What Is Nickel Plating? Surface Treatment For Hardness And Shine In Automotive Parts

Nickel plating explained for automotive performance

When you run your finger across a bright door handle or a fuel rail fitting, you are often seeing nickel at work. So, what is nickel plating. In auto plating and broader automotive plating, the nickel plating meaning is simple. It is the controlled application of a thin nickel coating onto a part to boost corrosion resistance, surface hardness, and cosmetic shine. Depending on the application, the layer can be applied to steel, brass, copper, aluminum, zinc, and even some plastics, helping parts last longer in harsh environments Dixon Valve.

What Nickel Plating Does For Automotive Parts

Imagine a fastener that sees road salt, heat cycles, and a wrench every service interval. Nickel plating helps it survive and still look good. You will notice these core benefits on nickel plated components:

- Corrosion protection that shields the base metal from road salts, fuels, and moisture

- Increased wear resistance and surface hardness for threads, bores, and sliding fits

- Reflective, bright appearance for visible trim and interior accents

- Improved adhesion for subsequent layers like paint or decorative chrome

Nickel plating balances protection, hardness, and aesthetics for automotive duty cycles.

Electrolytic And Electroless Methods At A Glance

There are two primary ways to deposit nickel. Electrolytic nickel plating uses an external current to drive nickel ions onto the part. Electroless nickel plating relies on a chemical reducing agent, so it does not need electricity and coats more uniformly, even inside recesses and threads. Electrolytic is a strong choice for simpler external surfaces and bright finishes, while electroless excels when you need even coverage and robust corrosion and wear performance Pavco.

Where Nickel Fits In Automotive Finish Stacks

On vehicle substrates like steel, brass, copper, and aluminum, nickel can play three roles. It can be a barrier layer that slows corrosion, a leveling finish that smooths minor roughness, or the foundation for decorative stacks such as nickel plus chrome. Nickel is widely used as an undercoat to improve adhesion and provide a bright, durable base for final chrome appearance on exterior trim and interior hardware Nickel Institute.

In short, if you are asking what is nickel plating for automotive parts, it is a practical way to make parts tougher and better looking without changing their underlying design. This guide will dive deeper into choosing electrolytic versus electroless methods, controlling the process, citing standards, and troubleshooting results so you can specify the right nickel coating with confidence.

Electrolytic and electroless methods demystified

Sounds complex? Imagine two ways to put nickel on a part. In one, you plug in a rectifier and drive metal ions to the surface. In the other, the chemistry plates by itself, wrapping every contour evenly. That is the practical difference engineers weigh when they compare electroless vs electrolytic nickel plating.

Electrolytic Nickel Fundamentals

Electrolytic nickel uses direct current and soluble anodes to deposit metal on the cathode part. When electroplating with nickel, current density controls both rate and local thickness, so edges and areas closest to anodes build faster than recesses. Bath chemistry typically includes nickel salts for metal supply, boric acid as a buffer, and addition agents like brighteners and wetting agents to shape grain structure and leveling. Throwing power, pH control, and anode setup all influence how uniformly the coating distributes across complex shapes Nickel Institute Nickel Plating Handbook.

In production, nickel electroplating can be tuned toward semi-bright or bright finishes for decorative stacks, or toward more ductile engineering deposits by adjusting additives and parameters. In short, with electrolytic nickel plating, geometry and current paths dictate uniformity more than anything else.

Electroless Nickel Chemistry In Practice

The electroless nickel plating process is autocatalytic. A reducing agent in the bath, commonly sodium hypophosphite, chemically reduces nickel ions to metal on the activated surface, co-depositing phosphorus and forming a nickel‑phosphorus alloy. Because no external current is used, the deposit forms with excellent uniformity on external surfaces, internal threads, deep recesses, and blind features. This is why teams often favor EN when consistent thickness and coverage outweigh maximum brightness. These principles and the role of hypophosphite in Ni‑P formation are well documented in industrial practice Micro Plating Electroless Nickel Overview.

If you are weighing electroless nickel plating vs nickel plating by electrolysis, remember that EN’s even build simplifies tolerance stackups on intricate parts, while electrolytic routes excel when a mirror-bright base for decorative chrome is the priority.

Why pH Temperature And Agitation Matter

Across both methods, bath stability is non-negotiable. Temperature steers reaction rate and influences hardness and stress. pH affects deposition efficiency, brightness range, and the risk of hydrogen-related defects. Agitation keeps solution uniform and helps release gas bubbles to avoid pitting. For current-driven systems, anode material, placement, and maintenance protect metal ion balance and thickness distribution, while for EN, steady chemistry control keeps deposition rate and phosphorus content consistent throughout the run Nickel Institute Nickel Plating Handbook.

| Aspect | Electrolytic nickel | Electroless nickel |

|---|---|---|

| Mechanism | DC power deposits metal on the cathode; anodes replenish ions | Autocatalytic reduction of Ni using hypophosphite, forming Ni‑P alloy |

| Uniformity and throw | Thickness follows current distribution; limited throw into recesses | Excellent uniformity on complex shapes and internal features |

| Finish tendencies | Bright or semi‑bright with leveling additives | Typically matte to semi‑bright; properties tied to P content |

| Typical use cases | Decorative bases under chrome, parts needing high luster | Intricate housings, threads, bores, areas where even coverage is critical |

- Decision factors to weigh

- Part geometry and whether recesses or blind holes must be covered

- Tolerance stack and the need for uniform thickness

- Surface roughness and leveling goals vs as‑plated matte needs

- Downstream operations like polishing, masking, or chrome topcoats

- Budget and throughput expectations for the specific program

Choose electrolytic for maximum brightness on simpler shapes, and EN when uniformity over complex geometry drives performance.

Next, we will detail how electroless Ni‑P composition classes influence hardness, corrosion, and magnetism, so you can match phosphorus level to the job.

Electroless nickel classes and when to use them

Where should you start when specifying EN for automotive parts? Begin with phosphorus. Sounds complex? Once you know the three classes, the electroless process becomes a clear decision tool for performance and cost.

Phosphorus Content And Properties

- Low P EN, about 1–4% P: harder as plated, good wear, better corrosion in alkaline environments, typically magnetic as deposited. Often chosen when you plan a post plate hardening step and need tough threads or bores Advanced Plating Tech EN Guide.

- Medium P EN, about 5–9% P: balanced choice with good hardness and wear plus moderate corrosion resistance. Can appear brighter and suits mixed service conditions.

- High P EN, about 10–12% P: highest corrosion resistance in neutral and acidic media and essentially non magnetic as plated. Ideal when uniform shielding and barrier performance dominate.

As plated EN typically measures around 500–720 HK100 microhardness, and with a suitable post bake it can reach roughly 940–1050+ HK100, approaching hard chrome hardness levels Advanced Plating Tech on P content and hardness.

Composition drives corrosion resistance, hardness, and magnetism in electroless nickel.

Choosing EN For Connectors Fuel And Powertrain

- Electrical connectors and sensor pins: high P electroless nickel coated contacts help avoid magnetic interference and resist aggressive atmospheres. You will often see electroless nickel plated shells or housings for uniform coverage of threads and blind features.

- Fuel system wetted parts, rails, and valves: high P resists ethanol and acidic species while maintaining a pore tight barrier in complex passages.

- Gears, shafts, and wear faces in powertrain: medium P balances hardness and corrosion for sliding and rolling interfaces. Low P can be selected when maximum as plated hardness and a post bake are desired.

- Fasteners and threaded inserts: medium P for general duty; low P plus heat treatment when you need extra bite on wear. Account for uniform build on internal threads in your tolerance stack.

- Connector stacks and housings: many designs use copper and nickel plating layers before final finishes, leveraging EN’s even build across recesses.

In many e nickel plating specs, picking the P class first ensures the coating matches the environment, fit, and lifecycle expectations.

Heat Treatment Effects On Electroless Nickel

Post plate heat treatment increases hardness across all classes. Typical hardening cycles in the 375–425 °C range for about an hour are used to maximize hardness, but be aware of tradeoffs. Elevated heat can increase magnetism in high P deposits and may reduce corrosion resistance due to microcracking, especially on high P films. Adhesion starts with good cleaning and activation, so lock down your electroless nickel plating procedure and temperature window before committing to a bake Nickel Institute, Properties and Applications of Electroless Nickel.

- Clean and rinse to remove oils and oxides.

- Activate the surface for uniform nucleation.

- Deposit the electroless nickel coating in a controlled bath.

- Rinse and optionally bake to increase hardness or stabilize properties.

This electroless nickel coating process naturally delivers even thickness into bores and blind holes, which helps with sealing and wear but also means you should specify thickness and measurement locations to protect critical fits. With composition chosen, the next step is dialing in pH, temperature, agitation, and bath control to hit those targets consistently.

Process variables that control quality and cost

How do you nickel plate metal and hit thickness, hardness, and finish every time? In the nickel electroplating process and in electroless baths, a small set of levers controls most outcomes and the budget. Dial these in and you will notice fewer defects, tighter tolerances, and more predictable cycle times.

Bath Chemistry Roles And Additives

In electrodeposited nickel plating, the bath supplies metal ions and manages pH, conductivity, and grain structure. Nickel salts provide the metal, chloride improves solution conductivity and supports anode dissolution, and boric acid buffers pH. Addition agents do the fine tuning: carriers and brighteners drive levelling and brightness, stress reducers influence internal stress, and wetting agents help release hydrogen bubbles to prevent pitting. Temperature and pH stability are critical because they influence brightness range, cathode efficiency, stress, and burning; for example, the well known Watts bath is typically operated in an acidic pH window with controlled temperature to balance appearance and properties Nickel Institute Nickel Plating Handbook.

Contaminants change everything. Insoluble particles lead to roughness, metallic impurities like copper or zinc cause dark low current density areas, and organics create haze or brittleness. Countermeasures include continuous filtration, periodic carbon treatment for organics, and low current density dummy plating to preferentially remove certain metals Finishing & Coating service tips. Anode bags and their upkeep also matter because they keep fines out of solution and maintain steady anode performance.

Current Density And Throwing Power

Current density controls deposition rate and local thickness. Edges and surfaces near anodes see higher current and build faster, while recesses lag. That makes racking, anode placement, agitation, and shields or auxiliary anodes powerful tools for more uniform coverage. Throwing power describes how well the bath evens out these differences. You can often improve metal distribution by moderating current density, optimizing conductivity, and maintaining temperature and pH within their target ranges. When adhesion is challenging, a strike layer, or a copper undercoat on some substrates, can improve bonding before full build, a practice widely used in decorative and functional stacks Nickel Institute Nickel Plating Handbook.

| Variable | If increased within range | Likely effect on deposit or cost |

|---|---|---|

| Current density | Faster rate | More edge build and risk of burning, less uniformity |

| Temperature | Higher reaction rate | Improved throwing power and brightness window, but watch stress and bath stability |

| pH | Shift upward or downward | Changes efficiency, stress, and brightness; extremes trigger defects or precipitation |

| Chloride level | Better anode dissolution | Stabilizes metal ion supply but can raise hardness and tensile stress |

| Agitation/solution motion | More uniform boundary layer | Reduces pitting, improves levelling and consistency |

| Anode area/placement | More uniform geometry | Flatter thickness distribution across the part |

| Additives dosage | Higher brighteners | More levelling and gloss, potential for increased internal stress if unbalanced |

| Filtration and purification | Higher turnover and periodic carbon | Lower roughness and haze, fewer rejects |

Thickness Targets And Tolerance Stackups

Thickness drives corrosion life, wear resistance, and fit. Specify local or average thickness, measurement locations, and the method. XRF is a fast, non destructive choice for many nickel systems, but it has upper thickness limits depending on substrate and alloy; for thicker deposits consider magnetic or phase sensitive eddy current methods where applicable, or coulometric testing and the STEP method when you need layer by layer control PFOnline on measuring thick nickel. This clarity up front avoids surprises in assemblies and threads.

- Clean and rinse to remove oils and oxides.

- Activate the surface and, if needed, apply a strike for adhesion.

- Plate in the chosen system, controlling current density, temperature, and pH for electro nickel plating, or chemistry balance for EN.

- Rinse, then topcoat, bake, or passivate if specified, and measure thickness.

- Inspect adhesion and appearance before release.

- Best practices

- Standardize pre clean and activation because most adhesion failures start there Nickel Institute Nickel Plating Handbook.

- Use Hull Cell panels to track brightness range, levelling, and impurity effects over time.

- Maintain and double bag anodes, and keep baskets properly filled to prevent polarization and fines release Finishing & Coating service tips.

- Run continuous filtration with scheduled media changes; add periodic carbon treatment when organics creep in.

- Plan low current density dummy plating if copper or zinc contamination is detected to keep the nickel plating process stable.

In short, if you are asking how to nickel plate or how to nickel plate metal without rework, control chemistry, current distribution, and measurement. Fine tune hardness versus ductility with additives, temperature, and, where applicable, post heat treatment, then choose the stack that suits the part. With these levers under control, the next section turns those controls into application ready choices for trim, fasteners, connectors, and underhood components.

Application driven selection for automotive metal parts

Which nickel system fits your part? Start with where it lives and how it works. Exterior trim, fasteners, underhood parts, and connectors face different chemicals, temperatures, and loads. Use the guide below to align finish with function on automotive metal so you get performance without guesswork.

Plating For Trim Fasteners And Underhood

When plating car trim or fasteners, you will notice that priorities shift between appearance, wear, and corrosion protection.

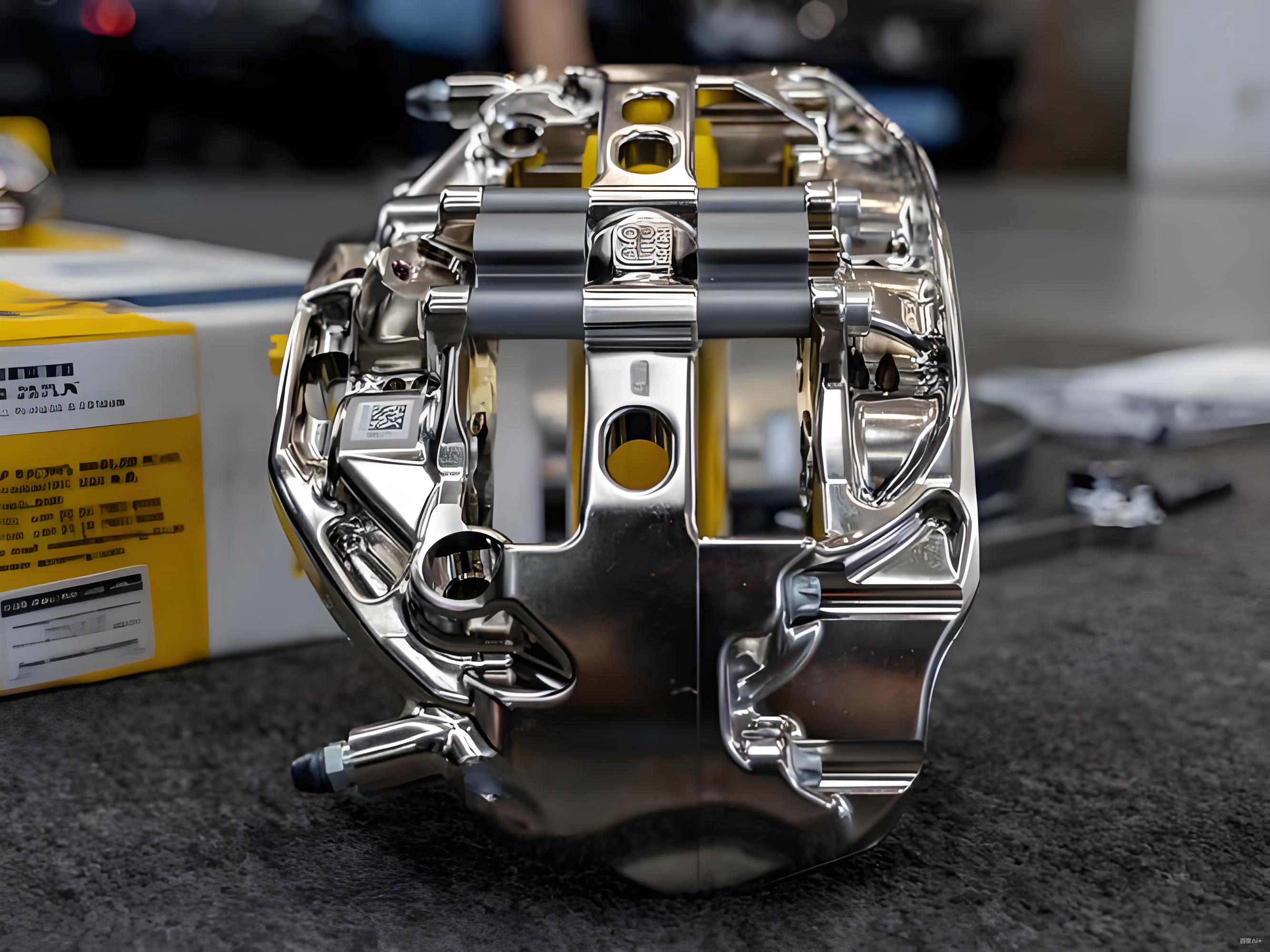

- Exterior bright trim: copper + nickel base with a thin chrome topcoat is common for chrome plating automotive parts. Nickel provides most of the leveling and barrier performance, while chrome adds the high-luster look. The expected nickel plating color is a bright, reflective silver tone that supports durable aesthetics Dixon Valve.

- Interior accents and knobs: bright nickel alone can deliver a durable, attractive nickel finish metal surface when a cool metallic look is desired without a chrome topcoat.

- Fasteners and brackets: nickel plating steel hardware is useful when you need thread wear resistance, consistent torque, and a unified appearance. In severe salt exposure, consider zinc-nickel as a sacrificial alternative to prioritize corrosion life.

- Engine and drivetrain wear surfaces: electroless nickel is helpful for even coverage in bores and complex shapes where uniform thickness supports fit and sealing. It also adds hardness for sliding interfaces.

- Fuel and fluid handling: choose nickel where a tough barrier against moisture and chemicals is required, especially on passages and housings that see frequent wetting.

Choose nickel system by environment severity and functional demands, not appearance alone.

Connector And Sensor Considerations

Electrical connectors and sensor housings need stable contact performance and a protective barrier. Nickel is an excellent conductor and also serves as a reliable base layer for subsequent coatings or paints, which helps durability in harsh locations Valence Surface Technologies. Electroless nickel is often selected for small or intricate connector shells because uniform coverage reaches recesses and threads with less risk of thin spots.

Lifecycle And Warranty Implications

Environment matters. Road salts, contaminants, and trapped moisture accelerate corrosion and can reach critical systems if surfaces are not protected. Where sacrificial protection is preferred, zinc-nickel coatings followed by passivation and a sealer have demonstrated strong salt spray performance, with tests showing up to 500 hours to white rust and about 1,000 hours to red rust Sharretts Plating Company. For visible or mixed-duty areas, nickel balances wear resistance, a durable barrier, and an attractive appearance on automotive metal parts.

- Rate environment severity: interior, exterior, underhood, underbody, exposure to fuels or road salts.

- Map base metal and geometry: steel vs aluminum or brass, threads, bores, and blind holes.

- Define function: cosmetic luster, wear resistance, corrosion barrier, electrical conductivity.

- Select stack and process: bright electrolytic nickel under chrome for maximum luster, electroless nickel for uniformity on complex shapes, or zinc-nickel where sacrificial protection is the priority.

- Close the loop: specify thickness and measurement locations, appearance criteria, and inspection methods on the drawing.

With the application set, the next section compares nickel systems with zinc and chrome so you can weigh appearance, coverage, and corrosion resistance side by side.

Choosing between nickel zinc and chrome systems

Debating nickel vs zinc plating for a fastener, or choosing a nickel metal finish under chrome plating auto parts? When you compare nickel plated vs zinc plated hardware, the right answer usually comes from geometry, environment, and appearance targets.

Quick Comparison Of Popular Plating Systems

| Process | Hardness | Corrosion resistance | Ductility | Uniformity/throw | Appearance | Typical uses | Notes |

|---|---|---|---|---|---|---|---|

| Electrolytic nickel plating (electroplated nickel) | Medium to high | Barrier, good | Moderate | Moderate on complex shapes | Bright to mirror-bright base | Decorative bases under chrome, trim, general hardware | Deposit follows current paths with more build on edges |

| Electroless nickel Ni-P, low P | High as-plated | Good | Moderate | Excellent, even in threads and bores | Functional to semi-bright | Wear-oriented surfaces, threaded features | Autocatalytic Ni-P alloy |

| Electroless nickel Ni-P, medium P | High | Good to high | Balanced | Excellent | Functional to semi-bright | Mixed wear and corrosion needs | Widely used for uniform coverage |

| Electroless nickel Ni-P, high P | Moderately high as-plated | High | Moderate | Excellent | Functional | Connectors, fluid path components, intricate housings | Lower magnetism in high-P varieties |

| Zinc plating | Low | Sacrificial, moderate with passivation | Good | Follows current distribution | Clear, yellow, black, or olive via passivation | Fasteners, brackets, stamped parts | Cost-effective; typically chromate passivated |

| Hard chrome | Very high | Low alone due to porosity | Low | Limited into recesses | Mirror bright | High-wear surfaces, tooling | Often applied over copper and nickel for corrosion |

How to read this table. Electroless nickel is an amorphous Ni-P alloy that plates uniformly across edges, diameters, threads, and even dead-end holes, and it can be heat treated to as high as about 69 Rc, roughly 90 percent of hard chromium hardness Impro Precision on chrome, nickel, and zinc and Advanced Plating Technologies on EN vs electrolytic. Zinc plating provides economical sacrificial protection and is typically paired with chromate conversion passivation to extend life and tune color on zinc vs nickel.

Electroless nickel shines when uniformity and complex geometry coverage outweigh the need for mirror-bright aesthetics.

When To Prefer Electroless Nickel Over Others

- Complex parts with internal threads or blind holes where even thickness is critical.

- Connector shells and fluid components that benefit from a consistent barrier across all surfaces.

- When tolerance stack risk makes non-uniform edge build unacceptable.

- If the choice is nickel plating vs zinc plating and coverage uniformity matters more than sacrificial behavior.

Electroless nickel Ni-P

- Pros: Uniform thickness, strong barrier protection, heat-treatable hardness.

- Cons: Typically specified for function first, not mirror-bright show surfaces.

Electrolytic nickel

- Pros: High luster base for decorative stacks and a durable nickel metal finish.

- Cons: Non-uniform on complex shapes with edge-heavy build.

Zinc plating

- Pros: Cost-effective sacrificial protection with many passivation colors.

- Cons: Softer surface, not ideal for high-friction interfaces.

Hard chrome

- Pros: Very high hardness and wear resistance.

- Cons: Brittle and porous on its own, often needs nickel underlayers for corrosion.

Comparing zinc nickel plating vs zinc plating usually happens within a zinc-based finishing strategy, while nickel plated vs zinc plated parts are a different barrier versus sacrificial decision. Next, we will tie these choices to the standards and test methods you can cite on drawings to make performance auditable.

Standards to verify nickel plating thickness in automotive electroplating

Sounds complex? When you write a drawing note, you want every shop to measure it the same way. Use recognized standards and clear language so your nickel coating process is auditable and consistent across suppliers.

Key Standards To Cite In Drawings

- Coating system standards: ISO 1456 for electroplated nickel and nickel plus chromium on metals and plastics define classes, service conditions, and how to describe multilayer decorative stacks Nickel Institute Nickel Plating Handbook.

- Thickness measurement: ISO 1463 microscopical cross-section, ISO 2177 coulometric, ISO 3497 X-ray spectrometry, ISO 2360 and ISO 2178 for eddy current and magnetic methods. XRF, magnetic, and eddy current gauges are widely used in production, and following ASTM and ISO methods improves repeatability VRXRF thickness analysis standards.

- Adhesion and ductility: Shop tests such as file, bend, and thermal shock are commonly used, with ISO 2819 reviewing adhesion methods. ASTM B571 is a well known adhesion test reference listed alongside these methods in industry overviews Pacorr testing guide.

- Corrosion tests: ISO 9227 neutral salt spray, ASTM B368 CASS for nickel chrome systems, and Corrodkote procedures referenced in coating specs help qualify exterior service performance Nickel Institute Nickel Plating Handbook.

Tests That Prove Performance

| Method | What it proves | Typical acceptance wording |

|---|---|---|

| XRF or magnetic/eddy current | Non destructive nickel plating thickness on significant surfaces | Meets drawing thickness at locations A/B/C |

| Coulometric or STEP | Layer by layer thickness and, for STEP, potential difference of multilayer nickel | Layers present as specified; potential difference trend acceptable for duplex nickel |

| Microscopical cross section | Referee measurement of local thickness and layer order | Confirms stack sequence and local thickness requirement |

| Adhesion tests | Bond integrity of the coating system | No peeling, flaking, or blistering after test |

| Neutral salt spray or CASS | Accelerated corrosion resistance for service conditions | Appearance or protection rating meets spec after test duration |

| Thermal shock or cycle | Adhesion and integrity across temperature swings, especially on plastics | No cracks, blisters, or distortion |

Specifying Thickness And Locations

- Define the nickel coating process up front: electrolytic or electroless. If electroless, state the phosphorus class. This anchors how thickness is measured and controlled Nickel Institute Nickel Plating Handbook.

- Call out local vs average nickel plating thickness and identify significant surfaces. For threaded or recessed features, state the method that best fits geometry.

- Choose the measurement method on the print. XRF or magnetic/eddy current gauges suit production checks, while coulometric or cross section works as a referee method for layered systems VRXRF thickness analysis standards.

- Add process notes that drive consistency in automotive electroplating: masking requirements, post plate bake if applicable, cleaning and activation expectations, and acceptable appearance criteria.

- Document inspection and sampling. Reference the test, the lot sampling plan, and what constitutes pass or fail in words a supplier can audit.

- For automotive approved plating, tie your drawing and control plan to ISO or ASTM tests plus any SAE or OEM specific clauses noted in your sourcing package Pacorr testing guide.

Plate to specified thickness on all functional surfaces; verify by XRF at locations A/B/C.

Tip: Because the thickness of nickel drives barrier life and fit, name the method, the locations, and the acceptance wording right on the drawing. Do the same for adhesion and corrosion tests so results are comparable across suppliers. Get these foundations right and the next step is catching and fixing defects quickly on the line.

Up next, we will translate these specs into a practical troubleshooting checklist to diagnose pitting, peeling, low build, and other common defects before they become returns.

Troubleshooting defects and improving yield

Seeing pits, haze, or peel after a run? Imagine catching the pattern early and fixing one variable instead of scrapping a batch. Use the checklist below to diagnose fast and prevent repeat issues in automotive duty parts.

Diagnosing Defects You Can See

- Pitting or porosity

- Blistering or peeling

- Roughness, nodules, or burning on edges

- Dull, cloudy, or hazy deposits

- Low or uneven thickness

- Discoloration or tarnished nickel plating

Most nickel plating failures start at the surface prep—cleaning and activation are the first places to audit.

Root Causes In The Line

- Inadequate cleaning or activation before electroplating nickel on steel or other substrates, leading to poor adhesion and later peeling Electroplatingmachines on peeling causes.

- Process parameter drift: pH, temperature, current density, agitation, or additive balance out of range, causing haze, burning, or poor leveling PFOnline Nickel Troubleshooting Guide.

- Contamination: organic decomposition products or metallic ions that darken low current areas and reduce ductility. Filtration and purification are key Finishing & Coating on troubleshooting baths.

- Racking or anode issues: poor contact, wrong placement, or depleted anodes driving uneven thickness and edge burning.

- Substrate or undercoat mismatch: porous castings, trapped compounds, or compatibility issues when nickel plating copper underlayers, leading to lift.

- Post plate stresses: handling damage or hydrogen embrittlement risk on high strength nickel plated steel if bake practices are inadequate Electroplatingmachines on peeling causes.

| Defect | Likely cause | First corrective action |

|---|---|---|

| Pitting | Particles, poor wetting, or gas entrapment | Improve filtration and agitation; consider purification/carbon treatment |

| Blistering or peeling | Insufficient cleaning/activation, high internal stress | Requalify preclean and activation; balance additives; review HE relief on steels |

| Roughness or nodules | Particulate or anode fines | Service filters; check anode bags and basket fill; remove dropped parts |

| Burning on edges | Excess current density or low nickel/boric acid | Reduce current density; adjust chemistry; increase solution motion |

| Hazy or dull areas | Additive imbalance or contamination | Run Hull cell; adjust brightener/carrier; carbon treat if organics present |

| Low or uneven thickness | Poor throw, contact issues, or anode layout | Fix rack contacts; optimize anode placement; moderate current density |

| Discoloration | Drag-in, contamination, or rinse issues | Improve rinsing; check bath balance; schedule purification |

Corrective Actions That Stick

- Standardize a robust preclean, electroclean, and activation sequence before parts are nickel-plated, especially on passive or high strength alloys Electroplatingmachines on peeling causes.

- Use Hull cell panels to pinpoint additive imbalance or metallic contamination, then plan dummy plating or carbon treatment as indicated Finishing & Coating on troubleshooting baths.

- Maintain filtration, anode bags, and basket fill; verify rectifier output and minimize AC ripple.

- For recurring corrosion complaints such as “does nickel plated steel rust,” audit for pits or thin spots first, then correct the pitting and thickness distribution following shop guides PFOnline Nickel Troubleshooting Guide.

- Buyer tip: request a corrective action report with bath analysis, recent Hull cell photos, and a thickness map from significant surfaces.

Quick checks pros

- Fast feedback on the line and low cost.

- Good at catching contact, agitation, or obvious chemistry drift.

Quick checks cons

- May mask deeper contamination or additive issues without a Hull cell study.

Full analysis pros

- Confirms contamination, guides purification, and stabilizes long runs.

Full analysis cons

- Takes time and coordination with the lab and supplier.

With defect prevention in hand, the next step is ensuring your supplier manages fume control, waste streams, and safe operations that keep quality consistent over time.

Environmental health and safety in automotive metal finishing

When you tour a plating line, what should you look for first? Start with controls that protect people, the environment, and uptime. In high volume automotive metal finishing, the right EHS practices keep quality stable and costs predictable, especially when electroplating cars components across multiple plants.

What To Ask Suppliers About EHS Controls

- Permits and records: wastewater, air, and hazardous waste permits plus recent inspection findings. Use a due diligence lens that weighs severity by scale, scope, and irremediable character OECD due diligence.

- Wastewater strategy: how spent baths and rinses are treated or regenerated, sampling frequency, and third party treatment certificates.

- Air and mist controls: local exhaust, capture devices, mesh pad or HEPA stages, and how they monitor effectiveness.

- Chemical choices: policy on PFOS/PFAS based fume suppressants in chrome steps and current alternatives or engineering controls.

- Training and PPE: documented training, spill drills, and lockout procedures for each nickel coating machine or process tank.

- Evidence of continuous improvement: CAPAs tied to EHS metrics, maintenance logs, and waste minimization projects.

Responsible plating couples performance with robust EHS management.

Common Waste Streams And Treatment Steps

Electroless nickel operations generate rinse waters and spent solutions containing nickel and significant phosphorus from hypophosphite chemistry. One study shows electrodialysis can remove harmful species from aged EN baths, enabling partial bath reuse, while peroxydisulfate oxidation plus Ca(OH)2 precipitation recover phosphorus and reduce nickel in concentrates; under defined conditions, the regenerated bath recovered about 60% plating activity and the downstream precipitation achieved over 98% total phosphorus and over 93% nickel removal MDPI Water research on EN wastewater regeneration.

Decorative stacks that include hard chrome require mist control at the tank. Chromic acid mist forms from gas bubbles during plating and draws intense regulatory scrutiny. Effective practices include engineered ventilation with mesh pad and HEPA elements and higher efficiency bath operation to reduce gassing, while many legacy fume suppressant chemistries have faced restrictions, pushing shops toward equipment based solutions Finishing & Coating on chrome misting controls. For buyers, this matters because chrome topcoats often sit over nickel barrier layers in protective metal plating stacks.

| Process area | Primary hazard | Standard mitigation |

|---|---|---|

| Electroless nickel bath and wastewater | Ni and phosphorus laden solutions and concentrates | Regeneration via electrodialysis, advanced oxidation, and Ca(OH)2 precipitation to recover resources and reduce load |

| Chrome topcoat tanks in finish stacks | Chromic acid mist from gassing at solution surface | Local exhaust, mesh pad or HEPA capture, and process efficiency improvements over chemical suppressants |

| Program level supplier risk | Inconsistent EHS controls across sites | Apply due diligence that evaluates impact severity and requires auditable controls and records |

Design Choices That Improve Sustainability

- Regenerate before you dispose: prioritize processes that allow chemical recovery and bath reuse where feasible, reducing sludge and trucking.

- Engineer mist capture first: favor ventilation and capture devices over chemistry where regulations restrict suppressants.

- Minimize drag out: racking, dwell, and counterflow rinses reduce chemical loss and cut water treatment volumes in metal plating lines.

- Specify measurable outcomes: require thickness, appearance, and EHS evidence in control plans for suppliers electroplating cars components.

In short, ask how the shop treats and recovers EN chemistry, how they capture chrome mists above nickel underlayers, and how they audit risk. These details translate directly into RFQ language and supplier criteria in the next section, where we provide procurement templates and a practical checklist to align quality and EHS from day one.

Procurement templates and supplier selection

Ready to send an RFQ but not sure what to ask? After you have checked a shop’s EHS controls, lock down specs with clear notes, auditable tests, and supplier evidence. Use the templates below to align quality for automotive finishing, whether you are electroplating car parts, plating for steel, or planning to nickel plate aluminum.

Spec And Drawing Note Templates

- Process type: electrolytic nickel electroplating or electroless nickel Ni P. If EN, state phosphorus class low, medium, or high.

- Base material and hardness condition: note if plating for steel high strength, cast iron, copper alloys, or if you will nickel plate aluminum with a suitable undercoat per supplier process.

- Thickness callout: state local or average thickness, measurement method, and locations. Reference recognized methods such as X ray spectrometry XRF, coulometric, or microscopical cross section as compiled by the Nickel Institute Nickel Institute Nickel Plating Handbook.

- Coverage and masking: define significant surfaces, threads, bores, and masked areas. Call out racking points if critical.

- Post processes: bake if specified, topcoats chrome or others, passivation, or sealing.

- Appearance and finish: bright, semi bright, or matte with no blisters, pits, or haze on significant surfaces.

- Verification plan: thickness measurement method and sample size, adhesion and corrosion tests aligned to ISO ASTM methods summarized by the Nickel Institute.

- Packaging and labeling: corrosion inhibiting wrap, part orientation, and lot traceability.

Process: Electroless nickel, medium P; Thickness: 12–20 µm on functional surfaces; Verify by XRF at locations A/B/C; Post bake per spec; No blisters, pits, or discoloration.

RFQ And Supplier Checklist

- Capability match: nickel electroplating services, electroless Ni P, duplex nickel under chrome, masking for threads and bores.

- Geometry and volume: part photo or print, critical dimensions, significant surfaces, rack vs barrel strategy, annual and lot sizes.

- Substrate details: steel grade, aluminum alloy, copper brass, heat treat condition.

- Target thickness and tolerance, measurement locations, and gauge type XRF, magnetic, or coulometric per Nickel Institute guidance Nickel Institute Nickel Plating Handbook.

- Test plan: adhesion shop tests, corrosion CASS or neutral salt spray for nickel chrome stacks, and any thermal cycle for plastics as outlined in industry references in the Nickel Institute handbook.

- Process control evidence: recent bath analysis summary, filtration and carbon treatment practice, Hull Cell monitoring, and anode bag maintenance.

- Supplier system checks: plating system assessment such as CQI 11 PSA during audits to evaluate special process controls CQI 11 reference.

- EHS and compliance: wastewater and air permits, waste treatment approach, and training records.

- Packaging and logistics: pack method, returnable dunnage, labeling, and ship terms.

Vendor short list example. If you prefer one stop machining to plating integration, request quotes from a small set of qualified suppliers. For instance, Shaoyi offers IATF 16949 certified quality, advanced surface treatments, machining, stamping, and assembly, which can simplify program control and traceability. See their services at Shaoyi services. Add a regional specialty plater for niche work and a high volume line operator for peak demand. Keep criteria consistent across all quotes.

Inspection And Acceptance Criteria

| Requirement on PO or drawing | Evidence from supplier |

|---|---|

| Defined process and stack | Traveler or control plan showing electrolytic or EN Ni P route and any topcoats |

| Thickness and locations | XRF or magnetic thickness map at A B C per listed method, plus referee coulometric or cross section if disputed, consistent with methods described by the Nickel Institute |

| Appearance and coverage | Visual acceptance sample and signed first article photos of threads, recesses, and edges |

| Adhesion | Shop test results file bend or thermal shock per practices consolidated by the Nickel Institute PDF |

| Corrosion performance if required | CASS or neutral salt spray report showing duration and rating per the cited standard family in your spec |

| Process control stability | Recent bath analysis summary, Hull Cell panels, filtration schedule |

| Traceability | Certificate of Conformance, lot traveler, and labeling that matches print rev |

| Packaging | Photos and description of corrosion protection and part orientation |

| Audit readiness | CQI 11 PSA or internal checklist with actions from last assessment |

Tip. Keep the RFQ language identical for every bidder and attach your inspection plan. That consistency helps you compare quotes for complex nickel work, from bright decorative bases to uniform EN on intricate housings, with less back and forth and fewer surprises.

Nickel plating FAQs for automotive parts

1. What is hard nickel plating?

Hard nickel plating commonly refers to electroless nickel that is heat treated to raise surface hardness for wear critical areas like bores and threads. Heat treatment can change properties, so note any required post bake on the drawing and consider tradeoffs such as potential shifts in corrosion behavior or magnetism.

2. Is nickel plating shiny?

It can be. Electrolytic nickel can be tuned to a bright, mirror like base used under decorative chrome. Electroless nickel is usually matte to semi bright and chosen for uniform coverage on complex shapes. If you want a show quality luster, electrolytic routes are typically preferred; if you need even build inside threads and recesses, electroless is often the better option.

3. Electroless nickel plating vs nickel electroplating — which should I use?

Choose by geometry and performance. Electroless nickel coats uniformly across edges, bores, and blind holes, simplifying tolerance control on intricate parts. Nickel electroplating relies on current paths, which favor edges but delivers the highest brightness for decorative stacks. Start with part geometry, required appearance, and thickness control, then specify process, thickness, and measurement locations on the print.

4. Does nickel plated steel rust?

Nickel is a barrier coating, so well applied layers resist moisture and salts. If pores, thin spots, or poor surface prep are present, the base steel can corrode. Prevent this by calling out proper pre clean and activation, adequate thickness on significant surfaces, and suitable topcoats where needed. For sacrificial protection on fasteners, zinc based systems may be specified instead.

5. How do I choose a supplier for automotive nickel plating?

Look for IATF 16949 quality systems, PPAP capability, plating system assessments, and clear bath control practices. Require auditable thickness checks, adhesion and corrosion tests, and evidence of EHS controls. If you want machining, stamping, plating, and assembly under one roof, consider short listing a turnkey partner. For example, Shaoyi provides IATF 16949 certified manufacturing plus advanced surface treatments, which can simplify traceability and delivery coordination. Learn more at https://www.shao-yi.com/service.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —