Embossing Automotive Metal Parts: The Engineer’s Guide to Design & Production

TL;DR

Embossing automotive metal parts is a precision metalforming process that presses sheet metal between matched dies to create raised or recessed features. Unlike surface engraving, this technique reshapes the material's cross-section, offering both functional benefits—such as enhanced structural rigidity, heat dissipation, and vibration damping (NVH)—and aesthetic value for branding and trim. It is a standard manufacturing method for critical components like heat shields, firewall insulators, and vehicle identification numbers (VINs).

For automotive engineers and procurement managers, understanding the distinction between hard tooling (for mass production) and urethane tooling (for prototyping) is essential for cost control. This guide covers the technical fundamentals, material selection criteria, and design guidelines necessary to implement metal embossing effectively in automotive applications.

Fundamentals of Automotive Metal Embossing

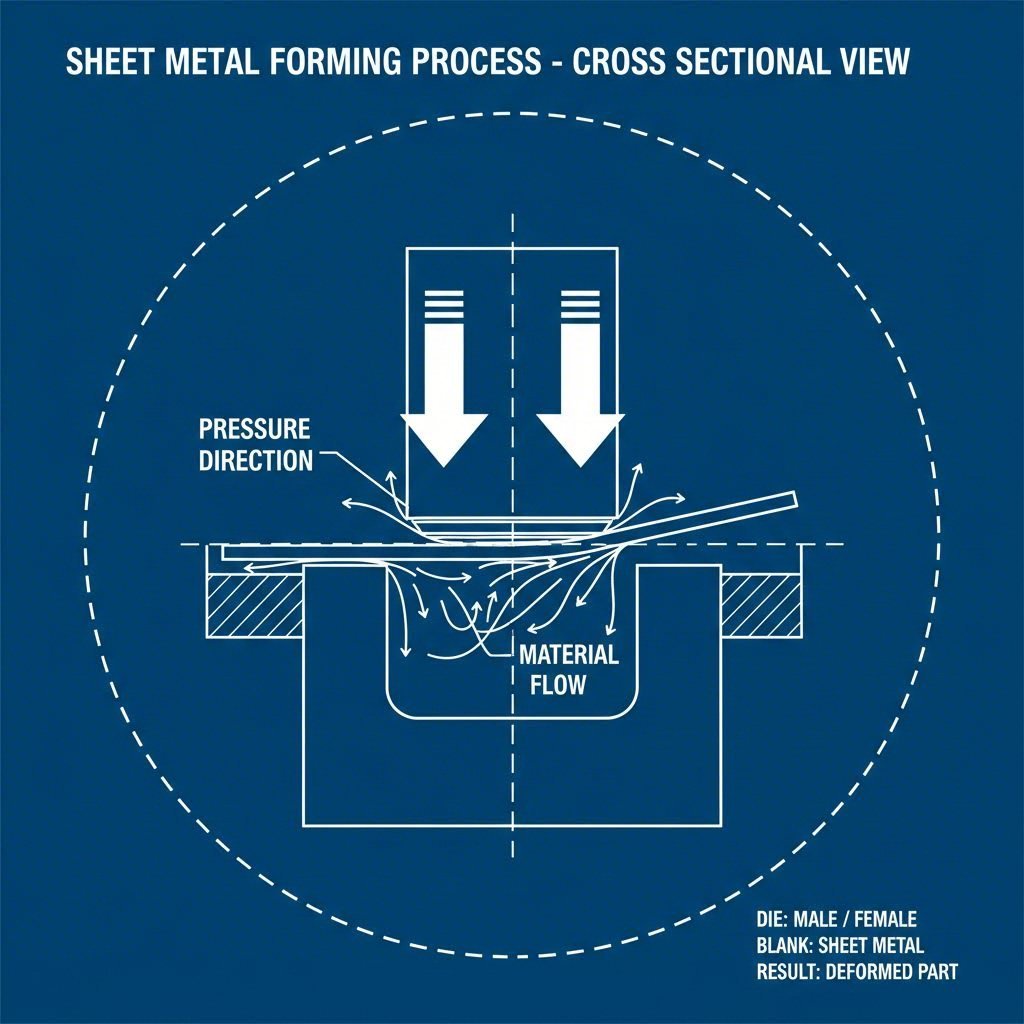

At its core, embossing automotive metal parts involves placing a flat metal sheet (the blank) between a male (punch) and female (die) tool. When pressure is applied—typically via a mechanical or hydraulic press—the metal permanently deforms into the die's cavity. This process stretches the material, increasing its surface area and stiffness without adding weight.

The Mechanics of the Process

The embossing operation relies on the material's ductility. The metal must stretch enough to conform to the die geometry without fracturing. This requires precise control over:

- Clearance: The gap between the male and female dies must accommodate the material thickness plus a specific clearance factor to prevent shearing (which would result in stamping or punching rather than embossing).

- Pressure: Tonnage requirements vary based on the alloy's tensile strength and the complexity of the pattern. Automotive presses often range from 100 to 600+ tons for heavy-gauge structural parts.

- Dwell Time: In some applications, particularly with harder alloys, the press may hold pressure briefly to set the shape and minimize springback.

Embossing vs. Stamping vs. Engraving

Confusion often exists between these terms. For automotive specification, the distinctions are critical:

| Feature | Embossing | Stamping/Coining | Engraving |

|---|---|---|---|

| Process | Reshaping metal between matched dies (raised/recessed). | Cutting or displacing metal under extreme pressure. | Removing material via cutting tools or lasers. |

| Material Flow | Stretches and thins the material slightly. | Compresses or shears material; changes thickness significantly. | Removes material; no deformation of surrounding area. |

| Automotive Use | Heat shields, VIN plates, aesthetic trim, stiffening panels. | Chassis brackets, engine covers, terminal connectors. | Precision marking, serialization, dashboard controls. |

| Cost Driver | Moderate tooling; very fast cycle times. | High tooling cost; extremely high volume. | Low tooling; slower cycle time per part. |

Critical Applications: Beyond Aesthetics

While often associated with logos, the functional utility of embossing in automotive engineering is paramount. It serves as a primary method for lightweighting and thermal management.

1. Thermal Management and Heat Shields

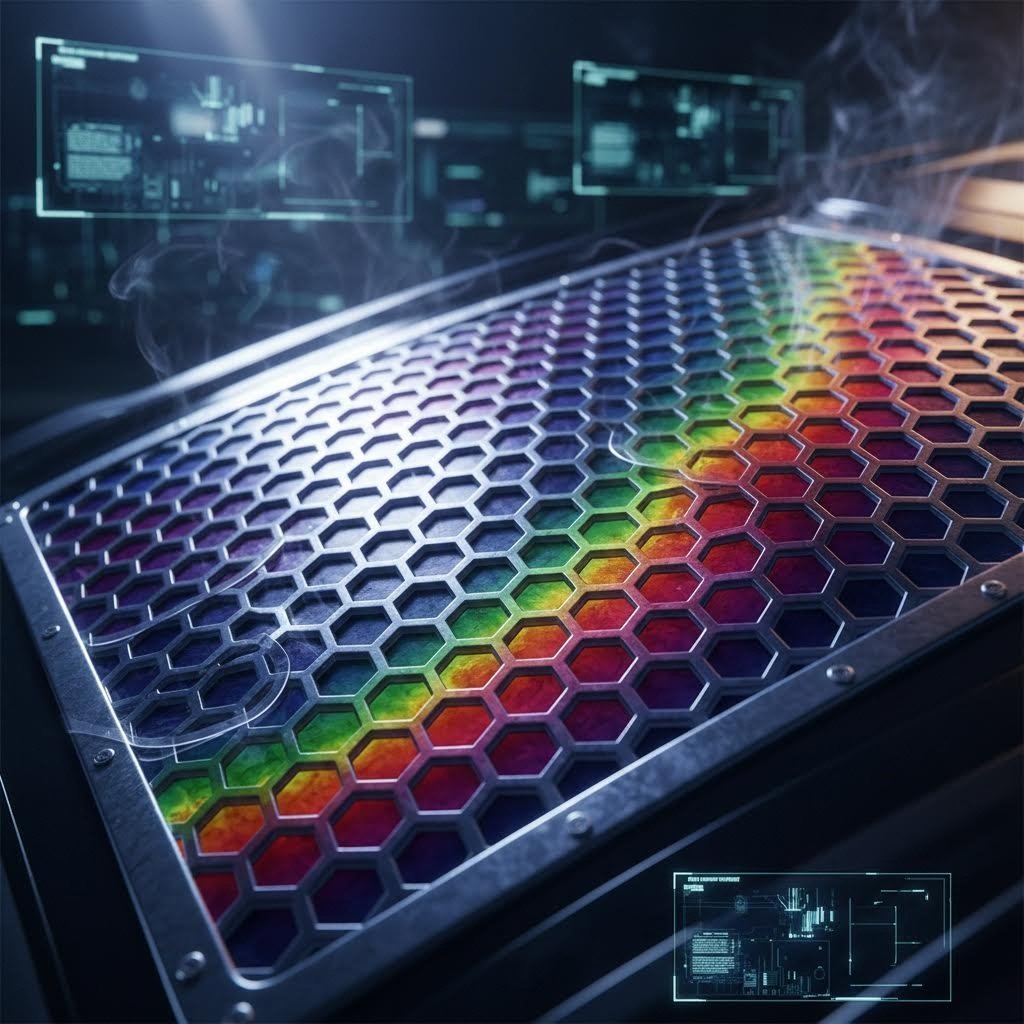

One of the most widespread uses of embossing automotive metal parts is in the manufacturing of exhaust heat shields and thermal barriers. By embossing a textured pattern (often a dimple or waffle pattern) into thin aluminum or stainless steel sheets, engineers achieve two goals:

- Increased Surface Area: The texture maximizes the metal's surface area, improving heat dissipation rates significantly compared to a flat sheet.

- Air Gap Creation: The raised relief creates micro-channels for airflow, preventing direct conductive heat transfer to sensitive components like fuel lines or the cabin floor.

2. Structural Rigidity and NVH Reduction

Automotive manufacturers constantly seek to reduce vehicle weight (lightweighting) without sacrificing strength. Embossing allows the use of thinner gauge metals by introducing geometric stiffness. A flat sheet of 0.5mm steel is flimsy and prone to "oil canning" (popping in and out). Embossing ribs or geometric patterns into that same sheet increases its moment of inertia, making it rigid enough for use in floor pans, door panels, and firewall insulators. This rigidity also dampens resonance, directly improving Noise, Vibration, and Harshness (NVH) scores.

3. Permanent Identification and Branding

Vinyl stickers and painted labels can degrade under the extreme heat and chemical exposure of an engine bay. Embossed characters—such as those on VIN plates or chassis components—provide permanent traceability. The raised characters remain legible even if the part is painted or coated.

Materials and Design Guidelines

Selecting the right substrate is crucial for successful embossing. The material must possess sufficient elongation properties to stretch without cracking.

Recommended Materials for Automotive Embossing

- Aluminum (1050, 3003, 5052): The industry standard for heat shields. Alloys like 3003 offer excellent formability and corrosion resistance.

- Stainless Steel (304, 316): Used for exhaust components and durable trim. Requires higher tonnage to emboss due to higher yield strength.

- Cold Rolled Steel (CRS): Common for structural panels. Often galvanized or coated after embossing to prevent rust.

- Brass and Copper: Primarily used for electrical contacts or niche aesthetic interior trim due to their high malleability.

Design Rules of Thumb

To avoid manufacturing defects like tearing or wrinkling, adhere to these general engineering guidelines:

- Depth-to-Thickness Ratio: Generally, the depth of an emboss should not exceed 1x to 2x the material thickness for standard hard tooling. Exceeding this increases the risk of material thinning and rupture.

- Draft Angles: Vertical walls are difficult to emboss cleanly. A draft angle of 20° to 30° on the sidewalls of the embossed feature allows the material to flow smoothly and facilitates easy part ejection from the die.

- Corner Radii: Avoid sharp corners. The radius at the base and top of the emboss should be at least equal to the material thickness to prevent stress concentrations.

The Manufacturing Process: Dies and Tooling

The choice of tooling strategy defines the project's lead time and unit cost. Automotive production typically categorizes tooling into two tiers.

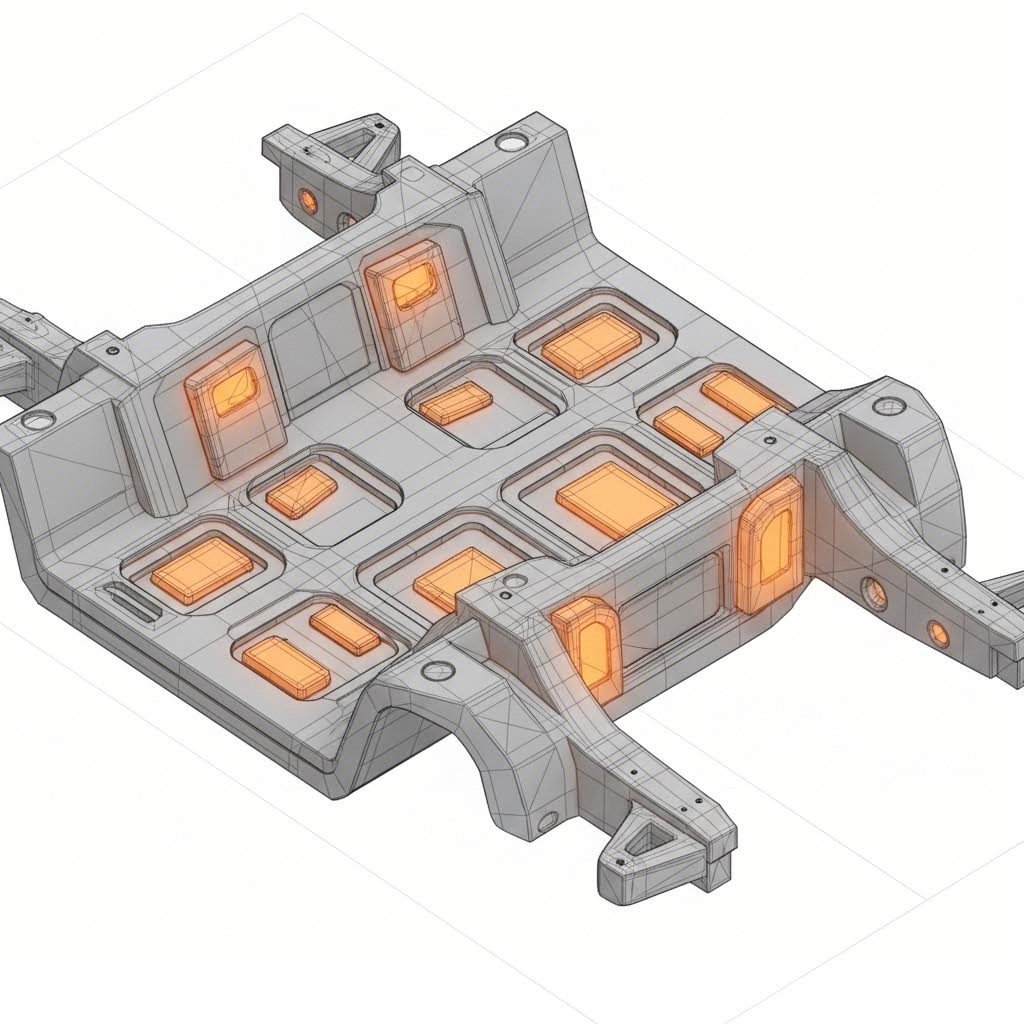

Hard Tooling (Matched Metal Dies)

For high-volume production (10,000+ parts), matched steel dies are the standard. These dies are CNC-machined from hardened tool steel to withstand millions of cycles. They offer the highest precision and sharpest detail but come with significant upfront investment and lead times of 4–8 weeks.

Urethane Tooling (Soft Tooling)

For prototyping or lower volumes (100–5,000 parts), urethane tooling is a cost-effective alternative. In this process, a metal punch (male) forces the sheet metal into a durable urethane pad (acting as the female die). The urethane acts as a hydraulic fluid, wrapping the metal around the punch. This method reduces tooling costs by 50–70% and eliminates die marks on the cosmetic side of the part.

Strategic Sourcing and Production

For B2B sourcing, selecting a partner with adequate tonnage and certification is crucial. Manufacturers like Shaoyi Metal Technology offer comprehensive stamping solutions, utilizing press capabilities up to 600 tons to deliver critical components like control arms and subframes with IATF 16949 precision. Whether bridging the gap from rapid prototyping to high-volume manufacturing, ensuring your vendor can handle the specific tonnage requirements of embossed structural parts is vital for program success.

Strategic Benefits: Why Emboss?

Integrating embossing into the automotive design process offers a compelling business case:

- Cost Efficiency: By replacing a thicker, heavier part with a thinner, embossed one, manufacturers save on raw material costs—a significant factor in high-volume automotive production.

- Production Speed: Embossing is typically integrated into progressive die stamping operations. This means the feature is added instantly with each stroke of the press, adding zero seconds to the cycle time.

- Perceived Quality: In vehicle interiors, tactile elements signal luxury. Embossed speaker grilles, door sills, and dashboard accents convey a level of craftsmanship that flat printed surfaces cannot match.

Conclusion

Embossing automotive metal parts is far more than a decorative finish; it is a fundamental engineering solution for modern vehicle challenges. From lightweighting structural panels to managing engine thermals with textured heat shields, the process bridges the gap between performance and cost-efficiency. For engineers, the key to success lies in early collaboration with manufacturing partners to optimize material selection and tooling geometry, ensuring that every raised relief serves a distinct functional or aesthetic purpose.

Frequently Asked Questions

1. What is the difference between embossing and debossing in automotive parts?

Embossing creates a raised design that protrudes from the surface, while debossing creates a recessed or depressed design. In automotive applications, the choice often depends on the assembly requirements—for example, a debossed area might sit flush with a mating part, while an embossed area might be used to catch airflow or provide grip.

2. Can high-strength steel be embossed?

Yes, but it requires significantly higher tonnage and specialized tool steel dies. The depth of the emboss is often more limited compared to softer metals like aluminum to prevent cracking. Engineers often use larger bend radii and shallower depths when embossing high-strength automotive steels.

3. Is embossing suitable for prototypes?

Absolutely. Using urethane tooling or simple single-stage dies allows engineers to test the form and function of an embossed part without investing in expensive progressive dies. This is common during the design validation (DV) phase of vehicle development.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —