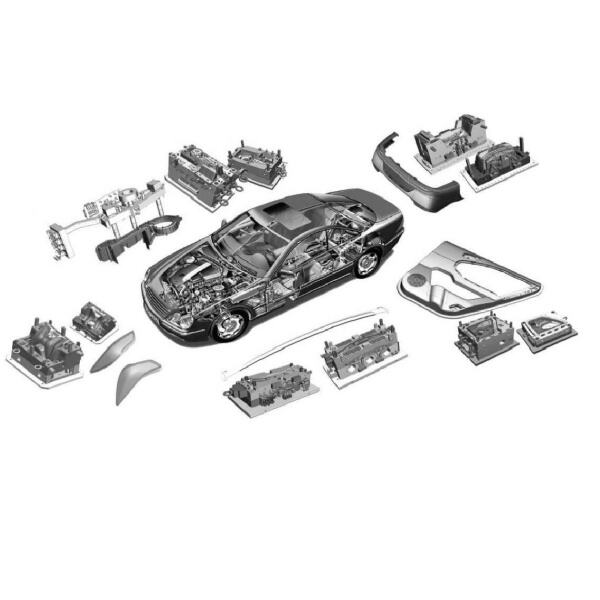

Plastic injection molds are used to produce a wide range of car components. For example, dashboards—or the panels in front of a driver containing a speedometer and other controls. They also produce engine components, which are vital for the performance of the car; and exterior parts, such as bumpers and fenders. They are catalysts, made of high quality materials to withstand high pressure and heat. Such has an essential role to play in that the process involved in manufacturing all such parts needs the molds to be able stand a lot of pressure. The precision injection molds used in production to determine that auto parts stamping all the parts manufactured have precise dimensions and uniformity are often extremely important. Car makers must have the ability to build cars that will be safe and dependable. When each component fits perfectly, the result is a well-functioning car with long-term performance.

So, the factory uses special techniques to control this process in order to create great car parts. This stamping auto parts is the way in which workers have to control how the plastic gets poured into those molds. Using the correct amount of plastic and injecting it with the right speed & at a defined pressure are crucial. If these factors were not controlled well the parts might be less than ideal. Focusing on these details helps to guarantee that the final part works out of using high quality standards and by fulfilling each and every single one of the requirements demanded by the car makers. And such attention to detail is what makes sure cars work and are roadworthy. There is a lot of reason why plastic molds are used in car making for manufacturers and consumers too. The main advantage is that plastic parts are typically more lightweight compared to metal components. The light weight of these composites enables the availability of fuel-efficient and environmentally friendly vehicles that consume low amounts of fuel.

The other benefit of plastic components is that they tend to be less expensive to manufacture than their metal counterparts. This drives down the total cost of building a car, and makes it stamping automotive parts more affordable to customers. Moreover, plastic components can be customized into various shapes and sizes. That versatility enables car makers to develop distinctive designs suitable for multiple models and vehicle types.

Mold life, as well as the number of parts to be produced, also has a significant impact on how designers must approach it. Manufacturers can design molds that save money and time by creating efficient designs when taking these automotive stamping part factors into consideration. Ensuring molds produce good parts for years to come, which is critical to car production.

The tools let designers see the components before they automotive metal stamping parts are even made, avoiding mistakes and time lag through actual assembly errors. Additional recent enhancements stem from stronger, newer high-performance materials that can withstand extreme conditions like high heat or heavy impact. On top of that, new technology is already coming in the form of a faster, lower-cost manufacturing processes. This enables the manufacturing of these parts more efficiently and according to the need for new vehicles.

Our company, which spans more than 10,000 square meters and is specialized in the production of metal parts for over 30 brands of automotive, has more than 15 years of experience in the business. The products we manufacture are created with the most advanced techniques, such as CNC machine machining and mold making. Our strict quality control measures assure consistency in measurements and shapes, as well as in performance. All which creates trust and satisfaction with our customers.

Over 90% of the products we manufacture are intended for the automotive industry. We offer high-quality parts that are suitable for a broad range of vehicles, including passenger automobiles golf carts, commercial vehicles as well as motorcycles, trucks and tractor. Our wide range of products is a testament to our ability to satisfy all the requirements of the market for automobiles. We're also privileged to be the leading supplier of suspension systems to Volkswagen in China that demonstrates our capacity to offer reliable and revolutionary solutions to the top automotive brands. Our long-standing industrial knowledge allows our products not only meet but exceed customer expectations regarding the performance and quality.

We are very proud of our committed R&D department, in which each engineer has over 10 years of experience in automotive. This experience allows us to recognize the unique nature and characteristics of the various materials, which allows us to tailor solutions for our customers. We offer professional CAE analysis, product development, and technical support, as well as detailed DFM reports to ensure that every element of the design is optimized to ensure it is ready for production. We are committed to innovation and provide high-quality metal components which meet the exact requirements of our customers.

We are very proud to be awarded our IATF certification 16949, which is an affirmation of the high standards of quality management that we strive to achieve in the automotive industry. Our quality department has mastery over five key quality tools, which include Statistical Process Control (SPC), Measurement Systems Analysis (MSA), Failure Mode and Effects Analysis(FMEA), Advanced Product Quality Planning and Production Part Approval Process. Furthermore, our quality staff has gone through extensive Six Sigma training, ensuring we follow the highest standards for quality of products. Our comprehensive approach to quality management ensures that each and every product we sell does not just meet, but often surpasses industry expectations, providing our customers with complete confidence and satisfaction in our products.