We live in a world largely driven by cars. They take us places, to the work, school or, even to the fun vacations. Many folks use cars to travel with ease. Car makers, for instance, use different materials to manufacture their cars including steel and aluminum. Different materials can affect the strength, appearance, and performance of the car. Shaoyi automotive parts die casting stainless steel is a specific grade of material that is frequently used for automotive parts. Let us find out why this substance is great for automobiles.

First of all, it is super solid, so it is hard to break. Even in the presence of harsh weather conditions and bad roads, stainless steel car parts have good durability. This is crucial when navigating bumpy streets which are not always in the finest condition. Because so, stainless steel is super easy to clean and maintain. It does not rust or corrode; therefore, not as much cleaning is required as with other materials, and it needs fewer repairs. This translates to lesser work for the car owners.

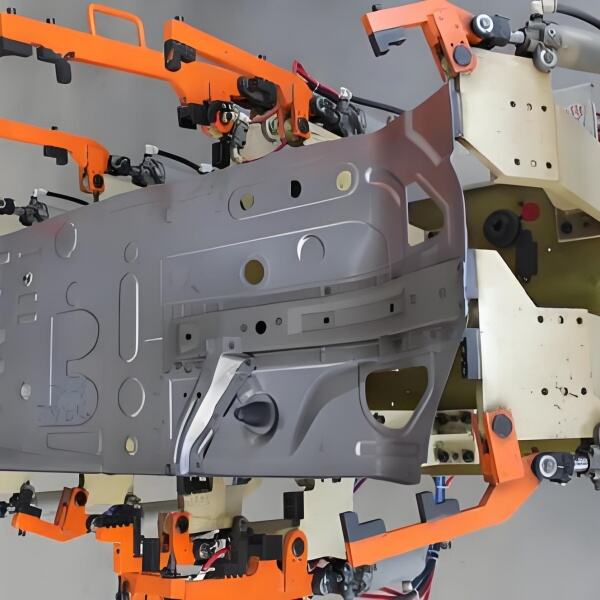

By example, replacing exhaust systems with stainless steels units can reduce weight making cars drive better. The Shaoyi automotive die casting supplier high durability also makes them less prone to cracking or breaking than other types of exhaust systems. Stainless steel is also used for brake discs, a common application for many car companies, since these parts must withstand high temperatures when the car stops. This will help maintain the vehicle's safety and functionality.

Automotive stainless steel is extremely versatile, allowing for a range of possible automotive applications. Automakers can use it for components such as the grille, fender trim and door handles. That is what makes stainless steel so great, it can be sculpted into various shapes and sizes. It provides car manufacturers the opportunity to achieve distinct and creative designs for their cars. Stainless steel finish is also responsible for its visual appeal.

There are plentiful arguments — as discussed here — advocating for the environmental advantages that correlate with using stainless steel in cars. For one thing, stainless steel is a recyclable substance, so it can always be re-used and re-purposed. This minimizes waste and uses less natural resources, making it more environmentally friendly! Secondly, Shaoyi automotive casting stainless steel does not require a lot of maintenance.

We are very proud to be awarded our IATF certification 16949. This is a testament to the quality management excellence we are striving to achieve within the auto industry. Our quality department has mastered five essential quality tools, comprising Statistical Process Control (SPC), Measurement Systems Analysis (MSA), Failure Mode and Effects Analysis(FMEA), Advanced Product Quality Planning and Production Part Approval Process. Our quality team has completed Six Sigma training to ensure we adhere the highest standards of product quality. This systematic system of quality management makes sure that every product we provide is not only up to but often surpasses industry expectations, providing our clients with confidence and satisfaction over our services.

With more than 15 years' experience in the automobile industry, our company spans over 10,000 square meters. We are experts in the manufacture of metal components for more than 30 auto brands. Our products are manufactured using the latest techniques like CNC machine machining and mold making. Our rigorous quality control measures ensure consistency in dimensions as well as performance. All which creates trust and satisfaction with our customers.

The majority of products we manufacture are intended specifically designed for the automotive industry. Our company offers high-quality components that fit a variety of automobiles including cars, golf carts and motorcycles. This extensive product portfolio showcases our versatility and commitment to satisfy the different requirements of the automotive industry. We're also proud to be the biggest supplier of suspension systems to Volkswagen in China. This proves the ability of our company to provide effective and reliable solutions to the top auto brands. We have a deep industry background that permits us to design and manufacture products that not only meet but exceed the expectations of our customers in regards to performance and quality.

We are extremely proud of our dedicated R&D department, where each engineer has more than 10 years of automotive experience. Our expertise allows us to recognize the unique features and processes of various materials, allowing us to provide customized solutions to our customers. We offer expert analysis of CAE, development and technical support, as well as detailed DFM reports to ensure that every aspect of the design is optimized to be produced. Our passion for innovation keeps us ahead of our industry, providing premium, customized metal parts that meet our customers' particular demands.