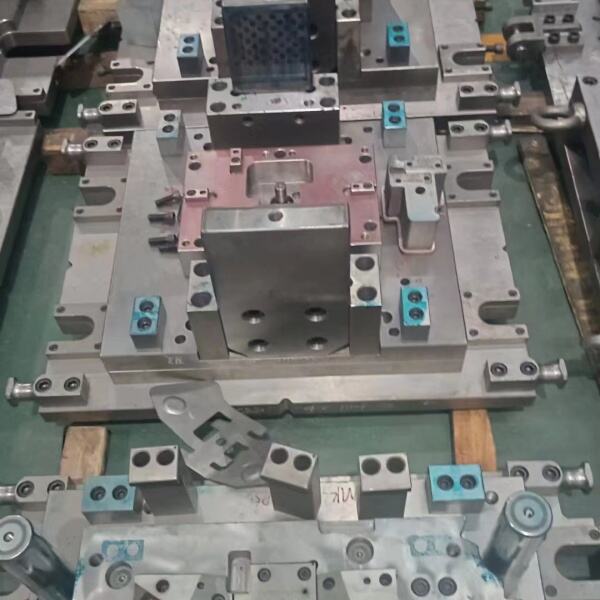

Have you ever given a thought about how cars are manufactured? Creating an automobile is a complicated process; it needs a lot of handling. Part of this process entails the making of car parts using mould technology. This is a Die Casting process which creates various components in the car. This automotive metal stamping suppliers is done using a tool known as a mould, meaning; any object that provides containment to create the right shape These moulds are used at Shaoyi to produce a large number of identical parts simultaneously, which certainly helps us when assembling an automobile.

Mould technology is an interesting science that most of the kids have not heard about. It offers unique and creatively making of various shapes. This science is highly useful in fabrication of car parts. It stamping automotive parts assist in making all vital components needed together to build a car. This means they are not only for the outside of the vehicle known as its body, but also an engine and loads more car essentials. It is important to understand how moulds operate, because they are what ensures each individual part aligns with the rest of them perfectly.

Using this method to produce components for the automobile is advantageous, but it automotive metal stamping parts comes with complications in certain situations. All sorts of issues we have to solve, to make the best components we can! We need to do this, for example, by making the parts stronger yet lighter and more sustainable. Which essentially means we need to think out-of-the-box on a regular basis. At Shaoyi we are striving solutions that not only enhances our products but also contributes in saving this earth. With this, we think that making amazing car parts comes with the responsibilities, which helps us to make a difference.

Overview of advantages using mould technology to create car parts. This is particularly useful, as we can create multiple identical parts all at once which is one of the greatest advantages of this technology. This automotive sheet metal stamping is doubly important for a car because the real world is still about hardware and every piece must fit into its place. Making many parts at the same time also helps to reduce the overall cost of manufacturing a car — which is beneficial for all parties. Moreover, components manufactured by means of mould technology usually are more exact and durable than their counterparts obtained through other methods. It implies that the parts function ideally and endure longer, which is critical for the car's safety and durability.

The ultimate objectives of mould technology for car parts include strength and reliability. At Shaoyi we know strong parts are needed to make sure the cars we build are safe. We have driven this for parts with the use of mould technology. Our moulds are made of premium materials to ensure the parts we produce are reliable and can survive in harsh environments. Importantly, the automotive sheet metal parts cars we make must be safe and work as intended for dozens of years, providing peace-of-mind to drivers.

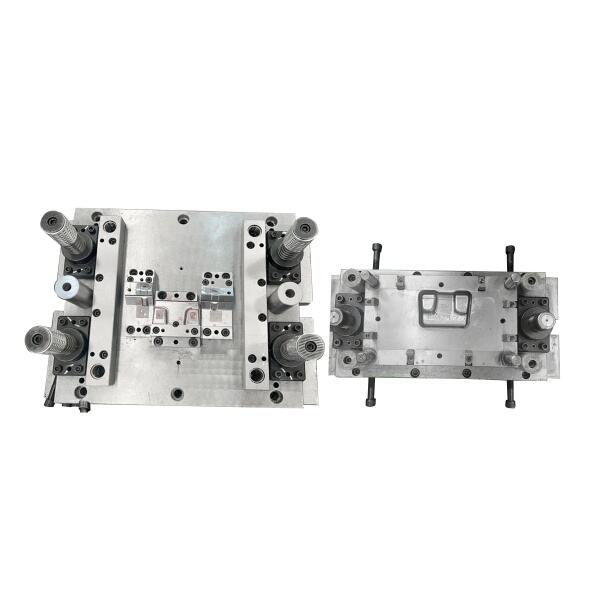

We are very proud of our committed R&D department, where every engineer has over 10 years of automotive experience. This expertise enables us to understand the unique nature and characteristics of the various materials, allowing us to offer customized solutions to our clients. We offer expert CAE analyses in product development, technical support as well as comprehensive DFM report to ensure that every aspect of the design is optimised for manufacturing. We're committed to advancing technology and provide top-quality metal products that are designed to meet the needs of our clients.

With more than 15 years of expertise in the automotive sector, our firm covers an area over 10,000 square meters and specialize in the manufacturing of metal parts for over 30 automotive brands. We utilize advanced processing techniques which include stamping, CNC machine machining, mold making, and aluminum die-casting to ensure that every product is of the highest quality standards. Our stringent quality control procedures ensure that our products are constant in terms of dimensions shape, form and performance. This creates confidence and trust with our customers.

The majority of products we produce are used in the automobile industry. We provide high-quality components that are suitable for a broad range of vehicles, including passenger cars commercial vehicles, golf carts motorbikes, trucks and tractors. Our extensive product range shows our flexibility and dedication to meet the diverse needs of the automotive market. We also are proud to be the leading supplier of suspension systems to Volkswagen in China. This proves the ability of our company to provide innovative and reliable solutions to the top auto brands. Our extensive industrial experience allows our products not only meet but exceed customer expectations for the performance and quality.

We are proud to have our IATF certification 16949. It is a testimony to our quality management excellence that we strive for in the automotive industry. Our quality department has mastered five crucial quality tools which include Statistical Process Control (SPC), Measurement Systems Analysis (MSA), Failure Mode and Effects Analysis(FMEA), Advanced Product Quality Planning and Production Part Approval Process. Our quality team also has completed Six Sigma training to ensure that we maintain the highest standards for product quality. Our systematic approach to quality management makes sure that our products not only match, but often surpass the standards of our industry, giving our customers confidence and complete satisfaction with our service.