SS Sheet Metal Fabrication: Fix Costly Defects Before They Happen

Understanding SS Sheet Metal Fabrication Fundamentals

SS sheet metal fabrication is the specialized process of transforming flat stainless steel sheets into functional components through cutting, bending, welding, and finishing operations. Unlike standard carbon steel work, fabricating a sheet of stainless steel demands precise control over heat input, tooling selection, and surface handling to preserve the material's inherent corrosion resistance.

Why does this matter? When you're working with stainless steel sheet metal, every decision—from cutting speed to welding technique—directly impacts whether your finished part will resist corrosion for decades or fail prematurely. Understanding these fundamentals helps manufacturers avoid costly defects before they occur.

What Makes Stainless Steel Fabrication Different

Imagine working with a material that work-hardens rapidly, conducts heat poorly, and demands pristine surface conditions. That's the reality of stainless sheet metal fabrication. Unlike mild steel, a stainless steel metal sheet requires specialized approaches at every stage.

The key differences include:

- Higher springback during forming: Stainless steel's greater strength means it resists permanent deformation, requiring overbending compensation.

- Work hardening sensitivity: The material strengthens as it's worked, making progressive operations increasingly difficult without proper technique.

- Thermal management challenges: Poor heat conductivity concentrates heat in localized areas, risking distortion and metallurgical changes.

- Surface contamination risks: Contact with carbon steel tools or particles can compromise corrosion resistance permanently.

These characteristics explain why experienced fabricators maintain separate tooling and dedicated work areas for sheet metal stainless steel projects.

The Role of Chromium in Corrosion Resistance

What makes stainless steel "stainless"? The answer lies in chromium content. According to metallurgical standards, stainless steel contains at least 10.5% chromium, which creates a remarkable self-healing phenomenon called passivation.

When chromium encounters oxygen, it forms an incredibly thin chromium oxide layer—only one to three nanometers thick, just a few atoms deep. This passive layer acts as an invisible shield, preventing iron in the alloy from reacting with moisture and oxygen. The fascinating part? If scratched or damaged, this protective layer reforms spontaneously when oxygen is present.

However, improper fabrication can deplete chromium from the surface or introduce contaminants that prevent passivation. This is precisely why ss sheet metal fabrication requires such careful attention to technique.

The core fabrication processes for ss steel sheet include:

- Cutting: Laser, plasma, waterjet, or mechanical shearing to separate material with minimal heat-affected zones.

- Bending and Forming: Press brake operations, roll forming, and stamping that account for springback and grain direction.

- Welding: TIG, MIG, or resistance welding with proper filler metals and shielding gases to maintain corrosion resistance.

- Finishing: Polishing, passivation, or electropolishing to restore the protective layer and achieve desired aesthetics.

Manufacturers and engineers choose stainless steel sheet for demanding applications because it delivers what carbon steel cannot: long-term corrosion resistance without protective coatings, excellent strength-to-weight ratios, and hygienic surfaces suitable for food, pharmaceutical, and medical environments. When properly fabricated, these components serve reliably for decades in challenging conditions.

Stainless Steel Grade Selection Guide for Fabrication Projects

Choosing the wrong stainless steel grade is one of the most expensive mistakes in ss sheet metal fabrication. You might save money upfront with a lower-cost alloy, only to face premature corrosion, cracking during forming, or weld failures that require complete component replacement. The solution? Understanding exactly how each grade performs before you commit to production.

Four grades dominate fabrication projects: 304, 316, 430, and 201. Each offers distinct advantages depending on your application's corrosion exposure, forming requirements, and budget constraints. Let's break down what makes each grade unique—and when to specify one over another.

Austenitic vs Ferritic Grades Explained

Before diving into specific grades, you need to understand the fundamental difference between austenitic and ferritic stainless steel sheets. This distinction affects everything from how your plate stainless steel behaves during forming to its long-term corrosion performance.

Austenitic grades (304, 316, 201) contain high levels of nickel (typically 8-10%) and chromium (16-26%). According to SSM Alloys, their face-centered cubic crystal structure provides excellent toughness, ductility, and formability at both room and elevated temperatures. These grades are non-magnetic in their annealed state—a useful identification characteristic.

Ferritic grades (430) contain minimal nickel (less than 1%) with chromium providing primary corrosion resistance. Their body-centered cubic structure offers higher strength but reduced ductility compared to austenitic alternatives. Ferritic stainless steel plate is magnetic, which sometimes matters for specific applications.

What does this mean for your fabrication project? Austenitic grades bend and form more easily without cracking, weld with fewer complications, and resist corrosion better in aggressive environments. Ferritic grades cost less but require more careful handling during forming and welding operations.

Matching Grades to Environmental Conditions

The environment your finished component will face should drive your grade selection. Here's where nickel and molybdenum content become critical decision factors.

Nickel content directly correlates with corrosion resistance and formability. Higher nickel means better performance in corrosive environments and easier fabrication—but also higher material costs. Grade 304 contains 8-10% nickel, while 316 bumps this to 10-14%.

Molybdenum is the secret ingredient in 316 stainless steel steel plate. This 2-3% addition dramatically improves resistance to pitting and crevice corrosion, especially in chloride-rich environments like seawater or chemical processing facilities.

| Grade | Corrosion Resistance | Formability | Weldability | Cost Tier | Ideal Applications |

|---|---|---|---|---|---|

| 304 | Excellent for general environments | Excellent | Excellent—no preheating required | Medium | Food processing, kitchen equipment, architectural, medical devices |

| 316 | Superior—resists chlorides and acids | Excellent | Excellent | High | Marine hardware, chemical processing, pharmaceutical equipment, surgical implants |

| 430 | Good for mild environments | Good | Poor—prone to brittle phases | Low | Automotive trim, appliances, indoor decorative applications |

| 201 | Moderate | Good | Good | Low | Low-cost appliances, utensils, decorative trim |

When should you upgrade from 304 to 316? Consider 316 whenever your stain steel plate will encounter marine environments, chlorinated water, sulfuric or hydrochloric acids, or aggressive chemical exposure. The molybdenum content in 316 provides protection that 304 simply cannot match in these conditions. Yes, you'll pay more for the material—but avoiding a premature corrosion failure easily justifies the cost difference.

When does 430 make economic sense? For indoor applications with minimal corrosive exposure—think appliance panels, automotive interior trim, or decorative elements—430 delivers acceptable performance at significantly lower cost. Just remember: 430 has poor weldability and requires careful temperature control during fabrication to avoid cracking. It's also vulnerable to chloride attack, making it unsuitable for coastal or outdoor installations.

What about 201 as a budget alternative? Grade 201 substitutes manganese for some nickel content, reducing material costs while maintaining reasonable formability. According to Topson Stainless, it works well for cookware, utensils, and decorative applications where high corrosion resistance isn't critical. However, the trade-offs are real: lower corrosion resistance than 304, reduced performance at extreme temperatures, and less predictable long-term durability. For ss steel plate applications requiring reliable performance, 304 remains the safer choice.

The grade you select ripples through every subsequent fabrication decision—from cutting parameters to welding filler metals. Getting this choice right from the start prevents the costly rework that comes from discovering mid-production that your material won't perform as needed.

Best Methods for Cutting Stainless Steel Sheet Metal

So, how do you cut stainless steel without compromising its corrosion resistance or creating defects that haunt you during welding? The answer depends on your material thickness, precision requirements, and budget constraints. Each cutting method brings distinct advantages—and limitations that can derail your project if overlooked.

Understanding how to cut stainless steel sheet properly is fundamental to successful ss sheet metal fabrication. The wrong method creates heat-affected zones that deplete chromium, work-hardened edges that resist bending, or rough surfaces requiring extensive secondary finishing. Let's examine each technique honestly so you can match the best way to cut stainless steel to your specific application.

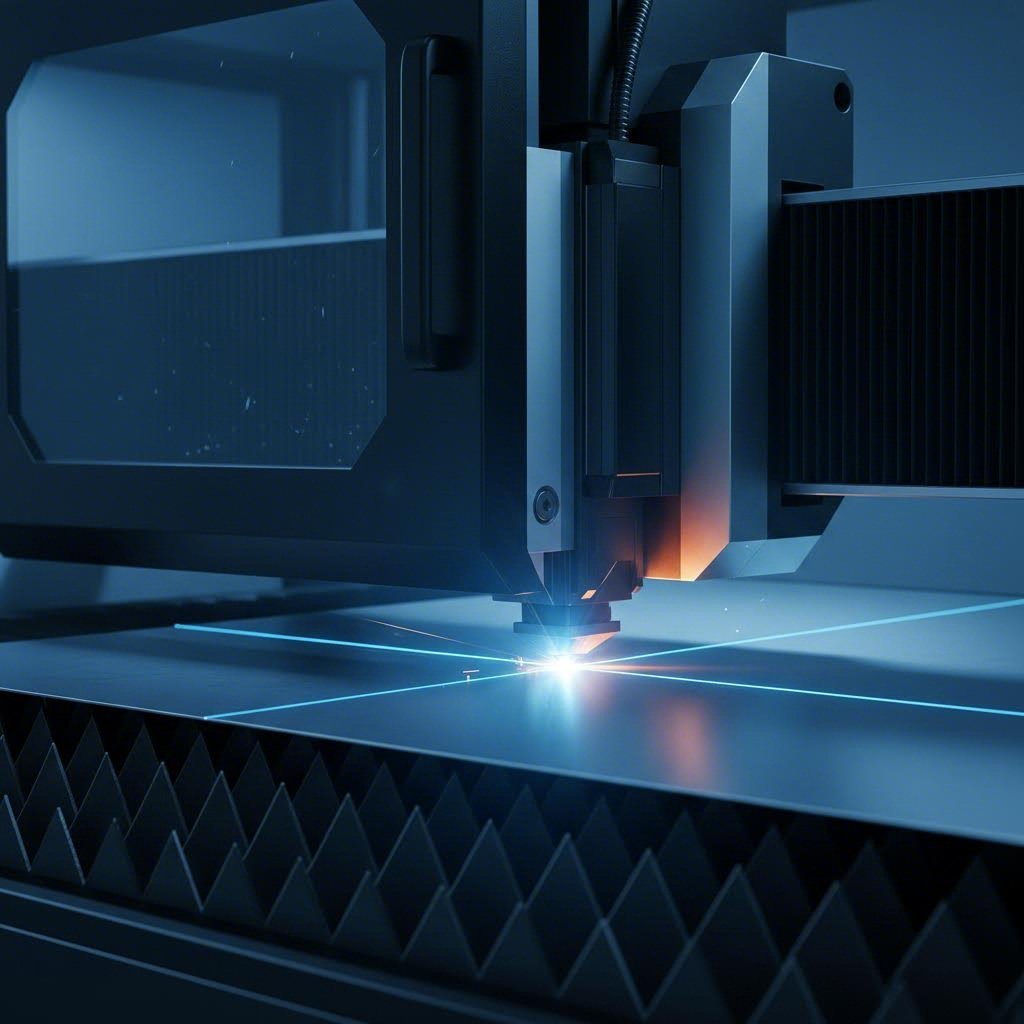

Laser Cutting for Precision and Clean Edges

When precision matters most, laser cutting delivers exceptional results on stainless steel sheets. A focused beam of light melts or vaporizes material with pinpoint accuracy, producing clean edges that often require no secondary finishing.

According to Lyah Machining, fiber lasers handle stainless steel up to 20-25 mm thickness, with optimal performance below 10 mm where you'll achieve the tightest tolerances and cleanest edge quality. For thin stainless steel cutting applications, nothing matches laser's combination of speed and precision.

The key advantages include:

- Superior edge quality: Minimal burr formation means less post-processing before welding

- Tight tolerances: Achievable accuracy within ±0.1 mm for critical dimensions

- Minimal heat-affected zone: Concentrated energy reduces chromium depletion compared to slower thermal processes

- Complex geometry capability: Intricate patterns and small features cut cleanly

However, laser cutting isn't without limitations. As AZoM research indicates, stainless steel's low thermal conductivity concentrates heat at the cutting site, potentially causing localized overheating on thicker sections. Assist gases—typically nitrogen for stainless—expel molten material and prevent oxidation that would compromise corrosion resistance.

When Plasma Cutting Makes Economic Sense

Plasma cutting uses an ionized gas jet at extremely high temperatures to melt and expel material. It's faster than laser for thicker plates and significantly less expensive for high-volume cutting stainless steel sheets above 6 mm.

Here's the honest assessment: plasma produces rougher edges than laser. According to Xometry's fabrication experts, "most plasma cutters out there on the network are for fabrication, where the edge condition will require some secondary treatment like cleanup and welding."

Does this mean you should avoid plasma? Not at all. When your downstream process includes welding anyway, plasma's edge quality becomes less critical. The cost savings on thick stainless steel plate—where plasma excels—often justify the additional edge preparation. Plasma handles stainless steel up to 38 mm thickness, making it ideal for structural components where speed and economy outweigh precision requirements.

Waterjet: The Cold-Cutting Alternative

Wondering how to cut steel sheet without any heat-affected zone? Waterjet cutting eliminates thermal concerns entirely. A high-pressure water stream mixed with abrasive particles erodes material through mechanical action rather than melting.

This cold-cutting process preserves stainless steel's metallurgical properties completely. No chromium depletion. No work hardening. No thermal distortion. For heat-sensitive applications or materials that will undergo critical stress, waterjet provides unmatched material integrity.

Waterjet also handles virtually any thickness—up to 150 mm or more on metals—making it the go-to choice when laser and plasma reach their limits. The trade-off? Slower cutting speeds and higher operating costs compared to thermal methods.

Mechanical Shearing for Straight Cuts

Sometimes the simplest method works best. Mechanical shearing uses high-pressure blades to slice through stainless steel sheets—no heat involved, no gas required, just clean physical separation.

Shearing excels at straight-line cuts on thinner material, typically up to 25 mm depending on machine capacity. It's fast, economical, and produces minimal waste. However, you're limited to linear cuts without the geometric flexibility of laser or waterjet.

| Cutting Method | Max Stainless Steel Thickness | Edge Quality | Precision | Speed | Best Application |

|---|---|---|---|---|---|

| Laser | 20-25 mm | Excellent | Very High | High | Precision parts, complex geometries, thin-to-medium sheets |

| Plasma | 38 mm | Medium | Medium-High | Very High | Thick plates, high-volume production, weldments |

| Waterjet | 150+ mm | High | High | Medium | Heat-sensitive work, extreme thickness, mixed materials |

| Shearing | 25 mm | Good | Medium | Very High | Straight cuts, blanking, high-volume sheet processing |

Avoiding Heat-Affected Zones and Work Hardening

Regardless of which thermal method you choose, minimizing heat-affected zones protects your material's corrosion resistance. The chromium that creates stainless steel's passive layer can migrate or combine with carbon at elevated temperatures—a phenomenon called sensitization.

To cut stainless steel while preserving its properties:

- Use appropriate cutting speeds: Too slow concentrates heat; optimize parameters for your thickness

- Select proper assist gases: Nitrogen prevents oxidation on laser-cut edges

- Consider cold cutting for critical applications: Waterjet eliminates thermal concerns entirely

- Plan for edge treatment: Passivation after cutting restores the protective chromium oxide layer

Can you cut stainless steel with any method and achieve good results? Yes—but matching the technique to your application prevents the downstream defects that transform a simple cutting operation into an expensive rework situation. Your edge quality directly impacts welding success, which we'll explore next.

Forming and Bending Stainless Steel Without Defects

You've cut your stainless steel sheets cleanly—now comes the challenging part. Bending stainless steel forming operations demand fundamentally different approaches than mild steel. Why? The material fights back harder, springs back more aggressively, and punishes improper technique with cracks, galling, and surface defects that can't be undone.

Understanding these behaviors before you bend your first piece prevents the costly scrapped parts and production delays that plague fabricators who treat stainless like ordinary steel. Whether you're working with thin stainless steel sheet for enclosures or heavier stainless steel shapes for structural applications, the principles remain consistent.

Calculating Springback Compensation

Here's the reality: stainless steel bounces back after bending far more than carbon steel. According to Datum Alloys, 304 stainless steel typically springs back 2-3 degrees on tight bends where the inside radius equals material thickness. For larger radius bends, springback can exceed 30-60 degrees—a massive difference that ruins parts if not anticipated.

Why does this happen? When you bend any metal, the outer surface stretches while the inner surface compresses. This deformation has two components: plastic (permanent) and elastic (temporary). Stainless steel's high yield strength means more of its deformation is elastic, causing greater recovery when you release the bending force.

Several factors influence how much your sheet metal cut to size will spring back:

- Yield strength: Higher strength grades exhibit more springback—half-hard 301 can spring back 4-43 degrees across the same radius range where annealed 304 shows only 2-15 degrees

- Bend radius to thickness ratio: Larger ratios mean greater springback; tight bends create more permanent deformation

- Material thickness: Thicker sheets experience less springback relative to thinner material

- Grain direction: Bending perpendicular to the rolling direction typically reduces springback

The practical solution? Overbend to compensate. If your target is 90 degrees and testing shows 5 degrees of springback, program your press brake for 95 degrees. Modern CNC press brakes with active angle control systems can measure the bend in real-time and adjust automatically—a worthwhile investment for production volumes where consistency matters.

Avoiding Cracking in Tight Radius Bends

Sounds complex? It gets more critical as bend radii tighten. Push stainless steel beyond its forming limits and the outer fibers crack—a defect you cannot repair without scrapping the part entirely.

According to PEKO Precision, the minimum bend radius depends directly on material type and thickness. For stainless steel, the general guideline is a minimum inside bend radius of 1.5 to 2 times the material thickness. Attempt a tighter radius and you're gambling with cracks.

The steel sheet cut to size you're forming also matters by grade:

- Austenitic grades (304, 316): More ductile, tolerate tighter radii—typically 0.5t to 1t minimum for annealed material

- Ferritic grades (430): Less forgiving, require larger radii—often 1t to 2t minimum

- Work-hardened material: Requires even larger radii or annealing before forming

Grain direction critically affects cracking resistance. When possible, orient bends perpendicular to the rolling direction. Bending parallel to grain concentrates stress along existing material flow lines, dramatically increasing crack risk.

Press Brake, Roll Forming, and Stamping Considerations

Each forming process brings unique challenges with stainless steel metal strips and sheets:

Press brake forming is the most common method for custom cut steel sheet bending. Use tooling with larger radii than you'd select for mild steel. Bottoming or coining techniques—where the punch forces material completely into the die—reduce springback compared to air bending but require higher tonnage capacity.

Roll forming progressively shapes stainless steel through sequential roller stations. The gradual deformation distributes stress and can achieve complex profiles, but work hardening accumulates through each station. Plan your roller sequence to minimize total strain.

Stamping operations face the highest galling risk. The combination of high contact pressure, sliding friction, and stainless steel's tendency to cold-weld to tooling creates perfect conditions for adhesive galling. According to The Fabricator, using D2 tool steel for stainless stamping is a poor choice—the chrome content in both materials causes excessive friction and surface migration.

Common Forming Defects and Prevention Strategies

Recognizing defects early—and understanding their root causes—saves material and time:

- Orange peel texture: Rough, dimpled surface appearing on stretched areas. Prevention: Use finer-grain material; avoid excessive stretching beyond material limits

- Cracking at bend apex: Fractures on the outer bend surface. Prevention: Increase bend radius; anneal work-hardened material; bend perpendicular to grain direction

- Galling on tooling and parts: Material transfer between stainless steel and dies creating scratches and buildup. Prevention: Apply proper lubrication on both sheet surfaces; use dissimilar tooling materials like aluminum bronze; maintain adequate clearances

- Springback variation: Inconsistent final angles across production run. Prevention: Verify material consistency; use bottoming or coining; implement real-time angle measurement

- Work hardening accumulation: Material becomes increasingly difficult to form through progressive operations. Prevention: Plan operations to minimize total strain; consider intermediate annealing for complex parts

Friction is the root cause of galling. Before resorting to expensive coatings or exotic tool steels, attempt to reduce friction through proper lubrication and tooling selection.

The key insight? Stainless steel forming demands respect for the material's properties. Tooling designed for mild steel won't deliver acceptable results. Lubrication matters more. Springback compensation is mandatory, not optional. Master these fundamentals and your formed stainless components will match specifications consistently—setting the stage for successful welding operations ahead.

Welding Techniques for Stainless Steel Fabrication Success

Your stainless steel sheets are cut and formed—now the critical joining phase begins. Welding stainless steel fabrications demands techniques that carbon steel fabricators rarely consider. Why? Because the same chromium that provides corrosion resistance creates unique metallurgical challenges when heat enters the equation. Get it wrong, and you'll compromise the very properties that made you choose stainless in the first place.

Successful ss steel fabrication requires understanding how different grades respond to welding heat, which filler metals preserve corrosion resistance, and how to prevent the invisible damage that leads to premature failure. Let's examine what separates professional stainless steel sheet metal fabrication from work that merely looks acceptable.

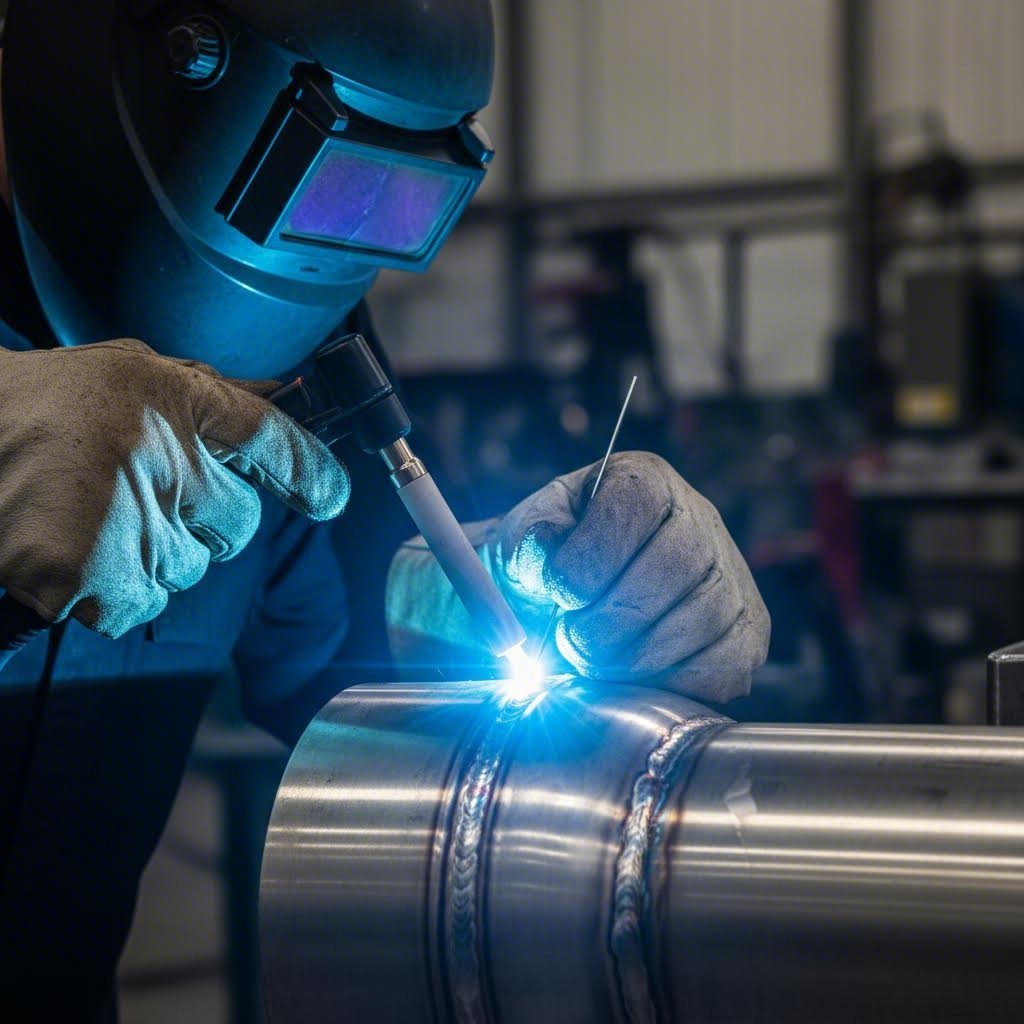

TIG Welding for Critical Stainless Applications

When precision and quality matter most, TIG (GTAW) welding remains the gold standard for stainless steel sheet fabrication. The process offers unmatched control over heat input—critical because stainless steel's low thermal conductivity concentrates heat in the weld zone, increasing distortion and metallurgical damage risks.

According to CK Worldwide's welding research, stainless steel presents three primary challenges during welding: low thermal conductivity that retains heat in the weld zone, high thermal expansion that increases distortion likelihood, and oxidation sensitivity that can contaminate welds without proper shielding.

Before striking an arc on any stainless steel metal sheets, complete these essential preparation steps:

- Clean surfaces thoroughly: Remove all dirt, grease, and oxides using a dedicated stainless steel brush or abrasive pads—never use tools previously used on carbon steel

- Verify filler rod condition: Ensure filler rods are clean and dry; moisture introduces hydrogen that causes porosity and cracking

- Set up proper shielding: Use 100% argon for most applications; consider 75% argon/25% helium mixtures for thicker stainless steel metal plates requiring better heat transfer

- Arrange back-purging equipment: For full-penetration welds, purge the reverse side with argon to prevent oxidation

- Position fixtures and clamps: Minimize distortion by restraining the workpiece before welding begins

Filler metal selection directly impacts weld performance. Match your filler to the base material for optimal strength and corrosion resistance:

- ER308L: Standard choice for 304 stainless steel—the "L" indicates low carbon content to reduce sensitization risk

- ER316L: Use for 316 base metal or when enhanced corrosion resistance is required, particularly in marine or chemical environments

- ER309L: Ideal for joining dissimilar metals, including metal stainless to carbon steel transitions

Heat control separates professional results from amateur work. Use foot pedal or fingertip controls to dynamically adjust amperage during welding. Pulsed TIG welding alternates between high and low currents, minimizing total heat input while maintaining adequate penetration—especially valuable on thin stainless steel sheet metal fabrication where burn-through risks are highest.

Preventing Sensitization and Carbide Precipitation

Here's where stainless steel welding gets tricky. When 300-series austenitic stainless steels remain too hot for too long, a damaging phenomenon called carbide precipitation occurs. Understanding this mechanism prevents corrosion failures that may not appear until months or years after fabrication.

According to Welding Tips and Tricks, stainless steels contain chromium, nickel, manganese, and small amounts of carbon. Chromium and carbon have a natural affinity for each other. When the metal is held at temperatures between 900-1600°F (480-870°C), these elements migrate toward each other and combine to form chromium carbides.

Why does this matter? Chromium carbides form preferentially at grain boundaries, depleting chromium from surrounding areas. Since chromium provides corrosion resistance, these chromium-deficient zones become vulnerable to intergranular corrosion—like termites weakening a wooden structure from within. The weld may look perfect yet fail catastrophically in service.

Prevention centers on one principle: minimize time at temperature. Practical strategies include:

- Use low-carbon grades: 304L and 316L contain maximum 0.03% carbon versus 0.08% in standard grades, reducing available carbon for carbide formation

- Control interpass temperatures: Allow welds to cool below 350°F (175°C) between passes to limit cumulative heat exposure

- Employ pulsed welding: Reduces average heat input while maintaining penetration

- Minimize weld bead size: Smaller beads mean less heat into the base material

- Sequence welds strategically: Distribute heat across the assembly rather than concentrating it in one area

Managing Distortion Through Fixturing and Sequencing

Stainless steel's high thermal expansion—about 50% greater than carbon steel—makes distortion a persistent challenge. The material expands more when heated and contracts more when cooled, creating internal stresses that pull weldments out of shape.

Effective distortion control starts before welding begins. Clamps, fixtures, and tack welds restrain movement during the thermal cycle. For critical assemblies, consider these sequencing strategies:

- Balanced welding: Alternate weld locations on opposite sides of the assembly to equalize shrinkage forces

- Back-step technique: Weld in short segments moving opposite to the overall progression direction

- Skip welding: Complete welds in non-adjacent areas, allowing cooling between passes

Allow welds to cool naturally—never quench with water or compressed air. Rapid cooling induces thermal shock that can cause stress cracking, particularly in thicker sections or highly restrained joints.

Post-Weld Passivation: Restoring Corrosion Resistance

Welding inevitably damages the protective chromium oxide layer that makes stainless steel corrosion-resistant. You'll notice heat tint—the rainbow discoloration around welds—indicating this protective film has been compromised. Without proper post-weld treatment, these areas become corrosion initiation sites.

According to TIG Brush research, passivation restores the damaged oxide layer through two mechanisms: removing free iron from the surface and enhancing chromium oxidation to form an inert protective layer.

Traditional passivation uses nitric acid or pickling paste containing hydrofluoric acid. While effective, these chemicals present significant safety hazards—exposure can cause severe burns, respiratory damage, or worse. Modern electrolytic weld cleaning systems offer safer alternatives, using electric current and specialized fluids to achieve equivalent passivation without hazardous chemical handling.

Regardless of method, passivation should occur after all welding, grinding, and mechanical finishing operations are complete. The process removes contaminants introduced during fabrication and ensures the chromium-rich surface layer reforms consistently across the entire component.

Passivation isn't about appearance—it's about preventing corrosion that begins at weld zones and propagates throughout the component. Every stainless steel weld requires post-weld treatment to restore full corrosion resistance.

The techniques covered here apply whether you're welding thin decorative panels or heavy structural components. Master heat control, prevent sensitization, manage distortion, and restore passivation—and your stainless steel fabrications will deliver the long-term performance that justifies the material's premium cost. Next, we'll examine how surface finish selection affects both appearance and functional performance.

Surface Finish Options and Their Impact on Performance

You've welded your stainless steel components beautifully—but your work isn't complete. The surface finish you select affects far more than aesthetics. It determines how easily bacteria can colonize food-contact surfaces, how aggressively corrosive environments attack your fabrication, and how much maintenance your finished product will demand over its service life.

Surface finish selection often receives less attention than cutting or welding decisions in ss sheet metal fabrication. That's a mistake. According to Ulbrich's surface finish research, the choice of finish affects corrosion resistance, electrical properties, weldability, manufacturing operations, and various economic considerations. Let's examine each option so you can match the right finish to your application requirements.

Mill Finish vs Polished Surfaces

When you receive sheet stainless steel from a supplier, it arrives with a mill finish—the baseline condition resulting from hot or cold rolling operations. Understanding this starting point helps you determine what additional finishing your application requires.

Mill finishes form the foundation for all stainless steel metal plate products and include several standard designations:

- No. 1 Finish: Hot rolled, annealed, and pickled. Dull, rough appearance with Ra values exceeding 100 microinches. Used for structural applications where appearance doesn't matter.

- No. 2D Finish: Cold rolled, annealed, and pickled. Smooth, non-reflective, dull surface ideal for deep drawing operations. Common in automotive exhaust components and hardware.

- No. 2B Finish: Cold rolled, annealed, pickled, then lightly temper-passed using polished rolls. This creates a smooth, somewhat reflective surface that serves as the general-purpose starting point for most sheets stainless applications.

Polished surfaces build upon these mill finishes through mechanical abrasion or buffing:

- #4 Brushed Finish: Created using 150-grit abrasives, producing the familiar polished stainless steel sheet metal appearance with visible directional grain lines. According to Apache Stainless, #4 finish delivers Ra values of 29-40 microinches—smooth enough for most food processing equipment while remaining economical to produce.

- #8 Mirror Finish: The most reflective standard finish, produced by polishing with successively finer abrasives and buffing. Think Chicago's famous "Bean" sculpture—that's #8 polished stainless steel metal panels creating those dramatic reflections.

- Bead Blasted Finish: Glass or ceramic beads create a uniform, non-directional satin texture with low reflectivity. Ra values typically exceed 45 microinches depending on media and process parameters.

The brushed stainless sheet finish remains popular because it hides fingerprints and minor scratches better than mirror finishes while providing adequate corrosion resistance for most environments.

How Surface Finish Affects Corrosion Performance

Here's what many fabricators overlook: smoother surfaces resist corrosion better than rough ones. The peaks and valleys in a rough surface create microscopic crevices where moisture and contaminants accumulate, initiating localized corrosion.

For food and pharmaceutical applications, surface roughness directly impacts cleanability and bacterial adhesion. The 3-A Sanitary Standards require a #4/Dairy finish with Ra values of 32 microinches or less for equipment contacting dairy products. Why? Smoother surfaces harbor fewer bacteria and clean more effectively during wash-down procedures.

| Finish Type | Ra Value (Microinches) | Typical Applications | Relative Cost |

|---|---|---|---|

| 2B Mill | 15-40 (varies by gauge) | Chemical equipment, industrial tanks, general fabrication | Low |

| #4 Brushed | 29-40 | Kitchen equipment, architectural panels, food processing | Medium |

| #4 Dairy | 18-31 | Dairy equipment, pharmaceutical vessels, clean rooms | Medium-High |

| #8 Mirror | 1-10 | Decorative panels, signage, quilted stainless steel accents | High |

| Bead Blasted | >45 | Architectural features, uniform matte appearance requirements | Medium |

| Electropolished | Up to 50% improvement | Pharmaceutical, semiconductor, surgical instruments | High |

Electropolishing: The Ultimate Surface Enhancement

When standard polishing isn't enough, electropolishing delivers both superior aesthetics and enhanced corrosion resistance. This electrochemical process dissolves surface material rather than abrading it mechanically, creating a microscopically smooth finish unachievable through conventional methods.

According to Harrison Electropolishing research, the process preferentially dissolves iron from the stainless steel surface, leaving a higher relative concentration of chromium. This improved surface forms a thicker, more uniform oxide layer with chromium-to-iron ratios greater than 1.5—significantly enhancing corrosion resistance.

The benefits extend beyond corrosion protection:

- Surface roughness improvement: Electropolishing can improve Ra values by up to 50%

- Reduced bacterial adhesion: USDA research indicates electropolished surfaces resist biofilm formation

- Deburring: The process simultaneously removes microscopic burrs from edges and features

- Passivation: Electropolishing inherently passivates the surface, eliminating the need for separate chemical treatment

For pharmaceutical equipment, semiconductor manufacturing, and surgical instruments, electropolishing represents the gold standard in stainless steel surface preparation.

Matching Finish to Application Requirements

Your finish selection should balance performance requirements against economic constraints. Consider these factors:

- Corrosion environment: Aggressive chemical exposure or marine conditions demand smoother, more corrosion-resistant finishes

- Cleanability requirements: Food-contact and pharmaceutical surfaces need finishes meeting specific Ra standards

- Aesthetic expectations: Visible architectural elements may justify premium polished finishes

- Maintenance accessibility: Surfaces difficult to clean regularly benefit from smoother finishes that resist contamination buildup

Surface finish isn't just about appearance—it's a functional specification that affects corrosion resistance, cleanability, and long-term maintenance costs.

The finish you specify ripples through your project economics. A #4 brushed stainless sheet costs more than 2B mill finish, and electropolishing adds another premium layer. But specifying inadequate finishes for demanding environments creates far greater costs through premature failure, contamination issues, or regulatory non-compliance. Understanding the full cost picture—including material costs and pricing factors—helps you make informed decisions that balance performance with budget.

Cost Factors and Pricing Considerations for SS Fabrication

You've selected your grade, planned your forming operations, and specified your finish—but do you actually know what your project will cost? Understanding the economics behind ss sheet metal fabrication prevents budget surprises and helps you make smarter material and design decisions before production begins.

Unlike carbon steel, stainless steel pricing fluctuates significantly based on commodity markets, particularly nickel and chromium. Add design complexity, tolerance requirements, and finishing specifications, and you're looking at a multi-variable equation that catches many buyers off guard. Let's break down exactly what drives fabrication costs so you can optimize your project without sacrificing quality.

Material Cost Drivers in Stainless Fabrication

When you buy stainless steel sheet, you're not just paying for iron—you're paying for the alloying elements that make it "stainless." According to Fastmarkets' 2025 analysis, nickel prices are expected to hover between $15,000–$20,000 per metric ton in 2025, supported by Indonesian mining restrictions and increased EV market demand.

Why does this matter for your project? Nickel content directly correlates with stainless steel material for sale pricing:

- 304 stainless steel: Contains 8-10% nickel, making it moderately sensitive to nickel price swings. According to Tirapid's cost analysis, raw material costs typically run $2.50-$3.50 per kilogram

- 316 stainless steel: Contains 10-14% nickel plus 2-3% molybdenum, amplifying commodity exposure. Raw material costs range $3.00-$4.00 per kilogram

- 430 ferritic: Minimal nickel content provides cost stability but limits performance

The impact is substantial. A $1,000 increase in nickel prices per ton raises 304 stainless steel prices by approximately 5% and 316 by about 7%. During 2022's market volatility, nickel surged from $16,000 to $25,000 per ton—causing 304 sheet prices to jump from $2,100 to $2,650 per ton, a 26% increase.

Chromium pricing adds another variable. A $500 increase per ton pushes 430 stainless costs up roughly 4%. Supply uncertainty from major producers like South Africa creates periodic price spikes that propagate through the stainless steel sheets for sale market.

Steel mills also charge surcharges based on real-time alloy element prices. According to industry data, these additional costs can represent 10-20% of total material cost during volatile market periods—a significant factor often overlooked in preliminary budgeting.

How Complexity Affects Fabrication Pricing

Material costs represent only part of your total investment. Fabrication complexity—cutting intricacy, forming difficulty, welding requirements, and tolerance specifications—often exceeds material costs on complex assemblies.

Design geometry directly impacts processing time and cost. According to fabrication cost research, complex or shaped contours require detailed CNC programming and path planning that simpler geometries avoid. The result? Parts with complex shapes typically cost about 35% more to fabricate than standard rectangular profiles.

Tolerance requirements multiply costs exponentially. Standard fabrication tolerances are economical; precision tolerances demanding ±0.1mm accuracy require slower processing speeds, more inspection time, and higher rejection rates. Before specifying tight tolerances everywhere, ask yourself: which dimensions actually matter functionally?

Material thickness affects processing economics counterintuitively. For thin sheets (1-3mm), heat deformation risks require slower cutting speeds and more careful handling, potentially increasing per-square-meter processing costs by 20% compared to thicker plates. When you're comparing stainless sheet metal for sale options, factor in these processing differences.

