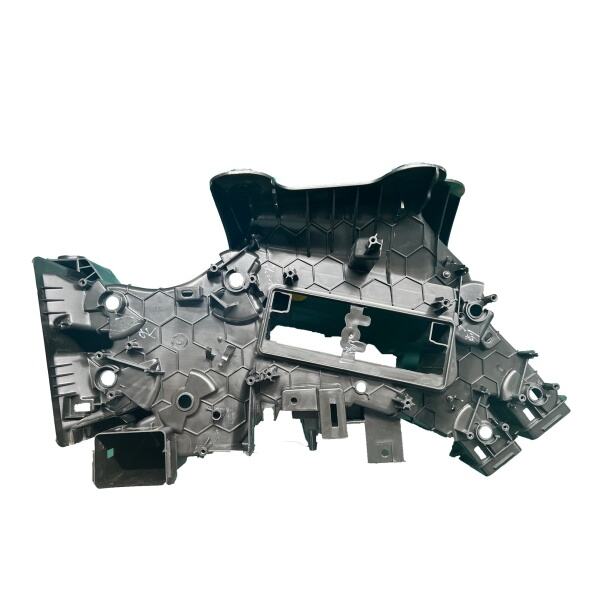

Plastic components are essential in modern automotive applications. They're created from a special substance known as plastic, which is unique because it gets easily molded into many forms and sizes. Plastic injection molding is the process through which these plastic parts are formed. It requires plenty of heat and pressure to size the parts properly. One company, Shaoyi, is well known for producing high quality car parts in plastic via this technique; they do a great job.

In the early days of car manufacturing, a majority of vehicle components were made from heavier materials such as steel and aluminum because plastic injection molding had not yet been invented.

Plastic car parts are also strong, however they are very cheap. They are also durable and do not rust or wear out easily, so they would be suitable for cars that get wet with rain or exposed to heat.

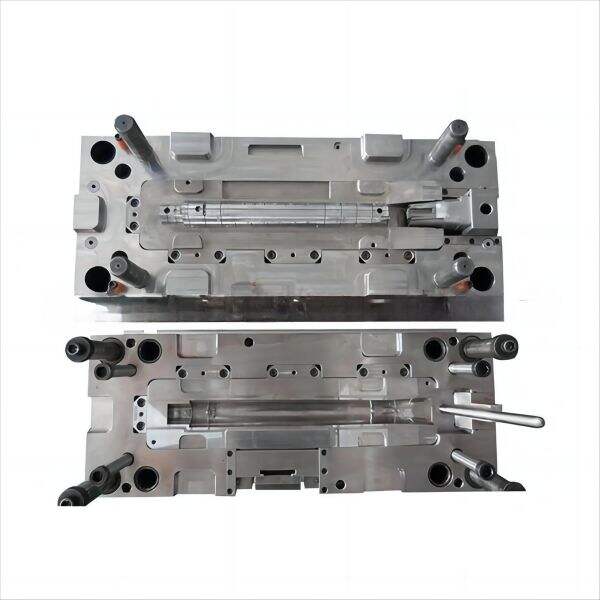

Plastic injection molding is one of the most precise fabrication processes available. This means that all the plastic car parts produced using this method will be identical, as well as having extremely high integrity. Shaoyi has a meticulous production process where every plastic part of the car is identical. And it matters more because that has traditionally made getting grease under the hood and swapping-out parts so much easier in automobiles. Therefore, when making the components of vehicles to fit properly — ensuring all systems are operational and safe for those using it.

Shaoyi employs a few different varieties of plastic to mold their high-end automotive components. They are made of several materials such as polypropylene, acrylic, polycarbonate and polyethylene.

We are incredibly proud to hold the IATF certification 16949, which is a testament to our quality management excellence that we strive to achieve within the auto industry. Our quality department has mastery over five crucial quality tools which include Statistical Process Control (SPC), Measurement Systems Analysis (MSA), Failure Mode and Effects Analysis(FMEA), Advanced Product Quality Planning and the Production Part Approval Process. Furthermore, our quality staff has completed extensive Six Sigma training, ensuring that we are adhering to the most stringent standards for quality of products. This comprehensive method of quality control ensures that every product we provide not only meets but often exceeds expectations of the industry, but also provides our clients with confidence and satisfaction over our services.

With more than 15 years of expertise in the automotive industry, our company covers an area over 10,000 square meters and are experts in the manufacture of metal parts for more than 30 auto brands. We employ cutting-edge processing techniques, including stamping, CNC machining mold manufacturing, and die-casting to make sure that every item is manufactured to the highest quality standards. Our strict quality control measures assure that our products are identical in terms of size shape, form and performance. This helps build confidence and trust with our customers.

The majority of products we produce are used in the automobile industry. We provide high-quality components that are suitable for a broad range of vehicles, including passenger cars commercial vehicles, golf carts motorbikes, trucks and tractors. Our extensive product range shows our flexibility and dedication to meet the diverse needs of the automotive market. We also are proud to be the leading supplier of suspension systems to Volkswagen in China. This proves the ability of our company to provide innovative and reliable solutions to the top auto brands. Our extensive industrial experience allows our products not only meet but exceed customer expectations for the performance and quality.

We are very proud of our committed R&D department, in which each engineer has over 10 years of experience in automotive. This experience allows us to recognize the unique nature and characteristics of the various materials, which allows us to tailor solutions for our customers. We offer professional CAE analysis, product development, and technical support, as well as detailed DFM reports to ensure that every element of the design is optimized to ensure it is ready for production. We are committed to innovation and provide high-quality metal components which meet the exact requirements of our customers.