It automotive stamping part also increases the safety levels of cars for both drivers and passengers, but it also increases their reliability on the road. There are different kinds of molds that can be utilized to create the automobiles parts based on the shape and technical design of each part that has to be developed when producing automobile components with plastic molding. One type of mold in general is an injection mold.

It is impact resistant and ideal for rugged parts such as bumpers and fenders. Plastic, too, it automotive metal stamping parts easily moulds into whatever form one desire. It also allows automobile makers to design cars that are more streamlined, and thus improve some car handling by allowing them to cut through the air more effectively.

There is other plastic used for car molding which proves to give better strength after the heating process. These are not the same kind of plastics; they will be heated then cooled again into a rigid form. After they stamping car parts are chilled, they will never get melt or restyle fresh.

Plastic molding will be a huge reason that the future of car manufacturing remains bright and that stamping automotive parts future is very, very bright.

A new exciting potential application for plastic molding in the future will be self-driving cars. Autonomous vehicles are able to drive themselves, without any human involvement. They automotive sheet metal stamping must be lightweight and aerodynamically efficient, or they will not perform well, nor use less energy.

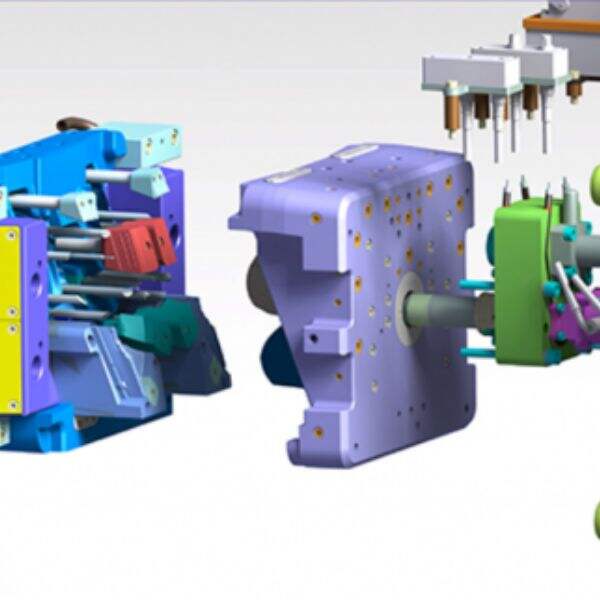

We are very proud of our committed R&D department, in which each engineer has over 10 years of experience in automotive. This experience allows us to recognize the unique nature and characteristics of the various materials, which allows us to tailor solutions for our customers. We offer professional CAE analysis, product development, and technical support, as well as detailed DFM reports to ensure that every element of the design is optimized to ensure it is ready for production. We are committed to innovation and provide high-quality metal components which meet the exact requirements of our customers.

Our company is a leader in manufacturing automotive components, with over 90 percent of our products designed for the automotive sector. We offer high-quality parts for a wide range of vehicles, including passenger cars golf carts, commercial vehicles, motorcycles, trucks, and tractor. Our broad product selection shows our dedication to meeting the diverse needs of the market for automobiles. We are also proud to be the largest supplier of suspension systems for Volkswagen in China, highlighting our capability to offer reliable and revolutionary solutions for major brands of automotive. Our extensive industrial experience allows our products to not only to be able to meet but even exceed customers' expectations regarding the performance and quality.

Our company, which spans more than 10,000 square meters and is specialized in the production of metal parts for over 30 brands of automotive, has more than 15 years of experience in the business. The products we manufacture are created with the most advanced techniques, such as CNC machine machining and mold making. Our strict quality control measures assure consistency in measurements and shapes, as well as in performance. All which creates trust and satisfaction with our customers.

We are proud to have the IATF certification 16949. It is an affirmation of the quality management excellence we aim to achieve in the automotive industry. Our quality department is proficient in the use of five essential quality tools: Statistical Process Control (SPC), Measurement System Analysis (MSA), Failure Mode and Effects Analysis (FMEA), Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP). In addition, our quality department has gone through extensive Six Sigma training, ensuring we follow the highest standards in product quality standards. Our comprehensive quality management approach assures that our products do not just are in line with but often surpass industry standards, but also give our customers confidence and complete satisfaction with our products.