Essential Control Arm Fabrication Parts for Your Custom Build

TL;DR

Building custom control arms involves fabricating them from specialized components to achieve superior suspension geometry and strength. The essential control arm fabrication parts you will need include high-grade tubing like Chromoly, weld-in bungs for threading, precision joints such as heim joints or uniballs, and various mounting brackets and tabs. These components are readily available from suppliers that specialize in racing and custom chassis applications.

Understanding the Essentials of Control Arm Fabrication

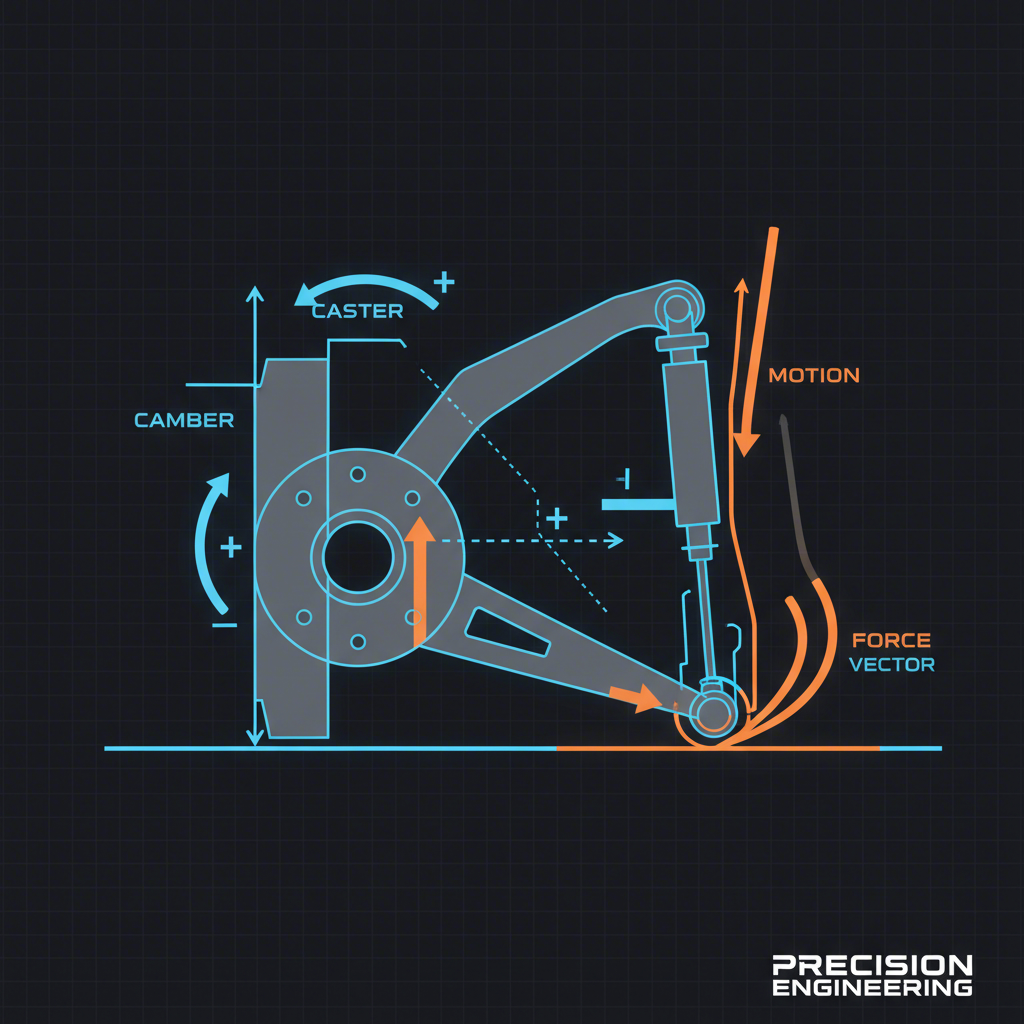

Custom control arm fabrication is the process of designing and building bespoke suspension arms tailored to a vehicle's specific needs, moving beyond the limitations of factory components. The primary goal is to optimize suspension geometry for better handling, increased strength for demanding applications like racing or off-roading, and often, reduced weight. Unlike off-the-shelf arms, fabricated control arms offer complete control over factors like length, angle, and pivot points, which are critical for correcting camber, caster, and roll center in modified vehicles.

The advantages over stock or even standard aftermarket arms are significant. As detailed in a custom fabrication project by Wilhelm Raceworks, fabricated arms allow for precise adjustments to improve tire contact with the road, leading to better grip and more predictable handling. They are also built with stronger materials, such as 4130 Chromoly steel, to withstand the extreme stresses of performance driving. This level of customization is essential when altering a vehicle's ride height, track width, or when swapping in different powertrain or suspension components.

A typical fabrication project follows several key phases. It begins with a detailed design phase, often using software to perform stress analysis and finalize geometry. This is followed by careful material selection, machining of custom fittings like tube ends and spacers, precise cutting and notching of tubes, and finally, meticulous TIG welding within a jig to ensure accuracy and repeatability. Each step requires a high degree of precision to achieve the desired performance outcomes.

| Feature | Custom Fabricated Arms | Off-the-Shelf Aftermarket Arms |

|---|---|---|

| Geometry | Fully customizable to specific vehicle needs and goals. | Fixed geometry designed for a range of common applications. |

| Strength & Material | Built with high-strength materials like 4130 Chromoly for maximum durability. | Varies by brand; may be stamped steel, forged aluminum, or tubular steel. |

| Fitment | Engineered for a perfect fit, accommodating unique modifications. | Designed to fit stock mounting points; may not suit highly modified chassis. |

| Effort & Cost | Requires significant skill, specialized tools, and time. Can be cost-effective if you have the skills. | Bolt-on installation with minimal effort. Higher upfront part cost. |

The Complete Parts List for Control Arm Fabrication

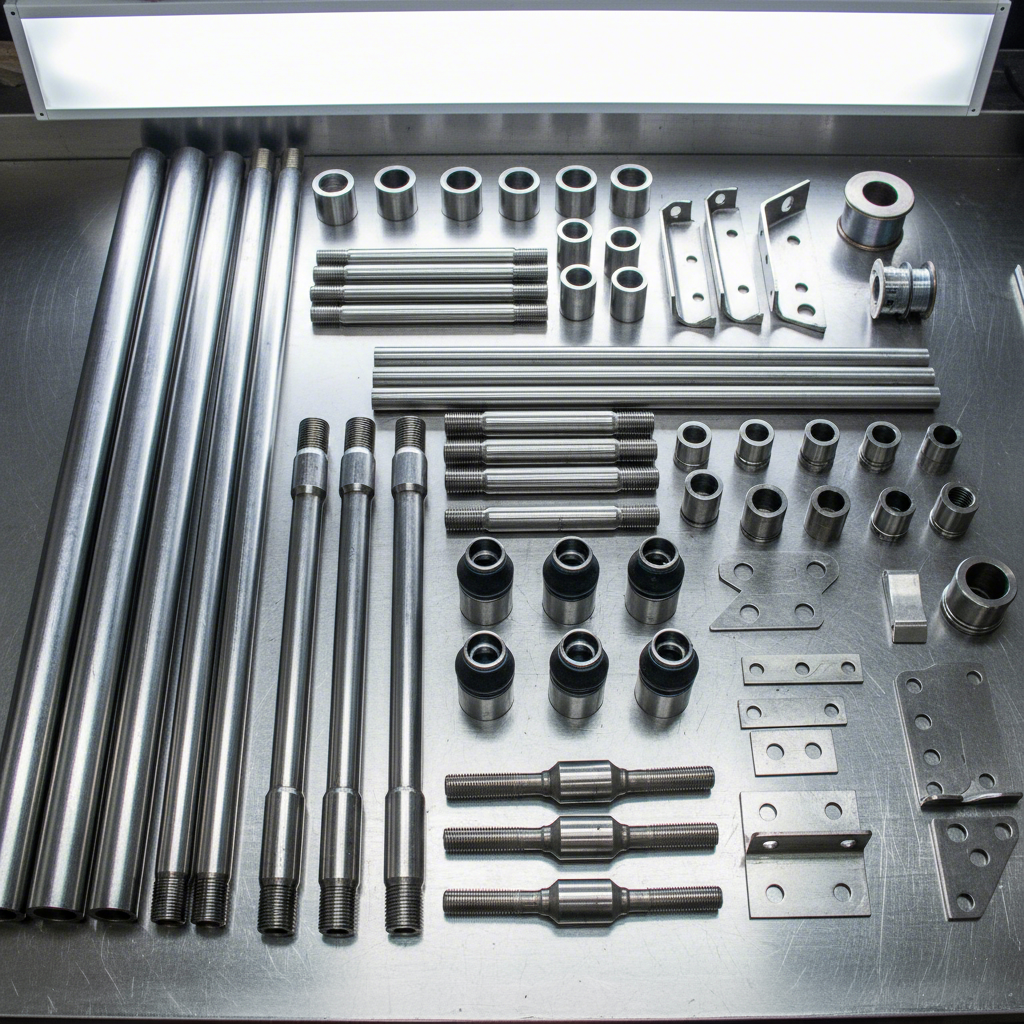

Sourcing the right control arm fabrication parts is the foundation of a successful build. These components can be broken down into several key categories: the structural tubing, the threaded ends, the pivoting joints, and the mounting hardware. Each piece plays a critical role in the arm's strength, adjustability, and overall performance.

Below is a detailed breakdown of the essential components you'll need, based on offerings from specialty suppliers like Pit Stop USA and CB Chassis Products.

- Tubing: The backbone of the control arm. 4130 Chromoly is the preferred material for its excellent strength-to-weight ratio. DOM (Drawn Over Mandrel) steel tubing is another strong and common alternative.

- Weld Bungs / Tube Ends: These are threaded inserts that are welded into the ends of the tubing. They provide the threads necessary to screw in heim joints or other rod ends, allowing for length adjustments. They come in various sizes to match both the tube diameter and the thread pitch of your chosen joint.

-

Joints: These are the pivot points of the control arm. The choice of joint depends on the application.

- Heim Joints (Rod Ends): Offer the most articulation and are ideal for race applications but can transmit more noise and vibration.

- Ball Joints: Commonly used, especially on A-arms. You'll need components like screw-in or bolt-in ball joint plates and sleeves to integrate them into a fabricated arm.

- Uniballs: A heavy-duty alternative to ball joints, often used in off-road applications for their strength and high range of motion.

- Bushings: Polyurethane or rubber bushings are used for street applications where absorbing vibration and noise is important. They offer less articulation than heim joints.

- Mounting Brackets & Tabs: These are welded to the vehicle's frame or axle to create mounting points for the control arms. Companies like JOES Racing Products offer specialized components like A-Plate Slugs that allow for quick geometry changes by moving the arm's inner pivot point.

- Cross Shafts: For A-arm designs, a cross shaft serves as the inner pivot assembly, connecting the two tubes of the A-arm and mounting to the frame. These are available in steel or lightweight aluminum.

- Fasteners & Spacers: High-grade bolts are a must. You will also need specialized spacers, such as High Misalignment Spacers from suppliers like CB Chassis Products, which allow heim joints to pivot at greater angles without binding.

Sourcing Your Components and Selection Tips

Once you have a parts list, the next step is sourcing the components from reliable suppliers. The top retailers are typically specialists in the racing, off-road, or custom chassis markets. Businesses like JOES Racing Products, Pit Stop USA, NFAMUS METAL, and CB Chassis Products are excellent sources, offering everything from individual bungs and brackets to complete component kits.

For those undertaking complex or high-volume manufacturing, sourcing precision components is key. Companies such as Shaoyi (Ningbo) Metal Technology Co., Ltd. specialize in automotive stamping dies and metal component manufacturing, providing OEM-level quality and precision that can be essential for producing brackets and other stamped parts in series production.

When ordering, precision is paramount to avoid costly mistakes. A pre-made kit, like the UNIVERSAL CONTROL ARM COMPONENT KIT from NFAMUS METAL, can be a great starting point. It bundles compatible parts, which is ideal for beginners. However, sourcing each part individually provides maximum control over your build. Use this checklist to ensure you order correctly:

- Check Material Specifications: Confirm you are ordering the correct grade of material, such as 4130 Chromoly for tubing.

- Verify Thread Pitch and Size: Ensure your weld bungs and heim joints have matching threads (e.g., 3/4"-16) and are the correct orientation (left-hand or right-hand thread).

- Match Ball Joint Tapers: If using factory-style ball joints, ensure any sleeves or mounting plates match the specific taper of your joint (e.g., 1-1/2" per foot).

- Account for All Hardware: Don't forget jam nuts for heim joints, high-misalignment spacers for increased pivot angles, and correctly graded bolts and nuts for all mounting points.

- Measure Twice, Order Once: Double-check all measurements from your design against the component specifications on the supplier's website before placing an order.

Essential Tools and a Basic Fabrication Workflow

Fabricating custom control arms is a task that demands both skill and the right equipment. While the parts are readily available, the assembly process requires precision tools to ensure the final product is strong, accurate, and safe. The primary tool categories are for cutting, welding, and measuring, with a TIG welder being the preferred choice for the clean, strong welds required for Chromoly tubing.

Based on the detailed process outlined by builders, here are the essential tools for the job:

- TIG Welder: Universally recommended for welding 4130 Chromoly due to the precise heat control it offers, which helps maintain the material's strength around the weld area.

- Tube Notcher: Essential for creating perfectly fitting joints where one tube meets another, which is critical for weld strength.

- Horizontal Bandsaw: Used for making clean, straight cuts on tubing and bar stock.

- Lathe and Mill: While not strictly necessary for every build, a lathe and mill are invaluable for creating custom components like tube end fittings, spacers, and bushings with high precision.

- Fabrication Jig: A fixture built to hold all the components in their exact positions during tacking and final welding. A well-built jig is the most critical element for ensuring the finished arms are identical and match your design specifications.

- Quality Measuring Tools: A set of calipers, a digital angle finder, and precise rulers are non-negotiable for accuracy.

The fabrication process itself follows a logical progression from raw materials to a finished product. A simplified workflow looks like this:

- Finalize Design & Measurements: Lock in all lengths, angles, and pivot locations before cutting any material.

- Machine Small Components: Turn any custom spacers, bushings, or tube ends on the lathe and mill.

- Cut and Notch Tubing: Cut all tubes to their final length and notch the ends for a tight fit.

- Assemble and Tack Weld in a Jig: Place all components into your jig, check alignment, and make small tack welds to hold everything together.

- Perform Final Welding: Once you've confirmed fitment, complete all welds. It's often recommended to alternate welds to distribute heat and minimize warping.

- Finish and Assemble: After cooling, the arms can be painted or powder-coated before installing the joints and mounting them on the vehicle.

From Raw Steel to a High-Performance Upgrade

Embarking on a control arm fabrication project is a significant undertaking that bridges the gap between off-the-shelf parts and professional race-level engineering. By carefully selecting the right control arm fabrication parts—from high-strength Chromoly tubing and precision heim joints to custom-machined fittings—you can build components that perfectly match your vehicle's unique performance requirements. While it demands skill, precision, and the right tools, the result is a suspension system with unparalleled strength and adjustability, optimized to deliver superior handling and control where it matters most.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —