Aluminium die casting mould is one of the important tools for factories produces different metal parts in mass scale. From cars and electronics to household kitchen appliances, these metal parts are in many of the products we use every day. Shaoyi is one of the reputable companies known for aluminium die casting mould-making to assist at this level of manufacturing. This article will cover the wide-ranging advantages of a Shaoyi mould die casting, exactly how the die casting process works from start to finish, why a proper mould is essential, tips for selecting the right type of mould that suits your needs as well novel advancements related to Aluminium Die Casting technology.

Aluminium die casting mould is a metal forming process that offers such great advantages when it comes to production of metal parts. More than any other, it is a low-cost method. That means saves dollars since it enables makers to produce elements on the cheap. It is also a rapid and efficient process, thus thousands of units can be made in the same short time frame. This is particularly beneficial to factories which require large volumes of quick production outputs.

Second, very high precision is attained by casting parts that are made in Shaoyi aluminum automotive die casting mould. That means they mesh with the other pieces and perform effectively, which is critical to the quality of the end product. Finally, the method used to make these metal parts results in them being strong and lightweight. This trait allows for them to be found in a various range of applications from automotive engines to small consumer electronics. In short, the die mold of an aluminum die casting provides you with a high-quality product at an affordable price; this is why it has become a popular option in the manufacturing industry.

The aluminium turns into a gooey, thick liquid when melted. Next, the molten aluminum is poured into the cavity completely. Once the mould is filled, the metal then cools and solidifies in the shape of the part. After cooling and firming up, the final piece can then be carefully removed from within the mould. The nice thing about this process is that the mould lasts for ages, producing thousands of metal parts. Such repeatability makes it a fast, efficient and economical process, which is the reason for its widespread use in factories.

Secondly, the configuration of the mould deserves to be very accurate. Having a properly designed mould makes certain that the manufactured machined metal parts are of good quality however precise with other pieces. Third, the mould should be made to last through a number of its uses without any change in shape or performance. Such durability is required to create consistent parts. Please maintain, retain and clean the mould carefully so that it will work properly for a longer duration. Preventing potential problems affecting the quality of parts being produced through routine maintenance.

The following step is to have a mould design reflecting the shape or function of the metal parts. The mould needs to be designed based on the fact that different parts have different shapes. Third, the mould should be made from a material that is strong and durable enough to withstand the heat and pressure during the casting process. Finally, the last consideration is to check the price of mould. Your manufacturing project should not break the bank which makes it reasonable and affordable. Considering these attributes will help you choose the most relevant option for your use.

There are also new software programs being developed that assist designers to realize accurate and precise moulds. That is to say, metal elements will be created with even additional precision and aspect. In conclusion, Shaoyi auto parts mould technology has a very bright future ahead, and Shaoyi is in the leading edge of these exciting developments. They have taken on a mission to be at the forefront of developing new design moulds that will contribute to the future of manufacturing.

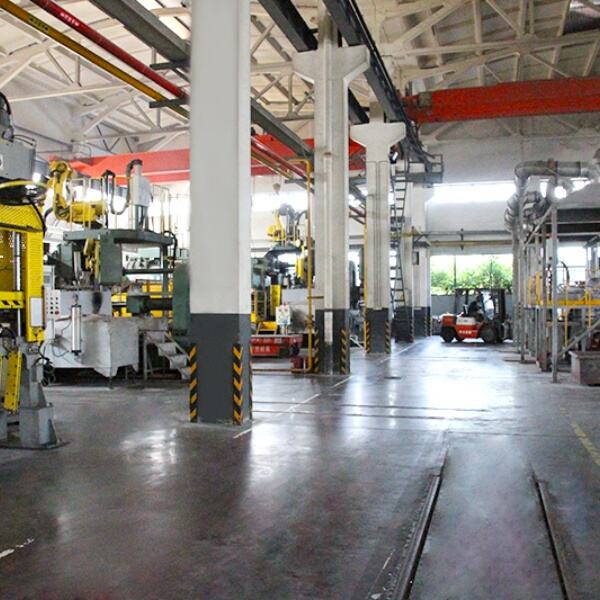

Our company, which covers over 10,000 square metres and is focused on the manufacturing of metal parts for over 30 automobile brands, boasts more than 15 years of experience in the business. We employ cutting-edge processing techniques such as stamping, CNC machine machining, mold manufacturing, and die-casting to make sure that every product is of the highest quality standards. Our stringent quality control procedures ensure that we have the same dimensions and shapes, as well as in performance. All those builds trust and satisfaction among our clients.

Our company is proud of having a dedicated R&D team with every engineer boasting over a decade of expertise in the automotive industry.This knowledge allows us to understand the distinctive features of various products and materials, allowing us to develop custom solutions for our clients. We offer expert CAE analyses, product development and technical support as well as thorough DFM report to ensure that each aspect of the design is developed to meet the demands of production. Our drive to innovate keeps us on top of the industry, delivering premium, customized metal parts that meet our customers' particular demand.

We are proud to have the IATF certification 16949. It is an affirmation of the quality management excellence we aim to achieve in the automotive industry. Our quality department is proficient in the use of five essential quality tools: Statistical Process Control (SPC), Measurement System Analysis (MSA), Failure Mode and Effects Analysis (FMEA), Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP). In addition, our quality department has gone through extensive Six Sigma training, ensuring we follow the highest standards in product quality standards. Our comprehensive quality management approach assures that our products do not just are in line with but often surpass industry standards, but also give our customers confidence and complete satisfaction with our products.

More than 90% of the products we manufacture are intended to be used by the automobile industry. Our company provides high-quality parts for a variety of vehicles such as golf carts, cars and motorcycles. Our extensive product range is a testament to our ability to satisfy the various requirements of the automotive market. We are also proud to be the most reputable supplier of suspension systems to Volkswagen in China and demonstrates our ability to offer reliable and revolutionary solutions to major automotive brands. We have a solid industry background that permits us to produce products that do not just meet but also exceed expectations of our customers in terms of performance and high-quality.