Batch Size Economics and Prototyping Considerations

How many parts do you need? This single question dramatically shifts your cost structure.

Setup costs remain relatively fixed regardless of quantity. Programming CNC equipment, preparing fixtures, and qualifying first articles cost roughly the same whether you're making 10 parts or 1,000. Spread across larger batches, these costs become negligible per unit. On small runs, they dominate your pricing.

Prototyping costs deserve separate consideration. Initial prototypes carry disproportionate per-unit costs because:

- Engineering time for DFM review and programming isn't amortized

- Material minimums may exceed actual needs

- Quality verification requires full inspection protocols

- Rush requirements often apply to prove concepts quickly

When do prototyping investments pay off? When they prevent expensive production-run defects. A $500 prototype that reveals a forming problem before you've ordered $50,000 in stainless steel sheet metal for sale delivers enormous return on investment.

Cost Optimization Strategies Without Sacrificing Quality

Smart fabrication buyers optimize costs through design and procurement decisions—not by pressuring suppliers to cut corners. Consider these proven strategies:

- Standardize material specifications: Custom sizes increase cutting complexity and waste. Standard gauge thicknesses and sheet dimensions from stainless sheets for sale inventories reduce material premiums

- Design for manufacturing: Collaborate with fabricators early. They can identify costly features—like unnecessarily tight radii or complex weld joints—that drive costs without functional benefit

- Consolidate purchases: Larger orders justify better material pricing and amortize setup costs. If you'll need parts quarterly, consider annual purchase agreements

- Simplify surface finish requirements: Specify premium finishes only where functionally necessary. A #4 brushed finish costs significantly less than electropolishing

- Right-size tolerances: Apply precision tolerances only to critical dimensions. General tolerances on non-functional features reduce inspection time and rejection rates

- Plan for material utilization: Nested cutting patterns reduce scrap. Discuss nesting options with your fabricator when placing orders

Lead Time Factors That Impact Your Schedule

Cost and schedule intertwine tightly in stainless fabrication. Understanding lead time components helps you plan realistically—and avoid expensive expedite fees.

Material availability varies by grade and specification. Common 304 sheet stainless steel for sale typically ships from distributor inventory within days. Specialty grades, unusual thicknesses, or certified material for aerospace applications may require mill orders with 8-16 week lead times.

Fabrication queue position depends on shop loading. Well-established fabricator relationships and advance scheduling improve priority. Last-minute orders compete for available capacity—often at premium pricing.

Finishing requirements extend timelines, particularly for outsourced processes. Electropolishing, passivation certification, or specialized coatings add days or weeks depending on processor backlogs.

The practical takeaway? Early planning reduces costs and improves schedule reliability. When you're ready to buy stainless steel sheet materials and begin fabrication, lead time awareness prevents the rush charges that erode project budgets.

The cheapest stainless steel fabrication isn't always the lowest quote—it's the project completed right the first time, on schedule, without defects requiring rework.

Understanding these cost factors positions you to make informed decisions throughout your project. But what happens when things don't go according to plan? The next section addresses troubleshooting common fabrication challenges—because even well-planned projects encounter obstacles that demand practical solutions.

Troubleshooting Common SS Fabrication Challenges

Even experienced stainless steel workers encounter defects that threaten project timelines and budgets. The difference between costly rework and efficient problem-solving lies in quickly identifying root causes—and knowing exactly how to address them. Whether you're dealing with mysterious weld discoloration or forming tools that suddenly seize, this troubleshooting guide provides the practical answers you need.

Can you cut stainless steel, bend it, and weld it without ever encountering problems? Unlikely. But you can minimize defect frequency and resolve issues faster when you understand what's happening at the material level. Let's examine the most common challenges in stainless sheet metal fabrication and their proven solutions.

Diagnosing Weld Discoloration Issues

You've completed a weld and notice rainbow colors spreading from the joint—blues, purples, browns, or even black tints. What went wrong? According to Sydney Welders' research, this heat tint indicates oxide layer formation caused by excessive heat exposure and inadequate shielding gas coverage.

The discoloration itself tells a story. Light straw colors indicate minimal oxidation and acceptable heat control. Darker blues and purples suggest moderate overheating. Browns and blacks signal severe oxidation that has likely compromised corrosion resistance in the affected zone.

Root causes and solutions include:

- Insufficient shielding gas coverage: Increase gas flow rate or improve torch angle. For critical applications, implement back-purging with argon on the reverse side of full-penetration welds

- Excessive heat input: Reduce amperage, increase travel speed, or switch to pulsed welding to decrease average heat input while maintaining penetration

- Contaminated surfaces: Cross-contamination from carbon steel tools or particles promotes oxidation. Clean all surfaces with dedicated stainless steel brushes before welding

- Inconsistent technique: Varying travel speeds and arc lengths create uneven heating. Practice consistent torch manipulation to achieve uniform heat distribution

Can discoloration be removed? According to fabrication experts, mild heat tint responds to passivation treatments—acidic solutions that dissolve oxide layers and restore the protective chromium surface. Electropolishing offers another effective remedy. However, severe discoloration penetrating deep into the material may indicate irreversible damage requiring weld removal and repair.

Solving Work Hardening Problems

Your stainless steel pieces formed easily during initial operations—but now the material resists bending, cracks unexpectedly, or wears tools rapidly. You're experiencing work hardening, a phenomenon where deformation actually strengthens the material and reduces ductility.

According to machining research, work hardening occurs because stainless steel's crystalline structure reorganizes during plastic deformation. Each forming operation increases hardness and reduces remaining formability—until the material becomes too brittle for further processing.

Effective strategies to manage work hardening include:

- Optimize cutting parameters: Higher cutting speeds minimize dwell time and reduce localized work hardening at cut edges. Adjust feeds and speeds based on material grade and thickness

- Use appropriate coolants: Adequate lubrication dissipates heat and reduces friction that accelerates hardening. Water-soluble or synthetic fluids provide better cooling than oil-based alternatives

- Plan operation sequences: Perform the most demanding forming operations first, while material remains in its softest condition. Save lighter operations for later stages

- Consider intermediate annealing: For complex parts requiring multiple forming steps, heat treatment between operations can restore ductility. Solution annealing at 1900-2050°F followed by rapid cooling softens work-hardened material

- Select appropriate tooling: Carbide inserts resist wear better than high-speed steel when machining work-hardened zones. Sharp tools with proper geometry minimize additional strain

Addressing Galling in Forming Operations

Suddenly your forming dies are scratching parts, material transfers onto tooling surfaces, and components seize during assembly. This adhesive wear—called galling—is particularly problematic in stainless steel manufacturing because the material's protective oxide layer makes it susceptible when that layer is damaged under pressure.

According to Fractory's technical analysis, galling occurs when microscopic high points on contacting surfaces rub together, generating heat and friction that induces cold welding between the materials. Once started, galling spreads rapidly as raised lumps create more adhesion.

Conditions that promote galling include:

- Similar metals in contact: Steel to stainless steel contact creates higher galling risk than dissimilar material pairings

- High contact pressures: Aggressive forming operations concentrate stress at contact points

- Insufficient lubrication: Dry surfaces under sliding contact are prime galling candidates

- Surface debris: Particles trapped between surfaces act as abrasives initiating damage

Prevention strategies focus on reducing friction and separating contact surfaces:

- Apply proper lubrication: Anti-galling compounds, greases, or specialized coatings create protective barriers between mating surfaces

- Select dissimilar tooling materials: Brass, bronze, or aluminum bronze dies resist galling against stainless steel workpieces

- Control surface finish: Both very rough (>1.5µm) and very smooth (<0.25µm) surfaces gall more readily. Target intermediate roughness values

- Reduce contact pressure: Larger contact areas distribute forces and lower local stress concentrations

Fabrication Stage Troubleshooting Checklist

When defects appear, systematic diagnosis saves time. Use this checklist organized by fabrication stage:

Cutting Stage Issues:

- Rough or burred edges → Check cutting speed, replace worn consumables, verify proper assist gas pressure

- Heat discoloration at cut edges → Reduce heat input, increase cutting speed, consider waterjet for heat-sensitive applications

- Warped sheets after cutting → Implement stress-relief cuts, optimize cutting sequence to balance thermal stresses

Forming Stage Issues:

- Cracking at bend apex → Increase bend radius, orient bends perpendicular to grain, anneal work-hardened material

- Excessive springback → Increase overbend compensation, use bottoming or coining techniques, verify material certification

- Surface scratches or galling → Apply lubrication, clean tooling and workpiece surfaces, consider dissimilar die materials

- Orange peel texture → Use finer-grain material, reduce stretch percentage

Welding Stage Issues:

- Porosity in welds → Verify shielding gas flow, clean surfaces thoroughly, check filler rod condition for moisture

- Excessive distortion → Improve fixturing, implement balanced welding sequences, reduce heat input per pass

- Heat tint discoloration → Increase gas coverage, back-purge when possible, reduce amperage

- Cracking in weld or HAZ → Use low-carbon filler metals, control interpass temperature, avoid over-restraint

Quality Inspection Methods

Wondering how to cut ss sheet quality concerns before they reach customers? Inspection catches defects that visual examination misses.

Dye penetrant testing reveals surface-breaking cracks invisible to the naked eye. The process applies a colored or fluorescent dye that seeps into defects, then a developer draws the dye out to create visible indications. This non-destructive method is particularly valuable for weld inspection and formed component verification.

Passivation verification confirms that corrosion resistance has been properly restored after fabrication. Testing methods include:

- Copper sulfate testing: Detects free iron contamination that compromises passivation

- Ferroxyl testing: Identifies iron deposits through chemical reaction producing blue spots

- High-humidity exposure: Accelerated testing reveals whether passivation will protect against atmospheric corrosion

Regular monitoring throughout stainless steel manufacturing prevents defect accumulation. Catching problems at their source—rather than discovering them during final inspection—dramatically reduces scrap rates and rework costs.

The fastest path to defect-free fabrication isn't avoiding problems entirely—it's recognizing them immediately and applying proven solutions before they propagate through your production run.

Mastering troubleshooting transforms fabrication challenges from project-derailing crises into manageable corrections. But even the best internal capabilities benefit from the right fabrication partner—one with the certifications, equipment, and expertise to handle complex stainless steel projects from prototype through production.

Choosing the Right SS Sheet Metal Fabrication Partner

You've mastered the technical fundamentals—grades, cutting methods, forming techniques, and troubleshooting strategies. But here's the reality: even the most knowledgeable engineers depend on fabrication partners who can execute flawlessly. Selecting the wrong ss metal fabricators leads to missed deadlines, quality failures, and costs that spiral beyond initial quotes.

What separates exceptional fabrication partners from adequate ones? Certifications demonstrate verified capabilities. Rapid prototyping accelerates development cycles. Design for manufacturability support prevents costly redesigns. And responsive communication keeps your project on track when challenges arise. Let's examine exactly what to evaluate when choosing your stainless steel fabrication partner.

Why IATF 16949 Certification Matters for Automotive Applications

If your custom stainless steel parts are destined for automotive applications, IATF 16949 certification isn't optional—it's essential. According to Qualityze's certification analysis, IATF 16949 defines quality management system standards specifically for the automotive industry, building upon ISO 9001's foundation with additional automotive-specific requirements.

What does this certification actually verify? IATF 16949-certified fabricators have demonstrated:

- Consistent defect prevention: Systems designed to catch problems before they reach customers

- Supply chain traceability: Complete documentation from raw material through finished component

- Continuous improvement culture: Ongoing process optimization verified by third-party audits

- Customer-specific requirement compliance: Capability to meet individual automaker specifications

Why does this matter for steel and stainless fabrication? Automotive components face extreme demands—thermal cycling, vibration, corrosive environments, and safety-critical performance requirements. A chassis bracket or suspension component that fails in service creates liability exposure far exceeding the part's manufacturing cost.

For automotive projects requiring precision stainless steel components, manufacturers like Shaoyi (Ningbo) Metal Technology combine IATF 16949 certification with specialized capabilities for chassis, suspension, and structural components—demonstrating the quality systems necessary for demanding automotive supply chains.

Understanding ISO 9001 and Industry-Specific Certifications

ISO 9001 serves as the foundational quality management standard across industries. According to Quest Tech's fabricator selection guide, ISO 9001 recognition demonstrates that a company has not only met stringent quality standards but has consistently provided products and services that meet customer and regulatory requirements.

What does ISO 9001 certification tell you about a custom stainless steel products manufacturer?

- Documented processes: Fabrication procedures are written, followed, and verified

- Quality objectives: Measurable targets drive continuous improvement

- Customer focus: Systems exist to capture and address customer requirements

- Corrective action protocols: When problems occur, root causes are identified and eliminated

Beyond ISO 9001, industry-specific certifications signal specialized capabilities. AS9100 addresses aerospace requirements. FDA registration matters for medical device components. ASME certifications verify pressure vessel fabrication competency. Match certifications to your application's regulatory environment.

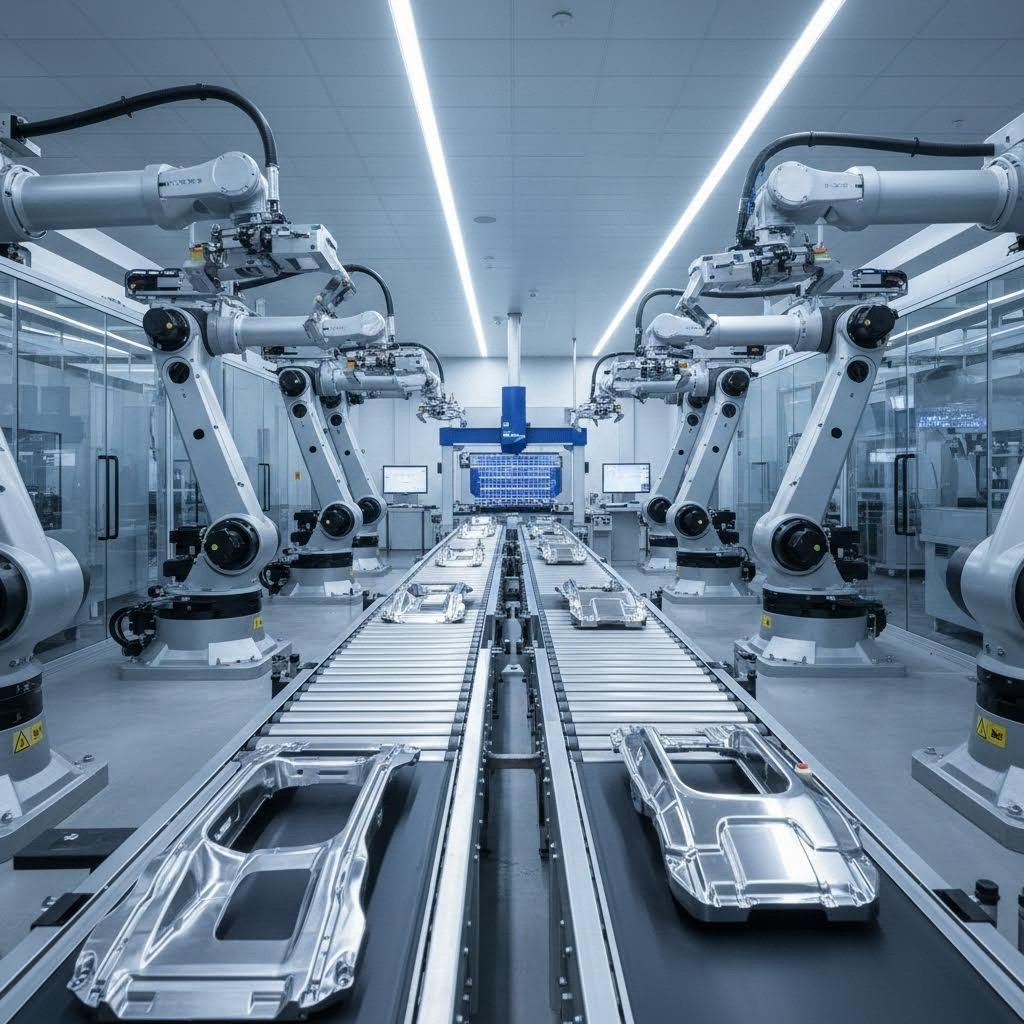

Evaluating Rapid Prototyping Capabilities

How quickly can your fabrication partner move from concept to physical prototype? In competitive markets, prototyping speed directly impacts time-to-market—and ultimately, project success.

According to Approved Sheet Metal's fabrication insights, precision sheet metal shops know the ins and outs of their machines. They understand that certain stainless steel thicknesses heat distort from welding while others hold shape, and that specific materials won't bend as expected without proper radii. This institutional knowledge accelerates prototyping when you engage early.

Effective rapid prototyping capabilities include:

- Fast quote turnaround: Leading fabricators provide detailed quotes within hours, not days. Shaoyi, for example, delivers 12-hour quote turnaround for custom cut stainless steel components—enabling faster decision-making

- Prototype-to-production timelines: Look for 5-day rapid prototyping capabilities that prove concepts before committing to production tooling

- Iterative refinement: Partners willing to collaborate through multiple prototype revisions help optimize designs efficiently

- Scalability: Ensure prototype suppliers can transition seamlessly to automated mass production when designs are validated

The Value of DFM Support in Optimizing Designs

Design for Manufacturability support transforms good designs into great ones—reducing costs, improving quality, and accelerating production timelines. But not all fabricators offer meaningful DFM collaboration.

According to fabrication research, if you want top-quality parts with a quick turnaround, understanding DFM isn't enough on its own. What you need to do is get your CAD models to a precision sheet metal shop as early as you can. Your fabricator needs flexibility to make the best decisions for your job, both in terms of materials and approach.

Meaningful DFM support includes:

- Material selection guidance: Recommendations on stainless steel custom grades that balance performance requirements with cost and formability

- Feature optimization: Identifying costly features that can be simplified without functional compromise

- Tolerance rationalization: Applying precision only where functionally necessary

- Manufacturing process recommendations: Suggesting forming sequences, welding approaches, or finishing methods that improve outcomes

Consider welding as an example where early DFM collaboration pays dividends. Welding can create complications—distortion, appearance issues, added heat sinks, and increased costs. Experienced fabricators often recommend interlocking tabs or alternative joining methods that reduce welding while improving strength. This guidance only comes from partners who engage with your design before production begins.

Comprehensive DFM support, like that offered through Shaoyi's engineering team for custom laser cut stainless steel automotive components, prevents the redesign cycles that delay production and inflate budgets.

Key Questions to Ask Potential Fabrication Partners

Before committing to any ss metal fabricators, conduct thorough due diligence. These questions reveal whether a potential partner can deliver on your project requirements:

- What certifications do you hold? Verify ISO 9001 at minimum; confirm industry-specific certifications (IATF 16949, AS9100, FDA) match your application requirements

- What is your quote turnaround time? Responsive partners provide detailed quotes within 12-24 hours for standard requests

- How quickly can you produce prototypes? Leading fabricators offer 5-day prototype capabilities for urgent development programs

- Do you provide DFM review before production? Partners invested in your success identify design improvements proactively

- What quality inspection methods do you use? CMM measurement, dye penetrant testing, passivation verification, and documented inspection protocols indicate serious quality commitment

- Can you provide customer references? Established fabricators readily share contacts from similar projects

- What is your capacity for scaling from prototype to production? Ensure automated production capabilities match anticipated volume requirements

- How do you handle material traceability? For certified applications, complete documentation from mill certificate through finished part is essential

Evaluating Financial Stability and Experience

According to fabricator selection research, financial stability is an important consideration when selecting a custom fabricator. A company with low turnover, competitive wages, and good vendor relations indicates solid financial footing and skilled labor availability.

Why does this matter for your project? Financially stable fabricators:

- Invest in modern equipment that improves quality and reduces lead times

- Maintain material inventory to respond quickly to orders

- Retain experienced personnel who understand stainless steel's fabrication challenges

- Honor commitments without cutting corners when margins tighten

Years in business, equipment age, and facility condition all provide indicators of long-term viability. A fabricator that won't complete your project—or compromises quality under financial pressure—creates far greater costs than selecting a slightly more expensive but reliable partner.

The right fabrication partner doesn't just execute your designs—they improve them, catch problems before production, and deliver consistent quality that protects your reputation with your customers.

Selecting the right ss sheet metal fabrication partner determines whether your stainless steel project succeeds or struggles. Certifications verify capability. Rapid prototyping accelerates development. DFM support optimizes designs. And responsive communication keeps complex projects on track. Invest time in partner selection upfront—the returns compound through every project you undertake together.

Frequently Asked Questions About SS Sheet Metal Fabrication

1. Is stainless steel hard to fabricate?

Yes, stainless steel presents unique fabrication challenges compared to carbon steel. Its high tensile strength makes cutting, bending, and welding more demanding. The material work-hardens rapidly during forming, exhibits 50% higher springback during bending, and requires careful heat management during welding to prevent chromium depletion. Successful fabrication requires specialized tooling, proper lubrication, and technique adjustments—but experienced fabricators with IATF 16949 certification routinely deliver precision stainless components for demanding automotive and industrial applications.

2. How much does sheet metal fabrication cost?

SS sheet metal fabrication costs vary based on material grade, complexity, and volume. Raw material costs range from $2.50-$4.00 per kilogram depending on grade (304 vs 316). Fabrication adds costs for cutting, forming, welding, and finishing—with complex geometries costing approximately 35% more than simple shapes. Tight tolerances, premium finishes like electropolishing, and small batch sizes increase per-unit costs significantly. For accurate pricing, request quotes from certified fabricators offering 12-hour turnaround times to compare options efficiently.

3. What is the price of SS sheet metal?

SS sheet metal pricing fluctuates with nickel and chromium commodity markets. Grade 304 stainless steel typically costs $2.50-$3.50 per kilogram for raw material, while 316 runs $3.00-$4.00 per kilogram due to higher nickel and molybdenum content. Steel mills add surcharges representing 10-20% of material cost during volatile market periods. Ferritic 430 grade offers lower costs but reduced corrosion resistance. Final pricing depends on thickness, sheet dimensions, surface finish, and quantity—standard sizes from distributor inventory cost less than custom specifications.

4. What is the highest paid sheet metal worker?

Sheet metal foremen typically earn the highest wages in the field, with salary ranges of $57,000-$77,000 annually. Sheet metal journeymen follow at $51,000-$64,500, while technicians earn $43,500-$61,000. Specialized stainless steel fabrication expertise—particularly TIG welding certification and experience with aerospace or pharmaceutical applications—commands premium compensation. Workers at IATF 16949-certified facilities serving automotive OEMs often receive competitive wages due to the precision and quality requirements of automotive component manufacturing.

5. How do you choose between 304 and 316 stainless steel for fabrication?

Choose 316 stainless steel when your components face marine environments, chlorinated water, or aggressive chemical exposure—the 2-3% molybdenum content provides superior pitting and crevice corrosion resistance that 304 cannot match. For general indoor applications, food processing equipment, or architectural uses without chloride exposure, 304 delivers excellent performance at lower cost. Both grades offer excellent formability and weldability, but 316's higher nickel content (10-14% vs 8-10%) increases material costs by approximately 20-30%.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —