Plastic injection molding is such a fascinating technology and it can really improve the quality, or performance, of a car significantly. This process is a crucial step as the carmakers know to develop strong, light and functional parts. Being a leader in plastic injection molding, Shaoyi is revolutionizing the car industry. Plastic Polymers Lighten the Load for Car Improvements The best part about this technology is, it uses recycled plastic as well. This stamping car parts helps save our environment, and at the same time makes cars more affordable for everyone. We here will discuss all the benefits of plastic injection molding for car parts, how this process is revolutionising the design & manufacture of cars and what future innovations may be just around the corner with new plastic injection molding processes. One metalworking process that assists in making the car parts efficiently is plastic injection molding. The plastic is, first, melted into a liquid. After melting down, it is injected into a mold where various shapes can be made. Using plastic for car parts has a lot of advantages. First, plastic is very light. In short, a car made with plastic parts is light in weight and therefore consumes less fuel. A lighter car requires less gas to drive the same distance, making it more environmentally friendly and inexpensive for drivers. Next, plastics are robust and long-lasting. Vehicles using plastic parts are more durable and reliable. That translates to less repairs and more quality drive time. Third, plastic is flexible. Plastic: In addition, this flexibility makes cars with plastic parts better able to absorb bumps or hits. They are safer for the driver and passengers because they withstand drubbing without breaking.

Shaoyi is heavily involved in using light plastics to transform this auto parts stamping automotive sector. Car manufacturers can produce lighter and therefore more fuel-efficient cars, as plastic weighs a fraction of metal. As plastic is much more pliable than metal, it can be made into more complex and elaborate forms. Which enables the designers to be more innovative and creative in their work. They can use fresh ideas on designs and functionality that eventually lead to more efficient and exciting vehicles.

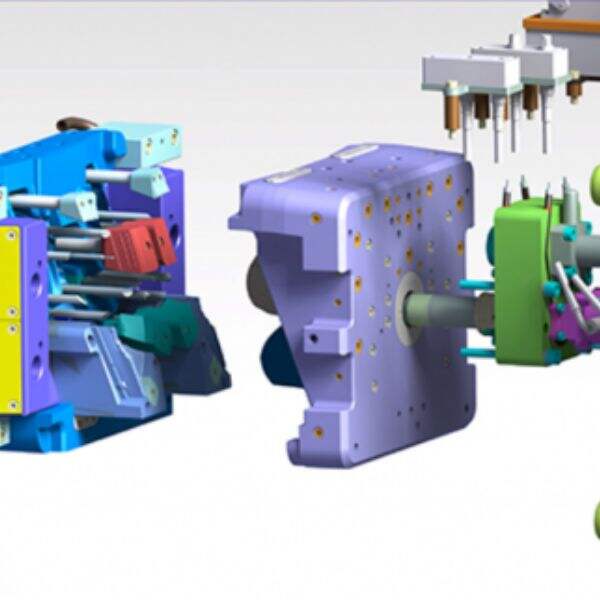

There are several key ways that plastic injection molding is transforming car design and production. First, this let car designers make complex components that could have been extremely difficult, or even impossible to produce using other techniques. For instance, plastic injection molding would be the go-to process for parts with complex shapes or features. Second, with injection modeling car manufactures can mass produce parts far more rapidly than other methods. This automotive metal stamping parts speed means more efficient car production, which is crucial to meet demand. Finally, car makers save money by using plastic injection molding. It lowers cost, too, because the whole process is efficient. This reduces costs that can be transfered to customers and make cars cheaper.

Recycled plastic in the manufacture of car parts is a great way to reduce costs and protect the environment. Plastic doesn't decompose so it can remain in a landfill for centuries. So using recycled plastic in car production contributes to minimizing plastic waste released into landfills. It's very important for keeping our earth, environment or planet clean & safe from any kind of disasters, so that automotive stamping part our future generation will live freely. Recycling plastic avoids the use of virgin materials and is thus more environmentally sound. It also show that carmakers gives a damn about being responsible and sustainable.

Exciting new plastic injection molding methods usher in an excellent prospect for car sophistication. And so Shaoyi is among a new era of innovators on the cutting edge of this area of research that'll eventually lead to improvements in cars. These sophisticate techniques include multi-component injection molding in which multiple materials are injected to produce a single part with different characteristics. That offers so many different types and ways to print any custom made functional car part. One more method is gas-assisted injection molding which uses gas to make hollow parts. This automotive sheet metal stamping keeps components lightweight and is crucial for increasing mileage. Along with these innovations, we should see even smarter, more safety-conscious and greener cars.

With more than 15 years of expertise in the automotive industry, our company covers an area over 10,000 square meters and are experts in the manufacture of metal parts for more than 30 auto brands. We employ cutting-edge processing techniques, including stamping, CNC machining mold manufacturing, and die-casting to make sure that every item is manufactured to the highest quality standards. Our strict quality control measures assure that our products are identical in terms of size shape, form and performance. This helps build confidence and trust with our customers.

Our company prides itself on having a committed R&D team, with each engineer possessing more than 10 years of experience in the automotive industry.This know-how helps us comprehend the distinctive characteristics of different types of materials and processes, which allows us to develop custom solutions to our customers. We offer professional analysis of CAE, development and technical support, as well as detailed DFM reports to ensure that each aspect of the design is optimized to be produced. Our commitment to innovation keeps us ahead of the market, offering high-quality, tailored metal parts to meet clients' specific demands.

We are incredibly proud to hold the IATF certification 16949, which is a testament to our quality management excellence that we strive to achieve within the auto industry. Our quality department has mastery over five crucial quality tools which include Statistical Process Control (SPC), Measurement Systems Analysis (MSA), Failure Mode and Effects Analysis(FMEA), Advanced Product Quality Planning and the Production Part Approval Process. Furthermore, our quality staff has completed extensive Six Sigma training, ensuring that we are adhering to the most stringent standards for quality of products. This comprehensive method of quality control ensures that every product we provide not only meets but often exceeds expectations of the industry, but also provides our clients with confidence and satisfaction over our services.

More than 90% of the products we manufacture are intended to be used by the automobile industry. Our company provides high-quality parts for a variety of vehicles such as golf carts, cars and motorcycles. Our extensive product range is a testament to our ability to satisfy the various requirements of the automotive market. We are also proud to be the most reputable supplier of suspension systems to Volkswagen in China and demonstrates our ability to offer reliable and revolutionary solutions to major automotive brands. We have a solid industry background that permits us to produce products that do not just meet but also exceed expectations of our customers in terms of performance and high-quality.