Control Arm Stamping Process: Engineering the Modern Suspension

TL;DR

The control arm stamping process is a high-volume manufacturing method where flat sheets of steel (typically High Strength Low Alloy or HSLA) are pressed into precise three-dimensional shapes using hydraulic or mechanical presses. Unlike solid cast or forged components, stamped control arms are usually constructed from two separate steel shells—an upper and a lower half—that are welded together to form a hollow, lightweight, and cost-effective structure.

This process relies on progressive or transfer dies to perform sequential operations like blanking, forming, and punching. For automotive engineers and buyers, the key distinction lies in the balance between mass-production efficiency and structural rigidity; while stamped arms are lighter and cheaper than cast iron alternatives, they require specific treatments like E-coating to prevent internal corrosion.

Part 1: Stamped vs. Cast vs. Forged: Contextualizing the Technology

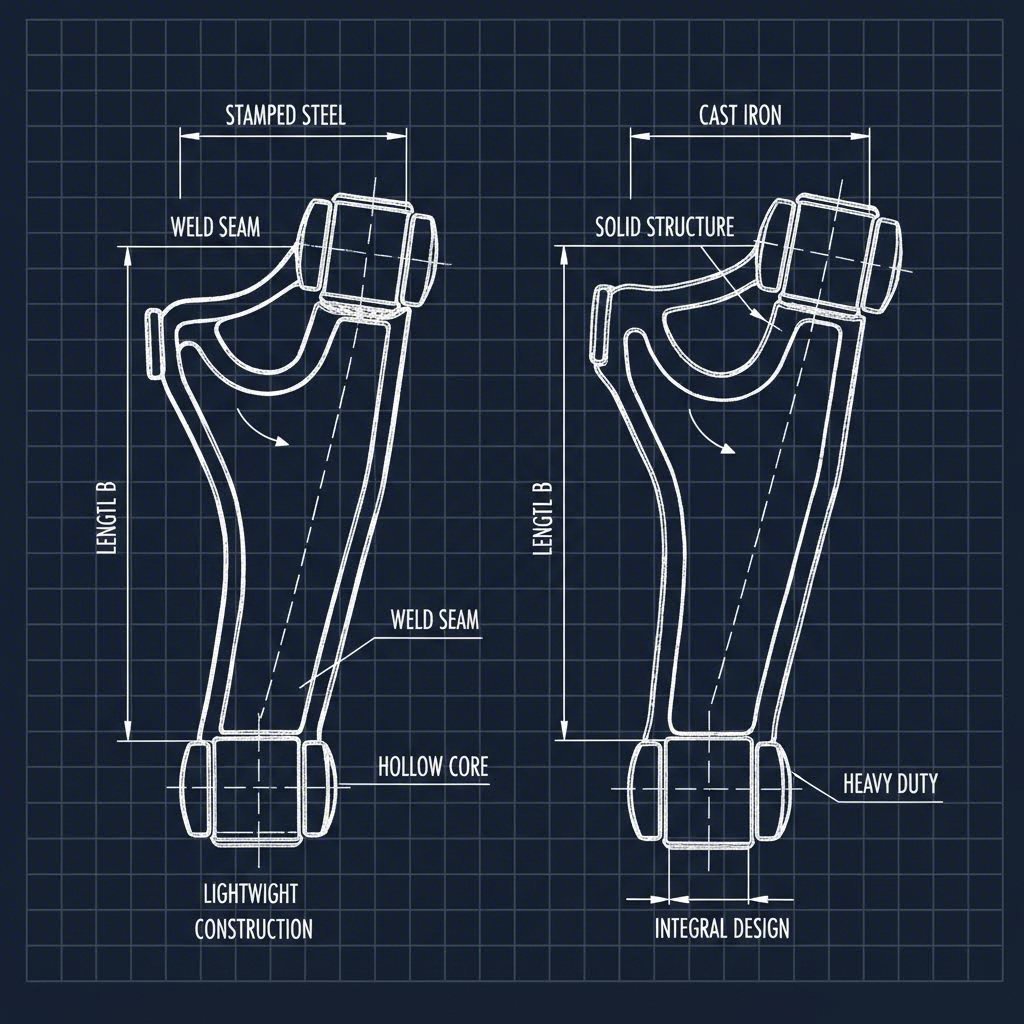

To understand the value of the control arm stamping process, one must first distinguish it from the alternative manufacturing methods: casting and forging. While all three methods produce suspension links that connect the chassis to the wheel hub, the engineering mechanics and resulting material properties differ fundamentally. Stamped arms dominate the economy and mid-range vehicle market due to their superior cost-to-weight ratio.

The primary structural difference is density. Cast iron and forged steel arms are solid, dense components. Stamped steel arms, conversely, are hollow structures created by welding two formed sheets together. This "clamshell" design allows manufacturers to achieve high rigidity with significantly less material mass.

Comparison of Control Arm Manufacturing Methods

| Feature | Stamped Steel | Cast Iron / Aluminum | Forged Steel |

|---|---|---|---|

| Process | Cold forming sheet metal (pressing) + Welding | Pouring molten metal into a mold | Hammering/pressing hot billet under extreme pressure |

| Structure | Hollow (Welded "Sandwich" construction) | Solid (Dense and continuous) | Solid (Aligned grain structure) |

| Weight | Low (Lightweight due to hollow core) | High (Iron) / Low (Aluminum) | High (Dense steel) / Low (Aluminum) |

| Cost | Low (Ideal for mass production) | Moderate | High (Performance applications) |

| Failure Mode | Deforms/Bends (Ductile) | Cracks/Shatters (Brittle behavior in iron) | Bends under extreme load (High yield strength) |

Part 2: The Stamping Process Flow: Step-by-Step Engineering

The manufacturing of a stamped control arm is a sequential operation that transforms a raw steel coil into a finished suspension component. This process typically utilizes progressive die technology, where a strip of metal moves through multiple stations within a single press, performing a different operation at each stop.

1. Raw Material Preparation

The process begins with a coil of High Strength Low Alloy (HSLA) steel. HSLA is preferred over standard carbon steel because it offers superior yield strength, allowing for thinner gauge sheets (typically 3–5mm) without compromising structural integrity. The coil is unwound, leveled to remove curvature, and lubricated to reduce friction during the pressing stages.

2. Blanking and Piercing

In the first die station, the 2D outline of the control arm halves is cut from the strip—a process known as blanking. Simultaneously, piercing operations create the initial holes for bushings and ball joints. Precision here is critical; the clearance between the punch and die is usually maintained at 2–10% of the material thickness to prevent excessive burrs and ensure a clean edge.

3. Forming and Deep Drawing

This is the core of the stamping process. The flat blanks are pressed into 3D shapes. The steel undergoes plastic deformation, pushed beyond its elastic limit to take the permanent shape of the die. For control arms with significant depth, a deep drawing technique is used. Engineers must calculate the "springback"—the tendency of the metal to try to return to its original shape—and over-bend the part slightly to compensate.

4. Assembly and Welding

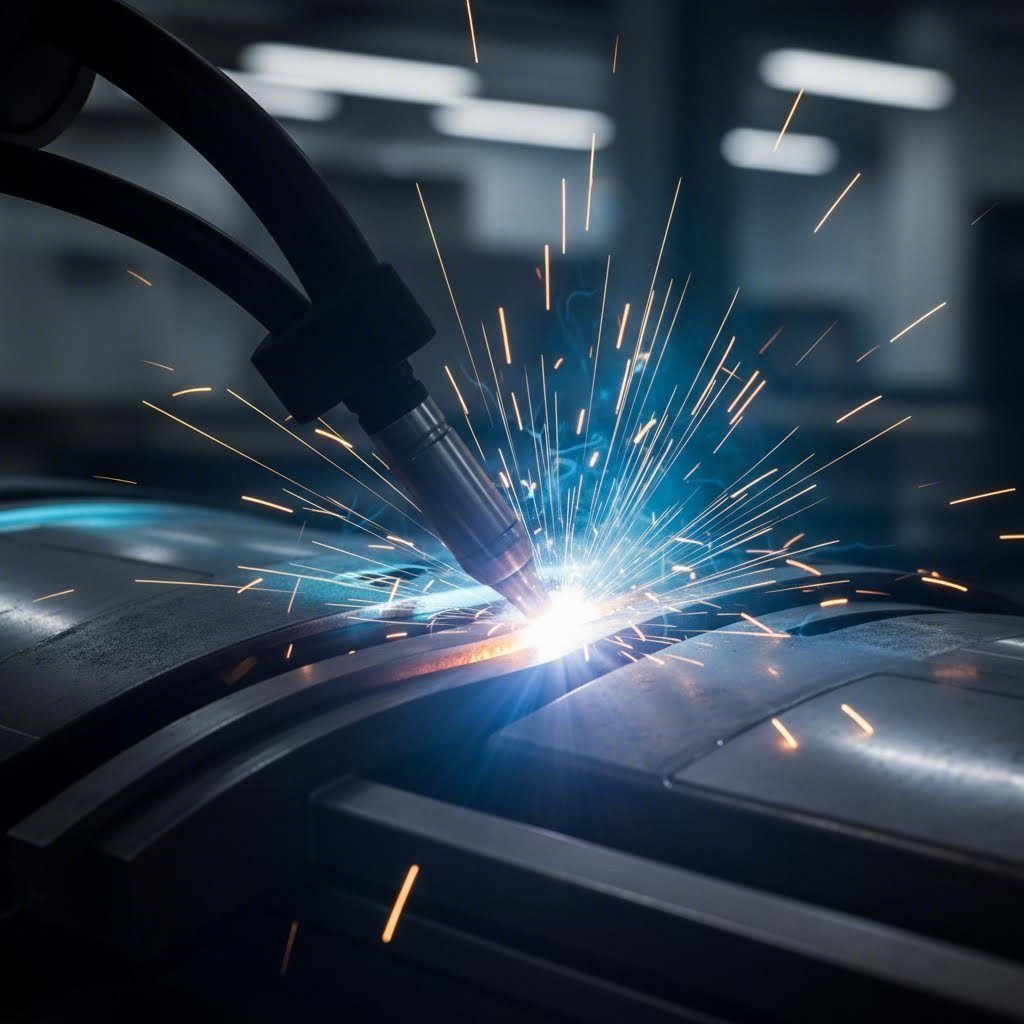

Unique to control arms, the stamping process rarely ends with a single piece. The upper and lower stamped shells are placed together in a fixture to form a box-like structure. They are then joined using automated MIG or laser welding along the perimeter seams. This step creates the final hollow geometry that provides the arm's torsional rigidity.

5. Surface Finishing

Because stamped steel is susceptible to oxidation, the final step involves aggressive corrosion protection. The assembled arms typically undergo E-coating (electrophoretic painting), where they are submerged in an electrically charged paint bath. This ensures the protective coating reaches inside the hollow cavity, preventing rust from compromising the welds.

Part 3: Tooling, Material Science, and Engineering Challenges

The efficiency of the control arm stamping process relies heavily on the quality of the tooling. Progressive dies are complex, multi-stage tools that can cost hundreds of thousands of dollars but are capable of producing millions of parts with consistent tolerances. These dies are designed using Finite Element Analysis (FEA) to predict how the metal will flow and to prevent defects like wrinkling or tearing during the deep draw phase.

For manufacturers requiring high-precision components, the capability to bridge the gap between prototyping and mass production is vital. Companies like Shaoyi Metal Technology leverage press capabilities up to 600 tons and IATF 16949-certified processes to deliver comprehensive stamping solutions. Their expertise in rapid prototyping allows engineers to validate tool designs and material flow before committing to full-scale hard tooling, ensuring that the final stamped control arms meet strict OEM specifications for safety and durability.

A critical engineering challenge in this phase is managing work hardening. As the steel is stamped and bent, its grain structure becomes compressed, making it harder but more brittle. If the deformation is too aggressive, the part may crack. To mitigate this, process engineers rely on the Forming Limit Diagram (FLD) to determine exactly how much the material can be stretched before failure occurs.

Part 4: Identification and Practical Inspection

For mechanics, enthusiasts, and parts buyers, distinguishing a stamped steel control arm from a cast unit is a necessary skill, particularly when sourcing replacement parts or planning suspension upgrades. The physical construction provides several clear indicators.

- Visual Inspection (The Weld Seam): The most definitive sign of a stamped arm is the welded seam running along the edge of the component. This seam joins the top and bottom stamped shells. Cast and forged arms are solid, single-piece units and will never have a perimeter weld.

- Texture and Finish: Stamped arms typically have a smooth, sheet-metal surface texture, often finished in glossy black E-coat paint. Cast iron arms have a rough, sandy surface texture resulting from the sand molds used in their creation.

- The Magnet Test: If you are unsure whether an arm is stamped steel or cast aluminum, use a magnet. It will stick firmly to stamped steel and cast iron but will not adhere to aluminum.

- The Sound Test: Tap the control arm with a wrench. A stamped steel arm is hollow and will produce a distinct ringing sound. A solid cast or forged arm will produce a dull thud.

When inspecting stamped arms for wear, pay close attention to the welded seam. Rust often begins here or inside the hollow cavity. Additionally, because stamped steel is ductile, impact damage from curbs or potholes may cause the arm to bend rather than crack. Any visible deformation in the arm's geometry is grounds for immediate replacement.

Engineering the Balance: Efficiency vs. Performance

The control arm stamping process represents a triumph of modern manufacturing efficiency. By utilizing advanced progressive dies and automated welding, automakers can produce suspension components that are light enough to improve fuel economy yet strong enough to ensure passenger safety. While they may lack the ultimate rigidity of forged race components, stamped steel arms offer the optimal balance for the vast majority of passenger vehicles on the road today.

Frequently Asked Questions

1. How do I tell if I have stamped steel control arms?

You can identify stamped steel control arms by looking for a welded seam that runs along the perimeter of the arm, joining two halves together. They typically have a smooth, black painted finish and will sound hollow when tapped with a metal tool. A magnet will stick to them, distinguishing them from aluminum parts.

2. Are stamped steel control arms better than cast iron?

It depends on the application. Stamped steel arms are generally lighter and less expensive, making them ideal for standard passenger vehicles where fuel economy and cost are priorities. Cast iron arms are heavier but more rigid, often used in heavy-duty trucks where maximum durability is required.

3. Can stamped control arms be repaired if bent?

No. If a stamped steel control arm is bent, it must be replaced. Attempting to bend it back into shape weakens the metal structure (work softening) and compromises the integrity of the welds, creating a significant safety hazard.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —