Deep Draw Stamping Automotive Applications: Engineering Benefits

TL;DR

Deep draw stamping is a specialized cold-forming process essential for manufacturing seamless, hollow automotive components where the depth exceeds the diameter. It is the industry standard for producing safety-critical parts like airbag housings and ABS brake modules, as well as fluid-handling systems such as fuel rails and injector cups. The process offers superior structural integrity through work hardening, ensuring leak-proof performance and significant weight reduction compared to casting or machining. For automotive engineers, deep draw stamping provides a cost-effective solution for high-volume production of complex, high-strength geometries.

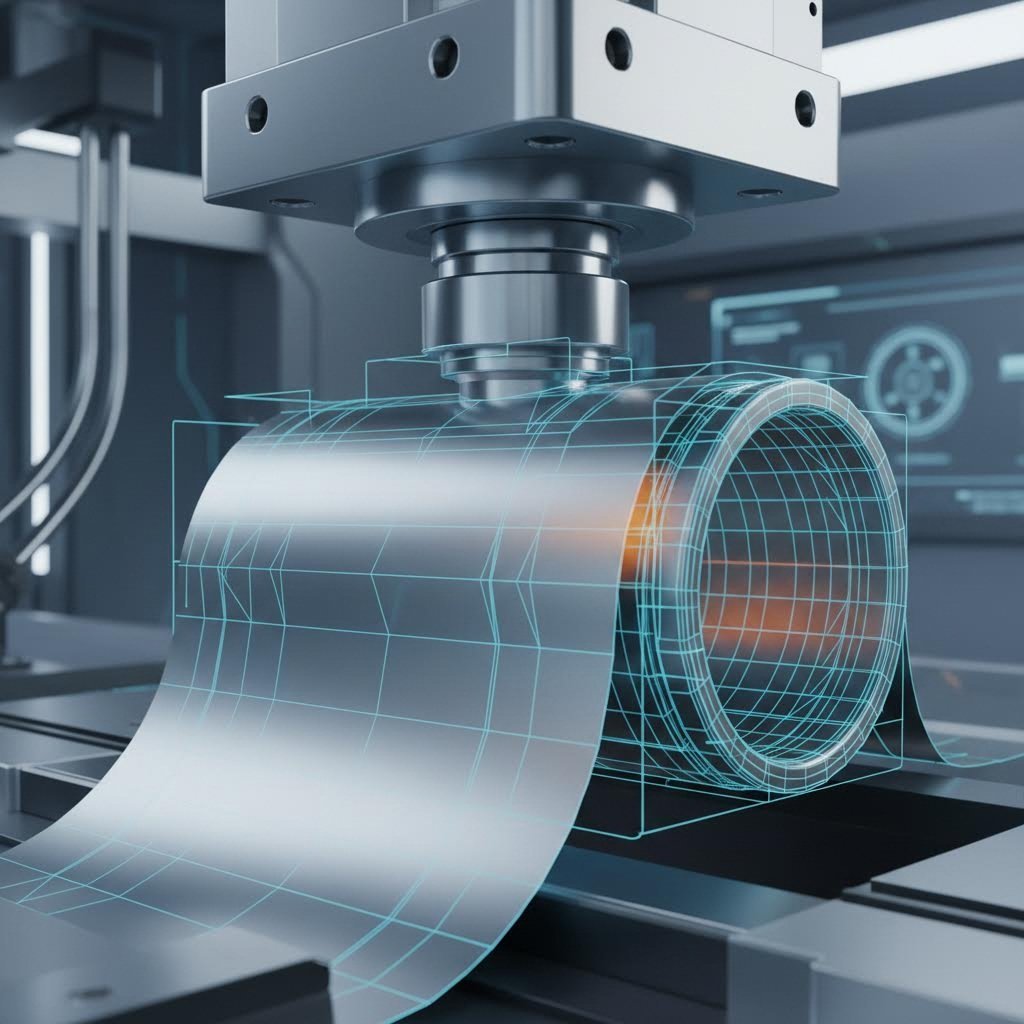

What is Deep Draw Stamping in Automotive Manufacturing?

Deep draw stamping is a metal forming process that transforms flat sheet metal blanks into hollow, three-dimensional shapes. The technical definition specifies that a part is considered "deep drawn" when its depth equals or exceeds its diameter. Unlike standard metal stamping, which typically involves cutting or shallow forming, deep drawing relies on plastic deformation.

The process begins with a metal blank placed over a forming die. A mechanical punch applies compressive force, pushing the metal into the die cavity while a blank holder controls the material flow to prevent wrinkling. This is a cold-forming operation, meaning the metal is shaped at room temperature. For the automotive industry, this distinction is critical because the process does not just shape the metal—it alters its mechanical properties.

Deep drawing is often performed using progressive die or transfer press systems. In a progressive die setup, the part remains attached to the metal strip (webbing) as it moves through multiple stations, each performing a specific operation (drawing, piercing, trimming). This method allows for high-speed production of complex, multi-feature components with exceptional repeatability, a requirement for meeting strict automotive OEM tolerances.

The Engineering Case: Why Choose Deep Draw?

Automotive engineers and procurement managers favor deep draw stamping over casting, machining, or welding for several strategic reasons. These benefits directly address the industry's push for lightweighting, safety, and cost efficiency.

1. Seamless Integrity and Leak Prevention

Because deep drawn parts are formed from a single piece of sheet metal, they have no seams or welds. This monolithic structure is non-negotiable for components that handle fluids or gases under pressure. Applications like fuel tanks, oil pans, and exhaust mufflers rely on this seamless construction to eliminate the risk of leakage points that are inherent in welded assemblies.

2. Work Hardening (Strain Hardening)

As the metal is drawn into the die, it undergoes significant stress, causing the crystal lattice structure to deform and lock. This phenomenon, known as work hardening, increases the tensile strength and hardness of the finished part. This allows engineers to specify thinner gauge materials without sacrificing structural integrity, directly contributing to vehicle weight reduction (lightweighting) goals while maintaining crash safety standards.

3. High-Volume Efficiency

Once tooling is developed, deep draw stamping is extremely fast. Presses can run thousands of strokes per hour, producing finished parts with minimal cycle times. Compared to the slow cycle times of machining or the cooling times required for casting, deep draw stamping is the most improved method for producing millions of identical components required for global vehicle platforms.

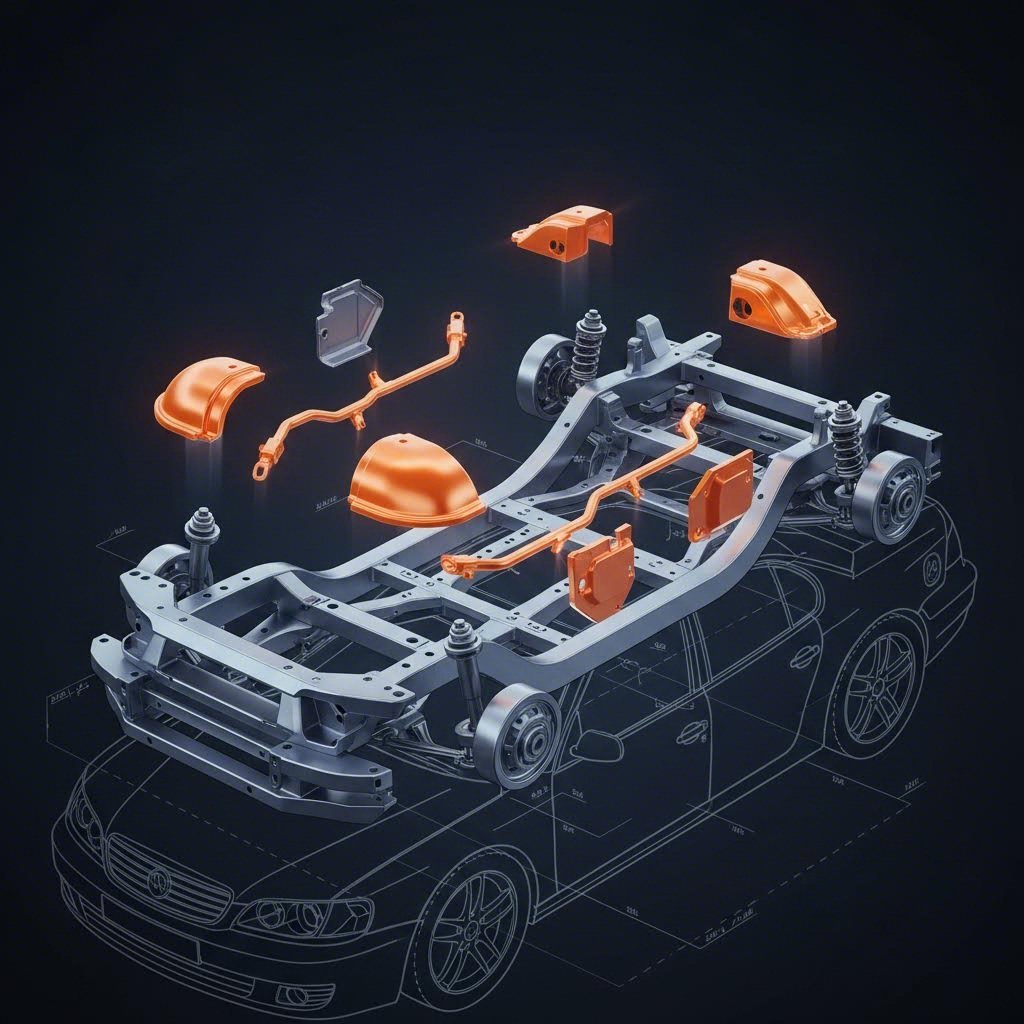

Critical Automotive Applications

Deep draw stamping is ubiquitous in modern vehicles, often utilized for parts hidden deep within vehicle sub-systems. These applications can be categorized by their function and critical requirements.

Safety and Restraint Systems

Safety components demand zero-failure reliability. Deep drawing is the primary method for manufacturing:

- Airbag Inflators and Diffusers: These pressure vessels must withstand explosive forces during deployment. Deep drawing creates high-strength, seamless canisters that contain the gas generant without rupturing.

- ABS Brake Modules: The housings for anti-lock braking solenoids requires precise tolerances to ensure hydraulic systems function correctly during emergency stops.

- Seatbelt Components: Retractor housings and other structural elements benefit from the work-hardened strength of deep drawn steel.

Powertrain and Fluid Handling

The transition to higher efficiency engines has increased the demand for precision drawn parts:

- Fuel Rails and Injector Cups: High-pressure direct injection systems require stainless steel deep drawn cups that resist corrosion and high fuel pressures.

- Oil Pans and Transmission Pistons: These parts utilize the depth capability of the process to hold large volumes of fluid while fitting into tight engine bays.

- Exhaust Components: Muffler shells, catalytic converter shields, and oxygen sensor bosses use high-temperature alloys formed via deep drawing.

Sensors and Electronics

As vehicles become more electrified, the volume of small, deep drawn housings has exploded:

- Sensor Housings: Protective shields for O2 sensors, temperature probes, and pressure sensors.

- Solenoid Bodies: Used in transmission control and variable valve timing systems.

- Motor Housings: Small electric motor shells for window regulators, wipers, and seat adjusters.

Material Selection for Deep Drawn Parts

Selecting the right material is a balance between formability (how well it stretches) and final performance requirements. The following materials are standard in automotive deep drawing:

| Material | Key Properties | Common Automotive Uses |

|---|---|---|

| Aluminum Alloys | Lightweight, corrosion-resistant, high strength-to-weight ratio. | Heat shields, electronic housings, body panels, structural brackets. |

| Stainless Steel (300/400 Series) | High heat resistance, excellent corrosion protection, durable. | Fuel delivery components, exhaust systems, oxygen sensor shields, injector cups. |

| Low Carbon Steel | Excellent formability, cost-effective, work hardens well. | Structural chassis parts, oil pans, mounting brackets, general housings. |

| HSLA (High-Strength Low-Alloy) | Superior structural strength, allows for thinner walls. | Safety-critical components, suspension parts, cross-members. |

| Copper & Brass | High electrical and thermal conductivity. | Electrical terminals, sensor contacts, thermostat components. |

Manufacturing and Sourcing Strategy

Implementing a deep draw stamping program requires careful consideration of tooling investment and production scalability. The initial cost for progressive dies can be significant, but the per-unit cost drops dramatically as volume increases. For this reason, the process is best suited for programs requiring 50,000 to millions of parts annually.

From Prototype to Mass Production

One of the challenges in automotive sourcing is bridging the gap between initial design validation and full-scale launch. Engineers often need rapid prototypes that mimic production intent. Leading manufacturers now offer soft tooling options to produce small batches for testing before committing to hard tooling.

For manufacturers requiring certified precision, partners like Shaoyi Metal Technology offer comprehensive solutions that bridge this gap. With IATF 16949 certification and press capabilities up to 600 tons, they can manage the entire lifecycle from rapid prototyping of 50 units to high-volume mass production of critical components like control arms and subframes. Access to such scalable manufacturing resources is vital for meeting aggressive automotive launch timelines.

Design for Manufacturability (DFM)

To maximize the benefits of deep drawing, engineers should observe specific DFM principles:

- Corner Radii: Avoid sharp corners. Generous radii facilitate material flow and prevent tearing during the draw.

- Wall Thinning: Anticipate some wall thinning at the bottom of the draw. Design tolerances should account for this natural variation.

- Draft Angles: While deep drawing can produce straight walls, adding a slight draft can extend tool life and ease part ejection.

Conclusion

Deep draw stamping remains a cornerstone of automotive manufacturing technology. Its unique ability to combine seamless construction, geometric complexity, and work-hardened strength makes it the ideal process for modern vehicle components ranging from airbag inflators to fuel systems. For automotive engineers and buyers, understanding the capabilities of this process—and partnering with capable suppliers—is key to delivering safer, lighter, and more efficient vehicles.

Frequently Asked Questions

1. How does deep draw stamping differ from standard metal stamping?

Standard metal stamping typically involves cutting, bending, or shallow forming of metal sheets. Deep draw stamping is specifically defined by the depth of the part being equal to or greater than its diameter. It involves significant plastic deformation (stretching) of the material, which requires specialized tooling and lubrication to manage material flow and prevent tearing.

2. Why is deep draw stamping preferred for safety components like airbags?

Deep draw stamping creates a seamless, monolithic part from a single piece of metal. This eliminates welds and mechanical joints, which are potential failure points under high pressure. For airbag inflators, which must contain rapidly expanding gases, this seamless integrity is critical for ensuring reliable deployment and passenger safety.

3. Can deep draw stamping handle high-strength materials?

Yes, modern deep draw presses can effectively form High-Strength Low-Alloy (HSLA) steels and other advanced materials. While these materials are less formable than mild steel and require higher tonnage presses and specialized die coatings, they allow for significant weight reduction by enabling the use of thinner walls without compromising structural strength.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —