Heat Treatment For Forged Automotive Parts: 9 Essential Points

Understanding Heat Treatment for Forged Automotive Components

Imagine a perfectly forged crankshaft—shaped under immense pressure, its grain structure aligned for strength. Yet without the right thermal processing, that same component could fail catastrophically under the demanding conditions of a high-performance engine. This is where heat treatment becomes the critical bridge between raw forged metal and automotive components you can trust.

So, what is heat treating in the context of automotive forging? Simply put, it's a controlled process of heating and cooling steel (or other metals) to transform their internal structure. This metallurgical procedure involves raising a forged part to specific temperatures, holding it there for precise durations, and then cooling it at carefully controlled rates. The result? Dramatic improvements in strength, hardness, toughness, and wear resistance—properties that modern vehicles absolutely demand.

Why Forged Automotive Parts Demand Precise Thermal Processing

Modern automotive components face extraordinary challenges. Suspension arms endure constant cyclic loading. Transmission gears experience high-contact stresses. Drive shafts must handle tremendous torque without failure. Even when forging creates an optimal grain flow and eliminates internal voids, the heat treatment process ultimately determines whether these parts can survive real-world conditions.

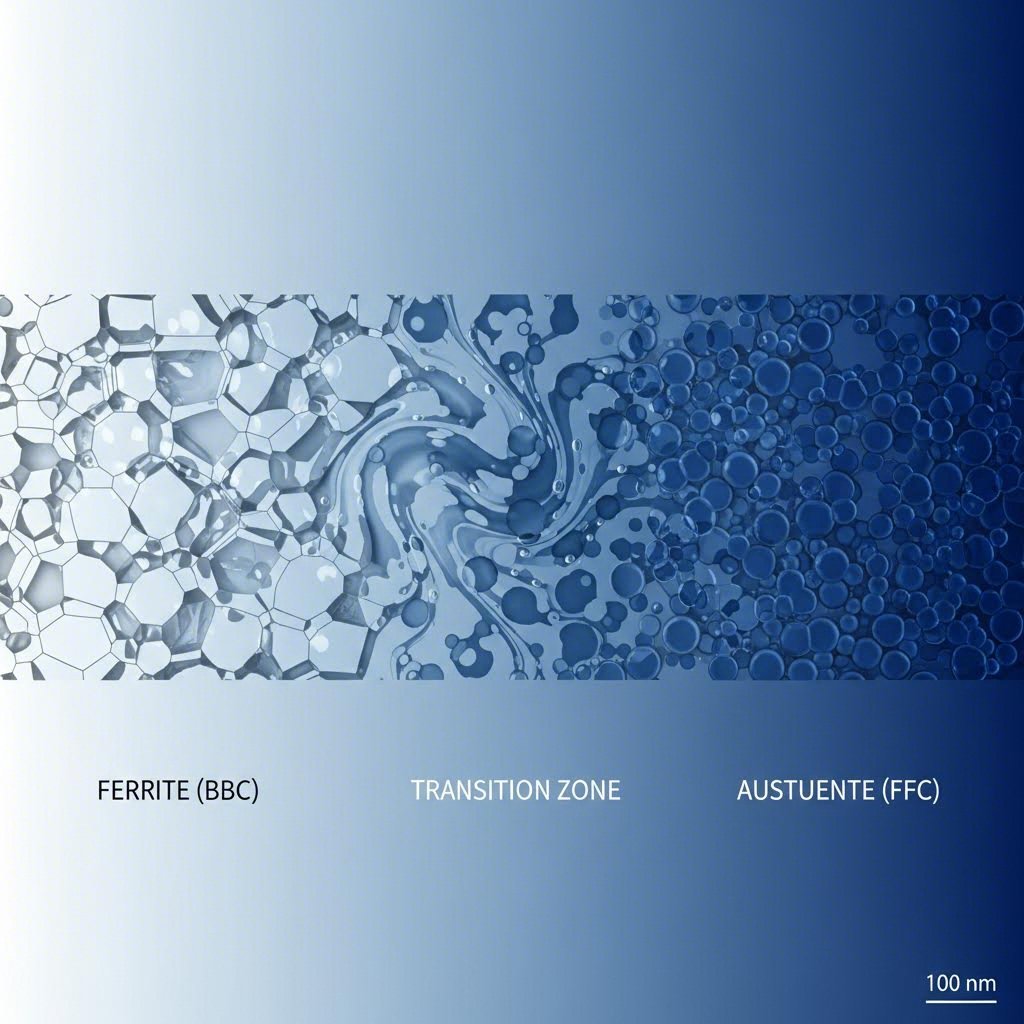

The heating and cooling steel undergoes during thermal processing triggers phase transformations at the atomic level. When you heat a steel forging above its critical temperature, its crystal structure shifts from ferrite to austenite. How you cool that part—rapidly through quenching or slowly through annealing—dictates whether you end up with hard martensite or softer, more ductile structures. This isn't just metallurgical theory; it's the practical foundation of every high-performance automotive component.

Heat treatment can determine up to 80% of a forged component's final mechanical properties, making it arguably the most influential processing step in automotive part manufacturing.

The Metallurgical Foundation of Component Performance

Understanding heat treatment helps engineers and procurement professionals specify the right processes for their applications. When you know how different thermal cycles affect material behavior, you can make informed decisions about:

- Which heat treatment process matches your component's loading conditions

- How to balance surface hardness with core toughness

- What testing and verification methods ensure consistent quality

- How material chemistry influences heat treatment parameter selection

The heat treatment process involves three fundamental variables: heating temperature, cooling rate, and quenching medium. By manipulating these factors, manufacturers can tailor the characteristics of forged components to meet exact specifications—whether that means maximizing fatigue resistance in a connecting rod or optimizing wear properties in a differential gear.

Throughout this guide, you'll discover the essential points every engineer and purchasing professional should understand about heat treatment of metals in automotive applications. From core processes like quenching and tempering to advanced surface treatments and quality verification methods, this knowledge empowers you to specify the right thermal processing for your forged automotive parts.

Core Heat Treatment Processes Explained

Now that you understand why thermal processing matters, let's explore the types of heat treating that transform forged automotive parts into reliable, high-performance components. Each heat treating process serves a distinct purpose—and knowing when to apply which method is essential for achieving optimal results.

The heating of steel triggers fundamental changes in its crystal structure. When you heat steel above approximately 723°C, its body-centered cubic ferrite structure transforms into face-centered cubic austenite. This austenite phase is the starting point for all major heat treatments. What happens next—during cooling—determines the final properties of your forged component.

Annealing and Normalizing for Workability

Before a forged part can be machined or prepared for final hardening, it often needs stress relief and improved workability. That's where annealing and normalizing come in.

