Choosing the Right Tool Steel for Automotive Dies

Tool steel is a category of high-carbon alloy steels engineered for exceptional hardness, wear resistance, and toughness. In the automotive industry, specific grades of tool steel for automotive dies are essential for creating durable tooling for high-volume manufacturing processes. Grades like D2 are used for cold stamping, while H13 is the standard for high-temperature applications like die casting and forging, ensuring precision and long service life.

Understanding Tool Steel: Properties and Role in Automotive Manufacturing

Tool steel is a class of high-carbon alloy steels specifically formulated and heat-treated to produce tools, dies, and molds. Unlike standard carbon steel, which is primarily iron and carbon, tool steel contains significant amounts of alloying elements such as chromium, molybdenum, vanadium, and tungsten. These elements form hard carbide particles within the steel's matrix, giving it the superior properties required for shaping other materials under immense pressure and temperature. The term 'die steel' is often used interchangeably with tool steel, though it typically refers to tool steel grades specifically selected for die-making applications due to their high hardness and wear resistance.

The performance of tool steel in automotive manufacturing hinges on a precise balance of mechanical properties, achieved through careful alloying and a meticulous heat treatment process involving austenitizing, quenching, and tempering. This process tailors the final microstructure of the steel to optimize its characteristics for a specific task. For example, a die for stamping body panels must resist abrasive wear over millions of cycles, while a die for forging a crankshaft must withstand extreme impact and heat without cracking or deforming.

The key properties that make tool steel indispensable for automotive dies include:

- Exceptional Hardness: Many hardened tool steels can achieve a hardness of over 60 HRC (Rockwell C scale), allowing them to cut and form other metals without losing their shape.

- High Wear Resistance: The presence of hard carbides, particularly in high-chromium grades like D2, allows the steel to resist abrasion from contact with sheet metal and other materials, which is critical for extending die life. According to manufacturing experts at Protolabs, this property ensures consistent part quality over long production runs.

- Toughness: This is the material's ability to absorb impact and energy without fracturing. Shock-resistant grades like S7 are designed to withstand the immense shock loads common in certain forming and punching operations.

- Thermal Stability: Hot-work steels, such as H13, are engineered to retain their hardness and strength at the elevated temperatures seen in die casting and forging, preventing softening and premature failure.

In high-volume automotive production, the use of the correct tool steel is a critical factor in operational efficiency. A well-chosen die material reduces downtime for maintenance and replacement, minimizes part defects, and ultimately lowers the cost per part. The initial investment in a high-performance tool steel pays dividends through increased productivity and reliability on the manufacturing line.

Key Tool Steel Grades for Automotive Dies: A Detailed Comparison

The selection of a specific tool steel grade is determined by the demands of the manufacturing process. The American Iron and Steel Institute (AISI) classification system groups these steels based on their properties and quenching method. For automotive dies, the most relevant categories are Cold-Work (A and D series), Hot-Work (H series), and Shock-Resistant (S series) steels. Understanding the characteristics of the most common grades is fundamental to designing robust and efficient tooling.

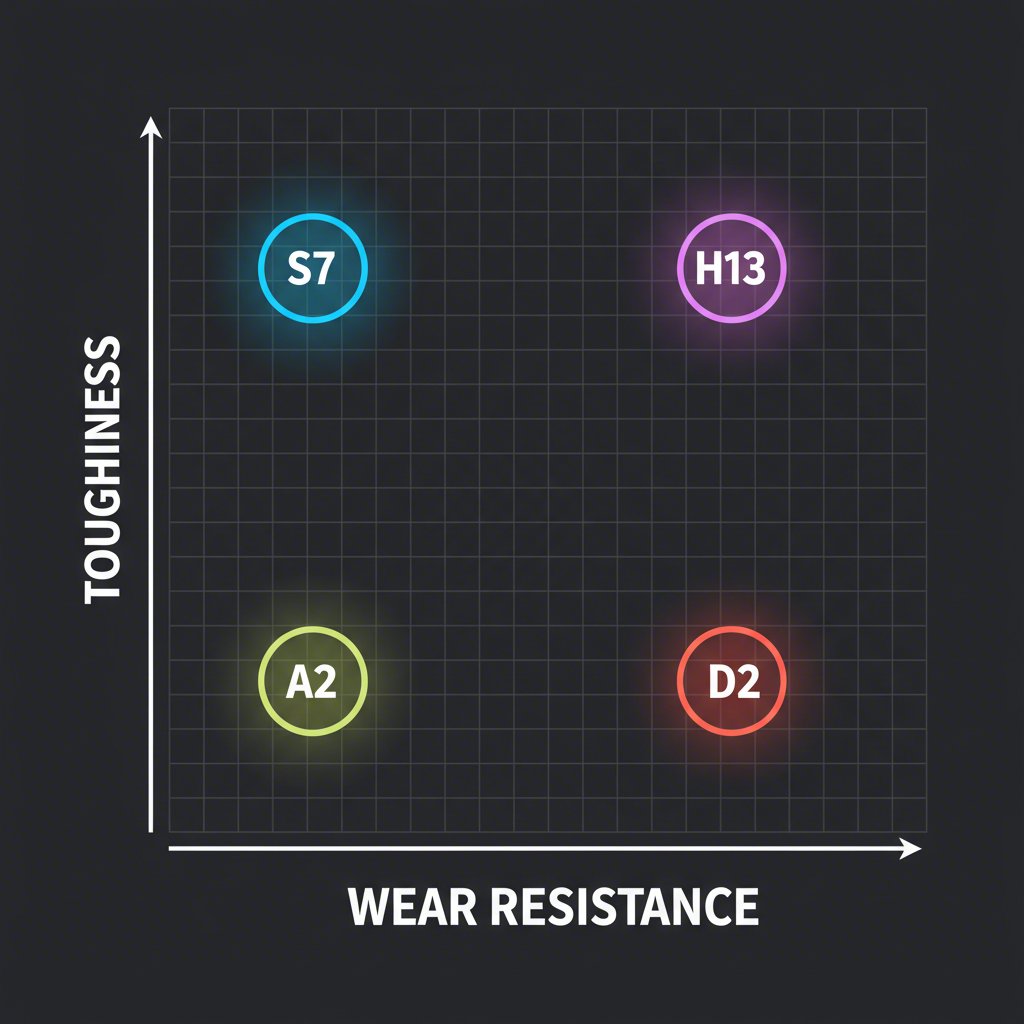

Among the most frequently specified grades for automotive applications are D2, A2, H13, and S7. Each offers a unique profile of properties. D2, a high-carbon, high-chromium steel, is renowned for its outstanding wear resistance, making it a top choice for cutting and stamping dies. A2 is an air-hardening steel that provides a good balance of wear resistance and toughness with excellent dimensional stability during heat treatment, making it a versatile option for forming dies. H13 is the industry standard for hot-work applications, offering superior resistance to thermal fatigue. S7 provides exceptional impact toughness, making it ideal for dies that must endure repeated, heavy blows.

To aid in selection, the following table compares these key tool steel grades used in automotive die manufacturing.

| Steel Grade | AISI Type | Key Properties | Primary Automotive Die Application |

|---|---|---|---|

| H13 | Hot-Work (H-Series) | High-temperature strength, good toughness, thermal fatigue resistance | Die casting, extrusion, and forging dies |

| D2 | Cold-Work (D-Series) | Excellent wear and abrasion resistance, high compressive strength | High-volume stamping, blanking, and forming dies |

| A2 | Cold-Work (A-Series) | Good balance of wear resistance and toughness, excellent dimensional stability | Forming dies, stamping dies, punches, trim tools |

| S7 | Shock-Resistant (S-Series) | Superior impact toughness, good wear resistance, high strength | Heavy-duty stamping, punching, and forming dies requiring shock absorption |

Choosing between these grades often involves a trade-off. For example, while D2 offers superior resistance to abrasive wear, it is more brittle than S7. An engineer might choose D2 for a simple blanking die but opt for the tougher S7 for a coining die that experiences high impact forces. Similarly, while A2 offers better toughness than D2, it does not match D2's longevity in high-wear scenarios. The final selection depends on a thorough analysis of the specific stresses the die will encounter during its operational life.

Matching Steel to Process: Applications in Automotive Die Making

Selecting the appropriate tool steel grade is directly linked to the specific manufacturing process it will be used for. Each method of forming metal in the automotive industry—from stamping sheet metal for a door panel to forging an engine component—imposes unique stresses on the die. Aligning the steel's properties with these demands is crucial for success.

Stamping & Forming Dies

Stamping, blanking, and forming are cold-work processes that involve shaping sheet metal at room temperature. The primary challenge for dies in these applications is abrasive wear from continuous contact with the workpiece, as well as the need for sharp, durable cutting edges. For these reasons, high-carbon, high-chromium cold-work steels are the industry standard. Leading suppliers like Southern Tool Steel recommend D2 tool steel for high-volume stamping runs where wear resistance is the top priority. Its abundant chromium carbides provide exceptional longevity. For applications requiring a better balance of toughness and wear resistance, or where more intricate shapes increase the risk of chipping, A2 tool steel is an excellent choice due to its superior dimensional stability and robust nature. When a project demands intricate and highly reliable stamping dies, working with a specialized manufacturer is key. For instance, Shaoyi (Ningbo) Metal Technology Co., Ltd. offers expert design and production of custom automotive stamping dies, leveraging deep material knowledge to optimize tool performance and lifespan for OEMs and Tier 1 suppliers.

Die Casting & Forging Dies

Die casting and forging are hot-work processes that involve shaping metal at extremely high temperatures. Dies used in these environments must withstand severe thermal shock—rapid heating and cooling cycles—as well as erosion from molten metal and high compressive forces. The primary material for these applications is H13 tool steel. As explained by experts at meviy, H13 is engineered to retain its hardness and strength even when operating at red-hot temperatures, which is essential for preventing premature die failure. Its excellent toughness and resistance to thermal fatigue allow it to endure thousands of cycles without cracking, making it the go-to choice for producing complex automotive parts like engine blocks, transmission cases, and suspension components.

Impact & Shock-Loading Dies

Certain automotive manufacturing operations, such as heavy-duty punching, coining, or shearing, subject the die to sudden and intense impact forces. In these scenarios, a steel with maximum toughness is required to prevent catastrophic failure from cracking or chipping. S7 tool steel is specifically designed for this purpose. Its composition is optimized to provide outstanding impact resistance, making it far tougher than highly wear-resistant grades like D2. While it may not last as long in purely abrasive applications, S7 is the safest and most reliable choice for tools that must absorb significant shock loads during operation.

Selection Criteria: How to Choose the Best Tool Steel for Your Dies

Selecting the optimal tool steel for an automotive die is a critical engineering decision that balances performance, manufacturability, and cost. A systematic approach that considers all operational variables will lead to a more reliable and cost-effective tool. The choice is rarely based on a single property but rather on finding the best compromise among competing characteristics to suit a specific application.

Engineers must evaluate several critical factors to make an informed decision. These factors determine how the die will perform and how long it will last in production. Neglecting any of these can lead to premature tool failure, costly downtime, and inconsistent part quality. The primary considerations include:

- Operating Temperature: This is the first and most important distinction. Is the process a cold-work application like stamping, or a hot-work process like forging? Hot-work steels like H13 are mandatory for high-temperature environments, while cold-work steels offer higher hardness for room-temperature operations.

- Wear Resistance vs. Toughness: This is the classic trade-off in tool steel selection. High wear resistance (ideal for cutting and stamping) is typically achieved with high hardness and carbide content, which can make the steel more brittle. High toughness (ideal for impact applications) requires a steel that can deform slightly without fracturing, often at the expense of some wear resistance.

- Required Hardness (HRC): The desired hardness, measured on the Rockwell C scale, must be specified based on the application. A cutting die may require a hardness of 60-62 HRC to maintain a sharp edge, while a forming die might be tempered to a slightly lower hardness to increase its toughness.

- Dimensional Stability: For complex and high-precision dies, it is crucial that the steel maintains its shape and size during the heat treatment process. Air-hardening steels like A2 are known for their excellent dimensional stability, minimizing distortion and reducing the need for costly post-heat-treat machining.

- Cost and Machinability: While performance is paramount, budget is always a factor. Highly alloyed, high-performance steels are more expensive and can be more difficult to machine than simpler grades. The total cost, including raw material, machining, and heat treatment, must be weighed against the expected life and performance of the die.

To put this into practice, consider this scenario: for a high-volume stamping die producing simple automotive brackets (a cold-work process), abrasive wear is the main concern. D2 would be a strong candidate due to its exceptional wear resistance. However, if that same die had sharp internal corners or was used to form a high-strength steel, the risk of chipping would increase. In that case, the tougher A2 or even S7 might be a better choice to prevent premature failure, even if it requires more frequent sharpening. Before finalizing a material, a designer should always ask these key questions:

- What is the primary failure mode I need to prevent (wear, chipping, cracking, or heat deformation)?

- What are the maximum temperature and impact forces the die will experience?

- How critical is dimensional accuracy after heat treatment?

- What is the target production volume and expected die life?

- What is the total budget for material, machining, and treatment?

Frequently Asked Questions

1. What tool steel is used for die casting?

The most common tool steel for die casting is H13. It belongs to the hot-work (H-series) category and is specifically designed to withstand the high temperatures and thermal cycling inherent in the die casting process. Its excellent combination of red-hardness, toughness, and resistance to thermal fatigue makes it ideal for handling molten metals like aluminum and zinc without cracking or softening prematurely.

2. What steel is used for dies?

A wide variety of tool steels are used for dies, depending on the application. For cold-work applications like stamping and forming, D2 and A2 are common choices. For hot-work processes like forging and die casting, H13 is the industry standard. For applications requiring high impact resistance, S7 shock-resistant steel is often used. The specific choice depends on factors like operating temperature, wear requirements, and impact loading.

3. What is the difference between die steel and tool steel?

Tool steel is the broad category of steels designed for making tools. Die steel is a term often used to refer to specific grades of tool steel that are particularly well-suited for making dies. Essentially, all die steels are tool steels, but not all tool steels are optimized for die-making. Die steels are selected for their specific combination of high hardness, wear resistance, toughness, and, in the case of hot-work dies, thermal stability.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —