Next question would be, have you ever seen a car that is in plastic? It may seem ridiculous to consider, but a lot of automobile parts are created from plastic! So, you may have a question that these plastic parts of cars how can they stamping car parts be made. Enter a particular company: Shaoyi. This is something they specialize in, making the molds that help to shape these plastic parts. Let us dig into details to understand better how Shaoyi revolutionizes the modern manufacture of cars. Traditionally, automobiles were primarily made out of metal. Metal is a durable material, but it can be heavy and difficult to mold. These days, plastic has become a more widespread choice by car makers. Why? Since plastic is also far easier to form into various shapes and sizes. This means that quite a lot more creative horsepower can be applied when designers come up with new car designs. Well, Shaoyi offers a variety of unique molds that let users make many exciting and unique shapes for cars. It gives a different and exciting look to cars with its creativity. Each of them gives more options for each buyers on their car purchase.

Here are a few of the benefits behind manufacturing plastic car components. For one thing, plastic is a lot lighter than metal. This is significant as lighter cars tend to consume less fuel, generating savings for car drivers. Well plastic does not rust and thus it has a great advantage over metal. Rust is a issue that to metal whenever it gets wet, which can weaken components with time. Plastic does not rust so it lasts ages before even breaking down. Plus, plastic is more malleable and can be molded into virtually any shape, meaning car makers can manufacture unique components that automotive metal stamping parts fit snugly inside the car. It does have the benefit of making the cars more effective overall.

One more advantage of plastic molds is cost saving for car manufacturers. How does this work? That's also because it's just easier to mold plastic than it is to metal. Which translates to Making the components of the cars faster and using less energy. If car makers could make parts more quickly, in turn they could build more cars faster. For example, plastic molds can be utilized to produce identical parts without the need of creating new molds for every individual component. This automotive sheet metal stamping also enables automakers to produce multiple components for a lower cost, using them as enablers of efficient car development.

Auto parts manufacturing needs patience and precision to create strong, reliable products. Shaoyi applies state-of-the-art plastic molding techniques to guarantee top-quality car parts. They automotive metal stamping suppliers also employ special computers for designing the molds that need to be made very accurately. They also test these parts after making them to verify they are safe for use inside vehicles. In other words, car manufacturers can rest assured that their parts will be safe and functional for drivers.

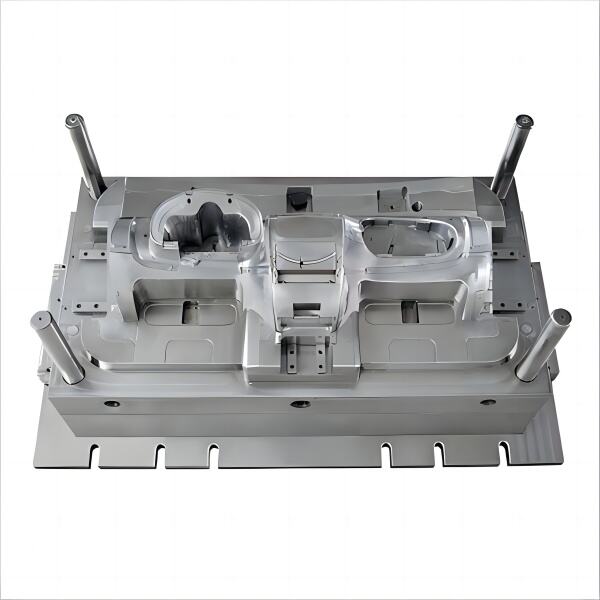

Now you are asking, how do they produce those plastic car parts from molds? It starts when a computer program generates an elaborate design of the mold that will shape the plastic. After that, they apply a method known as injection molding. This auto parts stamping procedure involves heating plastic alongside until soft and putting it into the mold. Once the plastic is in the mold, it crystallizes and solidifies into the geometry of the die. Then they peel the mold off, and the plastic part is now in a form that can be placed into a car.

We are incredibly proud to hold the IATF certification 16949. This is an affirmation of the quality management excellence we strive to achieve within the auto industry. Our quality department is skilled in using five critical instruments for quality: Statistical Process Control (SPC), Measurement System Analysis (MSA), Failure Mode and Effects Analysis (FMEA), Advanced Product Quality Planning (APQP) and the Production Part Approval Procedure (PPAP). Furthermore, our quality staff has completed intensive Six Sigma training, ensuring that we meet the highest standards in product quality standards. Our comprehensive method of quality control ensures that each product we offer not only meets, but frequently surpasses industry expectations, providing our customers with confidence and satisfaction regarding our services.

With more than 15 years of expertise in the automotive industry, our company covers an area over 10,000 square meters and are experts in the manufacture of metal parts for more than 30 auto brands. We employ cutting-edge processing techniques, including stamping, CNC machining mold manufacturing, and die-casting to make sure that every item is manufactured to the highest quality standards. Our strict quality control measures assure that our products are identical in terms of size shape, form and performance. This helps build confidence and trust with our customers.

More than 90% of the products we manufacture are intended to be used by the automobile industry. Our company provides high-quality parts for a variety of vehicles such as golf carts, cars and motorcycles. Our extensive product range is a testament to our ability to satisfy the various requirements of the automotive market. We are also proud to be the most reputable supplier of suspension systems to Volkswagen in China and demonstrates our ability to offer reliable and revolutionary solutions to major automotive brands. We have a solid industry background that permits us to produce products that do not just meet but also exceed expectations of our customers in terms of performance and high-quality.

Our company is proud of having a committed R&D team, with each engineer having more than a decade of experience in the automotive industry.This knowledge allows us to grasp the unique characteristics of various products and materials, allowing us to create custom solutions to our customers. We offer expert CAE analysis, product development and technical support, as well as detailed DFM reports to make sure that every element of the design is optimized for production. Our drive to innovate ensures that we remain at the forefront in the field, and we provide high-quality, tailored metal parts that meet our customers' particular needs.