Stamped Steel Control Arms on Lowered Trucks: An Essential Upgrade?

TL;DR

Factory-installed stamped steel control arms are often inadequate for lowered vehicles. Lowering your car or truck alters its suspension geometry, and stock arms typically cannot compensate for these changes. Upgrading to specialized aftermarket control arms—such as tubular or forged designs—is often necessary to correct alignment angles like camber and caster, which prevents uneven tire wear, improves handling, and ensures a safer ride.

Understanding Control Arms for Lowered Vehicles

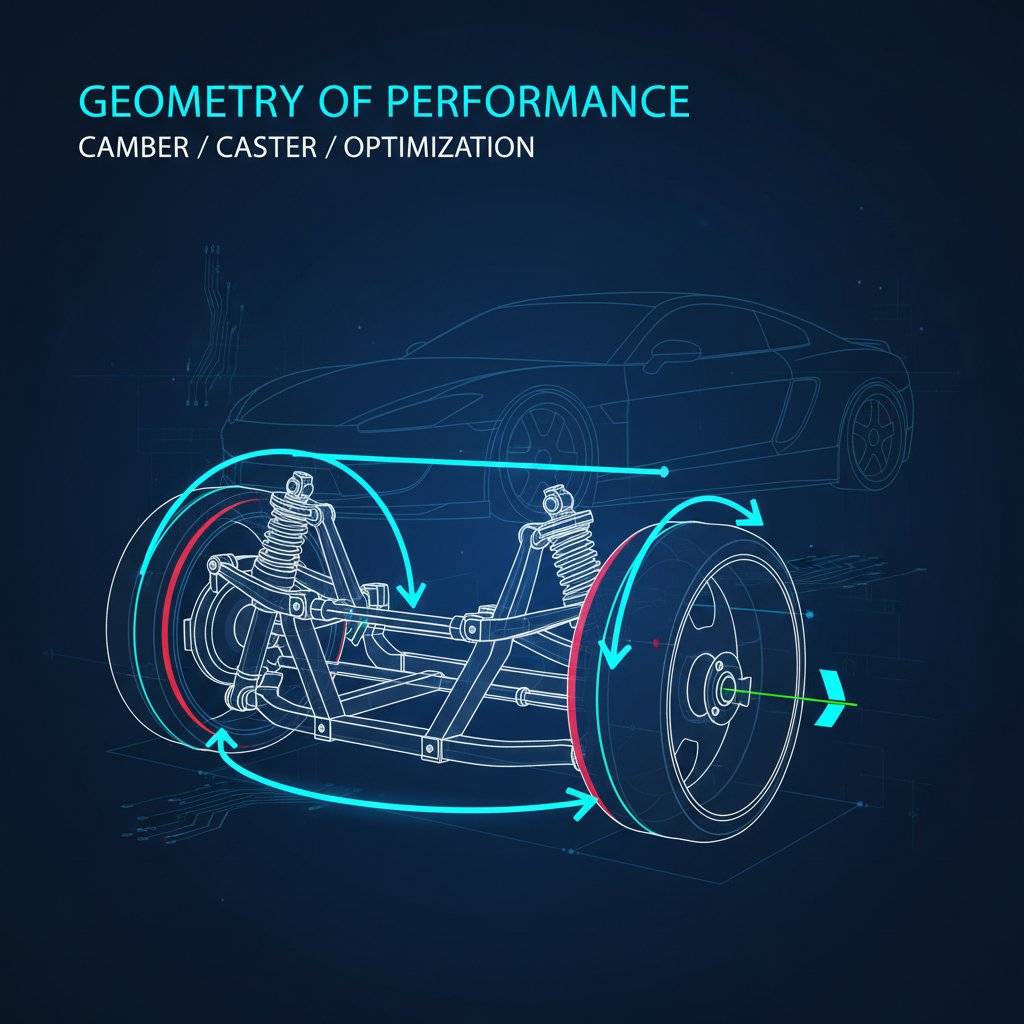

Control arms are a critical pivot point in your vehicle's suspension system, connecting the chassis to the steering knuckle or axle. They allow the wheels to move up and down in a controlled manner while keeping them aligned with the road. In a standard vehicle, the factory-installed arms, which are often made from stamped steel, are engineered precisely for the stock ride height. However, when you lower the suspension, this finely tuned balance is disrupted.

The primary issue is a change in suspension geometry. Lowering a vehicle typically causes the tops of the wheels to tilt inward, a condition known as negative camber. While a small amount of negative camber can improve cornering grip, excessive amounts lead to poor straight-line stability and rapid wear on the inner edge of your tires. This is where aftermarket control arms make a significant difference. As explained by suspension specialists like BDS Suspension, upgraded control arms are specifically designed with corrected ball joint angles and adjusted lengths to restore proper camber and caster alignment on modified vehicles.

Using stock stamped steel arms on a lowered vehicle can lead to several problems, including poor handling, a wandering or unstable feeling at speed, and costly premature tire replacement. Upgrading to arms designed for your new ride height provides tangible benefits that go beyond just aesthetics.

- Corrected Suspension Geometry: The primary benefit is restoring proper camber and caster angles, ensuring your tires make optimal contact with the road for better grip and even wear.

- Improved Handling and Stability: With corrected alignment, your vehicle will feel more stable, predictable, and responsive, especially during cornering and at highway speeds.

- Increased Strength and Durability: Many aftermarket arms are built from stronger materials like tubular or forged steel, offering greater resilience against bending and stress compared to OEM stamped parts.

- Enhanced Adjustability: Some performance control arms offer adjustability, allowing for fine-tuning of alignment settings to suit specific driving styles or track conditions.

Stamped Steel vs. Tubular vs. Forged: A Material & Design Comparison

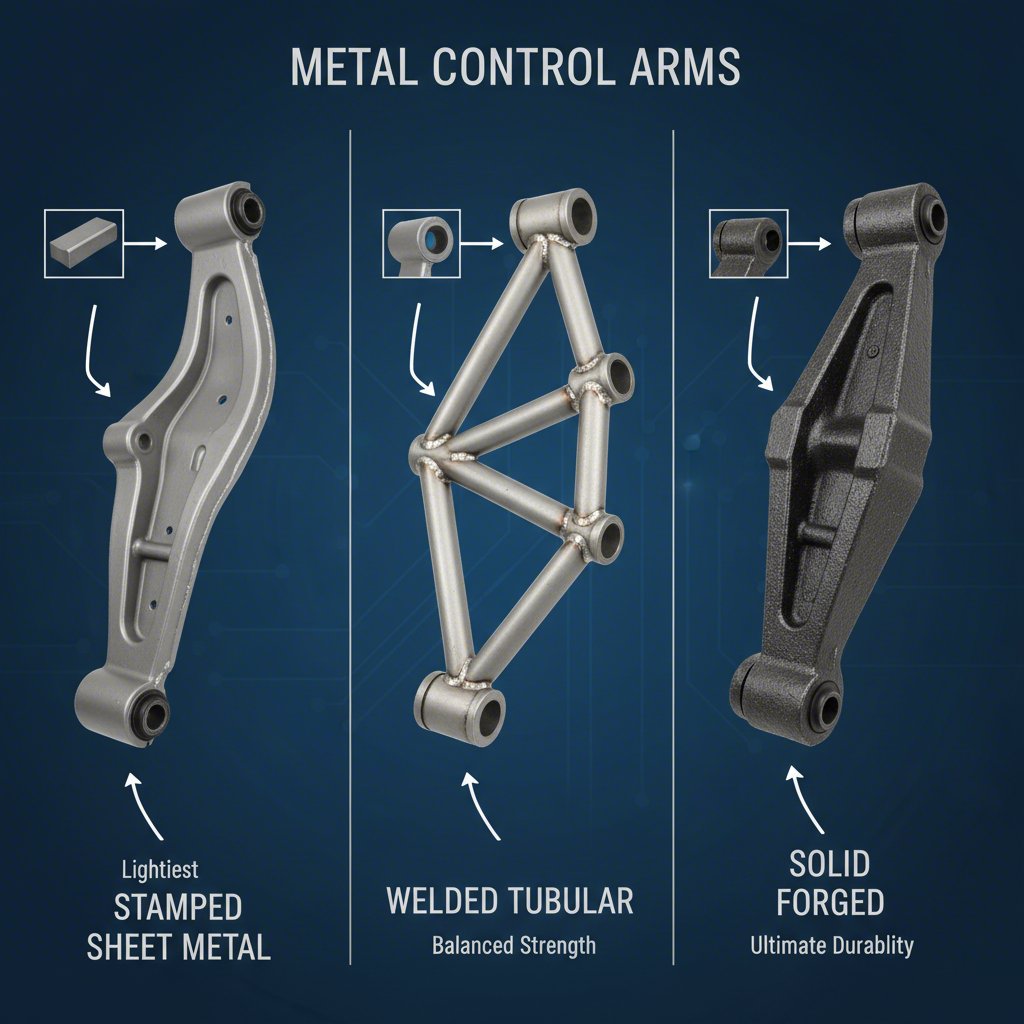

When choosing an aftermarket control arm, the material and construction method are among the most important factors. The three most common types are stamped steel, tubular, and forged. Each has distinct advantages and disadvantages that make them suitable for different applications and budgets, especially when dealing with the unique demands of a lowered suspension.

Stamped steel control arms are the most common OEM type, manufactured by pressing sheets of steel into a desired shape. This process is cost-effective for mass production, making them the standard for most passenger vehicles. While perfectly adequate for factory specifications, they are generally the weakest and least rigid of the three types. For manufacturers, the quality of this process is paramount. Companies specializing in high-precision automotive components, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., leverage advanced, IATF 16949-certified processes to produce reliable stamped parts for the automotive industry, ensuring consistency from prototyping to mass production.

Tubular control arms are a popular aftermarket upgrade. As described by manufacturers like Classic Perform, these are constructed from strong, welded steel tubing (e.g., 1-1/4” x .120” wall tubing). This design offers a significant increase in strength and rigidity over stamped arms without a massive weight penalty. Tubular arms are better at resisting the bending forces experienced during aggressive driving and can be designed with corrected geometry for lowered vehicles, making them an excellent all-around choice for performance and street use.

Forged control arms represent the pinnacle of strength. The forging process involves heating a solid piece of metal and compressing it under immense pressure into a die. This aligns the metal's internal grain structure, resulting in a component with exceptional density, strength, and fatigue resistance compared to stamped or even cast parts. While they offer the ultimate in durability, their higher cost and weight mean they are often reserved for heavy-duty trucks or dedicated high-performance racing applications where maximum strength is non-negotiable.

| Attribute | Stamped Steel | Tubular Steel | Forged Steel |

|---|---|---|---|

| Strength | Good (Standard) | Excellent (High Rigidity) | Superior (Maximum Durability) |

| Strength-to-Weight Ratio | Good | Excellent | Superior |

| Cost | Low | Moderate | High |

| Best Use Case for Lowered Vehicles | Not Recommended (OEM Replacement Only) | Street Performance, Show Cars, Daily Drivers | Heavy-Duty Trucks, Racing, Extreme Use |

Buyer's Guide: Selecting the Right Control Arms for Your Lowered Truck

Choosing the correct control arms for your lowered truck is essential for achieving the right stance, performance, and safety. With numerous options available for popular models like the Chevy Silverado, Ram 1500, and Ford F-150, it's crucial to consider several key factors before making a purchase. A systematic approach will ensure you get a compatible kit that meets your vehicle's specific needs.

First and foremost is ensuring vehicle-specific fitment. This includes the make, model, year, and drivetrain (2WD or 4WD). Suspension components are not one-size-fits-all. Equally important is identifying your truck's factory suspension type. As noted by suppliers like IHC Suspension and Reklez, some trucks come with factory stamped steel arms, while others use cast steel or cast aluminum. An aftermarket kit designed for a stamped steel setup will not fit a truck with factory cast arms, so visual confirmation is key.

Your desired drop height is another critical factor. Control arm kits are engineered for a specific range of lowering. For instance, a kit designed for a 4-inch drop will have different geometry corrections than one for a 2-inch drop. Finally, always verify the kit's contents. A complete kit should include both upper and lower control arms, pre-installed bushings, new ball joints, and all necessary installation hardware. Buying a comprehensive kit ensures all components are designed to work together seamlessly, simplifying installation and guaranteeing proper performance.

Follow this checklist to ensure you order the right parts the first time:

- Confirm Your Truck's Full Specifications: Write down the exact year, make, model, and drivetrain (2WD/4WD).

- Identify Your Factory Control Arm Type: Visually inspect your current control arms to determine if they are stamped steel, cast steel, or cast aluminum.

- Determine Your Target Drop Height: Measure or decide on the final amount of lowering you want to achieve (e.g., 2", 3", 4").

- Verify the Aftermarket Kit's Specifications: Cross-reference your vehicle details and drop height with the product description.

- Check the Kit Contents: Ensure the kit includes upper and lower arms, ball joints, bushings, and hardware for a complete installation.

Frequently Asked Questions

1. Do lower control arms make a difference?

Yes, lower control arms make a significant difference in a vehicle's handling, safety, and performance. They are a fundamental part of the suspension, connecting the chassis to the wheels and allowing for controlled movement. When they are worn or not suited for the vehicle's ride height (as with a lowered suspension), it can lead to improper wheel alignment, unstable handling, and accelerated tire wear. Upgrading them can restore proper geometry and dramatically improve driving dynamics.

2. What is the difference between stamped and forged control arms?

The primary difference is in their manufacturing process and resulting strength. Stamped control arms are made by pressing sheets of steel into a shape, which is a cost-effective method suitable for standard vehicles. Forged control arms are created by heating a solid piece of metal and compressing it into a die, which aligns the metal's internal grain structure. This process makes forged arms significantly stronger and more resistant to fatigue, making them ideal for heavy-duty or high-performance applications.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —