Trunk Lid Stamping Process: Engineering Precision for Defect-Free Panels

TL;DR

The trunk lid stamping process is a precision automotive manufacturing sequence used to form inner and outer closure panels from sheet metal blanks. It typically involves a five-stage transfer or tandem press line, progressing from OP10 (Deep Drawing) through trimming and flanging to OP50 (Final Piercing). The primary engineering challenge lies in balancing material flow to prevent wrinkling and cracking while ensuring Class A surface quality for outer panels and structural rigidity for inner panels.

Material selection—typically High-Strength Low-Alloy (HSLA) steel or aluminum alloys (5000/6000 series)—dictates the die compensation strategy required to manage springback. Success depends on rigorous control of process parameters, including blank holder force, lubrication levels, and die temperature stability.

Material & Design Priorities: Balancing Structure and Aesthetics

The engineering requirements for trunk lids are bifurcated: the Outer Panel demands cosmetic perfection, while the Inner Panel requires complex geometric forming for structural stiffness. Understanding these distinct priorities is the first step in optimizing the stamping line.

Outer Panels: The Class A Surface Standard

For trunk lid outer panels, the primary objective is achieving a flawless Class A surface. These components are visible to the consumer and must be free from even microscopic defects like ripples, lows, or "oil canning." The stamping process must maintain sufficient tension across the panel to ensure stiffness without thinning the material to the point of failure. According to industry insights, maintaining a uniform surface finish is critical, as even minor deviations in the drawing phase can become visible after painting.

Inner Panels: Complexity and Rigidity

Inner panels serve as the structural backbone, featuring intricate bosses, grooves, and mounting points for hinges and locks. This geometric complexity makes them prone to severe forming challenges. Case studies on trunk lid inner panels have shown thinning rates as high as 25.9% in critical zones, pushing materials near their failure limits. The design must accommodate deep draws while preserving enough material thickness to support the vehicle's structural integrity.

Material Selection: Steel vs. Aluminum

The choice between steel and aluminum fundamentally alters the stamping strategy. While steel offers superior formability and cost-efficiency, aluminum is increasingly favored for weight reduction in electric vehicles (EVs). However, aluminum requires distinct die compensation strategies due to its higher tendency for springback—the material's elastic recovery after forming. Engineers must simulate these behaviors during the design phase to prevent dimensional non-conformance.

Step-by-Step Process Flow (OP10–OP50)

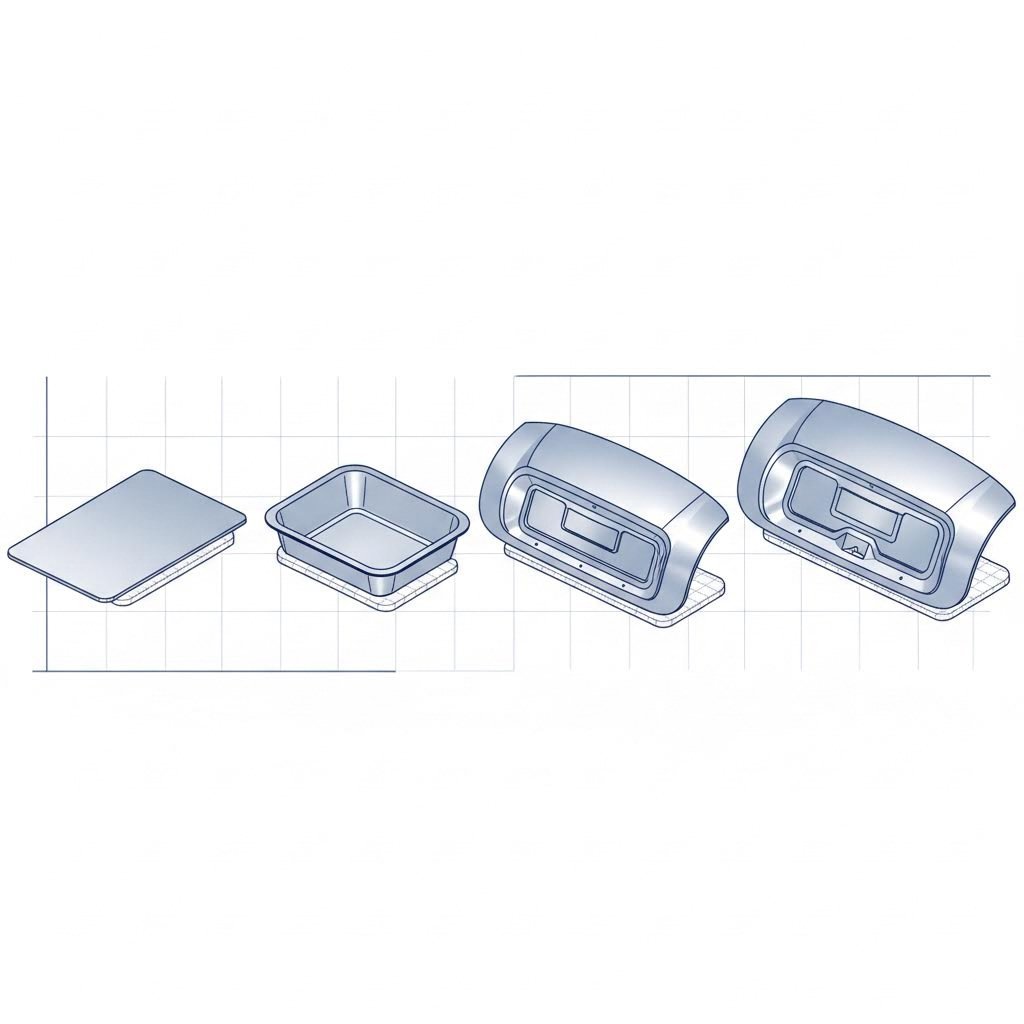

A standard high-volume trunk lid production line utilizes a tandem or transfer press setup divided into five operational stages (OP). This sequential approach allows for the gradual formation of complex features without overstressing the metal.

-

OP10: Deep Drawing

The flat blank (often arc-shaped to minimize scrap) is loaded into the first die. The press applies massive tonnage to stretch the metal over the punch, establishing the primary 3D geometry. This is the most critical stage for controlling material flow; incorrect binder pressure here causes the majority of forming defects. -

OP20: Trimming & Piercing

Once the general shape is set, the panel moves to the second station. Here, scrap cutters remove the excess material (addendum) used to hold the sheet during drawing. Preliminary holes for alignment or non-critical mounting points may be pierced at this stage. -

OP30: Flanging & Restriking

The edges of the panel are bent to form flanges, which are essential for the hemming process (joining inner and outer panels later). Restriking dies may sharpen specific radii or geometric features that could not be fully formed in OP10 due to material flow limitations. -

OP40: Cam Operations

Using cam-driven tools, the press performs side-action piercing or trimming. This is necessary for holes or features that are not perpendicular to the press stroke, such as side mounting holes for trunk hinges. -

OP50: Final Piercing & Calibration

The final station ensures all mounting points—for the lock mechanism, wiring harness, and emblems—are pierced with extreme precision. A final calibration strike may be applied to ensure the panel meets the tight tolerances required for assembly.

Common Defects & Engineering Solutions

Stamping large, complex panels like trunk lids is a constant battle against physics. Two opposing defects often plague the process: wrinkling (excess material) and cracking (insufficient material). In many cases, a process window of only a few millimeters exists between these two failure modes.

Thermal Expansion and Slip Lines

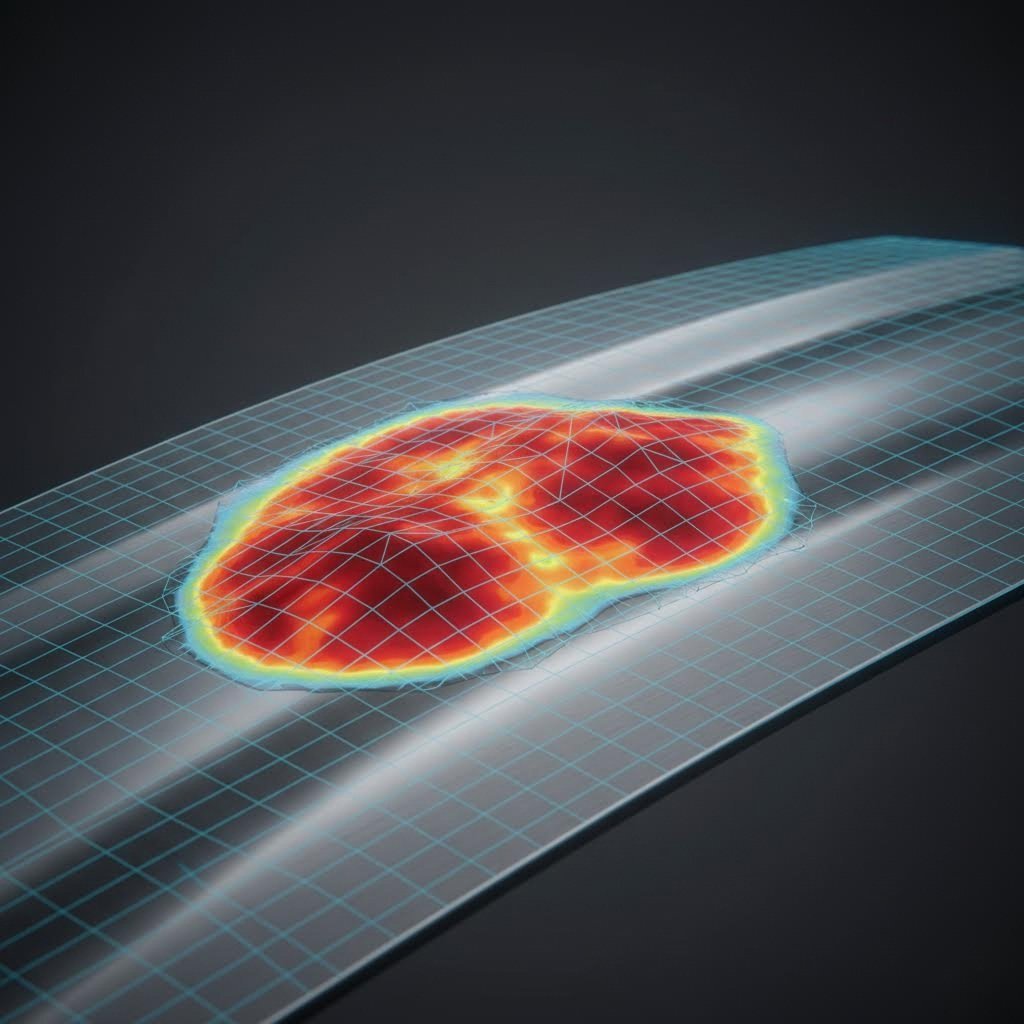

One often-overlooked variable is thermal expansion. In a detailed case study of a trunk lid inner panel, researchers found that friction generated heat caused the die to expand, narrowing the gap between the upper die and blank holder. Over a production run of 950 parts, this thermal shift caused the "slip line" (material draw-in boundary) to move by approximately 9mm. This fluctuation can push a stable process into failure, causing cracks late in the shift.

Advanced Process Corrections

To combat these issues, engineers employ sophisticated countermeasures:

- Dynamic Cushion Force: Instead of a constant holding pressure, modern presses use a segmented force profile. A lower force is applied initially to allow material draw-in, followed by higher force to lock the sheet and stretch it taut, preventing wrinkles.

- Lubrication Management: Adjusting the oil coating weight is a precise lever for quality control. Increasing the oil density from 0.5g/m² to 1.0g/m² can significantly reduce friction, resolving cracking issues caused by material drag.

- Active Die Cooling: Installing pneumatic blowing devices to cool the die surface helps maintain a stable temperature, preventing the thermal expansion that alters die gaps.

Achieving this level of process stability, especially when managing thermal fluctuations and material variations, requires capable manufacturing partners. For automotive OEMs and Tier 1 suppliers seeking to bridge the gap from rapid prototyping to high-volume manufacturing, Shaoyi Metal Technology offers comprehensive stamping solutions. Leveraging IATF 16949-certified precision and press capabilities up to 600 tons, they deliver critical components like control arms and subframes with strict adherence to global standards—whether you need 50 prototypes in five days or millions of mass-produced parts.

Quality Control: The Final Checking Fixture

The "Final Checking Fixture" is the ultimate arbiter of quality before a trunk lid reaches the assembly line. It functions as a physical negative of the vehicle's rear body structure, designed to verify dimensional accuracy, fit, and flushness.

Key components of a robust inspection strategy include:

- Master Datum System (MCS): A three-plane system of pins and pads that positions the trunk lid in its exact nominal location, replicating how it mounts to the car.

- Surface Verification Plates: Often made of aluminum or resin, these contour gauges check the gap and flushness of the panel's outer perimeter against the vehicle body.

- Sealing Surface Verification: A critical check for the inner panel's flange, ensuring it provides a continuous, defect-free surface for the weatherstrip seal. Any deviation here leads to water leaks and wind noise.

- Blue Light Scanning: While physical fixtures are essential, many manufacturers now augment them with non-contact laser scanning to generate heat maps of surface deviations, allowing for rapid feedback to the press line.

Integrated FAQ

1. What are the critical stages in automotive stamping?

The automotive stamping process typically follows a sequence of five to seven operations. It begins with blanking (cutting the raw sheet), followed by drawing (forming the 3D shape), trimming (removing excess metal), and flanging (bending edges for assembly). Final steps often include piercing mounting holes and restriking to calibrate dimensions. For complex parts like trunk lids, these are performed in a transfer or tandem press line.

2. How is springback managed in trunk lid manufacturing?

Springback—the tendency of metal to return to its original shape after forming—is managed through die compensation. Engineers modify the tool geometry to "over-bend" the material, anticipating its elastic recovery. Advanced simulation software (CAE) is used to predict these movements, especially for aluminum panels which exhibit higher springback than steel.

3. What is the role of a checking fixture in stamping?

A checking fixture is a precision tool used to validate the quality of stamped parts. It physically replicates the vehicle's mounting points to verify the part's dimensional accuracy, hole locations, and surface contours. For trunk lids, it specifically checks the "gap and flushness" relative to the rear fenders and ensures the weatherstrip sealing surface is within tolerance to prevent leaks.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —