Sheet Metal Services Decoded: From First Quote To Finished Part

Understanding Sheet Metal Services and Their Industrial Applications

Ever wondered how flat metal sheets transform into the precise components found in everything from smartphones to aircraft? That's exactly what sheet metal services accomplish. Whether you're sourcing parts for a California sheet metal project or exploring options at a local sheet metal workshop, understanding these fundamental processes helps you make smarter purchasing decisions.

At its core, sheet metal fabrication is the process of converting flat metal sheets—typically steel, aluminum, stainless steel, or copper—into functional parts and structures. According to industry data from Geomiq, the global sheet metal fabrication services market is projected to surpass £15 billion by 2030, reflecting just how essential these services have become across manufacturing sectors.

What Sheet Metal Fabrication Actually Means

Think of sheet metal fabrication as a series of carefully orchestrated steps. You start with a raw metal sheet—sometimes as thin as a few thousandths of an inch or several millimeters thick—and apply various techniques to shape it into something entirely new. Unlike processes that add material (like 3D printing) or remove large portions (like CNC machining from solid blocks), fabrication sheet metal work manipulates the existing material through cutting, bending, and joining.

The beauty of this approach? It creates strong structural parts that remain relatively lightweight and cost-effective. Many custom sheet metal fab projects require no specialized tooling upfront, which reduces both capital costs and project timelines. This flexibility makes these services accessible whether you need a single prototype or thousands of identical components.

From Raw Material to Finished Component

The journey from flat sheet to finished part typically follows three key stages: cutting the metal to size and shape, forming or bending it into the desired geometry, and assembling individual pieces into complete structures. Each stage offers multiple technique options depending on your project's requirements.

Here are the primary service categories you'll encounter when working with fabrication providers:

- Cutting Services: These include laser cutting for precision work, waterjet cutting for heat-sensitive materials, plasma cutting for thicker metals, and mechanical shearing for straight cuts. Punching operations also fall here, creating precise holes or patterns.

- Bending and Forming: Press brake bending creates angles and channels, while roll forming produces curves and cylindrical shapes. Stamping and deep drawing transform flat sheets into three-dimensional forms.

- Welding and Assembly: TIG and MIG welding fuse components permanently, while riveting and fastening provide mechanical joining options. Some projects use industrial adhesives for aesthetic finishes.

- Finishing Operations: Powder coating, anodizing, plating, and other surface treatments enhance appearance, corrosion resistance, and durability.

Much like how someone might research options before committing to hertz car rental for a cross-country trip, taking time to understand these service categories helps you select the right fabrication approach for your specific needs. The goal isn't necessarily choosing the most advanced technique—it's matching the process to your project's requirements for cost, quality, and timeline.

Throughout this guide, you'll discover how each process works, what factors influence pricing, and how to communicate effectively with fabrication partners. Consider this your vendor-neutral roadmap to navigating the world of sheet metal services with confidence.

Core Sheet Metal Cutting and Punching Processes

Now that you understand the basic service categories, let's dive deeper into how cutting operations actually work. Sounds complex? It doesn't have to be. Each cutting method uses a different mechanism to separate metal, and understanding these differences helps you specify the right process for your project—whether you're working with metal fabrication Los Angeles providers or suppliers anywhere else.

Cutting Methods Explained

Cutting is typically the first manufacturing step in any sheet metal project. The method you choose affects everything from edge quality to production speed to final part cost. Here's what happens behind the scenes with each major technique.

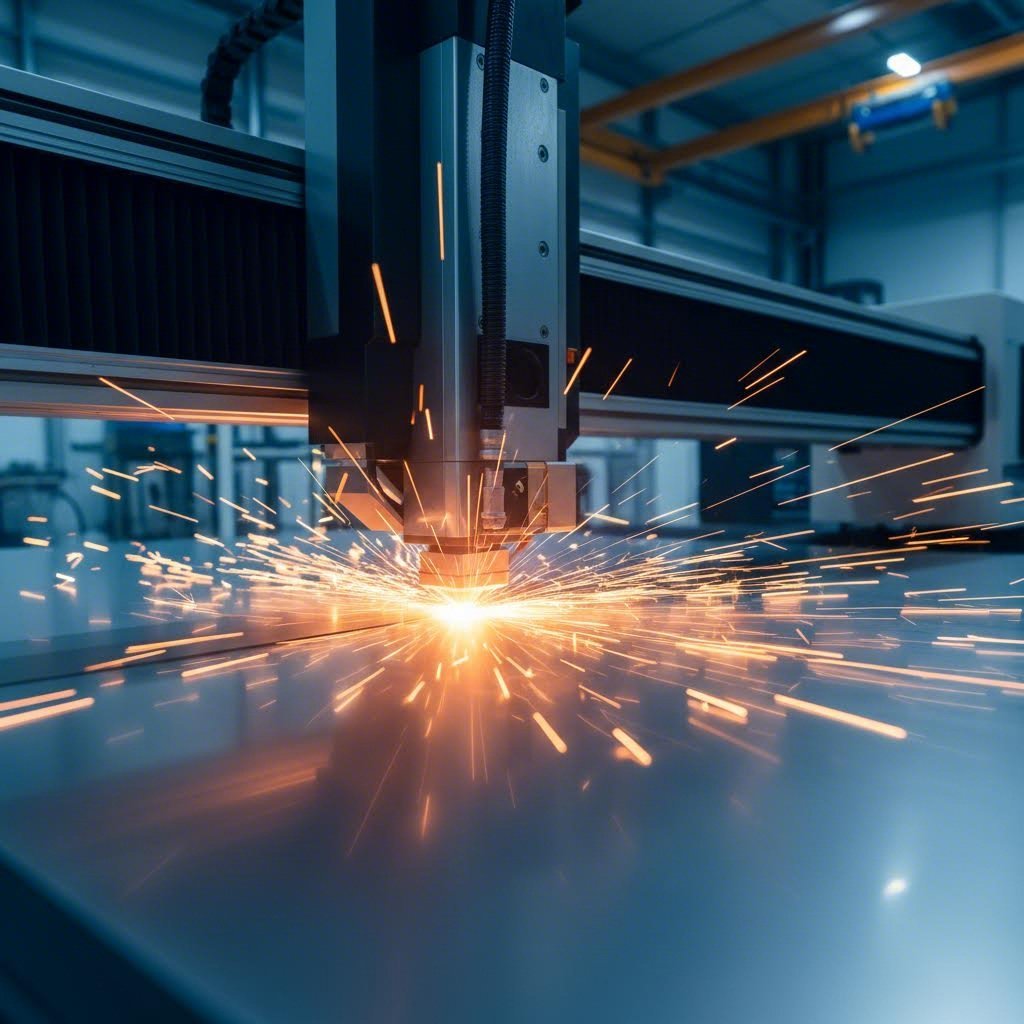

Laser Cutting uses a focused, high-powered beam of coherent light to vaporize material along a programmed path. According to Xometry's design guide, laser cutting produces the thinnest kerf (cut width) at approximately 0.2-0.4 mm. This precision makes laser cutting ideal for intricate designs, small holes, and parts requiring clean edges with minimal post-processing. Sheet metal fabrication Los Angeles shops frequently rely on laser cutting for electronics enclosures, decorative panels, and medical device components.

Waterjet Cutting takes a completely different approach. Imagine water compressed to extremely high pressure and forced through a tiny nozzle—that stream cuts through virtually anything. For harder materials like metals, fabricators add abrasive particles (typically garnet or aluminum oxide) to the water stream. The result? Clean cuts with no heat-affected zones, making waterjet perfect for heat-sensitive materials. The trade-off is a wider kerf of 1-1.2 mm and slower cutting speeds compared to laser.

Plasma Cutting creates an electrical arc through compressed gas, generating a superheated plasma stream that melts and blasts through conductive metals. Industry testing shows plasma cutting excels with thick steel plates—cutting 1-inch steel approximately 3-4 times faster than waterjet. The kerf starts around 3.8 mm, making plasma less suitable for fine detail work but extremely cost-effective for structural steel, heavy equipment, and shipbuilding applications.

Mechanical Shearing works like a giant pair of scissors. Upper and lower blades apply tremendous force to separate metal along a straight line. This process creates no kerf (material loss) and operates quickly, making it economical for straight cuts on thinner materials. However, shearing only produces linear cuts—no curves or complex geometries.

Precision Punching and Stamping Techniques

While cutting separates material along a path, punching and stamping use shaped tools to create specific features in a single stroke. Think of it as using a cookie cutter versus drawing with a knife.

CNC Turret Punching uses a rotating tool holder (turret) loaded with various punch shapes. The machine rapidly positions the sheet and selects appropriate tools to create holes, slots, and cutouts across the part. Custom metal fabrication Los Angeles facilities often use turret punching for parts requiring numerous identical features—like ventilation panels with hundreds of small holes.

Stamping involves pressing sheet metal between matched upper and lower dies to form specific shapes. For high-volume production, progressive die stamping moves metal through a series of stations, performing multiple operations with each press stroke. This approach dramatically reduces per-part costs when quantities justify the tooling investment.

When should you choose punching over laser cutting? Punching typically wins when you need standard hole shapes (rounds, squares, oblongs) in moderate to high quantities. Laser cutting makes more sense for complex contours, one-off projects, or when tooling costs aren't justified.

Cutting Method Comparison at a Glance

Selecting the right cutting process depends on balancing several factors. This comparison table helps you match your project requirements to the appropriate technology:

| Method | Material Thickness Range | Edge Quality | Speed | Best Applications |

|---|---|---|---|---|

| Laser Cutting | Up to 25 mm (steel) | Excellent—minimal burr, smooth finish | Fast for thin materials | Precision parts, intricate designs, electronics, medical devices |

| Waterjet Cutting | Up to 200+ mm | Good—no heat-affected zone | Slower than laser/plasma | Heat-sensitive materials, composites, stone, glass, aerospace |

| Plasma Cutting | Up to 50+ mm (conductive metals) | Moderate—may require edge finishing | Very fast on thick material | Structural steel, heavy equipment, shipbuilding |

| Mechanical Shearing | Up to 12 mm typical | Good—clean straight edges | Very fast | Straight cuts, blank preparation, high-volume straight-edge work |

| CNC Turret Punching | Up to 6 mm typical | Good for standard shapes | Fast for repetitive features | Multiple holes/slots, ventilation panels, enclosures |

Notice how each method occupies a distinct niche. Metal fabrication Los Angeles CA shops—and fabricators worldwide—typically maintain multiple cutting technologies to handle diverse project requirements. A complete plasma system costs around $90,000, while comparable waterjet equipment runs approximately $195,000, which explains why many shops specialize in specific processes.

Understanding these cutting fundamentals puts you in a stronger position when requesting quotes. You'll recognize why a fabricator recommends one process over another and can ask informed questions about alternatives. Next, we'll explore what happens after cutting—the bending and forming operations that transform flat cut pieces into three-dimensional components.

Metal Bending and Forming Operations Demystified

Once your flat blanks are cut to shape, the real transformation begins. Bending and forming operations take those two-dimensional pieces and create the angles, curves, and complex geometries that define functional parts. Whether you're exploring metal bending services for a prototype or scaling up custom sheet metal forming for production, understanding these processes helps you design better parts and communicate more effectively with fabricators.

Here's the reality: bending metal isn't as simple as folding paper. Every material has its own personality—some spring back stubbornly, others crack if pushed too far. Mastering these behaviors separates successful projects from costly failures.

