For cars, car bodies are like really big deal. They are what gives cars their shape and cool style, so without car designers cars wouldn’t look as smooth or stylish as they do today. Car bodies can be produced from various materials such as plastic, fiber glass and sheet metal. Today, we will discuss sheet Shaoyi sheet metal for cars and why they the best option for many cars.

The brightest spot in raw sheet metal automobile bodies is their durability. They can withstand challenging weather events, ranging from hail to thunderstorms and even deep snow. Since these are durable in nature, you will not have to worry about it being damaged due to bad weather. Also a bonus, sheet metal barely rusts. That also means more time until you need to have things repaired on your car. However, if your car got a dent or minor bump, it could be repaired pretty easily using the hammer tool or hydraulic press. This simplifies maintenance for car owners.

Also, car bodies built on sheet metal are done at a lower cost. It makes their manufacturing cost-effective relative to other materials—like carbon fiber. This matters because it allows car manufacturers to cut costs, which can help lower the price tag for buyers. In conclusion, there is just so many things going for a Shaoyi automotive sheet metal car body that not only make it practical but also the smart choice as well.

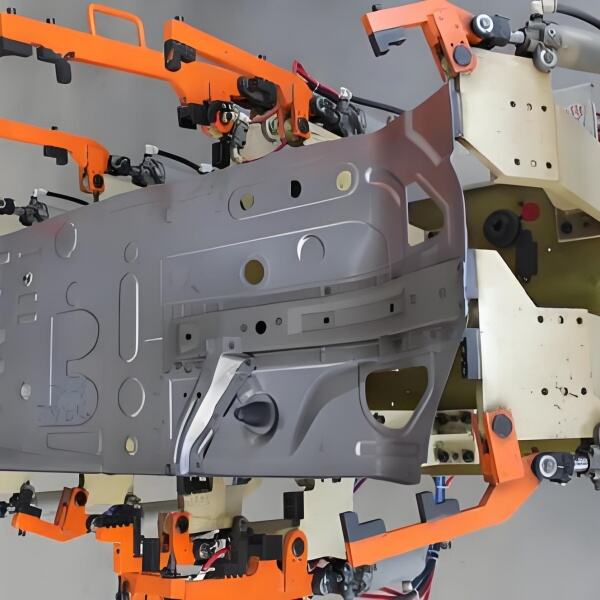

Making a sheet metal car body is more frequently, actually an involved process. Step 1: Workers stamp and weld together pieces of metal for the car body. It is critical to the design of a car first step, the car body was designed. This part of the design outlines the size and shape vehicle will be. Once the design is made, machines such as laser cutters or hydraulic shears cut the sheet metal into appropriate shapes.

Creativity and careful planning bear an essential role when designing a car body sentry parted into sheet metal. It allows car designers to create a 3D definition of the body using software. Using this software designs visuals are produced that depict the way the car would appear from various angles and its performance on road. Designers can tweak the design to optimize aspects such as aerodynamics, ride comfort, and passenger safety.

What makes these sheet metal car bodies so special is you shape it into whatever look the car designers’ desire. This has allowed designers to have the outlet for creating exotic cars but again include the practicality and function that this group of higher end cars is able to do without getting caught up in pure beauty. The other amazing thing, every kind of sheet metal can be recycled therefore it is eco-friendly. That ensures that at the end of a car's lifetime, the metal can be recycled into production for other items.

Shaoyi is famous for its low-cost engineering quality level sheet metal car body manufacturers. Employing state-of-the-art technology, the company provides strong and long-lasting bodies of cars that are anti-rust. You can also customize your Shaoyi stamping car parts to your heart's desire, according to your taste and requirements. When you order a Shaoyi car body, rest assured that your car will look good and all set for many years.

We are very proud to be awarded our IATF certification 16949. This is a testament to the quality management excellence we are striving to achieve within the auto industry. Our quality department has mastered five essential quality tools, comprising Statistical Process Control (SPC), Measurement Systems Analysis (MSA), Failure Mode and Effects Analysis(FMEA), Advanced Product Quality Planning and Production Part Approval Process. Our quality team has completed Six Sigma training to ensure we adhere the highest standards of product quality. This systematic system of quality management makes sure that every product we provide is not only up to but often surpasses industry expectations, providing our clients with confidence and satisfaction over our services.

Our company is proud of having a committed R&D team, with each engineer having more than a decade of experience in the automotive industry.This knowledge allows us to grasp the unique characteristics of various products and materials, allowing us to create custom solutions to our customers. We offer expert CAE analysis, product development and technical support, as well as detailed DFM reports to make sure that every element of the design is optimized for production. Our drive to innovate ensures that we remain at the forefront in the field, and we provide high-quality, tailored metal parts that meet our customers' particular needs.

The majority of products we produce are used in the automobile industry. We provide high-quality components that are suitable for a broad range of vehicles, including passenger cars commercial vehicles, golf carts motorbikes, trucks and tractors. Our extensive product range shows our flexibility and dedication to meet the diverse needs of the automotive market. We also are proud to be the leading supplier of suspension systems to Volkswagen in China. This proves the ability of our company to provide innovative and reliable solutions to the top auto brands. Our extensive industrial experience allows our products not only meet but exceed customer expectations for the performance and quality.

With more than 15 years of expertise in the automotive industry, our company covers an area over 10,000 square meters and are experts in the manufacture of metal parts for more than 30 auto brands. We employ cutting-edge processing techniques, including stamping, CNC machining mold manufacturing, and die-casting to make sure that every item is manufactured to the highest quality standards. Our strict quality control measures assure that our products are identical in terms of size shape, form and performance. This helps build confidence and trust with our customers.