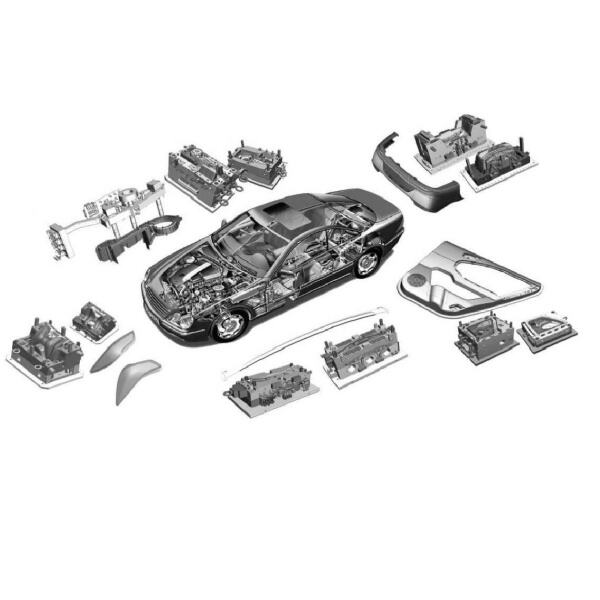

Injection molding is enclosed in this guide because it forms a crucial process when taking advantage of the car manufacturing industry. What does injection molding, then? That means pouring liquid material into a specific form (called a mold). That forces the liquid to cool, where it will become a solid component. This is an incredibly tired technique that has been utilized throughout various factories for ages.

Injection molding gives any ordinary car parts a real special touch to regular car parts. Car manufacturers previously made use of dense metals like iron, copper and aluminum for auto parts. Great as these metals were, they all came with a hefty weight and often didn’t look that great.

They can produce a lot of different parts simultaneously, saving money on car assembly. Secondly, this method is significantly quicker than producing the parts via people, which takes a lot more time. When process is done properly then it can be done by machines within no time. Also, it decreases the errors while using to machines.

One more great thing about injection molding is that it can make special designs and shapes. Using this method, the manufacturers have the ability to produce car parts of their own shape as well as design requirements. Injection molding is a technique that allows workers to produce parts with elaborate designs that would be difficult to duplicate with other manufacturing methods.

These components not only provide the distinctive looks we see few cars but also deliver protection and functionality. The injection molding method allows for high quality, precision car parts to be made from the best materials possible as well as technology and workmanship. It's this commitment to quality that sets Shaoyi apart as a leader in the automotive industry.

We are proud to have our IATF certification 16949. It is a testimony to the high standards of quality management that we are striving to achieve in the automotive industry. Our quality team is experienced in using five critical instruments for quality: Statistical Process Control (SPC), Measurement System Analysis (MSA), Failure Mode and Effects Analysis (FMEA), Advanced Product Quality Planning (APQP) and the Production Part Approval Process (PPAP). Our quality team has completed Six Sigma training to ensure we are adhering to the highest standards of product quality. Our comprehensive quality management approach guarantees that our products are in line with but often surpass industry standards, but also give our clients confidence and satisfaction with our service.

Our company specializes in automotive manufacturing, with over 90 percent of our products focused on the automotive industry. We provide high-quality components for a wide range of vehicles, including passenger cars, commercial vehicles, golf carts as well as motorcycles, trucks and tractors. This extensive product portfolio illustrates our versatility and commitment to meet the diverse needs of the automobile market. Furthermore, we are proud to be the top supplier of suspension systems to Volkswagen in China that demonstrates our capacity to offer reliable and revolutionary solutions to major automotive brands. Our vast industrial experience makes our products not only meet but exceed customer expectations for the performance and quality.

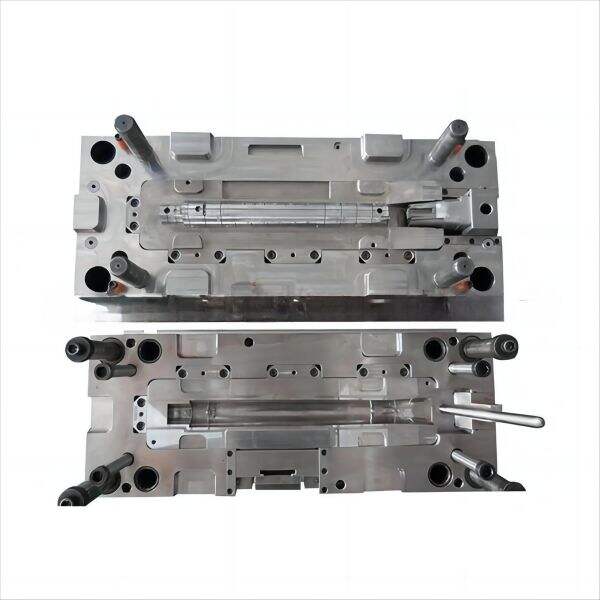

We are proud of our dedicated R&D department, where every engineer has over 10 years of experience in automotive. This expertise enables us to understand the unique features and processes of various materials, allowing us to tailor solutions for our customers. We offer professional CAE analysis, product development and technical support along with detailed DFM reports to ensure that every aspect of the design is optimized for production. We're committed to advancing technology and offer high-quality metal parts that meet the specific needs of our customers.

Our company, which covers over 10,000 square metres and is focused on the manufacturing of metal parts for over 30 automobile brands, boasts more than 15 years of experience in the business. We employ cutting-edge processing techniques such as stamping, CNC machine machining, mold manufacturing, and die-casting to make sure that every product is of the highest quality standards. Our stringent quality control procedures ensure that we have the same dimensions and shapes, as well as in performance. All those builds trust and satisfaction among our clients.