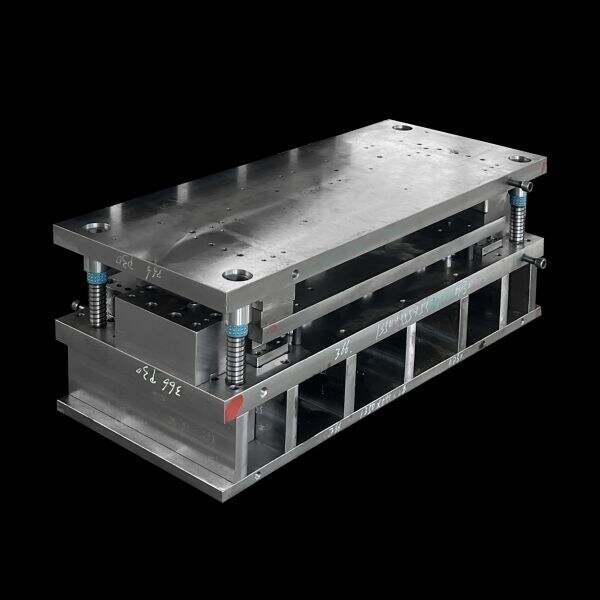

Some of the examples include a stamping die which is an essential tool made by Shaoyi. Which assists in shaping, bending, and cutting sheets of metals to make different types of shapes. These include stamping, which is used in numerous manufacturing jobs to shape a wide array of products.

A stamping die transforms a flat piece of metal into something new and exciting, like a toy car or some water bottle made up of metal. There are two main parts of the stamping die called “holders.” These holders cooperate to clamp the sheet metal. The holders press so closely together the metal conforms to the shape of the die. In this case, the metal forms into the pattern of Shaoyi custom metal stamping dies to produce a final product.

A well-crafted stamping die helps determine the quality of the end product. Even a perfect stamping die can be distorted by the smallest amount and alter what the final product looks like — larger or smaller. If a stamping die has been worn down enough, for example, even if it produces a toy car from the die it will not fit together properly. This is why a good stamping die is of paramount importance. Barrel Stamp Dies: Good stamping dies make for effective stamping products with precision size and shape.

On occasion, issues arise in the stamping phase. For instance, the die plates might not match up precisely and the stamping may not be uniform. These issues can originate from several factors. These can occur due to misalignment of the stamping die, issues with the metal sheet, or even problems with the stamping press itself. A team well aware of the problems, trained regularly to identify & mitigate these issues is crucial to solving all these. By slashing the time it takes to troubleshoot a problem, the system ensures that output won’t suffer and that everything remains on course.

You have to be very efficient in any manufacturing process — stamping die making is no different. Shaoyi custom metal stamping dies should be designed to carry out a specific job in an effective manner. This also means that the design can only be appropriate for the type of product being designed. Also, the team who is working on the project need to trained well. Training is essential to stay safe — as stamping dies are dangerous when handling improperly, so keep those safety rules and precautions in check. Having everyone trained working together safely while making product is a good way to keep everyone out of harm's way.

Stamping dies should be getting progressively better as also technology is improving. Advances in new ideas and innovations have also improved the speed, precision, and safety of stamping die manufacturing. This involves better materials for the Shaoyi metal stamping automotive and improvements in the stamping machines. These advances enable producers to manufacture products faster and at a higher quality.

Our company is proud of having a dedicated R&D team with every engineer boasting over a decade of expertise in the automotive industry.This knowledge allows us to understand the distinctive features of various products and materials, allowing us to develop custom solutions for our clients. We offer expert CAE analyses, product development and technical support as well as thorough DFM report to ensure that each aspect of the design is developed to meet the demands of production. Our drive to innovate keeps us on top of the industry, delivering premium, customized metal parts that meet our customers' particular demand.

Our company, which spans more than 10,000 square meters and is specialized in the production of metal parts for over 30 brands of automotive, has more than 15 years of experience in the business. The products we manufacture are created with the most advanced techniques, such as CNC machine machining and mold making. Our strict quality control measures assure consistency in measurements and shapes, as well as in performance. All which creates trust and satisfaction with our customers.

We are incredibly proud to hold the IATF certification 16949. This is an affirmation of the quality management excellence we strive to achieve within the auto industry. Our quality department is skilled in using five critical instruments for quality: Statistical Process Control (SPC), Measurement System Analysis (MSA), Failure Mode and Effects Analysis (FMEA), Advanced Product Quality Planning (APQP) and the Production Part Approval Procedure (PPAP). Furthermore, our quality staff has completed intensive Six Sigma training, ensuring that we meet the highest standards in product quality standards. Our comprehensive method of quality control ensures that each product we offer not only meets, but frequently surpasses industry expectations, providing our customers with confidence and satisfaction regarding our services.

Our company specializes in automotive manufacturing, with over 90% of our products catering to the automotive sector. We supply high-quality components that are suitable for a broad range of automobiles, such as passenger cars commercial vehicles, golf carts as well as motorcycles, trucks and tractor. Our broad product selection illustrates our commitment to meet the varied requirements of the market for automobiles. We are also proud to be the most renowned supplier of suspension systems to Volkswagen in China. This proves our ability to provide innovative and reliable solutions to major auto brands. Our deep-rooted industrial experience enables our products not only to exceed but also surpass the customer's requirements in terms of the performance and quality.