Annealing is a heat treatment process that slowly heats the metal to a specific temperature, holds it there, and then cools it at a controlled—usually very slow—rate. For automotive forgings, annealing typically occurs at temperatures around 790°C to 870°C. The slow cooling, often inside the furnace itself, allows the steel's internal structure to reach near-equilibrium conditions.

What does this accomplish? According to industry research, annealing delivers several key benefits:

- Reduces hardness for easier machining

- Eliminates residual stresses from forging operations

- Improves ductility and prevents cracking

- Refines grain structure and corrects microstructural defects

Normalizing follows a similar heating pattern but with one crucial difference: the part cools in still air rather than inside the furnace. Steel is heated to 30-50°C above its critical temperature (typically around 870°C for medium-carbon steels) and held briefly before air cooling begins.

Why choose normalizing over annealing? The slightly faster cooling rate produces a finer, more uniform grain structure. This translates to improved toughness and strength compared to annealed material. Normalizing is particularly valuable for eliminating the coarse, overheated structures sometimes found in forgings and castings. When production timelines are tight and annealing would work equally well, normalizing offers a shorter cycle time.

Quenching and Tempering for Strength

When automotive components need maximum hardness and wear resistance, quenching enters the picture. This heat treating process involves heating steel above its critical temperature—typically 815°C to 870°C—and then rapidly cooling it in water, oil, or polymer solutions.

Here's what happens at the atomic level: the rapid cooling traps carbon atoms within the iron crystal structure before they can diffuse out. Instead of transforming back to ferrite and pearlite, the austenite converts directly to martensite—a very hard, needle-like microstructure. This diffusionless shear transformation is what gives quenched steel its exceptional hardness.

However, there's a trade-off. As noted in metallurgical research from TWI, martensite is inherently brittle. A fully quenched component would likely crack under the dynamic loads experienced by automotive parts. That's why the tempering metal process almost always follows quenching.

Tempering involves reheating the quenched steel to a temperature below the critical point—anywhere from 200°C to 650°C depending on desired properties—and holding it there before controlled cooling. This allows some of the trapped carbon to precipitate as fine carbides, relieving internal stresses while preserving most of the hardness gained during quenching.

The heat treat and temper combination delivers the best of both worlds:

- High hardness for wear resistance

- Improved toughness to resist impact and fatigue

- Dimensional stability during service

- Reduced risk of brittle fracture

Think of it this way: quenching creates a hard but fragile structure, while tempering balances that hardness with the ductility needed for real-world performance. The specific tempering temperature determines where that balance falls—lower temperatures preserve more hardness, while higher temperatures favor toughness.

Comparing the Four Primary Heat Treatments

Understanding when to apply each process requires knowing their distinct characteristics. The following table provides a practical comparison of these core heat treatments for automotive forging applications:

| Process Name | Temperature Range | Cooling Method | Primary Purpose | Typical Automotive Applications |

|---|---|---|---|---|

| Annealing | 790°C – 870°C | Slow furnace cooling | Stress relief, improved machinability, increased ductility | Pre-machining of complex forgings, stress relief for welded assemblies |

| Normalizing | 850°C – 900°C (30-50°C above critical) | Air cooling | Grain refinement, uniform microstructure, improved toughness | Connecting rods, crankshafts, structural forgings requiring uniform properties |

| Quenching | 815°C – 870°C | Rapid cooling in water, oil, or polymer | Maximum hardness through martensite formation | Gears, shafts, wear-critical components (always followed by tempering) |

| Tempering | 200°C – 650°C | Air cooling or controlled cooling | Reduce brittleness, balance hardness with toughness | All quenched components: transmission gears, drive shafts, suspension parts |

Notice how these types of heat treatment work together. Annealing and normalizing typically serve as intermediate steps—preparing forgings for machining or establishing a baseline microstructure. Quenching and tempering, used in sequence, deliver the final mechanical properties that automotive components demand.

The selection of the right process depends on your component's specific requirements. A suspension control arm might need normalizing for uniform toughness, while a transmission gear requires the full quench-and-temper cycle for surface hardness and fatigue resistance. Understanding these distinctions helps you specify exactly what your forged parts need—setting the stage for the advanced surface hardening treatments we'll explore next.

Surface Hardening Through Thermochemical Treatments

What if you need a component that's extremely hard on the outside but tough and ductile on the inside? Standard quenching and tempering can only take you so far. For automotive gears, camshafts, and bearings that face punishing surface contact stresses, thermochemical treatments offer a powerful solution—one that fundamentally changes the surface chemistry while preserving core toughness.

Unlike conventional heat treatments that modify the entire part, thermochemical processes treat steel by diffusing specific elements into the surface layer. This creates a hardened "case" surrounding a softer, more resilient core. The result? Components that resist wear and surface fatigue without becoming brittle throughout. Understanding how to surface harden steel through these methods is essential for anyone specifying critical automotive parts.

Carburizing for High-Contact Stress Components

Carburizing is the most widely used thermochemical surface hardening process in automotive manufacturing. The principle is straightforward: you diffuse carbon atoms into the surface of low-carbon steel at elevated temperatures, typically between 850°C and 950°C. After sufficient carbon enrichment, the part undergoes quenching to transform the carbon-rich surface into hard martensite.

Why start with low-carbon steel? Because it gives you the best of both worlds. The carbon-enriched case achieves exceptional hardness after quenching, while the low-carbon core remains tough and shock-resistant. This metal hardening process is ideal for components that experience high contact stresses—think transmission gears meshing under load or camshaft lobes riding against valve lifters.

Several carburizing methods exist, each suited to different production requirements:

- Gas Carburizing – Performed in furnace atmospheres enriched with methane or propane; the most common industrial method

- Vacuum Carburizing (Low-Pressure Carburizing) – Offers precise carbon control with minimal distortion; ideal for high-precision automotive components

- Plasma Carburizing – Uses plasma discharge for efficient carbon transfer; increasingly popular for its environmental benefits

The metal tempering process following carburizing and quenching is critical. Without tempering, the martensitic case would be too brittle for dynamic automotive applications. A carefully selected tempering temperature—usually lower than for through-hardened parts—preserves surface hardness while improving toughness.

Key benefits of carburizing for automotive applications:

- Achieves surface hardness levels exceeding 58 HRC while maintaining ductile cores

- Improves fatigue strength through beneficial compressive residual stresses

- Enables deeper case depths (typically 0.5–2.5 mm) for heavily loaded components

- Works exceptionally well with common automotive steels like 8620 and 9310

Nitriding and Carbonitriding Applications

When dimensional stability matters as much as surface hardness, nitriding offers distinct advantages. This process diffuses nitrogen into the steel surface at significantly lower temperatures—typically 500°C to 550°C—well below the transformation range. Because there's no quenching involved, hardening and tempering metal in the conventional sense doesn't apply here. Instead, hard nitride compounds form directly during the treatment.

The lower processing temperature translates to minimal distortion—a major advantage for precision automotive components that can't tolerate significant dimensional changes. Crankshafts, cylinder liners, and precision valve components often benefit from nitriding precisely because they emerge from treatment with their geometry intact.

Nitriding methods include:

- Gas Nitriding – Uses ammonia atmosphere for nitrogen diffusion; produces consistent results across complex geometries

- Plasma (Ion) Nitriding – Employs glow discharge plasma for excellent control over case depth and hardness; enables selective treatment of specific surfaces

Key benefits of nitriding:

- Produces extremely hard surfaces (often exceeding 60 HRC equivalent) without quenching

- Minimal distortion due to low processing temperatures

- Excellent corrosion resistance from the nitride layer

- Superior fatigue resistance for cyclically loaded components

Carbonitriding combines elements of both processes, diffusing both carbon and nitrogen into the steel surface. Performed at temperatures between carburizing and nitriding ranges (typically 760°C to 870°C), carbonitriding followed by quenching produces a hard case with enhanced wear resistance compared to straight carburizing. This metal heat treating method is particularly valuable for smaller automotive components like valve seats and light-duty gears where moderate case depths suffice.

Understanding Case Depth in Automotive Applications

When specifying thermochemical treatments, case depth becomes a critical parameter. But what exactly does it mean?

Effective Case Depth (ECD) refers to the depth at which hardness reaches a specified value—commonly 50 HRC for carburized parts. According to heat treatment research, this is measured by performing microhardness traverses on cross-sectioned samples and identifying where hardness drops to the target threshold.

Total Case Depth (TCD) represents the complete depth of atomic diffusion—where nitrogen or carbon has actually penetrated. For nitrided parts, TCD is typically defined as the depth where hardness measures 50 HV above core hardness.

Why does this distinction matter for automotive components? Consider a transmission gear experiencing Hertzian contact stresses. The case must be deep enough to prevent subsurface cracking where maximum shear stresses occur. Specify too shallow a case, and fatigue failures initiate beneath the hardened layer. Specify excessive depth, and you've increased processing time and cost without proportional benefit.

Typical case depths for automotive applications:

- Carburized gears and shafts: 0.5–2.5 mm effective case depth

- Nitrided precision components: 0.1–0.6 mm total case depth

- Carbonitrided small parts: 0.1–0.75 mm effective case depth

The relationship between surface treatment and core properties underscores a fundamental principle: thermochemical hardening creates a composite structure where the hard case handles surface loading while the tough core absorbs shock and prevents through-cracking. This balance—achievable only through precise control of diffusion parameters and case depth—is what makes these processes indispensable for critical automotive components.

With surface hardening methods established, the next consideration becomes matching these treatments to specific component categories—understanding which automotive parts demand carburizing versus nitriding, and how loading conditions dictate heat treatment selection.

Heat Treatment by Automotive Component Category

You've seen how different thermal processes work—but how do you know which treatment fits which automotive part? The answer lies in understanding the specific demands each component faces during service. A transmission gear endures vastly different stresses than a suspension control arm. Matching heat treating processes to these real-world conditions is where theory becomes practical application.

Let's organize this by component category, examining the loading conditions that drive heat treatment selection for each major automotive system.

Powertrain Component Heat Treatment Requirements

Powertrain components operate in the most demanding thermal and mechanical environments within any vehicle. These parts must handle extreme rotational forces, cyclic loading, and constant friction—often at elevated temperatures. The temperature for forging steel used in these components typically ranges from 1,100°C to 1,250°C, and subsequent heat treatment must transform that forged structure into something capable of surviving millions of stress cycles.

Crankshafts convert reciprocating piston motion into rotational power. They face immense bending and torsional stresses with every engine revolution. According to JSW One MSME research, heat treated steel—specifically quenched and tempered grades—is essential for improving crankshaft toughness and wear resistance. Carbon steel forging in medium-carbon grades like 4140 or 4340, followed by hardening and tempering, delivers the fatigue resistance these components demand. Surface treatments, particularly induction hardening of bearing journals, add localized wear resistance where the crankshaft interfaces with main and rod bearings.

Connecting rods transfer motion between pistons and crankshaft, experiencing intense compressive and tensile forces during each combustion cycle. Heat treated steel forgings—typically normalized or quenched and tempered—provide the strength and fatigue resistance needed. The challenge? These parts must remain lightweight while handling extreme loading. Heat treatment optimization allows engineers to achieve target properties with minimal material, balancing strength against vehicle mass.

Transmission gears represent perhaps the most demanding application for heat treated steel forging. These components experience:

- High Hertzian contact stresses at tooth surfaces

- Repeated bending loads at gear roots

- Constant sliding friction during meshing

- Shock loading during aggressive shifts

This combination requires surface hardness for wear resistance plus core toughness to prevent tooth fracture. Carburizing is the predominant choice—low-carbon alloy steels like 8620 undergo carbon enrichment followed by quenching to produce case hardnesses often exceeding 58 HRC while cores remain tough at 30-40 HRC.

Camshafts control valve timing and experience significant friction at lobe-to-lifter interfaces. Surface hardening extends their lifespan while maintaining the toughness required for dynamic operation. Induction hardening or gas nitriding of lobe surfaces is common, providing localized wear resistance without affecting core properties.

Suspension and Steering Part Specifications

Unlike powertrain components that primarily face rotational stresses, suspension and steering parts must handle complex multi-directional loads—vertical impacts from road surfaces, lateral forces during cornering, and longitudinal loads during braking and acceleration.

Control arms connect the wheel hub to the vehicle body and must absorb road shocks while maintaining precise wheel geometry. These components typically use normalized or quenched-and-tempered medium-carbon or low-alloy steels. The steel forging temp during initial forming (typically 1,150°C to 1,200°C) establishes grain flow that aligns with primary stress directions. Subsequent heat treating refines this structure for optimal toughness.

Steering knuckles are among the most critical suspension components—they support wheel hubs, connect to control arms via ball joints, and must withstand forces from steering, braking, lateral loads, and road impacts. Research published in Mobility & Vehicle Mechanics journal identifies low-alloy steel 25CrMo4, hardened at 865°C, as an optimal steering knuckle material. This chromium-molybdenum steel offers an excellent combination of:

- High flexural strength for multi-directional loading

- Good fatigue resistance for cyclic stresses

- Adequate ductility to prevent brittle fracture

- Excellent forgeability (recommended forging temperature of 1,205°C)

Interestingly, the same research shows that aluminum alloy AlZn5.5MgCu T6 also performs well when weight reduction is prioritized—demonstrating how material selection and heat treatment work together to meet specific design requirements.

Tie rods transmit steering input to the wheel assemblies and experience primarily axial and bending loads. Medium-carbon steels, typically normalized or quenched and tempered, provide the necessary strength. Surface treatments are less common here since wear occurs primarily at ball joint interfaces rather than on the rod body itself.

Drivetrain Component Requirements

Drivetrain components transmit power from the transmission to the wheels, handling high torque loads while rotating at variable speeds. These parts combine the rotational demands of powertrain elements with the durability requirements of chassis components.

Drive shafts must handle significant torsional loads while resisting fatigue from constant rotation. Heat treated steel forging in grades like 4140 or 4340, quenched and tempered to medium hardness levels, delivers the torsional strength needed. The balance point matters—shafts too hard become prone to brittle fracture, while those too soft may yield under peak torque.

CV (constant velocity) joints allow power transmission through variable angles while maintaining smooth rotation. The internal components—particularly the cage, inner race, and balls—require exceptional surface hardness with tough cores. Carburizing followed by quenching and low-temperature tempering is standard practice, achieving surface hardnesses that resist the rolling contact fatigue these components experience.

Differential gears distribute power between drive wheels while allowing speed differences during cornering. Like transmission gears, they face high contact stresses and require case-hardened surfaces. Ring and pinion sets typically undergo carburizing to develop wear-resistant tooth surfaces capable of surviving millions of meshing cycles.

Component Heat Treatment Reference Guide

The following table organizes common automotive components by their typical heat treatment requirements and target hardness specifications:

| Component Category | Typical Components | Common Heat Treatment | Target Hardness Range | Primary Selection Factors |

|---|---|---|---|---|

| Powertrain – Rotating | Crankshafts, Camshafts | Quench & Temper + Surface Hardening (Induction or Nitriding) | Core: 28-35 HRC; Journals/Lobes: 50-60 HRC | Fatigue resistance, localized wear resistance |

| Powertrain – Reciprocating | Connecting Rods | Normalizing or Quench & Temper | 28-38 HRC (through-hardened) | Fatigue strength, weight optimization |

| Powertrain – Gears | Transmission Gears | Carburizing + Quench & Temper | Surface: 58-62 HRC; Core: 30-40 HRC | Surface wear, bending fatigue, contact stress |

| Suspension | Control Arms, Knuckles | Normalizing or Quench & Temper | 25-35 HRC (through-hardened) | Toughness, multi-directional loading, fatigue |

| Steering | Tie Rods, Steering Knuckles | Quench & Temper (Cr-Mo steels) | 28-36 HRC (through-hardened) | Flexural strength, fatigue, forgeability |

| Drivetrain – Shafts | Drive Shafts, Axle Shafts | Quench & Temper | 28-38 HRC (through-hardened) | Torsional strength, fatigue resistance |

| Drivetrain – Joints | CV Joints, Universal Joints | Carburizing + Quench & Temper | Surface: 58-62 HRC; Core: 30-38 HRC | Rolling contact fatigue, wear resistance |

| Drivetrain – Gears | Differential Ring/Pinion | Carburizing + Quench & Temper | Surface: 58-63 HRC; Core: 30-42 HRC | Contact stress, tooth bending fatigue |

Notice a pattern? Components facing surface contact stresses—gears, CV joints, camshaft lobes—consistently require case hardening through carburizing or surface treatments. Parts experiencing primarily bending, torsion, or multi-directional loads—connecting rods, control arms, drive shafts—typically use through-hardening via quench and temper.

This component-by-component approach reveals why heat treating specifications must be tailored to each application. A universal approach simply doesn't work when loading conditions vary so dramatically across automotive systems. The next critical consideration? How the base material chemistry influences which heat treatment parameters will achieve these target properties—and that brings us to material-specific protocols.

Material-Specific Heat Treatment Protocols

You've seen how component categories dictate thermal processing choices—but there's another critical variable: the steel itself. Not all alloys respond identically to heating and cooling steel makes it stronger. The chemistry locked within each grade determines which heat treatment parameters will unlock optimal performance. Understanding these material-specific protocols separates good specifications from great ones.

The history of heat treatment of steel spans thousands of years, yet modern automotive applications demand precision that ancient blacksmiths could never imagine. Today's forging steels are carefully engineered alloys where every element—carbon, chromium, nickel, molybdenum—plays a defined role in determining how the material responds to thermal processing.

Alloy Steel Selection and Heat Treatment Pairing

When specifying heat treatment of steel for automotive forgings, four alloy families dominate the conversation. Each brings distinct characteristics that make it suited to particular applications—and each demands specific thermal processing parameters to achieve its potential.

4140 Steel – The General Purpose Workhorse

If you need a versatile, cost-effective alloy for medium-strength applications, 4140 is likely your starting point. According to Michlin Metals, this chromium-molybdenum steel contains 0.38–0.43% carbon with 0.80–1.10% chromium and 0.15–0.25% molybdenum. The higher carbon content compared to 4130 enables greater hardness achievement during the heat treating of steel.

What makes 4140 so popular for automotive components? Its balanced chemistry allows for:

- Direct hardening through quenching—no carburizing required

- Good depth of hardness penetration for moderate cross-sections

- Excellent response to tempering across a wide temperature range

- Reliable performance in drive shafts, axle shafts, and structural components

Common specifications include AMS 6349, AMS 6382, and MIL-S-5628 for bars and forgings. When you heat treat steel in this grade, expect austenitizing temperatures around 845°C–870°C followed by oil quenching and tempering to achieve final hardness levels typically between 28–38 HRC.

4340 Steel – When Strength Can't Be Compromised

Need superior toughness alongside high strength? 4340 steps up where 4140 reaches its limits. This nickel-chromium-molybdenum alloy shares 4140's carbon range but adds 1.65–2.00% nickel along with higher chromium (0.70–0.90%) and molybdenum (0.20–0.30%).

The nickel addition fundamentally changes how this steel responds to steel heat treatment. As ASM International research explains, hardenability—the property determining how deeply hardness penetrates during quenching—depends heavily on alloy content. The nickel in 4340 provides greater depth of hardening and additional toughness compared to 4140, making it ideal for large cross-section components where uniform properties throughout are essential.

Applications demanding 4340 include:

- Heavy-duty crankshafts and connecting rods

- Critical aerospace-automotive crossover components

- High-performance racing drivetrain parts

- Any application where failure consequences are severe

Steel heat treating parameters for 4340 typically involve austenitizing at 815°C–845°C, oil quenching, and tempering. The common specification—AMS 6415—covers bars, forgings, and tubing for demanding applications.

8620 Steel – The Carburizing Champion

When components require hard, wear-resistant surfaces with tough cores, the heat treat steel approach shifts from through-hardening to case hardening. That's where 8620 enters the picture.

This low-carbon alloy (0.18–0.23% carbon) contains chromium, nickel, and molybdenum in moderate amounts. Why the low carbon? Because carburizing will enrich the surface layer with carbon during processing—starting with low carbon ensures the core remains tough and ductile after treatment.

The steel heat treating sequence for 8620 differs fundamentally from direct-hardening grades:

- Carburizing at 850°C–950°C to diffuse carbon into the surface

- Quenching to transform the carbon-rich case to hard martensite

- Low-temperature tempering to relieve stresses without sacrificing surface hardness

Transmission gears, differential components, and CV joint elements commonly use 8620 because they need surface hardness exceeding 58 HRC while maintaining core toughness around 30–40 HRC. The AMS 6274 specification covers this workhorse for automotive and aerospace carburizing applications.

9310 Steel – Aerospace-Grade Performance for Critical Automotive

Some automotive applications—particularly in high-performance and motorsport contexts—demand the exceptional properties typically reserved for aerospace. 9310 delivers exactly that.

With just 0.07–0.13% carbon combined with high nickel content (3.00–3.50%), 9310 represents the premium tier of carburizing steels. Industry sources note that the high nickel content adds toughness to both the carburized case and the core compared to 8620—critical for components facing extreme loads or shock conditions.

Why choose 9310 over 8620? Consider these factors:

- Superior fatigue resistance for high-cycle applications

- Enhanced impact toughness at the core

- Better performance under extreme operating conditions

- Meeting aerospace-derived specifications like AMS 6260 and MIL-S-7393

The trade-off? Cost. 9310 commands a premium over 8620, so its use is typically reserved for applications where performance absolutely justifies the investment—racing transmissions, high-end performance vehicles, or safety-critical components.

Matching Material Chemistry to Thermal Processing

Understanding why different alloys require different heat treatment parameters comes down to three fundamental factors: carbon content, alloying elements, and hardenability.

Carbon content directly determines maximum achievable hardness. Higher carbon means harder martensite after quenching. However, as ASM research confirms, the maximum hardness depends solely on carbon content—but achieving that hardness throughout a component requires sufficient hardenability.

Alloying elements—chromium, molybdenum, nickel—don't significantly increase maximum hardness. Instead, they slow the transformation kinetics during cooling, allowing martensite to form even with slower quench rates. This translates to deeper hardening and more uniform properties through thicker cross-sections.

Hardenability, as defined by the ASM Handbook, is the property that determines the depth and distribution of hardness induced by quenching. Steels with deep hardness penetration have high hardenability; those with shallow penetration have low hardenability. For automotive components with varying cross-sections, selecting a steel with appropriate hardenability ensures consistent properties throughout.

The Forging-Heat Treatment Connection

Here's a relationship that few specifications address: the forging temperature directly influences subsequent heat treatment requirements. According to industry research, utilizing residual forging heat for heat treatment offers significant advantages—saving energy, shortening processing cycles, and potentially improving properties.

When forgings cool from their forming temperature (typically 1,100°C–1,250°C), the microstructure that develops depends on cooling rate. Rapid cooling might produce bainite or martensite; slow cooling yields ferrite and pearlite. This starting microstructure affects how the material responds to subsequent thermal processing.

The research notes that residual heat quenching—where forgings are quenched directly while their temperature remains above the critical point—followed by tempering can yield higher strength and hardness compared to conventional treatments. The coarser grain structure also improves machinability, an often-overlooked benefit.

For carburizing grades like 8620 and 9310, isothermal normalizing using residual forging heat is particularly effective. Parts are rapidly cooled from forging temperature to an isothermal holding range (typically 550°C–680°C) chosen based on the pearlite transformation curve, then air cooled. This process achieves proper hardness, avoids undesirable bainite, and saves approximately 150 kWh per ton in energy costs.

Key Considerations by Alloy Family

When specifying heat treatment for forged automotive components, use these guidelines for each major alloy family:

For 4140 (General Purpose Applications):

- Austenitize at 845°C–870°C for complete transformation

- Oil quench for balanced cooling rate—water quenching risks cracking

- Temper based on target hardness: lower temperatures (200°C–400°C) for higher hardness, higher temperatures (500°C–650°C) for greater toughness

- Consider normalizing before final heat treatment for complex shapes

- Verify hardenability is adequate for your component's cross-section

For 4340 (High-Strength Applications):

- Austenitize at 815°C–845°C—slightly lower than 4140 due to higher alloy content

- Oil quench is standard; air cooling may suffice for thin sections due to high hardenability

- Double tempering may be specified for critical applications to ensure stress relief

- Expect higher strength and toughness at equivalent hardness compared to 4140

- Ideal for components where cross-sections exceed 4140's hardenability limits

For 8620 (Carburizing Applications):

- Carburize at 850°C–950°C depending on desired case depth and cycle time

- Control carbon potential carefully—typically 0.80–1.00% for surface carbon

- Quench from carburizing temperature or after reheating to 815°C–845°C

- Temper at 150°C–200°C to relieve stresses while preserving case hardness

- Specify effective case depth based on component loading—typically 0.5–2.0 mm for gears

For 9310 (Premium/Aerospace-Grade Applications):

- Carburize similar to 8620, but expect enhanced core toughness from high nickel content

- Stricter process control typically required—follows aerospace-derived specifications

- Often requires sub-zero treatment to transform retained austenite

- Verify compliance with AMS 6260 or equivalent for full aerospace traceability

- Reserve for applications where 8620's properties are genuinely insufficient

With material-specific protocols established, the next critical question becomes: how do you verify that heat treatment actually achieved the intended results? That brings us to quality control and testing methods—the essential verification step that ensures your forged components will perform as specified.

Quality Control and Testing for Heat Treated Forgings

You've specified the right material, selected the appropriate thermal process, and your forged components have completed their heat treatment cycle. But how do you know the treatment actually worked? Without rigorous verification, even the most carefully planned heat treat process remains an assumption rather than a guarantee. Quality control bridges this gap—transforming thermal processing from a hopeful procedure into a certified result.

According to industry research from Grupo TTT, heat treatment represents a "special process" in manufacturing—one where the final mechanical properties cannot be verified through simple inspection of the finished part. A heat treated metal component might look identical whether it achieved target hardness or not. This reality makes systematic testing and documentation essential for automotive applications where failures can have serious consequences.

Hardness Testing and Verification Methods

Hardness testing is the most common method for verifying metal heat treatment effectiveness. But which testing method fits your application? The answer depends on material type, treatment process, and the specific information you need.

Rockwell Testing is the workhorse of heat treatment verification. As Paulo's metallurgical research explains, this method works by applying loads through either a tungsten carbide ball or a spheroconical diamond indenter. First, a light "minor" load (typically 3 or 5 kgf) zeros the testing machine. Then a heavier "major" load (15 to 150 kgf depending on material) is applied and held before release. The downward distance traveled by the indenter determines hardness.

Common Rockwell scales for automotive components include:

- Rockwell C (HRC) – Uses diamond indenter with 150 kgf major load; standard for hardened steels

- Rockwell B (HRB) – Uses ball indenter with 100 kgf major load; suited for softer steels and non-ferrous metals

- Superficial Rockwell – Uses lighter loads for thin sections or case-hardened surfaces

Brinell Testing applies relatively high loads through a 10mm tungsten carbide ball—typically 3,000 kgf for steel. Unlike Rockwell testing, Brinell measures the diameter of the indentation rather than its depth. Why choose Brinell? The larger indentation provides a more representative average hardness, making this method ideal for castings and forgings that may have rough surfaces or slight chemical variations across their structure.

Microhardness Testing (Vickers and Knoop) applies considerably lighter loads using precisely cut diamonds. These tests excel at measuring hardness in small, localized regions—exactly what you need when verifying case depth on carburized or nitrided components. Heating metal through thermochemical processes creates hardness gradients from surface to core, and microhardness traverses reveal whether those gradients meet specification.

One critical note: when specifying microhardness testing, always identify the method (Vickers or Knoop) and the test load. As Paulo's research emphasizes, too-light loads can produce falsely high readings, while too-heavy loads may punch through a thin case entirely. While 304 steel hardness testing follows similar principles, automotive-grade alloy steels require careful load selection based on expected hardness levels and case depths.

Microstructure Analysis for Quality Assurance

Hardness numbers tell part of the story—but they don't reveal what's happening at the microstructural level. According to quality control research, microscopic examination of metallographic structure provides detailed information about phase distribution and characteristics that hardness testing alone cannot capture.

Why does microstructure matter? Consider a quenched and tempered component that achieves target hardness. If the martensite wasn't properly tempered, residual stresses could lead to brittle fracture under service loads. If excessive retained austenite remains, dimensional instability may develop over time. Metallographic analysis confirms whether intended transformations actually occurred and detects problems like:

- Excessive grain growth from overheating

- Incomplete transformation structures

- Decarburization at surfaces

- Unwanted phases or inclusions

For surface treatments like carburizing or induction hardening, verifying case depth requires cutting representative samples and measuring hardness at various depths or observing microstructural changes under microscopy. Since this destroys the test piece, automotive manufacturers typically process representative samples under identical conditions to the production lot.

The Complete Quality Verification Sequence

Effective quality control spans the entire heat treatment workflow—not just final inspection. Based on CQI-9 Heat Treat System Assessment requirements, a comprehensive verification sequence includes:

- Incoming Material Inspection – Verify material chemistry and certifications match specifications; confirm material identification and traceability

- Pre-Treatment Verification – Check part geometry, surface condition, and cleanliness; ensure proper loading patterns for uniform heating

- In-Process Monitoring – Track temperature uniformity, atmosphere composition, and timing throughout the thermal cycle using calibrated instruments

- Post-Treatment Visual Inspection – Detect surface defects such as cracks, warping, or discoloration indicating processing issues

- Hardness Testing – Verify surface and core hardness meet specifications using appropriate test methods

- Case Depth Verification – For surface-hardened parts, confirm effective case depth through microhardness traverses

- Microstructure Analysis – Examine metallographic samples to confirm proper phase transformations

- Documentation and Certification – Complete all traceability records linking parts to specific heat treatment lots, equipment, and parameters

This structured approach prevents common automotive component failures—fatigue cracking from improper tempering, wear failures from insufficient surface hardness, and brittle fracture from undetected transformation problems. In automotive supply chains governed by IATF 16949, this documentation becomes essential evidence that special processes met requirements.

With quality verification methods established, the next consideration becomes understanding which industry standards and certifications govern these practices—and how compliance reduces risk throughout the automotive supply chain.

Industry Standards and Certification Requirements

Quality testing verifies that individual components meet specifications—but how do you ensure consistent results across thousands of parts, multiple production lots, and global supply chains? That's where industry standards and certifications enter the picture. These frameworks transform heat treatment processes from isolated procedures into systematically controlled operations that OEMs can trust.

For automotive suppliers, certification isn't optional. Major OEMs require compliance with specific standards before approving suppliers for production programs. Understanding these requirements helps you evaluate potential partners and ensures your own operations meet industry expectations.

IATF 16949 and Automotive Quality Standards

IATF 16949 serves as the foundational quality management standard for automotive suppliers worldwide. But here's what many overlook: this standard specifically addresses "special processes" like industrial heat treating through supplementary requirements.

According to Automotive Quality Solutions, the AIAG (Automotive Industry Action Group) created CQI-9—the Heat Treat System Assessment—to help organizations identify gaps and implement corrective actions in their thermal processing operations. This heat treatment procedure manual supplements IATF 16949 section 4.3.2 covering customer-specific requirements.

Major OEMs including Stellantis, Ford, and GM reference CQI-9 in their supplier requirements. The standard mandates annual self-assessments conducted by appropriately certified internal lead auditors. What does compliance involve?

- Process Control Documentation – Written procedures for each heat treatment processes type, including temperature parameters, timing, and atmosphere specifications

- Equipment Qualification – Temperature uniformity surveys, pyrometry certification per AMS2750, and documented calibration schedules

- Traceability Systems – Linking every component to its specific heat treatment lot, equipment used, and processing parameters

- Continuous Improvement – Using FMEA, SPC, and capability analysis to prevent defects and optimize processes

Conducting a heat treatment system assessment provides a structured approach to managing thermal processes, fostering continuous improvement, and preventing defects while reducing scrap costs throughout the supply chain.

Meeting OEM Heat Treatment Specifications

Beyond baseline IATF 16949 compliance, individual OEMs impose customer-specific requirements for heat treatment steel processes. As Alloy Heat Treatment notes, modern heat treating operations must adhere to multiple standards simultaneously—including AMS2750 for furnace control, AIAG CQI-9 for process management, and applicable ISO, DIN, and ASTM specifications for testing and material verification.

What does this mean practically? Certified manufacturers maintain:

- Documented Process Recipes – Each component type has defined parameters that cannot be changed without formal engineering approval

- Statistical Process Control – Key variables are monitored continuously, with defined control limits triggering investigation when exceeded

- Laboratory Accreditation – Testing facilities hold ISO/IEC 17025 certification or equivalent, ensuring measurement accuracy

- Supply Chain Documentation – Material certificates, processing records, and test results trace back through every tier

The relationship between certification and component qualification is direct. Before a forged part enters mass production for an automotive program, it must pass Production Part Approval Process (PPAP) requirements—including evidence that all special processes like heat treatment are properly controlled. Without valid CQI-9 assessments and documented process capability, component qualification stalls.

For engineers and procurement professionals, this certification framework reduces supply chain risk significantly. When you source from IATF 16949-certified suppliers with documented CQI-9 compliance, you're not simply trusting a supplier's claims—you're relying on systematically audited processes that major OEMs have validated. This foundation of certified quality becomes especially important when selecting heat treatment partners and specifying processes for your specific applications.

Selecting the Right Heat Treatment Partner

You understand the processes, know the material protocols, and recognize which certifications matter. Now comes the practical challenge: how do you actually select a heat treatment partner and specify requirements that translate into consistently excellent components? This decision-making process—from initial design specifications through supplier qualification—determines whether your forged automotive parts meet expectations or fall short.

Whether you're an engineer finalizing component drawings or a procurement professional evaluating potential suppliers, the workflow follows predictable stages. Getting each stage right prevents costly rework, qualification delays, and the supply chain headaches that arise when specifications don't match capabilities.

Specifying Heat Treatment in Component Drawings

Clear specifications prevent confusion. Ambiguous callouts lead to misinterpretation, rejected parts, and finger-pointing between engineering and manufacturing. According to NASA's Process Specification PRC-2001, engineering drawings should explicitly state the heat treat process, final temper condition, and applicable specification. For example:

- For quench and temper: "QUENCH AND TEMPER TO 160-180 KSI PER [SPECIFICATION]"

- For case hardening: "CARBURIZE AND HARDEN TO [CASE DEPTH] EFFECTIVE CASE DEPTH, [SURFACE HARDNESS] HRC MIN"

- For stress relief: "STRESS RELIEVE AT [TEMPERATURE] FOR [DURATION] AFTER WELDING"

Notice what these callouts include: the specific heat and treatment process, measurable acceptance criteria, and reference to governing specifications. This level of detail eliminates guesswork during the heat treat process.

Common specification mistakes to avoid:

- Specifying hardness without process – Stating "55-60 HRC" without indicating whether this applies to surface or core, or which treatment achieves it

- Omitting case depth requirements – For carburized parts, both effective case depth and surface hardness must be defined

- Ignoring test location – NASA specifications emphasize that when hardness tests must occur on finished parts, the test location should be chosen to avoid functionality impact

- Missing material condition – Failing to specify whether incoming material should be annealed, normalized, or in another condition before processing

For general metal heat treating applications, these principles apply universally. However, aerospace heat treating specifications—often referenced for high-performance automotive components—add requirements for process documentation, pyrometry certification, and traceability that go beyond typical automotive callouts.

Evaluating Heat Treatment Capabilities

Specification clarity is only half the equation. Your supplier must actually deliver what you've specified. According to industry research on evaluating forging suppliers, three capability areas deserve close examination.

Equipment and Facilities

High-quality suppliers possess in-house heat treatment facilities or established partnerships with reputable providers. Look for:

- Controlled atmosphere furnaces for preventing decarburization

- Quenching systems matched to your material requirements

- Tempering ovens with documented temperature uniformity

- Carburizing or nitriding capabilities if surface treatments are required

As full-service forging research emphasizes, integrated suppliers who manage forging and thermal processing under one roof deliver better quality control, reduced lead times, and potentially lower overall costs compared to fragmented supply chains.

Quality Systems and Certifications

IATF 16949 certification is the baseline for automotive suppliers. Beyond this foundation, verify:

- Current CQI-9 self-assessment with documented corrective actions

- AMS2750-compliant pyrometry and furnace calibration

- Accredited laboratory capabilities for hardness and metallographic testing

- Complete traceability systems linking parts to processing records

Technical Expertise

Advanced heat treaters employ metallurgists and process engineers who understand how material chemistry, component geometry, and thermal parameters interact. This expertise becomes invaluable when optimizing processes for new components or troubleshooting unexpected results.

Balancing Cost, Lead Time, and Quality

Every procurement decision involves trade-offs. Here's how to navigate them intelligently:

| Priority | Considerations | Potential Trade-offs |

|---|---|---|

| Lowest Cost | High-volume batching, standard processes, offshore sourcing | Longer lead times, less flexibility, potential communication challenges |

| Fastest Lead Time | Integrated suppliers, dedicated capacity, regional proximity | Premium pricing, minimum order requirements |

| Highest Quality | Extensive testing, aerospace-grade controls, advanced equipment | Higher cost per part, longer qualification processes |

The sweet spot often lies with integrated forging suppliers who combine hot forging with in-house heat treatment capabilities. This consolidation eliminates transportation between facilities, reduces handling damage risk, and enables tighter process control.

For example, Shaoyi (Ningbo) Metal Technology exemplifies this integrated approach—combining precision hot forging with comprehensive thermal processing under IATF 16949 certification. Their capability to deliver components like suspension arms and drive shafts from rapid prototyping in as little as 10 days through high-volume production demonstrates how vertical integration accelerates timelines without sacrificing quality. Their location near Ningbo Port further streamlines global logistics for international programs.

When evaluating potential partners, request evidence of heat treatment applications similar to your requirements. Ask for capability studies showing process control on comparable components. Verify that their documented procedures match your specification requirements—and that they have the technical depth to solve problems when they arise.

With partner selection complete, the final consideration becomes forward-looking: how will emerging technologies shape heat treatment specifications, and what action steps should you take to optimize your forged component requirements?

Optimizing Your Forged Component Specifications

You've journeyed through the fundamentals of thermal processing, explored material-specific protocols, and learned how to evaluate potential partners. Now the question becomes: what's next? The heat treatment landscape continues evolving rapidly, with emerging technologies reshaping how manufacturers strengthen metal with heat and verify results. Understanding these trends—and taking concrete action—positions you to specify forged automotive components that meet tomorrow's demands, not just today's requirements.

Emerging Technologies in Thermal Processing

The thermal processing industry stands at what Heat Treat Today describes as a pivotal crossroads. Advances in industrial furnace technology, energy efficiency, and sustainable operations are transforming how materials are hardened, strengthened, and perfected. Several key developments deserve attention as you plan future specifications.

Digitization and Industry 4.0 Integration

Modern heat treating operations increasingly rely on smart furnaces equipped with sensors that communicate operating data in real time. These systems enable continuous monitoring and fine-tuning throughout the heating stage and cooling cycles. According to industry analysis, trends in temperature curves or burner parameters can provide early indication that maintenance is required—allowing operators to achieve interruption-free production through predictive maintenance rather than reactive repairs.

Digital twins now simulate furnace behavior and facilitate parameter optimization without interrupting real-time operation. This virtual modeling reduces trial-and-error approaches that waste material and energy. For engineers specifying heat treatment, this means suppliers with advanced digital controls can offer tighter process windows and more consistent results.

Energy Efficiency and Sustainability

With increasing energy costs and strict climate targets, how do you heat treat steel while minimizing environmental impact? Several measures have emerged:

- Advanced insulation materials minimize heat loss, significantly reducing specific energy demand per processed piece

- Waste heat recovery using high-temperature heat pumps or ORC systems captures energy that would otherwise escape

- Electrification offers high process efficiency and emissions reductions, though challenges remain for high-temperature processes

- Hydrogen as fuel is being investigated for decarbonization in industries currently using natural gas

McKinsey & Company estimates the global waste heat potential that can be exploited at least 3,100 TWh annually—representing potential savings of up to $164 billion per year if fully utilized. Progressive heat treatment suppliers are integrating recuperators, regenerative burners, and heat exchangers as standard equipment.

Advanced Process Controls

The first AI-based optimization systems are being implemented to thermally strengthen metal in real time. These systems learn from process data and adapt parameters—furnace atmosphere, power control, heating and cooling rates—automatically to reduce energy consumption and throughput time. Quenching—the process of rapidly cooling heated steel—is becoming increasingly precise through automated monitoring of quench delay, temperature, and agitation.

Carbonitriding of bearing steel has experienced somewhat of a renaissance, as industry research notes, facilitating higher levels of power density and temperature resistance. Modular heat treatment processes—combining nitriding and low-pressure carburizing—adapt more flexibly to different workpieces.

Taking Action on Your Heat Treatment Requirements

Theory becomes valuable only when translated into action. Whether you're specifying components for a new vehicle program or optimizing existing supply chains, these practical steps guide your path forward.

Assess Your Current Specifications

Review existing component drawings and purchase orders. Do they clearly communicate heat treatment requirements? Ambiguous callouts create interpretation problems. Ensure specifications include:

- Specific heat treatment process (not just target hardness)

- Measurable acceptance criteria for surface and core properties

- Reference to governing industry specifications

- Case depth requirements where applicable

- Test locations and methods

Evaluate Supply Chain Capabilities

Audit current and potential suppliers against the certification and capability requirements covered in this guide. Integrated suppliers who heat treat metal in-house offer quality advantages over fragmented supply chains. Verify IATF 16949 certification, CQI-9 compliance, and technical depth to support your specific applications.

Consider Total Value

The lowest piece price rarely represents the lowest total cost. Factor in qualification timelines, reject rates, communication efficiency, and logistics when evaluating partners. Suppliers with rapid prototyping capabilities accelerate development cycles—getting you to market faster.

Key Considerations Checklist

Use this concise reference when specifying heat treatment for forged automotive parts:

- Material selection: Match alloy chemistry to intended heat treatment—through-hardening grades (4140, 4340) versus carburizing grades (8620, 9310)

- Process selection: Align thermal processing with component loading conditions—surface hardening for contact stress, through-hardening for toughness

- Specification clarity: Include process type, target properties, test methods, and governing standards on all drawings

- Case depth requirements: For surface-hardened components, specify effective case depth based on stress analysis

- Quality verification: Define hardness testing methods, microstructure requirements, and documentation expectations

- Supplier certification: Require IATF 16949 and CQI-9 compliance as baseline qualification criteria

- Equipment capabilities: Verify furnace types, atmosphere control, and quenching systems match your requirements

- Traceability systems: Ensure complete documentation linking parts to specific heat treatment lots and parameters

- Technical support: Confirm access to metallurgical expertise for process optimization and problem resolution

- Lead time and flexibility: Evaluate prototyping speed and production scalability for your program timeline

Your Path Forward

Heat treatment for forged automotive parts represents both science and craft—where metallurgical principles meet practical manufacturing expertise. The nine essential points covered in this guide equip you to make informed decisions, specify requirements precisely, and select partners capable of delivering components that perform under demanding conditions.

For manufacturers seeking to streamline procurement with a globally compliant partner, suppliers like Shaoyi Metal Technology offer engineering support from prototyping through mass production. Their rigorous quality control ensures components meet exact specifications, while integrated forging and heat treatment capabilities under one roof eliminate supply chain complexity. Explore their comprehensive automotive forging capabilities to see how precision hot forging combined with advanced thermal processing delivers the performance your applications demand.

The technology continues advancing. The standards keep evolving. But the fundamental principle remains constant: properly specified and executed heat treatment transforms forged metal into automotive components worthy of the vehicles—and the people—they serve.

Frequently Asked Questions About Heat Treatment for Forged Automotive Parts

1. What is the heat treatment of forged parts?

Heat treatment of forged parts involves controlled heating and cooling cycles that transform the metallurgical structure of components after forging. Common processes include annealing for stress relief and improved machinability, normalizing for grain refinement, quenching for maximum hardness through martensite formation, and tempering to balance hardness with toughness. Many forged automotive parts undergo multiple sequential treatments—for example, annealing followed by quenching and tempering after machining—to achieve optimal mechanical properties for demanding applications like transmission gears, crankshafts, and suspension components.

2. What are the 4 types of heat treating processes?

The four primary heat treating processes for forged automotive components are annealing (slow cooling from 790-870°C for stress relief and improved machinability), normalizing (air cooling from 850-900°C for grain refinement and uniform microstructure), quenching (rapid cooling in water, oil, or polymer from 815-870°C for maximum hardness), and tempering (reheating to 200-650°C after quenching to reduce brittleness while preserving strength). Each process serves distinct purposes, and they often work in combination—quenching and tempering together deliver the high hardness and toughness that automotive gears and shafts require.

3. What metals cannot be heat treated?

Pure metals like iron, aluminum, copper, and nickel cannot be hardened through conventional heat treatment because they lack the alloying elements needed to lock harder crystalline structures in place. Heat treatment effectiveness depends on carbon content and alloying elements that enable phase transformations during heating and cooling. For automotive forgings, alloy steels like 4140, 4340, 8620, and 9310 are specifically engineered with carbon, chromium, nickel, and molybdenum to respond predictably to thermal processing, achieving the hardness, toughness, and wear resistance that vehicle components demand.

4. How does heat treatment affect automotive component performance?

Heat treatment can determine up to 80% of a forged automotive component's final mechanical properties. Proper thermal processing improves fatigue resistance for cyclically loaded parts like connecting rods, enhances surface hardness for wear-critical components like transmission gears, and optimizes toughness for impact-resistant suspension parts. Without appropriate heat treatment, even perfectly forged components cannot meet modern vehicle performance requirements. The process also creates beneficial compressive residual stresses that extend fatigue life, making it essential for safety-critical automotive applications.

5. What certifications should heat treatment suppliers have for automotive parts?

Automotive heat treatment suppliers should hold IATF 16949 certification as the foundational quality management standard, plus compliance with CQI-9 (Heat Treat System Assessment) mandated by major OEMs including Stellantis, Ford, and GM. Additional requirements include AMS2750-compliant pyrometry for furnace calibration, ISO/IEC 17025 accredited testing laboratories, and documented traceability systems linking every component to specific processing parameters. Suppliers like Shaoyi Metal Technology maintain these certifications while offering integrated forging and heat treatment capabilities, ensuring consistent quality from prototyping through mass production.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —