Surface Finishing for Stamped Car Parts: Standards & Options

TL;DR

For stamped automotive parts, the industry standard for corrosion resistance and durability is the "Duplex System"—an E-Coat primer followed by a Powder Coat topcoat. This combination ensures protection in deep recesses (via immersion) and withstands stone chips and UV exposure (via spray). For high-strength fasteners and under-hood components where coating thickness must be minimized, Zinc-Nickel plating with a hexavalent chrome-free (CrVI-free) passivate is the superior choice, often exceeding 1,000 hours in salt spray tests compared to standard zinc's 120–200 hours. All automotive finishes must now comply with strict ELV directives, necessitating a shift to trivalent chromium chemistries.

The "Duplex" Standard: E-Coating vs. Powder Coating

In automotive manufacturing, specifying a single finish is often insufficient for exterior or chassis parts exposed to harsh road environments. The "Duplex System" combines the strengths of Electro-coating (E-Coat) and Powder Coating to create a finish that is superior to the sum of its parts.

Layer 1: E-Coat (The Immersion Primer)

E-coating, or electrophoretic deposition, functions like "plating with paint." The stamped part is submerged in a water-based solution where an electric current deposits a uniform protective layer, typically between 15–25 microns thick. Its primary advantage is throw power—the ability to coat internal geometries, blind holes, and the inner surfaces of U-shaped brackets that line-of-sight spray processes cannot reach. Without E-coat, a complex stamped control arm would rust from the inside out.

Layer 2: Powder Coat (The Durable Topcoat)

While E-coat provides total coverage, it is generally not UV-stable and can chalk or fade under sunlight. Powder coating is applied electrostatically as a dry powder and cured to form a thick, durable "skin" (typically 50–100+ microns). This layer provides essential resistance to stone chips (impact resistance), UV radiation, and road debris. By applying powder over E-coat, engineers achieve a dual defense: the E-coat protects the steel substrate from corrosion in hidden areas, while the powder coat provides the aesthetic finish and physical armor.

Corrosion Protection: Plating & The Chrome-Free Shift

For fasteners, clips, and small stamped brackets where thick paint layers would interfere with threads or assembly tolerances, electroplating remains the dominant choice. However, the landscape of automotive plating has shifted dramatically due to environmental regulations.

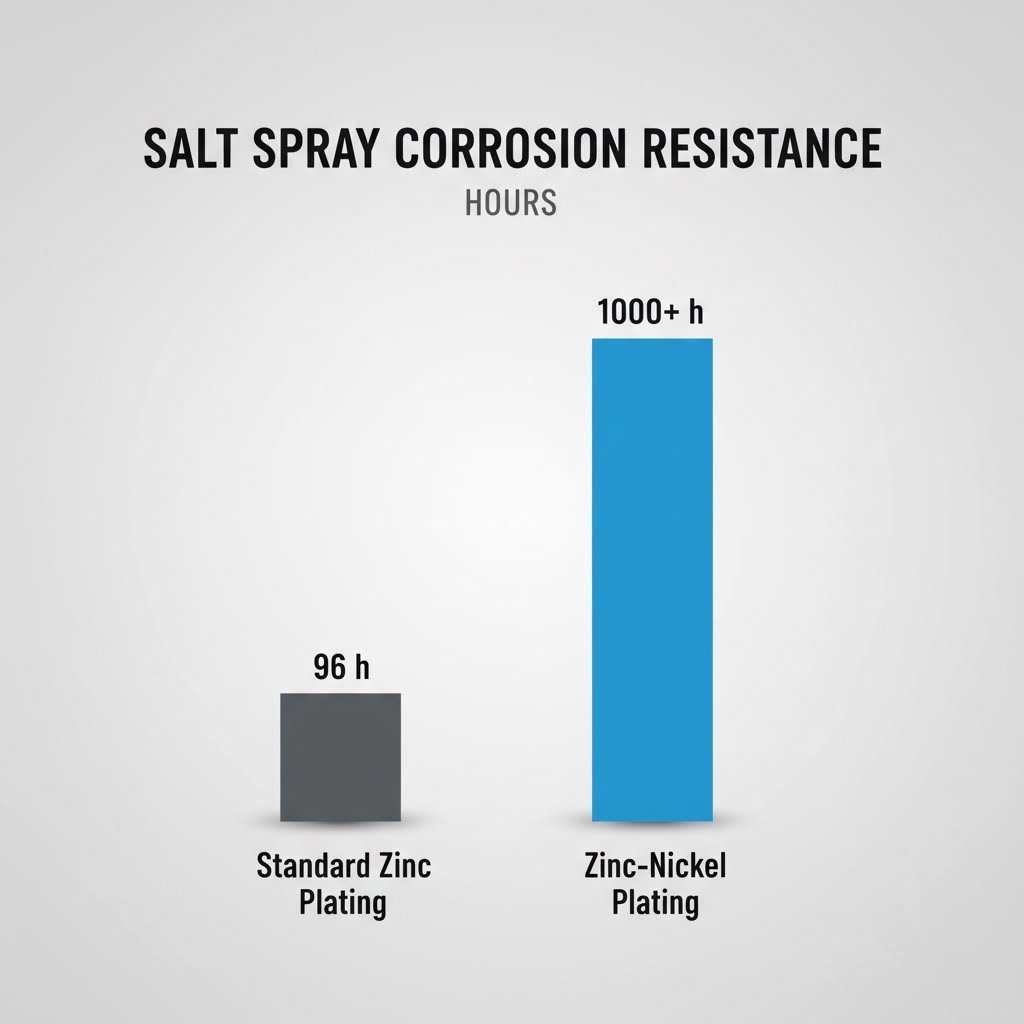

Zinc vs. Zinc-Nickel Performance

Standard Zinc plating is cost-effective but limited in performance, typically failing (showing red rust) after 120–200 hours in neutral salt spray tests (ASTM B117). For critical automotive applications, Zinc-Nickel (Zn-Ni) plating has become the gold standard. With a nickel content of 12–16%, Zn-Ni coatings provide a barrier that is significantly harder and more thermally stable than pure zinc. A 10-micron Zn-Ni layer frequently withstands 1,000+ hours of salt spray exposure before red rust appears, making it mandatory for many OEM powertrain and chassis specifications.

The ELV Directive and CrVI-Free Passivates

Historically, zinc plating relied on hexavalent yellow chromate (CrVI) for corrosion resistance. Since the European Union's End of Life Vehicle (ELV) Directive banned CrVI due to toxicity, the industry has transitioned to trivalent chromium (CrIII) passivates. Modern thick-film trivalent passivates, often sealed with a topcoat, meet or exceed the performance of legacy hexavalent coatings. Engineers must explicitly specify "CrVI-free" or "trivalent passivate" (often referencing ISO 19598) to ensure compliance with global environmental standards.

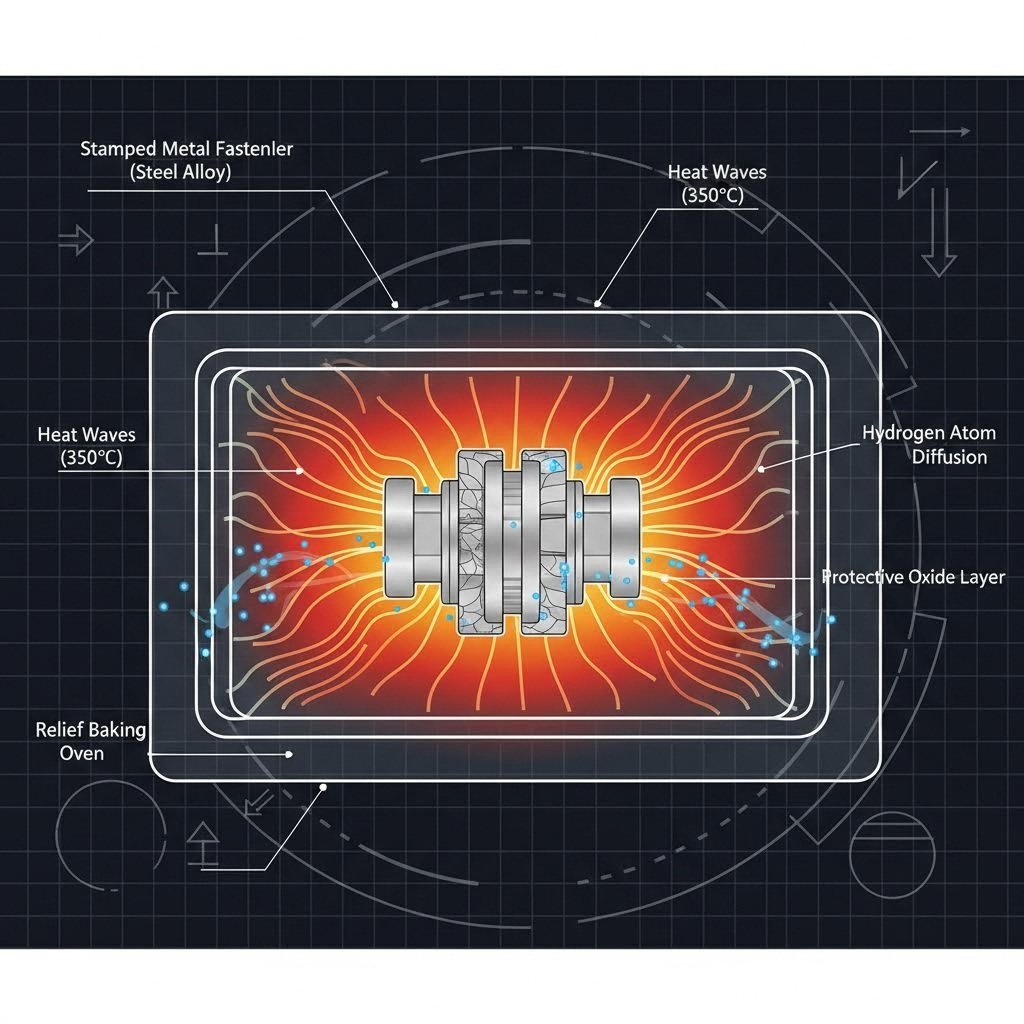

Hydrogen Embrittlement Relief

Stamped parts made from high-strength steel (tensile strength >1000 MPa) are susceptible to hydrogen embrittlement during the pickling and plating process. Hydrogen atoms can diffuse into the steel lattice, causing sudden, catastrophic failure under load. To prevent this, specifications must include a mandatory baking cycle (typically 4–24 hours at 190°C–220°C) immediately after plating to drive out trapped hydrogen.

Surface Quality & Defect Troubleshooting

The quality of the final finish is inextricably linked to the quality of the raw stamped part. Finishing processes often highlight, rather than hide, surface defects.

- Burrs and Sharp Edges: Coatings pull away from sharp edges during curing (the "edge creep" effect), leaving them exposed to corrosion. Mechanical deburring or tumbling is a non-negotiable pre-treatment for stamped parts to ensure uniform coating adhesion.

- Orange Peel: A common defect in powder coating where the finish resembles the texture of an orange skin. This is often caused by applying the powder too thick or curing it too quickly. For stamped parts with large flat surfaces, this visual defect can be grounds for rejection.

- Oil and Lubricant Residue: Stamping presses use heavy lubricants that can carbonize during welding or heat treating. If not removed by aggressive alkaline cleaning or vapor degreasing before finishing, these residues cause blistering and poor adhesion (peeling) of the final coat.

Matching Finish to Function: An Application Matrix

Selecting the right finish requires mapping the component's location to its environmental stress factors. Use this decision matrix to guide specification:

| Vehicle Zone | Typical Parts | Primary Stressors | Recommended Finish |

|---|---|---|---|

| Underbody / Chassis | Control arms, subframes, brackets | Stone chips, road salt, constant moisture | Duplex System (E-Coat + Powder) or Zinc-Nickel (for fasteners) |

| Under-the-Hood | Engine brackets, clips, fuel rails | High heat, thermal cycling, automotive fluids | Zinc-Nickel (heat resistant) or Phosphating (oil retention) |

| Interior (Visible) | Trim bezels, door handles, speaker grilles | Touch wear, UV (sunlight), aesthetics | PVD (Physical Vapor Deposition), Chrome Plating, or Decorative Powder |

| Electronics | Busbars, connectors, sensor housings | Conductivity, oxidation, fretting corrosion | Tin, Silver, or Gold plating (for conductivity) |

Key Automotive Standards & Specifications

Reliable sourcing depends on adherence to internationally recognized standards. Procurement teams should require validation against these benchmarks to verify supplier capability.

- ASTM B117 / ISO 9227: The universal standard for Neutral Salt Spray (NSS) testing. While not a perfect predictor of real-world life, it is the primary comparative metric (e.g., "Must pass 480 hours to white rust").

- ISO 19598: The governing standard for electroplated coatings of zinc and zinc alloys on iron or steel with supplementary CrVI-free treatments.

- ASTM B841: Specific standard for electrodeposited zinc-nickel alloy coatings, defining the required nickel content (12–16%) for optimal corrosion resistance.

- IATF 16949: Beyond specific coating norms, the overall quality management system is critical. Suppliers like Shaoyi Metal Technology leverage IATF 16949-certified processes to ensure that precision stamped components—from prototypes to mass production—maintain consistent surface quality and dimensional adherence to these rigorous global OEM standards.

Conclusion

Surface finishing for stamped car parts is no longer just about aesthetics; it is a complex engineering challenge driven by extended warranty requirements and strict environmental mandates. The shift to Zinc-Nickel and CrVI-free passivates represents the new baseline for functional hardware, while the Duplex E-Coat/Powder system remains the champion for structural durability.

For engineers and procurement specialists, success lies in detailed specification. defining the exact plating thickness, salt spray hours, and hydrogen embrittlement relief cycles prevents costly field failures. By aligning design choices with these modern standards, manufacturers ensure their stamped parts survive the punishing reality of the automotive lifecycle.

Frequently Asked Questions

1. What is the difference between E-coating and Powder coating?

E-coating (electro-coating) is an immersion process that deposits a thin, uniform film (15–25 microns) using an electric current, making it ideal for protecting internal recesses and acting as a primer. Powder coating is a dry spray process that applies a thicker layer (50+ microns) for superior impact resistance, UV stability, and aesthetics, but it cannot coat deep inner surfaces as effectively as E-coat.

2. Why is Zinc-Nickel plating preferred over standard Zinc for automotive parts?

Zinc-Nickel plating offers vastly superior corrosion resistance and heat tolerance. While standard zinc may fail after 120 hours in a salt spray test, Zinc-Nickel (with 12–16% nickel) typically withstands over 1,000 hours. It is also harder and less likely to corrode galvanically when in contact with aluminum components, making it essential for modern vehicle warranties.

3. What is the standard salt spray test duration for automotive parts?

Requirements vary by component location. Interior parts may only require 96–120 hours to white rust. Underbody and exterior parts typically require 480 to 1,000+ hours of neutral salt spray (ASTM B117) resistance without red rust. OEM-specific standards (like those from GM, Ford, or VW) often dictate the exact duration.

4. How do you prevent hydrogen embrittlement in plated stamped parts?

High-strength steel parts (typically those with hardness >31 HRC or tensile strength >1000 MPa) must undergo a baking process immediately after plating—usually within 1–4 hours. Baking the parts at 190°C–220°C for at least 4 hours facilitates the diffusion of trapped hydrogen out of the steel, preventing brittle failure under load.

5. What are common surface defects in stamped parts that affect finishing?

Common defects include burrs, which cause coating failure at sharp edges; lubricant residues, which prevent adhesion; and scratches or die marks, which show through thin coatings like E-coat. Proper deburring and aggressive cleaning/degreasing prior to finishing are critical steps to prevent these issues.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —