Annealing Process in Metal Stamping: The Engineering Guide to Defect-Free Parts

TL;DR

Annealing in metal stamping is a critical heat treatment process designed to restore ductility to work-hardened metals, enabling them to undergo severe deformation without failure. By heating the material above its recrystallization temperature and controlling the cooling rate, the process relieves internal stresses and resets the grain structure.

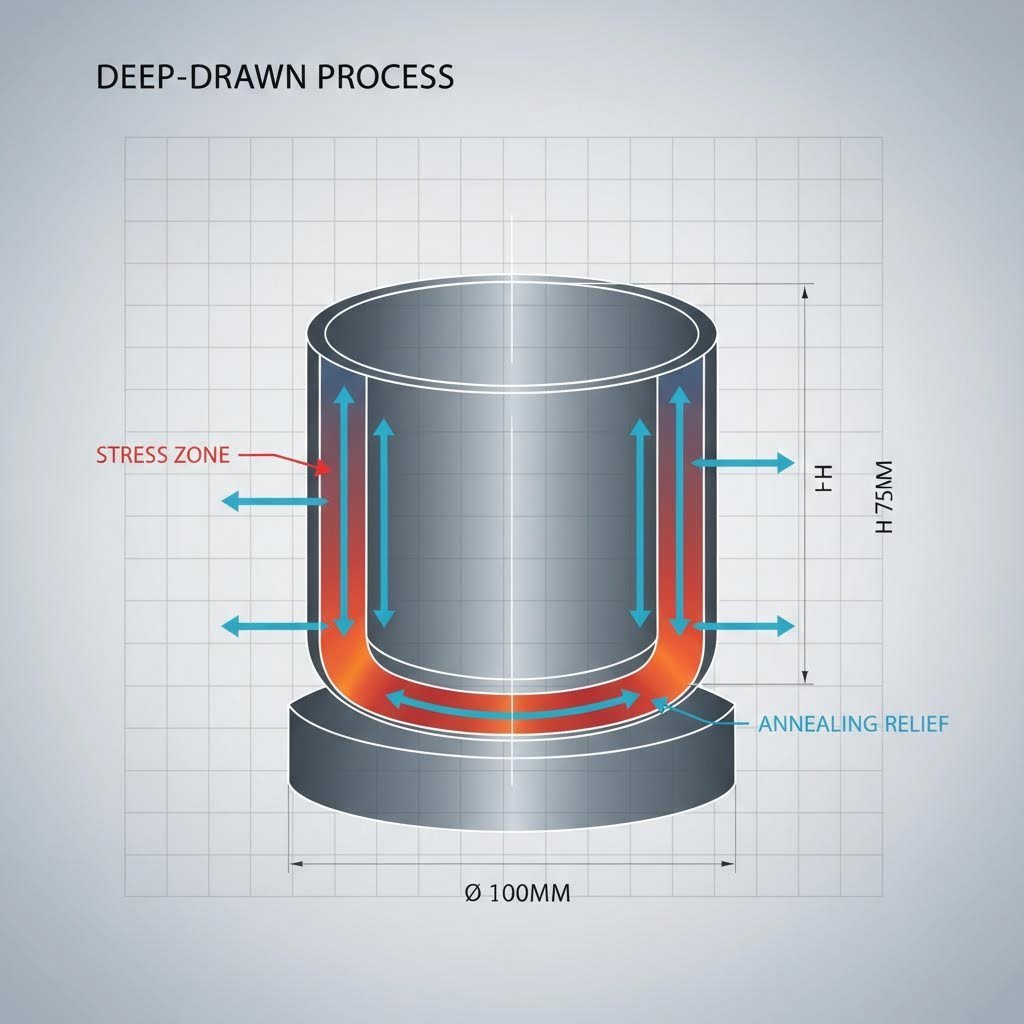

For stamping engineers, this process is essential for preventing common defects like cracking, tearing, and springback during deep drawing or complex forming operations. It allows for multi-stage forming of parts that would otherwise become too brittle to process, ensuring consistent quality in high-precision components.

Why Annealing is Critical for Metal Stamping

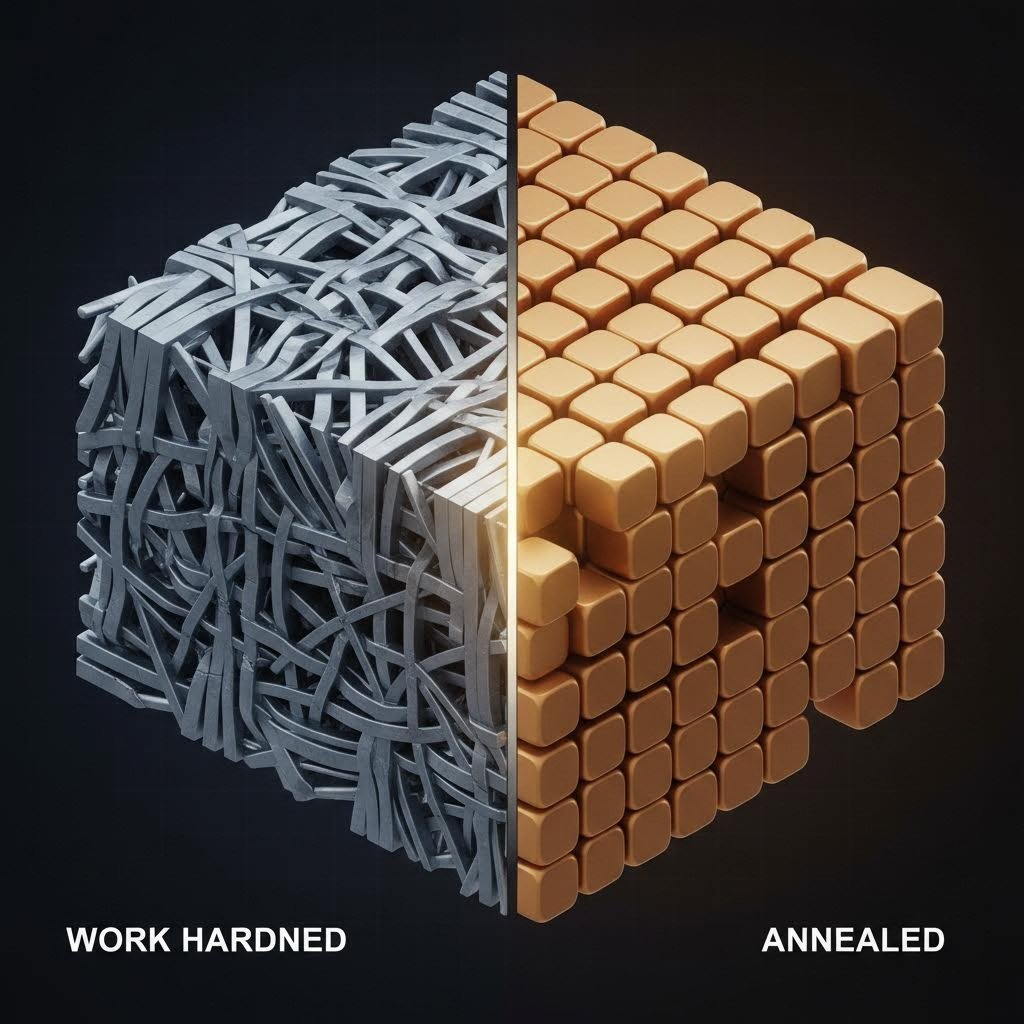

In the metal stamping ecosystem, the primary adversary of precision forming is work hardening (also known as cold working). As a metal sheet is subjected to the immense compressive and tensile forces of a press, its crystal lattice becomes distorted. Dislocations—defects in the atomic structure—pile up, making the material harder and stronger but significantly less ductile.

Without intervention, this increased brittleness leads to catastrophic forming failures. If a work-hardened part is forced into a subsequent draw station, it is likely to fracture, tear at the corners, or exhibit excessive springback, compromising dimensional accuracy. Annealing acts as a metallurgical reset button. By thermally treating the part, manufacturers can erase the history of cold work, softening the metal back to a formable state.

The economic impact of this process is profound. While annealing adds a step to the manufacturing workflow, it dramatically reduces scrap rates and extends die life. For complex geometries requiring deep draws—such as automotive control arms or beverage cans—annealing is often the only variable allowing the metal to stretch beyond its initial plasticity limits without structural failure.

The Annealing Lifecycle: 3 Technical Stages

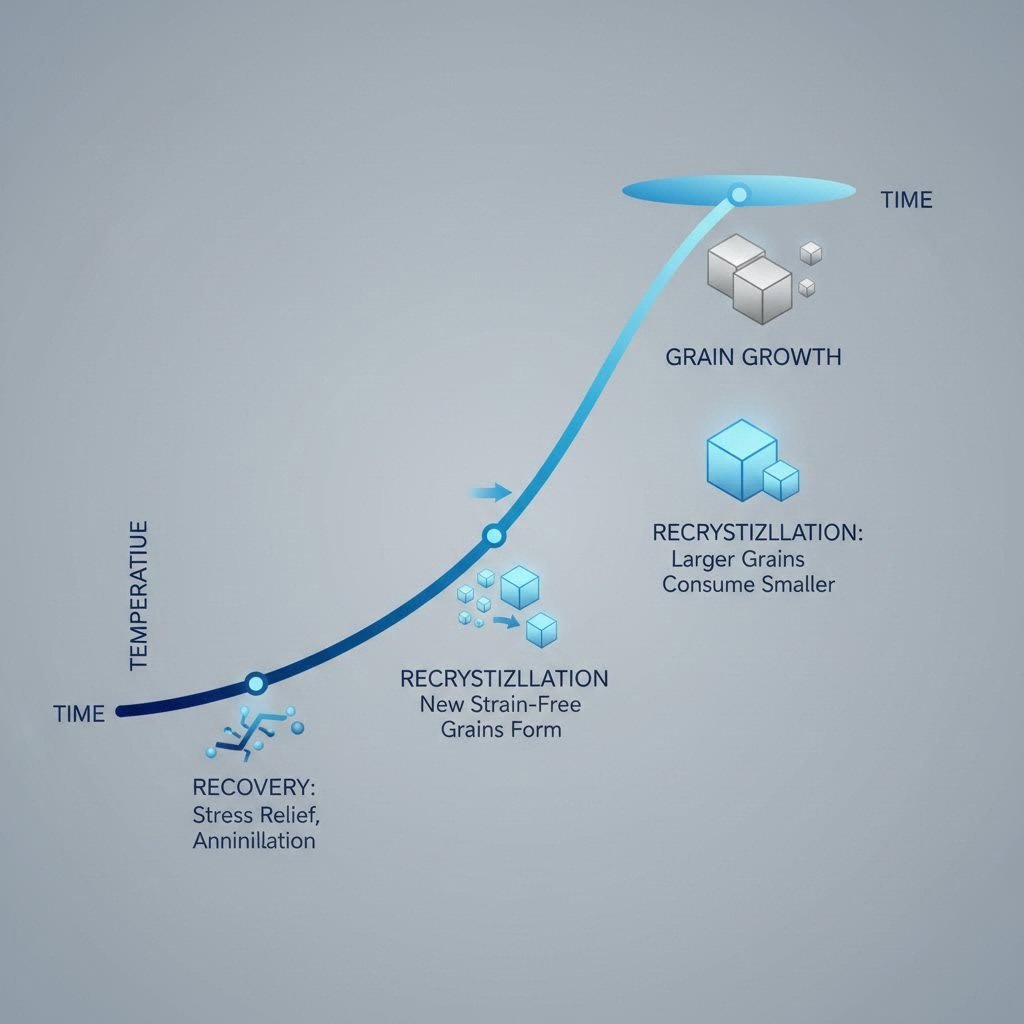

To the naked eye, annealing appears to be a simple heating and cooling cycle. However, at the microscopic level, three distinct metallurgical events occur that dictate the final quality of the stamped part.

1. Recovery Phase

The first stage, known as recovery, occurs at lower temperatures. Here, the furnace provides just enough thermal energy to mobilize the atoms within the metal lattice. Internal stresses stored during the initial stamping passes are relieved as atoms migrate to more stable positions. Crucially, the visible grain structure remains largely unchanged during this phase, but the material's electrical and thermal conductivity begins to improve, preparing the matrix for structural transformation.

2. Recrystallization Phase

This is the critical threshold for stamping applications. As the temperature rises above the metal's recrystallization temperature, the distorted, elongated grains caused by cold working are replaced by a new set of stress-free, equiaxed grains. The density of dislocations drops precipitously, and the mechanical properties of the metal are effectively reset. For deep drawing operations, achieving complete recrystallization is non-negotiable, as this restores the ductility required for the next forming operation.

3. Grain Growth Phase

If the material is held at temperature too long or heated excessively, the newly formed grains will begin to consume one another, growing in size. While some grain growth is acceptable, excessive growth leads to a coarse microstructure. In stamping, coarse grains can cause the "orange peel" effect—a rough, textured surface finish that often results in cosmetic rejection or premature tearing. Precision control of soak time is vital to arrest the process before grain growth degrades the surface quality.

Types of Annealing in Stamping Workflows

Not all annealing processes serve the same purpose. Stamping engineers must select the specific variation that aligns with their production volume and part geometry.

- Interstage (Process) Annealing: This is the workhorse of deep drawing. When a part requires a draw ratio that exceeds the metal's forming limit, it is stamped, annealed to restore ductility, and then stamped again. This cycle allows for the production of elongated shapes, such as cartridge cases or high-pressure cylinders, which are impossible to form in a single hit.

- Stress Relief Annealing: Unlike full annealing, this process uses lower temperatures to relax residual stresses without altering the material's gross hardness or grain structure. It is frequently applied after the final stamping operation to prevent warping or dimensional instability during service.

- Batch vs. Continuous Annealing: The choice of method often dictates production speed. Batch annealing involves heating large loads in a sealed furnace, ideal for lower volumes or parts requiring long soak times. Conversely, continuous annealing feeds strip metal through a tunnel furnace, aligning perfectly with high-speed stamping lines.

For manufacturers scaling from prototyping to mass production, the ability to manage these heat treatment variables is a key differentiator. Advanced automotive suppliers like Shaoyi Metal Technology leverage these integrated capabilities to deliver complex components—from prototypes to millions of IATF 16949-certified units—ensuring that even high-tonnage parts like subframes maintain critical ductility and structural integrity throughout the forming process.

Material-Specific Guidelines

Successful annealing requires adhering to strict temperature windows tailored to the alloy's chemistry. Deviating from these ranges can result in incomplete softening or melting.

| Material Family | Approx. Annealing Temp | Cooling Method | Stamping Considerations |

|---|---|---|---|

| Carbon Steel | 700°C – 900°C | Slow (Furnace Cool) | Requires controlled atmosphere to prevent heavy scaling (oxidation). |

| Aluminum Alloys | 300°C – 410°C | Air Cool | Narrow temperature window; overheating can permanently degrade strength. |

| Copper / Brass | 370°C – 650°C | Rapid Quench or Air | Rapid cooling can help prevent oxidation scales; highly responsive to annealing. |

| Stainless Steel (300 Series) | 1010°C – 1120°C | Rapid Quench | Must be cooled quickly to prevent carbide precipitation which reduces corrosion resistance. |

Aluminum requires particular care because its annealing temperature is much closer to its melting point compared to steel. Precise furnace controls are mandatory to prevent the workpiece from slumping or distorting under its own weight.

Annealing vs. Tempering vs. Normalizing

Confusion often exists between these heat treatments, yet their objectives in a stamping context are diametrically opposed.

- Annealing is about softening. It is performed before or between stamping steps to maximize formability. The goal is to make the metal as pliable as possible.

- Tempering is performed after hardening. If a stamped part is heat-treated to be hard (martensitic), it becomes brittle. Tempering gently reheats it to sacrifice a little hardness in exchange for toughness, preventing it from snapping under impact.

- Normalizing involves heating steel and air-cooling it to refine the grain size and achieve a uniform microstructure. While it restores some ductility, the resulting metal is harder and stronger than annealed metal. It is often used for structural parts requiring higher strength, whereas annealing is reserved for parts needing maximum deformability.

Troubleshooting: Defects and Quality Control

Even with established parameters, annealing defects can arise. Recognizing these symptoms early saves batches from the scrap bin.

Oxidation and Scaling

If parts emerge from the furnace with a flaky, dark crust, the atmosphere was uncontrolled. For precision stampings, this scale ruins surface finish and damages dies. The solution is using a vacuum furnace or an inert gas atmosphere (nitrogen/hydrogen) to protect the metal surface during the soak.

The "Orange Peel" Effect

A rough, textured surface appearing on the radius of a drawn part typically indicates excessive grain growth. This suggests the annealing temperature was too high or the soak time too long. Reducing the cycle time will keep the grain structure fine and the surface smooth.

Inconsistent Hardness

If one area of a batch forms perfectly while another cracks, the furnace may have uneven temperature distribution (cold spots). Regular thermal profiling of the furnace and ensuring proper spacing of parts in the basket are essential for uniform recrystallization.

Mastering Metallurgy for Stamping Success

Annealing is more than just a heating step; it is a strategic enabler of complex metal forming. By understanding the interplay between work hardening and recrystallization, engineers can push the limits of what is possible in metal stamping. Whether alleviating stress in a simple bracket or enabling the multi-stage draw of a deep vessel, the correct application of annealing ensures that the metal works with the press, not against it. Success lies in the details: precise temperature control, appropriate atmosphere selection, and rigorous quality validation.

Frequently Asked Questions

1. What happens at the annealing stage?

During the annealing stage, the metal is heated to a specific temperature where the atoms within its crystal lattice gain enough energy to migrate and rearrange. This process eliminates the dislocations caused by previous cold working, effectively relieving internal stresses. New, stress-free grains form (recrystallization), which restores the metal's softness and ductility, preparing it for further deformation.

2. Does annealing make metal harder or softer?

Annealing makes metal softer. Its primary purpose is to reduce the hardness and brittleness induced by work hardening. By restoring the metal's natural ductility, annealing makes the material more workable and easier to cut, shape, or stamp without cracking. If you need to harden the metal, you would use a different process, such as quenching and tempering.

3. How many times can you anneal metal?

There is generally no theoretical limit to how many times a piece of metal can be annealed. The process is a "reset" for the material's grain structure. In complex deep-drawing operations, a part may be stamped, annealed, and re-stamped multiple times until the final shape is achieved. However, each cycle consumes energy and time, so manufacturers optimize the process to use the fewest annealing steps necessary.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —