immersion effects, and shield the substrate from aggressive electrolytes. Strike selection and preparation sequencing are often the difference between success and failure in these cases Products Finishing, Strike Chemistry. As that guidance notes, if the next step is electroless nickel, additional activation may be required after a copper strike, whereas for subsequent electrolytic steps the benefits generally outweigh the drawbacks.

Line Integration Pitfalls To Avoid

Most defects trace back to preparation mismatches or contamination between steps. You will notice issues like blistering or poor adhesion when soils remain, immersion deposits form, or rinse discipline slips. Build your controls around each handoff in the stack so the electroplated copper base arrives clean and consistent to nickel.

- Validate cleaning and activation on coupons before full release

- Match the strike chemistry to substrate and geometry

- Maintain rinse cascades to prevent chemistry carryover

- Confirm rack contact, masking, and agitation reach recessed areas

- Document QA gates between copper, nickel, and chrome operations

With the stack role clear, the next question is method selection, namely when electroless or electrolytic copper best fits your part geometry, coverage needs, and throughput.

Electroless Or Electrolytic Choosing The Right Method

Trying to decide between electroless and electrolytic copper for an automotive part? Start by matching the method to geometry, substrate, and the role of the copper base. Both are forms of electrochemical plating, but they differ in how metal is delivered to the surface and what that means for coverage, speed, and cost.

When Electroless Copper Outperforms

Use electroless when uniform coverage and access to recesses matter most, or when the substrate is not conductive. Electroless deposition occurs without external power and plates evenly across complex shapes. With the right surface preparation, it can coat plastics or ceramics, and while electroless plating is most common with nickel, some electroless copper plating options exist for specific needs ChemResearch Co., Electroplating vs. Electroless.

Pros

- Very uniform thickness, including deep recesses and internal features

- Can start on non-conductive surfaces with proper activation

- Useful as a seed layer before subsequent electrolytic steps

Cons

- Slower deposition and higher bath chemistry costs

- Limited material options compared with electrolytic routes

- More ongoing bath monitoring and replenishment

When Electrolytic Copper Leads

Choose electrolytic copper for speed, cost efficiency, and the ability to build thicker copper bases. This method requires a conductive substrate and an external power source. It is typically faster and less expensive to maintain during production, though it tends to plate more on edges and less in recesses compared with electroless methods Sharretts Plating, Electroless vs. Electrolytic.

Pros

- Fast results and cost-effective production

- Capable of building thicker copper layers

- Lower routine bath maintenance during runs

Cons

- Requires an electrically conductive surface

- Less uniform coverage in recesses with potential edge buildup

- Non-conductives need an electroless seed before electroplating of metals

Choosing By Geometry Throughput And Cost

| Method | Conductivity requirement | Coverage of recesses | Equipment and upkeep | Common automotive use-cases |

|---|---|---|---|---|

| Electroless copper or nickel as a copper-enabling base | Works on non-conductive surfaces after proper prep | Highly uniform across complex internal features | Chemical bath needs closer monitoring and replenishment | Uniform seed on complex geometries or non-conductives before copper; parts needing even coverage and high corrosion resistance with electroless nickel |

| Electrolytic copper | Requires a conductive substrate or prior seed | Less uniform in deep recesses, more at edges | Power supply and anodes; generally lower ongoing maintenance | High-throughput decorative or functional bases where speed and cost dominate and uniformity is less critical |

- If geometry is intricate or non-conductive, favor electroless to establish an even, adherent base.

- If cycle time and cost drive the decision, electrolytic copper is usually the better fit.

- Confirm exact bath chemistries and activation steps with current supplier data before locking parameters.

With your method selected, the next step is translating it into clear, step-by-step rack and barrel workflows for launch.

How To Copper Plate Metal Workflows For Rack And Barrel

Ready to move from concepts to the line? The copper plating procedure below shows how to copper plate metal with clear, shop friendly steps. Use this as a launch playbook, then source exact numeric targets from current standards and your supplier data sheets.

Rack Plating Workflow For Large Components

- Pre treatment and prep Disassemble, strip legacy coatings, and polish to create a uniform base. Strong pre treatment helps prevent flaking or blistering and improves adhesion.

- Clean and activate Perform thorough cleaning. In many lines the part is dipped in cleaning solution and electrified to remove soils before plating. Verify a bright, reactive surface.

- Plan racks, contacts, and masking Choose contact points that can be finished later, confirm stable mechanical and electrical contact, and apply masking where selective copper is required. Record rack orientation on the traveler.

- Electroplating setup Connect the negative lead of the rectifier to the workpiece and the positive lead to the plating system per your process plan. Confirm polarity, current control mode, and continuity before entering the tank.

- Deposit copper Immerse in the qualified copper bath and apply DC current within your approved window. Time and current govern thickness, so log start stop times and amperage. Maintain consistent agitation and filtration per your line plan.

- Rinse cascades Move through counterflow rinses to prevent chemistry carryover. Keep parts wet between steps to avoid staining.

- Post treatment as specified Where required, apply anti tarnish or clear coat to protect freshness of the copper surface before downstream operations, then dry thoroughly.

- Inspect and document Perform visual and dimensional checks per the control plan and record results on route cards and travelers. Escalate any deviations with a documented process deviation log.

Barrel Plating Workflow For Small Parts

- Bulk clean and sort Degrease and clean to remove oils and oxides. Separate mixed alloys if your specification requires different preps.

- Load the barrel Verify part size compatibility, load segmentation, and closure integrity so parts tumble freely without damage.

- Immerse and connect Place the barrel in a copper sulfate and sulfuric acid bath, then power the line. Barrel plating is ideal for small parts and cost effective for high volume, while rack plating serves larger or delicate items Zemetal, copper electroplating overview.

- Apply current and plate Maintain rotation for even coverage. Control current and time to meet the approved thickness range. Record lot and bath IDs for traceability.

- Unload, rinse, and dry Use staged rinses, then dry promptly to prevent spotting.

- Final checks and packaging Inspect representative samples, verify count and segregation, and package to protect the fresh copper surface.

Critical Checkpoints Before Nickel Or Chrome

- Line readiness Verify clean surfaces for good wetting, stable rack contacts, and correct masking. Run a small set of test coupons to prove coverage before full release.

- Trial runs Perform a dummy run to confirm current distribution, agitation, and filtration are stable.

- Documentation Ensure travelers, route cards, and lot level traceability are complete. Log any process deviations with causes and corrective actions.

- Handoff discipline Keep rinse cascades effective, avoid chemistry carryover, and stage parts promptly for the next operation.

Wondering how to copper plate different part families consistently? The next section breaks down the equipment and bath care that make these workflows repeatable, from rectifiers and racks to anodes, agitation, and filtration.

Equipment Buying Guide And Bath Maintenance Essentials

Ready to make those workflows repeatable? The right copper plating equipment and disciplined bath care make yield predictable. Use this checklist before you power up a copper plating machine on your line.

Rectifiers Racks And Barrels That Make Or Break Yield

- Rectifier process fit Confirm power capacity, waveform indicators, and adjustable current and voltage ranges. Also review reliability aspects like structure, circuit design, and heat dissipation, and weigh overall cost effectiveness. See this guide on how to choose an electroplating rectifier for the core criteria and sizing approaches using bath volume or plated area Liyuan, How to choose an electroplating rectifier.

- Control stability Specify constant current capability and low ripple to minimize roughness and burning downstream.

- Racks for consistency Plan solid electrical contact points that you can finish later, maintain consistent distance and orientation to anodes, and use masking to protect no-plate regions.

- Barrel design for small parts Choose durable, nonconductive barrels with open windows for solution flow, reliable internal contacts, and rotation that tumbles parts evenly without damage.

Anodes Filtration And Agitation Fundamentals

Wondering is copper anode or cathode in most baths? Your workpiece is the cathode. A copper electrode serves as the soluble anode and replenishes copper ions during plating.

For copper systems, established guidance covers anode choice by chemistry plus continuous filtration and effective agitation to keep deposits smooth and ductile SubsTech, Copper plating.

- Anode type and quality Use phosphorized copper for common acid copper sulfate or fluoborate baths, and high purity oxygen free copper for cyanide or pyrophosphate systems. Lower purity can shed sludge that roughens deposits.

- Anode management Bag copper electrodes to trap fines, inspect for passivation, and maintain appropriate spacing and area balance per your bath supplier.

- Filtration strategy Run continuous fine filtration to remove particles that cause pitting and roughness. Choose media compatible with your chemistry and plan easy changeouts.

- Agitation method Use solution flow, oil free air, or oscillating cathodes to maintain uniform ion transport at the surface.

- Rectifier quality link High ripple can contribute to roughness in acid copper baths, so confirm low ripple when qualifying power supplies.

Bath Care Replenishment And Contamination Control

- Replenishment planning Let the anode dissolve to maintain metal content and supplement additives as required. Track amp hours and visual cues to schedule top ups.

- Additive management Monitor brighteners and levelers carefully; dull deposits often signal low brightener or organic contamination in many copper systems.

- Contamination isolation Keep oils and solids out with robust cleaning and rinse discipline. Segregate tooling and tanks by chemistry to avoid cross carryover.

- Particle control Change filter media on a set cadence and verify solution clarity. Check anode bags for tears that might release sludge.

- Solution transfer hygiene Use dedicated pumps and hoses, minimize splashing and air entrainment, and keep returns below the liquid surface.

- Electrode condition Document the condition of copper electrodes and replace or resurface when films or damage persist after normal maintenance.

Routine lab analysis and simple trend charts turn copper bath behavior into predictable, audit ready performance.

With hardware, fixtures, and bath care defined, the next step is a QA plan that measures thickness, adhesion, and corrosion before release.

Quality Control And Standards For Reliable Copper Plating

What should you verify before your base coat heads to nickel or chrome? A tight QA plan. Think in gates. Measure thickness. Prove adhesion. Check corrosion behavior. Then document everything your customer and auditors will ask for.

What To Measure Thickness Adhesion Corrosion

Start simple. Pick thickness methods that suit your substrate and stack. Use non-destructive tools for routine control and reserve destructive checks for confirmations or failure analysis. Pair adhesion checks with visual and ductility indicators. For corrosion, choose accelerated tests that reflect your end-use.

| Test method | Purpose | Typical timing | Reference standard |

|---|---|---|---|

| X-ray fluorescence thickness | Non-destructive layer thickness per location | In-process and final | ASTM B568 |

| Coulometric thickness | Destructive thickness and layer sequence check | FA, periodic audits | ASTM B504 |

| Magnetic thickness | Nonmagnetic coating on magnetic basis metals | Incoming calibration checks, final | ASTM B499 |

| Cross-section microscopy | Layer order, thickness, and defects | FA, problem solving | ASTM B487 |

| Qualitative adhesion | Quick screen for bond integrity | In-process and final | ASTM B571 |

| Mechanized tape test | Repeatable adhesion assessment | Qualification, periodic | ASTM B905 |

| CASS salt spray | Accelerated corrosion of decorative stacks | Qualification, periodic | ASTM B368 |

| Corrodkote | Porosity and corrosion tendency of decorative coatings | Qualification, periodic | ASTM B380 |

For multilayer nickel chrome over copper, appearance and site counting can also be rated using dedicated methods such as surface rating and corrosion site techniques listed in ASTM Volume 02.05, which catalogs B456, B568, B571, B368, and related practices ASTM standards, Volume 02.05.

Which Standards Apply And When

- Decorative automotive stacks Use ASTM B456 for copper plus nickel plus chromium systems and align your thickness and corrosion tests with that framework. Many buyers cite this spec in drawings or supplier quality agreements, sometimes as astm b456.

- Engineering copper Where copper is the functional layer, reference copper and test standards from the same ASTM volume and choose thickness, adhesion, and porosity tests accordingly.

- Military and aerospace MIL-C-14550 defines classes of electrodeposited copper with thickness and adhesion expectations. The range spans extremely thin to heavy builds, and XRF is commonly used for verification Valence Surface Technologies, MIL-C-14550 overview.

For automotive approved plating programs, always obtain the latest issue of the cited standard and lock methods during APQP. Your electroplating lab should maintain calibrated instruments, written procedures by method, and training records.

Sampling Documentation And Release Criteria

- Sampling plans Use attribute and variables sampling approaches to structure lot checks and reaction plans per recognized guides such as ASTM B602, B697, and B762.

- Control plan linkage Tie each gate to a method and record format. Example thickness by XRF before nickel, adhesion per B571 after copper, and corrosion per B368 during qualification.

- Traceable records Capture lot numbers, bath ID, instrument calibration, operator, locations measured, and rework disposition.

- Nonconformance flow Hold product, contain suspect lots, run a destructive cross-section if needed, and document corrective actions before release.

Next, turn these checks into faster problem solving with a defect to cause to action matrix for copper plating.

Troubleshooting Copper Electrolyte Defects With A Practical Action Matrix

Seeing pits, nodules, or blisters after copper plating? Use this quick action matrix to link what you see to likely causes and fast fixes, so the electrochemical plating process gets back on track without guesswork.

Start at the beginning of the line. On ferrous parts, most adhesion problems trace to surface preparation, not the copper tank. Practical detective work includes scrubbing substitution to isolate the faulty step, verifying a water-break-free surface, and checking acid dips for contamination that can create immersion deposits. Cleaner performance hinges on chemistry makeup, temperature, agitation, and time, so confirm each before changing the plating step Finishing and Coating, Frank Altmayer troubleshooting guide.

When defects point to the copper bath itself, think particles and flow. Dummy plating a scrap panel can sweep debris from a copper sulfate for electroplating bath, while healthy anodes carry a uniform black film. One practical manual recommends daily dummy plating and leaving conditioned anode baskets in the bath, with filtration recirculation running as needed to keep the solution clean Think & Tinker, Dummy plating practice.

Visual Defects And What They Signal

| Defect | Likely cause(s) | Immediate actions | Preventive process changes |

|---|---|---|---|

| Pitting or peppery roughness | Particles in the copper electrolyte, drag-in soils, disturbed anode film | Run a dummy plate to sweep debris, verify solution clarity, refresh filters | Daily dummy plating and steady recirculation, keep conditioned anode baskets in-tank and intact |

| Nodules or coarse roughness | Sludge or fines from anodes, torn baskets, poor capture by filters | Inspect baskets for damage, replace media, recondition anodes until a uniform black film returns | Maintain basket integrity, do not remove conditioned baskets unnecessarily, schedule filter changes |

| Burning or edge overdeposit | High local current density, poor current distribution, inadequate solution movement | Reduce current, adjust contact orientation or shielding, confirm steady agitation before resuming | Qualify rack contact points and spacing, prove distribution with test coupons before full release |

| Porosity or pinholes | Residual oils or smut from inadequate cleaning or de-smut, gas entrapment at the surface | Use scrub-substitution to isolate the prep step, re-clean or de-smut, replate a test coupon | Lock cleaner chemistry, temperature, agitation, and time; validate water-break-free surfaces |

| Discoloration or rapid tarnish | Chemistry carryover, poor rinsing, unprotected fresh copper | Improve rinse cascades, re-rinse affected parts promptly, apply an approved copper corrosion inhibitor or anti-tarnish | Strengthen rinse discipline between steps, keep parts wet between tanks, stage promptly for downstream processes |

| Adhesion failure or blisters | Improper prep on steel, immersion deposits from contaminated acid dips, heat-treat scale, persistent boundary lubricants | Start-of-line focus: scrub-substitution to pinpoint the step, analyze acid dips for metallic contamination, verify scale removal, re-clean and re-activate | Control cleaner makeup and conditions, monitor de-smut and pickling steps, prevent copper contamination in activation acids |

Immediate Corrective Actions To Stabilize The Line

- Pause production, run a dummy plating pass to clean the bath, and check solution clarity.

- Rework a small set of test coupons after re-establishing water-break-free prep.

- Analyze the activation acid if immersion copper is suspected on steel parts.

Longer Term Fixes And Preventive Controls

- Establish routine filter media changes and basket inspections.

- Document cleaner chemistry, temperature, agitation, and time as controlled variables.

- Keep records of dummy plating and bath observations so trends are visible.

- Routine checks solution clarity, filter change intervals, anode basket integrity, and scheduled dummy plating for contamination cleanup.

If recurring issues outpace in-house fixes, the next step is to evaluate suppliers for lab capability, process discipline, and end-to-end integration that reduces handoff defects.

Choosing A Capable Partner And Moving From Plan To Production

Sounds complex? When you need to plate copper on real automotive parts at scale, the right partner determines whether your base coat passes PPAP and survives launch. Here is a concise way to qualify suppliers and move from plan to production with fewer surprises.

What To Look For In An Automotive Copper Plating Partner

- Quality system and assessments Verify ISO 9001 or IATF 16949 alignment, readiness for APQP and Level 3 PPAP, and evidence of CQI-11 plating and CQI-12 coating assessments where applicable. Confirm lot traceability and the ability to use an in-house lab or an ISO 17025 third party for testing. These expectations are typical in automotive supplier manuals and help ensure audit-ready performance GB Manufacturing Supplier Requirements Manual.

- Process coverage and part types Ask for proven runs on copper plated steel stampings, copper plating on aluminum with appropriate activation and strike steps, and copper plated electrical components when fine features and selective areas matter.

- Equipment and fixturing depth Review racks and barrels, contact strategies, masking, and the ability to plate copper consistently across complex geometries and mixed assemblies.

- Baths and controls Request the current list of copper chemistries, rectifier control modes, anode management, filtration, agitation, and documented maintenance routines. Look for routine lab checks and trend charts.

- QA methods and documentation Confirm thickness and adhesion methods, in-process checks, reaction plans, and complete travelers. Ensure sampling, containment, and SCAR responsiveness are defined.

- Launch discipline Look for early production containment, pilot builds, and clear handoff plans into nickel and chrome without chemistry carryover.

Integrating Prototyping Tooling And Surface Finishing

You will notice fewer handoff defects when stamping, fixturing, and plating live under one roof. Providers that integrate tooling, forming, and in-house plating often cut lead time, improve repeatability, and strengthen traceability across the production cycle Batten & Allen, integrated stamping and plating. That same integration helps you iterate faster during APQP and stabilize current distribution before ramp.

If an integrated partner fits your sourcing plan, consider shortlisting a provider like Shaoyi when end-to-end support matters from rapid prototyping through surface finishing and assembly. Maintain due diligence by confirming copper bath families, rack and barrel capability, QA methods, traceability, and pilot sample turnarounds against your drawing and control plan.

Next Steps To Validate Capability And Launch

- Clarify scope Send a complete RFQ package that specifies substrate families you expect to run, such as copper plated steel brackets, copper plating on aluminum housings, and copper plated electrical components. Include target stack order and acceptance tests.

- Process review Conduct an on-site or virtual audit of baths, rectifiers, anode bagging, filtration, and lab routines. Request recent CQI-11 self-assessments and example control plans.

- Pilot builds Run DOE-style samples on representative geometries to prove coverage and adhesion, then adjust racks, masking, or agitation before committing capacity.

- Documentation and approvals Align on APQP deliverables and PPAP evidence. Lock sampling plans, reaction plans, and traceability records prior to SOP.

- Ramp with containment Start with early containment, monitor thickness and adhesion at defined gates, and release containment only after stable performance.

Choose a partner who proves capability on your parts, documents control, and integrates upstream steps to reduce rework.

With a disciplined checklist and integrated execution, you can plate copper confidently and hand off a clean, adherent base to nickel and chrome without slowing your launch.

FAQs

1. What is the purpose of copper plating?

In automotive stacks, copper plating creates a ductile, conductive base that improves adhesion, levels minor surface defects, and serves as a buffer before nickel and chrome. On its own it is not a long term rust solution on steel, so it is usually used under nickel and chromium for appearance and corrosion performance.

2. How long does plated copper last?

Service life depends on the full coating system, the environment, and quality control. In automotive, copper is a base layer that works with nickel and chrome. Durability is validated with thickness checks, adhesion tests, and accelerated corrosion methods such as CASS per ASTM B368 during qualification and periodic audits.

3. What is a copper coating called?

It is commonly called copper plating. When current is used it is electrolytic copper electroplating. When chemical reduction is used without external power it is electroless copper, often chosen for hard to reach areas or non conductive surfaces after proper activation.

4. How is copper thickness verified in automotive QA?

Non destructive XRF is widely used for in process and final checks, while coulometric methods and cross section microscopy confirm layer sequence and resolve disputes. These methods align with common practices such as ASTM B568 for XRF, ASTM B504 for coulometric checks, and ASTM B487 for cross sections.

5. What should I look for in an automotive copper plating supplier?

Prioritize IATF 16949 level quality, APQP and PPAP readiness, proven rack and barrel capability, stable rectifiers and anode management, documented bath control, and an on site lab or trusted lab partner. Integrated providers reduce handoff defects between stamping, fixturing, and plating. For example, Shaoyi offers end to end metal processing and certified quality for rapid prototyping through production https://www.shao-yi.com/service.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —