How to Identify a Stamped Steel Control Arm in Minutes

TL;DR

To identify a stamped steel control arm, start with a simple magnet test. If a magnet sticks to the arm, it's made of either steel or cast iron, which successfully rules out aluminum. Next, perform a visual inspection: a stamped steel arm will have a smooth, often painted surface with a visible welded seam where the metal was joined. In contrast, a cast iron arm has a rough, textured finish and a distinct ridge from the casting mold.

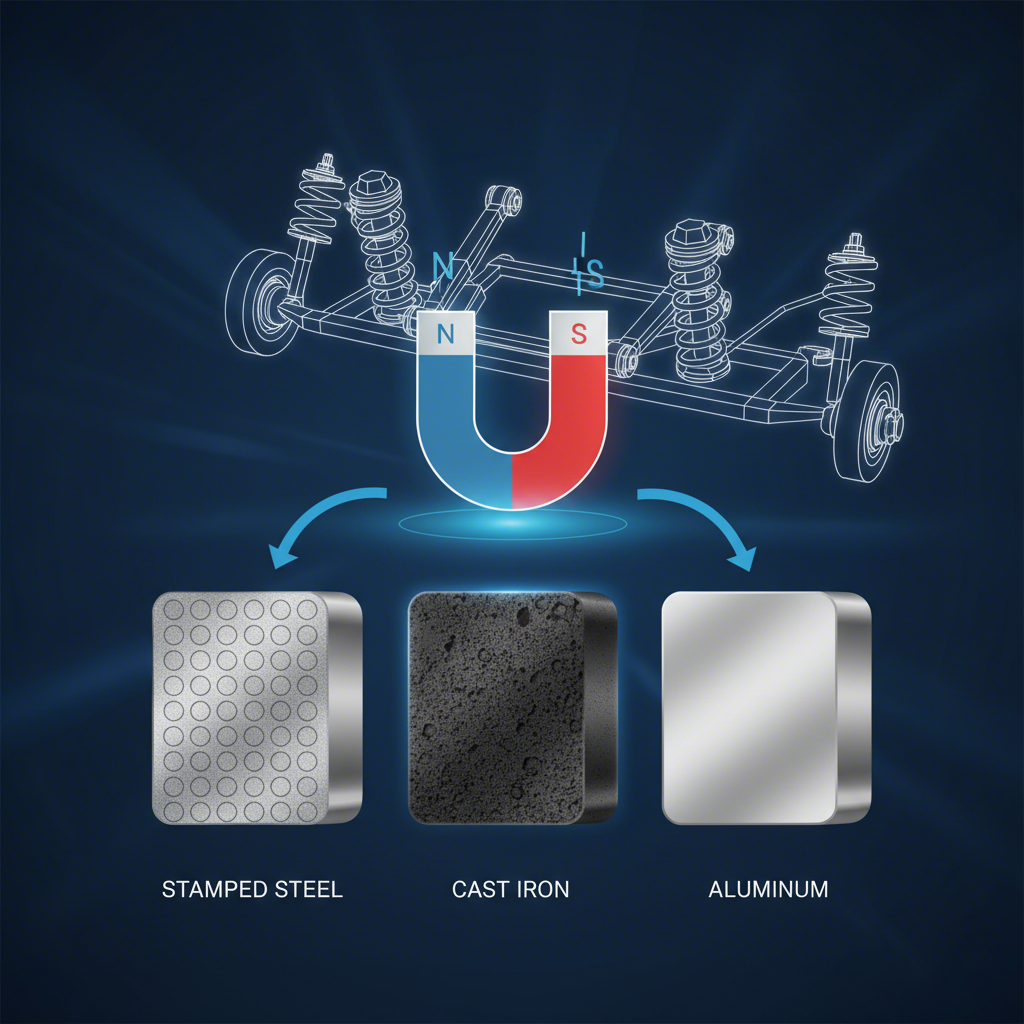

The Magnet Test: Your First Step for Material Identification

The quickest and most reliable first step to identify your control arm's material is the magnet test. This simple diagnostic tool works because of the fundamental properties of the metals used in suspension components. Steel and iron are ferrous metals, meaning they contain iron and are magnetic. Aluminum, on the other hand, is non-ferrous and will not attract a magnet.

The process is straightforward and requires no special equipment. First, ensure the control arm is relatively clean, as a thick layer of dirt or grime could interfere with the test. Take any common magnet and place it against the surface of the control arm. If the magnet adheres firmly, you can confidently conclude that the arm is made of either stamped steel or cast iron. If there is no magnetic pull at all, you have an aluminum control arm.

This method is widely recommended by parts manufacturers for its simplicity and accuracy in making the initial distinction. For example, experts at MOOG Parts suggest this as the primary method to differentiate steel from aluminum. However, it's crucial to understand the limitation of this test. While it definitively separates aluminum from the others, it cannot tell you whether you have stamped steel or cast iron. For that, you must proceed to a visual inspection.

Visual Inspection: Key Differences Between Stamped Steel, Cast, and Forged Arms

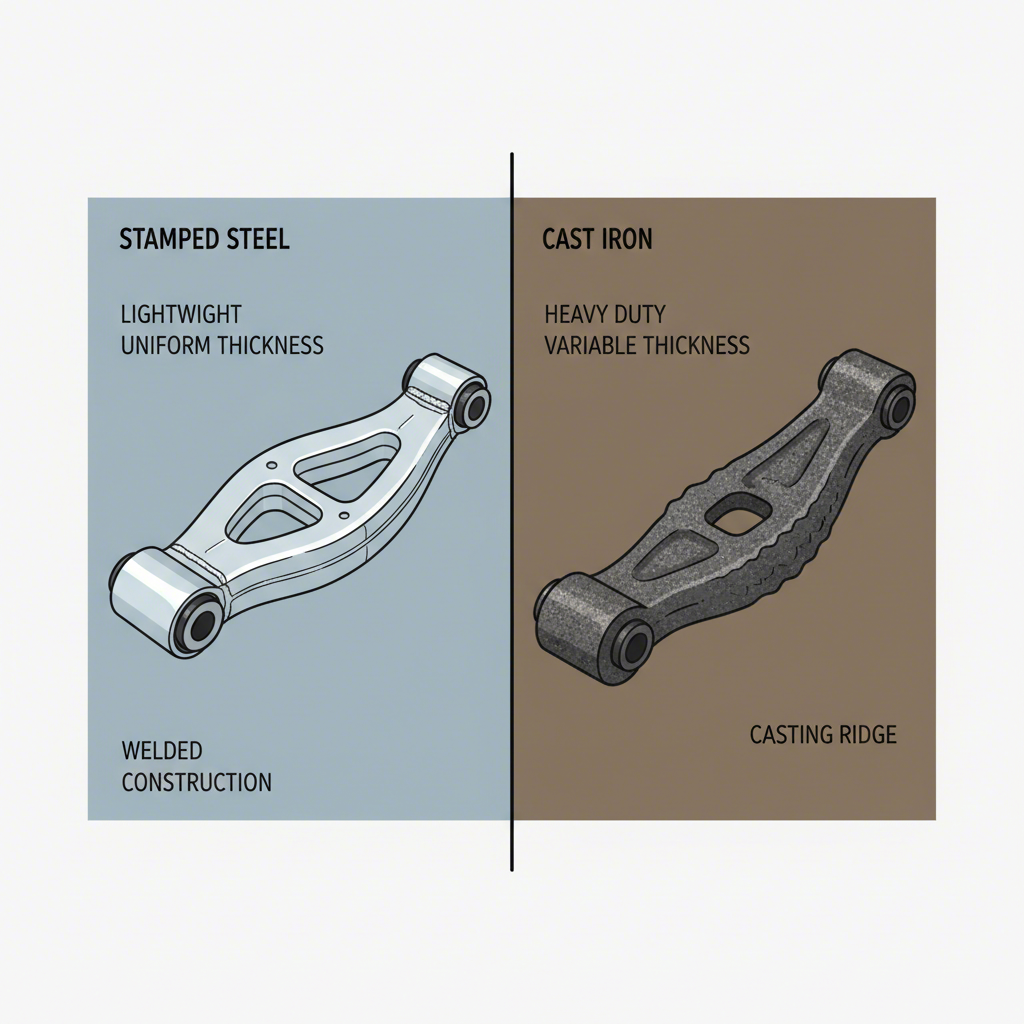

After confirming your control arm is magnetic, a close visual examination will reveal its specific type. Stamped steel, cast iron, and forged steel arms each have unique physical characteristics that result from their distinct manufacturing processes. Understanding what to look for is the key to a positive identification.

Stamped steel control arms are fabricated from sheets of high-strength steel that are cut and pressed into shape, then welded together. This process gives them a characteristic appearance. According to guidance from Maxtrac Suspension, you should look for a smooth surface, often with a glossy black painted finish. The most telling feature is a clean, visible welded seam running along the edges where the pieces of steel were joined. This construction method allows for precise, lightweight, and strong components, which is why it's a staple in modern vehicle production. For automotive manufacturers seeking the utmost precision in this area, companies like Shaoyi (Ningbo) Metal Technology Co., Ltd. specialize in the advanced metal stamping processes that produce these reliable parts. You can learn more about their capabilities at their website, https://www.shao-yi.com/auto-stamping-parts/.

Cast iron or cast steel arms are made by pouring molten metal into a mold. This results in a completely different look. These arms will have a rough, textured surface, similar to a cast iron skillet. You will also typically find a thin ridge or line, known as a casting seam, where the two halves of the mold met. Forged arms, while also made of steel, are formed under extreme pressure, which aligns the metal's grain structure for superior strength. They often have a rougher appearance than stamped steel but may not have the prominent casting seam of a cast part.

To simplify these distinctions, here is a quick comparison table:

| Feature | Stamped Steel | Cast Iron / Cast Steel | Forged Aluminum |

|---|---|---|---|

| Magnetic? | Yes | Yes | No |

| Surface Finish | Smooth, often painted black | Rough, textured | Raw silver color, textured |

| Key Visual Feature | Visible welded seam | Casting ridge or seam line | Parting line, non-magnetic |

Beyond the Arm: Using Your Vehicle's Model and Year as a Guide

While physical inspection is the most definitive method, your vehicle's model and year can provide strong contextual clues about which control arms it likely has. Manufacturers often switch materials during a production run for reasons like design updates, cost adjustments, or part availability. This is particularly true for high-volume vehicles like pickup trucks.

For example, owners of certain General Motors trucks should pay close attention to the production year. According to information from BDS Suspension, there was significant variation in 2014-2018 GM 1500 trucks. As a general rule, models from 2014 to early 2016 could have been equipped with any of the three types: stamped steel, cast steel, or aluminum. However, from 2016 to 2018, most of these trucks were built with aluminum control arms.

This kind of model-specific information can help you form an educated guess before you even look under the vehicle. It's especially useful when ordering parts online, as it can help narrow down your options. However, because exceptions and mid-year changes are always possible, you should always treat this information as a guide, not a guarantee. The most reliable approach is to use this knowledge in combination with the magnet test and a thorough visual inspection to ensure you have the correct identification.

Frequently Asked Questions

1. How do I tell if I have stamped steel control arms?

The process involves two steps. First, confirm the material is steel by using a magnet; if it sticks, it's either steel or cast iron. Second, visually inspect the arm. A stamped steel control arm will have a characteristically smooth surface and a clear welded seam along its edges, distinguishing it from the rough, ridged surface of a cast iron arm.

2. How do I tell what kind of control arms I have?

Start by placing a magnet on the control arm. If it doesn't stick, you have an aluminum arm. If it does stick, you have either stamped steel or cast steel. To tell those apart, look at the surface: a smooth finish with a welded seam indicates stamped steel, while a rough, textured finish with a casting ridge indicates cast steel.

3. What is the difference between cast iron and stamped steel control arms?

The primary difference lies in their manufacturing process and appearance. Stamped steel arms are made by pressing and welding sheets of metal, resulting in a smooth, hollow, and relatively lightweight part with visible welds. Cast iron arms are made by pouring molten iron into a mold, creating a solid, heavier part with a rough, textured surface and a casting seam.

4. What is the difference between stamped and forged control arms?

While both can be made of steel, the manufacturing method creates a key difference in strength. Stamped arms are bent and welded into shape. Forged arms are created by heating a piece of steel and pressing it into a die under extreme pressure. This forging process aligns the internal grain of the metal, making forged arms exceptionally strong and resistant to fatigue compared to stamped or cast alternatives.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —