Automotive Die Hardness: A Technical Specification Guide

TL;DR

Automotive die material hardness is a critical specification, typically requiring tool steels to be hardened to between 58 and 64 HRC. This level is essential to withstand the extreme working loads of forming modern materials like Advanced High-Strength Steels (AHSS). Achieving the correct hardness ensures the die has sufficient wear resistance to prevent premature failure while retaining enough toughness to avoid chipping or cracking, directly impacting production efficiency and part quality.

Understanding Why Hardness is Critical for Automotive Dies

Material hardness is formally defined as a material's ability to resist localized plastic deformation, such as scratching or indentation. In the context of automotive die manufacturing, this property is paramount. Dies are subjected to immense, repetitive forces as they shape sheet metal into complex automotive components. If a die's material is too soft, it will deform, scratch, or wear out quickly, leading to inconsistent part quality and costly production downtime. The need for precise hardness has become even more acute with the widespread adoption of Advanced High-Strength Steels (AHSS) in vehicle manufacturing to improve safety and reduce weight.

The primary challenge stems from the superior properties of AHSS, which can exert working loads up to four times higher than those of conventional mild steel. These advanced materials also exhibit significant work hardening, meaning they become stronger and harder as they are formed. This places extraordinary stress on the die surfaces. A die without adequate hardness will quickly succumb to abrasive and adhesive wear, where microscopic particles are torn from the tool surface, leading to scratches (galling) on the parts and rapid degradation of the die itself. Therefore, a high surface hardness is the first line of defense against these failure modes.

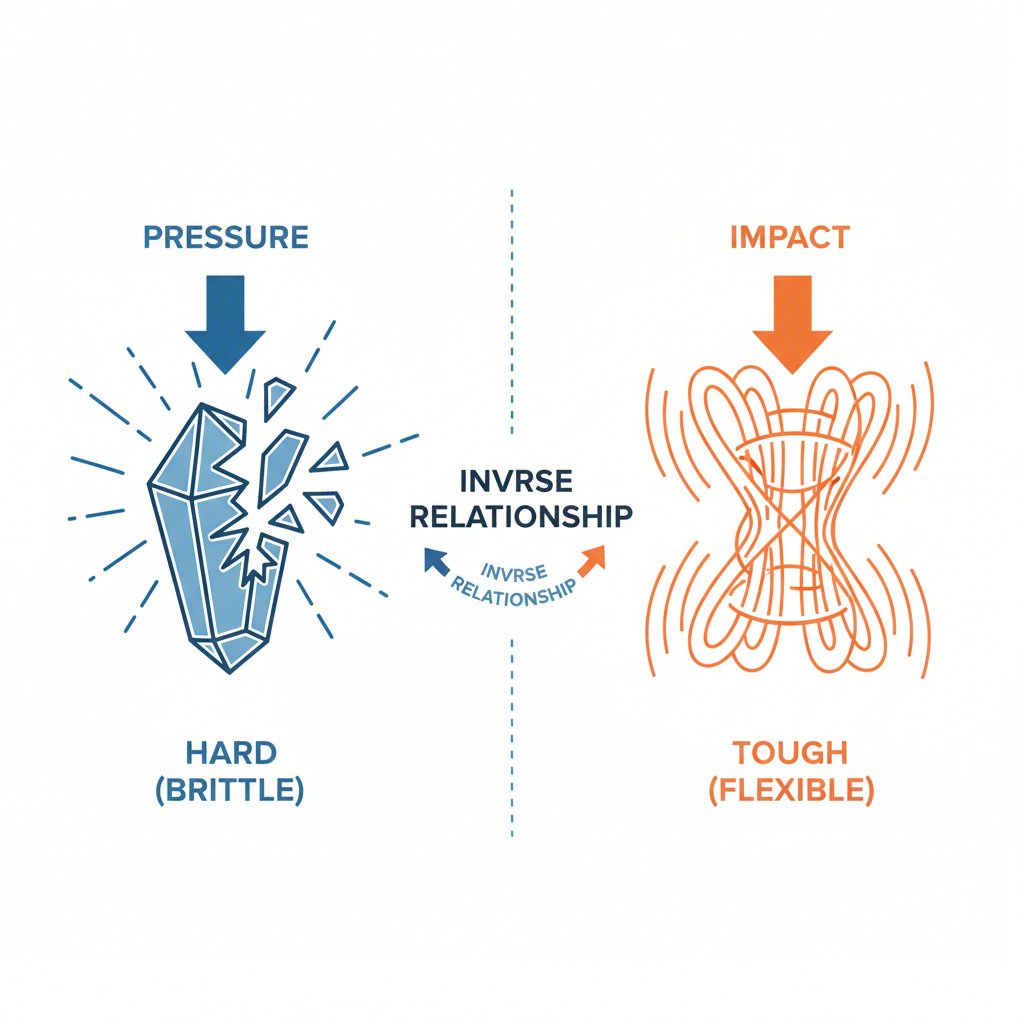

However, hardness does not exist in a vacuum. It shares a critical, inverse relationship with toughness—the material's ability to absorb energy and resist fracturing. As a material's hardness is increased, its brittleness typically increases as well. A die that is excessively hard may be highly resistant to wear but could chip or crack under the shock loads of the stamping operation. This trade-off is the central challenge in selecting die materials. The goal is to find a material and heat treatment process that yields a hardness level high enough for wear resistance but retains sufficient toughness to prevent catastrophic failure. This balance is essential for creating durable, reliable, and cost-effective tooling.

Common Materials for Automotive Dies and Their Hardness Specifications

The selection of materials for automotive stamping dies is a precise science, revolving around high-quality tool steels and specific grades of cast iron that offer the necessary combination of hardness, wear resistance, and toughness. These materials are engineered to shape sheet metal accurately over millions of cycles. For high-wear components and cutting edges, tool steels are the primary choice, while cast iron is often used for the larger, structural bodies of the dies due to its stability and cost-effectiveness.

Tool steels are special alloys containing elements like chromium, molybdenum, and vanadium, which allow them to be heat-treated to very high hardness levels. For instance, D-Series tool steels are known for their excellent wear resistance due to high carbon and chromium content. Cast irons, particularly ductile cast iron, provide a robust and vibration-dampening base for the die assembly, offering a good balance of performance and manufacturability. Selecting the right material from this list is a complex process requiring deep expertise. Companies specializing in custom tooling, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., leverage advanced simulations to match the ideal material and hardness to specific manufacturing needs, from rapid prototyping to mass production.

To provide a clear reference, the table below summarizes common materials used in automotive dies, their typical working hardness, and primary applications. The hardness values, measured on the Rockwell C scale (HRC), are achieved through carefully controlled heat treatment processes.

| Material Grade | Typical Hardness Range (HRC) | Primary Application & Properties |

|---|---|---|

| D2 / 1.2379 | 55–62 HRC | High-wear cutting and forming dies. Excellent abrasion resistance but moderate toughness. Used for medium-strength materials. |

| D3 / 1.2080 | 58–64 HRC | High-carbon, high-chromium steel with exceptional wear resistance. Good dimensional stability after heat treatment. |

| H13 | 44–48 HRC | Hot-work applications like die casting. Offers good toughness and resistance to thermal fatigue. Less wear-resistant than D-series steels. |

| A2 | 58–60 HRC | Air-hardening steel with a good balance of wear resistance and toughness. Versatile choice for many die components. |

| High-Speed Steel (e.g., 1.3343 HSS) | 63–65 HRC | Superior hardness and wear resistance, especially for thick or high-strength sheet materials. |

| Powder Metallurgy (PM) Steels | 58–64 HRC | Homogeneous structure provides very high toughness and wear resistance. Used for heavy-load dies forming high-strength materials. |

| Ductile Cast Iron | Variable (lower than tool steel) | Used for large die bodies and bases. Good strength, machinability, and vibration damping. |

Key Factors Influencing Hardness Selection

There is no universal hardness value that fits all automotive die applications. The optimal hardness is determined by a careful analysis of several interconnected factors. Selecting the correct hardness specification requires a holistic understanding of the entire manufacturing process, from the raw material being formed to the specific function of the die. An incorrect choice can lead to premature tool failure, poor part quality, and increased operational costs.

The most significant factors that influence the required hardness include:

- Workpiece Material: The strength and thickness of the sheet metal being formed are the primary determinants. Forming soft aluminum alloys for a die-cast part requires a different die hardness than stamping high-strength, abrasive AHSS for a structural body component. As a rule, harder and thicker workpiece materials demand higher die hardness to resist wear.

- Application Type: The nature of the operation dictates the required balance between hardness and toughness. For example, a cutting or trimming die requires a very hard edge (**HRC 60–65**) to maintain sharpness and prevent chipping, as detailed in guides on blade hardness selection. In contrast, a deep-drawing die might prioritize toughness to withstand high impact forces without cracking, potentially using a slightly lower hardness.

- Production Volume: For high-volume production runs, wear resistance is paramount to minimize downtime for die maintenance. Therefore, a higher hardness, often supplemented with surface coatings like PVD (Physical Vapor Deposition), is specified to maximize the tool's lifespan. For low-volume or prototype runs, a less wear-resistant (and less costly) material might be acceptable.

Ultimately, the decision involves a trade-off analysis. Maximizing wear resistance often comes at the cost of toughness. The table below illustrates this fundamental compromise:

| Focus on Wear Resistance (Higher HRC) | Focus on Toughness (Moderate HRC) |

|---|---|

| Pros: Longer tool life, better for abrasive materials (e.g., AHSS), maintains sharp cutting edges. | Pros: Higher resistance to chipping and cracking, better for high-impact operations, more forgiving of slight misalignments. |

| Cons: More brittle, higher risk of catastrophic failure from cracking, less resistant to shock loads. | Cons: Wears faster, requires more frequent maintenance, edges can dull more quickly. |

Engineers must weigh these factors to specify a hardness that provides the most reliable and cost-effective performance for the intended application. This often involves selecting a robust base material and then applying surface treatments or coatings to enhance wear resistance in critical areas without making the entire tool brittle.

Frequently Asked Questions

1. What is the hardness of die steel?

The hardness of die steel varies significantly based on its composition and heat treatment but typically falls within a specific range for automotive applications. For cold-work tool steels like D2, the working hardness is generally between 55 and 62 HRC, while for D3 it is between 58 and 64 HRC. This high hardness provides the necessary wear resistance for cutting and forming sheet metal. Hot-work steels like H13, used in die casting, have a lower hardness, usually around 44-48 HRC, to improve toughness and resist heat-related fatigue.

2. What is the best material for a die?

There is no single "best" material for all dies; the optimal choice depends on the application. For high wear resistance in stamping dies, high-carbon, high-chromium tool steels like D2 are a classic choice. For applications requiring higher toughness and resistance to chipping, shock-resistant steels like S7 or tough powder metallurgy (PM) steels are superior. For large die bodies, ductile cast iron is often preferred for its cost-effectiveness and stability. The best material balances performance requirements—wear, toughness, and cost—against the specific demands of the manufacturing process.

3. What is the hardness of D3 material?

D3 tool steel, also known as 1.2080, is a high-carbon, high-chromium tool steel known for its exceptional wear resistance. After proper heat treatment, D3 steel can achieve a hardness in the range of 58-64 HRC. This makes it highly suitable for cutting and forming dies where longevity and resistance to abrasive wear are the primary requirements.

4. What is the hardness range of H13 steel?

H13 is a versatile chromium-molybdenum hot-work tool steel. Its hardness is typically lower than cold-work steels to provide the toughness needed for high-temperature applications. For die casting dies, the usual hardness range is 44 to 48 HRC. In applications requiring greater shock resistance, it may be tempered to a lower hardness of 40 to 44 HRC. This balance makes it resistant to thermal fatigue and cracking in demanding environments like die casting.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —