So before you come to create a car mould with Shaoyi, it automotive stamping part is vitally important for you to understand: What does the process of making a car mould entail. Car moulding involves the making of a special tool used to create other components that get installed into cars. We refer to this tool as a mould.

Aluminum is also light and easy to handle while steel is strong and incredibly durable. Composite materials are often used for this continuously because they auto parts stamping can be very strong, yet lightweight. Before making that decision, however, you should consider which material is best for your specific needs.

The design of your car mould is what is very important for you to have a successful project. You will face production problems if the mould is not well designed. That automotive metal stamping suppliers also means you might be paying more than initially intended and adding additional waste to your clutter.

Shaoyi helps you to select the best design options with its Experts available. They stamping automotive parts are able to give you helpful guidance to help ensure that you have a well constructed mould that is designed to function correctly. A well thought out design can save you a lot of headaches down the line.

This automotive sheet metal stamping necessitates detailed planning and specific measurements that ensure everything is set up properly.

Our company specializes in automotive manufacturing, with over 90 percent of our products focused on the automotive industry. We provide high-quality components for a wide range of vehicles, including passenger cars, commercial vehicles, golf carts as well as motorcycles, trucks and tractors. This extensive product portfolio illustrates our versatility and commitment to meet the diverse needs of the automobile market. Furthermore, we are proud to be the top supplier of suspension systems to Volkswagen in China that demonstrates our capacity to offer reliable and revolutionary solutions to major automotive brands. Our vast industrial experience makes our products not only meet but exceed customer expectations for the performance and quality.

We are proud of being able to hold the IATF certification 16949, as a proof of our commitment to quality management excellence within the automotive industry. Our quality department is skilled in using five key instruments for quality: Statistical Process Control (SPC), Measurement System Analysis (MSA), Failure Mode and Effects Analysis (FMEA), Advanced Product Quality Planning (APQP) and the Production Part Approval Procedure (PPAP). Our quality staff has gone through extensive Six Sigma training, ensuring that we are adhering to the most stringent standards in product quality standards. Our comprehensive quality management approach makes sure that our products not only match, but often surpass industry standards, but also give our customers confidence and complete satisfaction about our services.

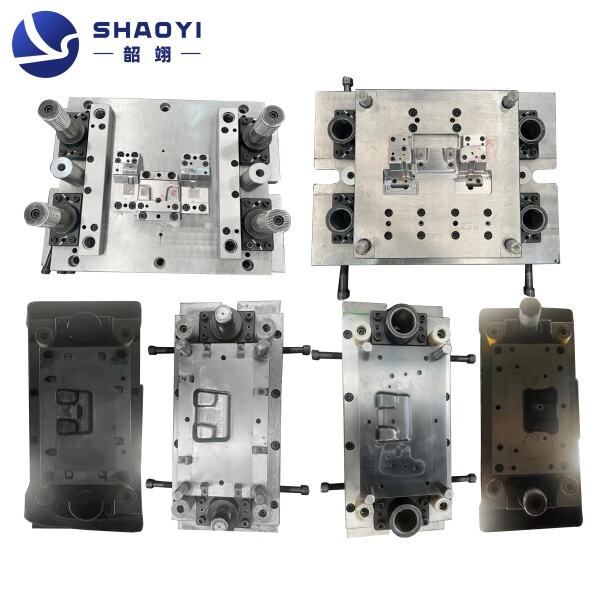

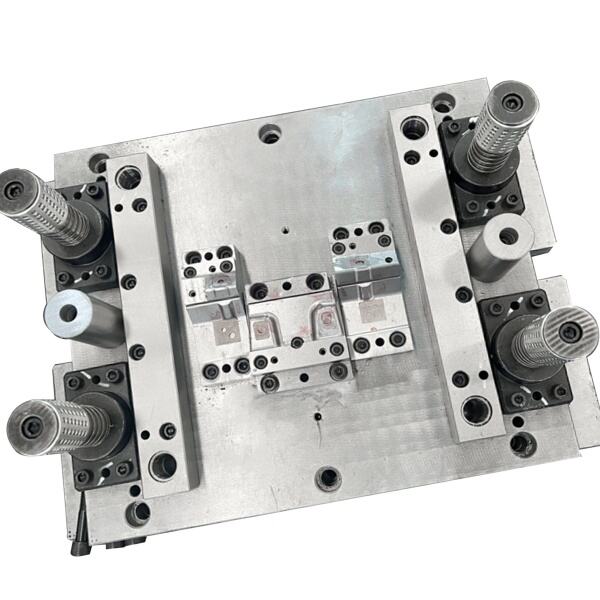

Our company, which covers more than 10,000 square meters and specializes in the manufacture of metal components for more than 30 brands of automotive, has more than 15 years of experience in the industry. We employ cutting-edge processing techniques that include stamping, CNC machine machining, mold making, and aluminum die-casting, to ensure that each item is manufactured to the highest quality standards. Our stringent quality control procedures guarantee consistency in sizes of shapes, performance, and other aspects, all that builds trust and a sense of satisfaction among our clients.

Our company prides itself on having a committed R&D team, with each engineer possessing more than 10 years of experience in the automotive industry.This know-how helps us comprehend the distinctive characteristics of different types of materials and processes, which allows us to develop custom solutions to our customers. We offer professional analysis of CAE, development and technical support, as well as detailed DFM reports to ensure that each aspect of the design is optimized to be produced. Our commitment to innovation keeps us ahead of the market, offering high-quality, tailored metal parts to meet clients' specific demands.