Car making requires auto moulds, which are crucial to the entire operation. They are crucial in manufacturing various types – sizes of different automobile components. The parts include bumpers, doors, and even dashboards; pretty important stuff for a car to look and work right. We have an exceptional team that works on auto moulds and here at Shaoyi we are happy for what we do. That means we ensure that the design and manufacture of our moulds is very precise and thorough. We do this so that every car part they produce is first time right, everytime. Imagine ensuring that every piece of a puzzle fits perfectly (pun intended). There are many factors why precision engineering is crucial as it automotive stamping part aids in the entire manufacturing process. Firstly, it allows us to consume less material. We make car parts with less material than would be needed ifthe auto mould is not made correctly. Not only does this save money, it also saves resources that are environmentally friendly. Secondly, a precision engineering service helps with the safety of individuals. Cars must have secure hard parts to ensure security when driving all. With the help of precise auto moulds, high quality vehicle components are formed which ensures safe as well as a long self life. Now that is extremely crucial for the safety of road users.

By perfect, we mean the best at every single thing when it comes to car parts. Those components must be durable, long-lasting, and aesthetically pleasing! We then manufacture such perfect parts using a unique process — auto moulding at Shaoyi. Auto moulding — it is the process where we use a special auto mould, to manufacture various parts of a car. Like with cookie cutters when you baking cookies, you can make a lot of the same type. Auto moulding is among the most crucial processes involved in car manufacturing. Through auto moulding, we are able to confirm that our parts are the same size/shape each and every time. This automotive metal stamping parts consistency is important because it ensures that all the constituent parts of a car fit together precisely. Everything that fits, works together like the proverbial well oiled machine. Plus, auto moulding minimizes waste allowing us to maximize our materials and enhance the entire auto manufacturing process. It’s a win-win situation.

The manufacture of auto moulds involves being pretty clever and consistent. In other words, we are being smart: we are using our materials wisely and making wise use of our time. Here at Shaoyi, we always seek the most efficient way to manufacture your auto mould. We've been searching for ways to work quicker and more efficiently, allowing us to result quality parts and save money at the same time. By enabling more pieces to auto parts stamping be produced without any wastage of natural resources; working smart!

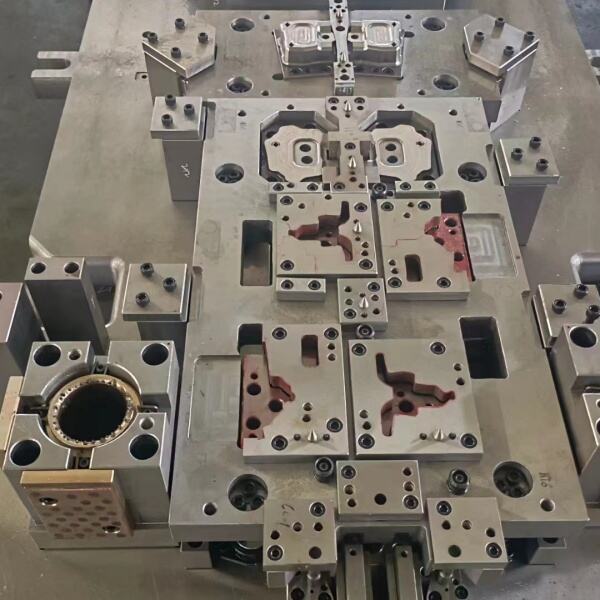

This is also true when making auto moulds. Every time we manufacture parts, consistency means that we will create the same quality of those parts. This is essential for safety and reliability, because drivers expect their cars to be safe at road. Shaoyi applies advanced techniques and technology that ensures every production batch of auto moulds are uniform or consistent. This involves creating our moulds using advanced computer-aided design tools, as well as producing the parts with high precision through state-of-the-art equipment. This automotive metal stamping suppliers way we will know that our customers get the top quality products.

Recently, we have been getting a lot of new ideas through 3D printing technology which is exciting! Using technology, we can quickly and easily create models or prototypes of our auto moulds. Creating these prototypes allows us to validate our designs before we go ahead and manufacture the actual mould. This allows us to validate that everything operates as it should before we commence production for real. We are also innovating by employing new computer aided design tools. To automotive sheet metal stamping keep up in this field, these tools help us create exactness and complexity in the designs we create.

Over 90% of the items we create are made specifically designed for the automobile industry. Our company supplies high-quality parts for a range of vehicles including cars, golf carts and motorcycles. Our wide range of products demonstrates our commitment to meet the diverse needs of the automobile market. We're also proud to be the leading supplier of suspension systems to Volkswagen in China. This demonstrates our ability to provide innovative and reliable solutions to major auto brands. We have a deep industry background that permits us to create products that not only meet, but exceed the expectations of our customers in terms of performance and quality.

We are very proud to be awarded our IATF certification 16949, which is an affirmation of the high standards of quality management that we strive to achieve in the automotive industry. Our quality department has mastery over five key quality tools, which include Statistical Process Control (SPC), Measurement Systems Analysis (MSA), Failure Mode and Effects Analysis(FMEA), Advanced Product Quality Planning and Production Part Approval Process. Furthermore, our quality staff has gone through extensive Six Sigma training, ensuring we follow the highest standards for quality of products. Our comprehensive approach to quality management ensures that each and every product we sell does not just meet, but often surpasses industry expectations, providing our customers with complete confidence and satisfaction in our products.

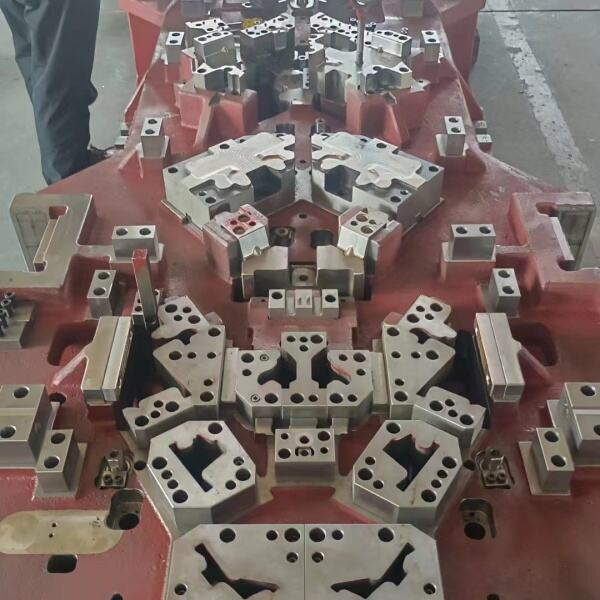

Our company, which covers over 10,000 square metres and specializes in the manufacture of metal components for more than 30 auto brands, has more than 15 years of expertise in the industry. We employ cutting-edge processing techniques which include stamping, CNC machine machining, mold manufacturing, and die-casting, to ensure that each item is manufactured to the highest quality standards. Our rigorous quality control measures ensure that our products are identical in terms of size of shapes, performance and sizes. This increases trust and satisfaction with our clients.

Our company is proud of having a committed R&D team, with each engineer having more than a decade of experience in the automotive industry.This knowledge allows us to grasp the unique characteristics of various products and materials, allowing us to create custom solutions to our customers. We offer expert CAE analysis, product development and technical support, as well as detailed DFM reports to make sure that every element of the design is optimized for production. Our drive to innovate ensures that we remain at the forefront in the field, and we provide high-quality, tailored metal parts that meet our customers' particular needs.