Press Brake Bending Fundamentals

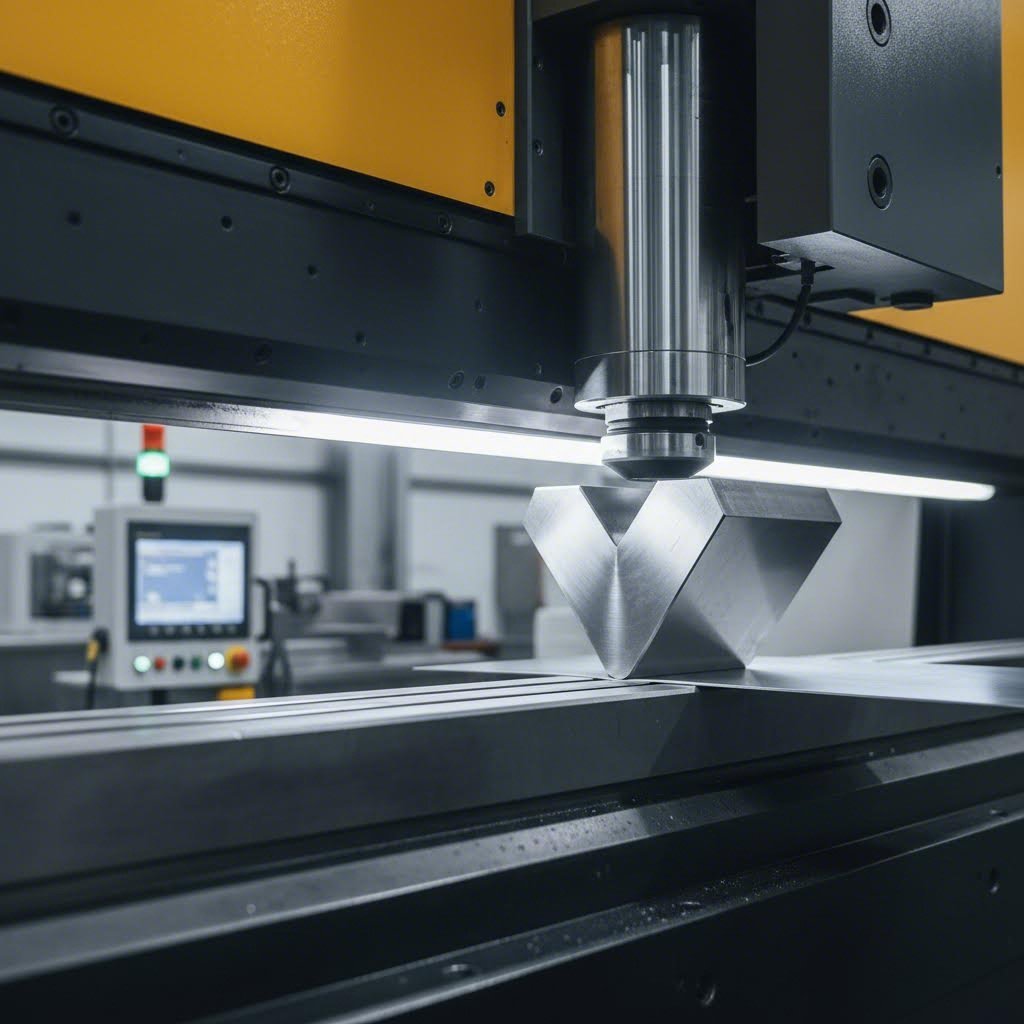

The press brake is the workhorse of sheet metal bending services. Imagine a powerful machine with a punch (upper tool) pressing downward and a V-shaped die (lower tool) positioned below. The metal sheet slides between them, and when the punch descends, it forces the material into the die opening, creating a precise bend.

What makes press brake bending so versatile? The process accommodates various angles—from subtle 10-degree bends to sharp 120-degree returns—simply by adjusting punch depth and die geometry. Modern CNC press brakes take this further with programmable controls that ensure identical results across thousands of parts.

Several critical parameters determine bend quality:

Minimum Flange Length represents the shortest material section you can successfully bend from the base sheet. According to Moore Machine Tools, attempting to bend a flange shorter than this limit causes the material to twist, deform, or even tear because it won't seat correctly on the die.

Bend Line Positioning ensures your bend occurs exactly where the blueprint specifies. Even slight misalignment compromises dimensional accuracy. Modern CNC controls offer programmable settings that precisely control this position, enabling consistent accuracy for complex designs and extended production runs.

Flange Angle Tolerance defines the acceptable deviation around your specified bend angle. Industries like aerospace and automotive demand extremely tight tolerances here—even small variations can cause parts to fail inspection or disrupt complex assemblies. Regular monitoring for tool wear and consistent machine calibration are essential for maintaining these standards.

Understanding Springback: The Hidden Challenge

Ever bent a piece of metal only to watch it partially unbend when you release pressure? That's springback—metal's elastic memory trying to return toward its original flat state. Every metal bending service provider battles this phenomenon daily.

The solution? Overbend compensation. Operators intentionally bend the material slightly beyond the target angle, knowing it will relax back to the desired position. As noted in Jeelix's aluminum bending guide, advanced facilities use several compensation strategies:

- Process-based compensation: Adjusting punch depth based on material characteristics and bend angle

- Technology-driven compensation: CNC systems that automatically calculate and apply springback corrections

- Thermo-mechanical compensation: Using heated dies to soften outer fibers while keeping inner fibers cool, reducing springback by up to 20%

Different materials exhibit vastly different springback behavior. High-strength steels spring back more aggressively than mild steel. Aluminum alloys vary dramatically based on temper—soft, annealed aluminum (like 3003-O) behaves quite differently from heat-treated varieties (like 6061-T6).

Advanced Forming Techniques for Complex Geometries

When standard press brake bending can't achieve the geometry you need, advanced forming techniques step in. Each method addresses specific design challenges.

Roll Forming passes sheet metal through a series of roller stations, progressively shaping it into consistent cross-sectional profiles. Think of metal studs, gutters, or automotive trim pieces. Roll forming excels at producing long parts with uniform shapes at high speeds.

Stretch Forming grips the sheet's edges and stretches it over a form die, creating large-radius curves without wrinkling. Aircraft fuselage panels and automotive body sections frequently use this technique for smooth, sweeping contours.

Hydroforming uses pressurized fluid to push sheet metal into a die cavity, enabling complex shapes with uniform wall thickness. This process produces components impossible to achieve through conventional stamping—think automotive structural frames or plumbing fixtures with intricate internal geometries.

Factors Affecting Bend Quality

Achieving consistent, high-quality bends requires controlling multiple variables simultaneously. Here are the key factors every custom sheet metal forming project must address:

- Material Type: Steel, aluminum, and stainless steel each respond differently to bending forces. Aluminum's lower modulus of elasticity means more springback; stainless steel work-hardens during forming, affecting subsequent operations.

- Grain Direction: Rolling processes create directional grain structures in sheet metal. Bending perpendicular to the grain (across it) generally allows tighter radii without cracking. Bending parallel to the grain risks fractures along the bend line—particularly critical for aluminum alloys.

- Bend Radius: Every material has a minimum bend radius—the tightest curve possible without cracking. Softer, annealed materials tolerate sharper bends; harder, heat-treated alloys require larger radii. For aluminum, this minimum is often expressed as a multiple of sheet thickness (for example, 6T for 6061-T6).

- Tooling Selection: V-die opening width directly influences the resulting inside bend radius. A widely accepted industry guideline suggests the inside radius equals approximately 0.15 times the V-die opening. Worn or improperly matched tooling causes inconsistent results.

- Machine Calibration: Regular alignment checks and calibration ensure the press brake performs identically from the first part to the thousandth. Crowning systems compensate for beam deflection across the machine's length—critical for long parts requiring uniform bend angles edge to edge.

How Different Materials Behave During Forming

Understanding material behavior prevents costly surprises. Here's what to expect from common sheet metals:

Mild Steel offers predictable, forgiving behavior. It accepts relatively tight bend radii, exhibits moderate springback, and tolerates minor design oversights. This makes it the default choice for many structural and industrial applications.

Stainless Steel work-hardens significantly during forming, meaning each bend increases the material's hardness and reduces ductility. Plan your bend sequence carefully—secondary bends near initial ones become progressively more difficult. Stainless also requires more forming force than mild steel of equivalent thickness.

Aluminum demands respect for its unique characteristics. As emphasized in technical literature, treating aluminum like "lighter steel" leads to failure. Springback is more pronounced, minimum bend radii vary dramatically by alloy and temper, and surface scratching occurs easily without proper tooling protection. However, aluminum's lighter weight and corrosion resistance make it essential for aerospace, automotive, and consumer electronics applications.

With bending fundamentals covered, the next critical step involves designing parts that fabricators can actually manufacture efficiently—where Design for Manufacturability guidelines become your roadmap to avoiding costly mistakes.

Design for Manufacturability Guidelines That Save Time and Money

You've selected your cutting method and understand how bending works. Now comes the question that separates smooth projects from expensive headaches: Is your design actually manufacturable? Design for Manufacturability—commonly called DFM—ensures your custom sheet metal parts can be produced efficiently without unexpected complications.

Here's a reality check: design changes become exponentially more expensive as projects progress. According to Consac's manufacturing research, catching issues during the design phase costs a fraction of fixing them during production. Prevention genuinely costs far less than correction.

Think of DFM guidelines as guardrails that keep your project on track. They're not arbitrary restrictions—they reflect the physical realities of how metal behaves during fabrication. Master these rules, and you'll communicate more effectively with fabricators while avoiding the costly reworks that derail timelines.

Essential DFM Rules for Sheet Metal Design

Every custom sheet metal work project benefits from following these fundamental principles. Let's break down each rule and explain the reasoning behind it.

Rule 1: Respect Minimum Bend Radii

Imagine folding a piece of cardboard too sharply—the outer edge cracks or shows stress marks. Metal behaves similarly. According to Norck's DFM guide, the inside curve of your bend should at least match the material thickness. Designing all bends with consistent radii allows fabricators to use a single tool for every fold, saving setup time and reducing your labor costs.

Rule 2: Maintain Proper Hole-to-Bend Distance

Placing holes too close to bend lines causes distortion. As the metal bends, it stretches—and nearby holes deform into ovals rather than staying round. The fix? Keep holes a minimum of two times the material thickness from any bend location. This simple rule ensures your components fit together flawlessly the first time, eliminating costly reworks or scrapped parts.

Rule 3: Include Bend Relief Cuts

When a bend line meets a flat edge, the metal wants to tear at the corner. Bend relief—a small rectangular or circular cut-out at the end of bend lines—prevents this tearing. Industry standards recommend relief dimensions proportional to material thickness, typically 1 to 1.5 times the thickness. Proper relief guarantees clean, professional finishes that won't fracture under stress.

Rule 4: Design Adequate Flange Lengths

The flange—the portion being bent upward—needs sufficient length for tooling to grip effectively. Picture trying to fold a tiny paper sliver with oversized fingers. As Norck's fabrication specialists note, flanges should be at least four times as long as the material is thick. Short, undersized flanges require custom tooling that can double production costs.

Rule 5: Align Bends with Grain Direction

Metal sheets have grain structure from the rolling process, much like wood. Bending parallel to the grain dramatically increases the risk of cracking—sometimes months after delivery. Design your parts so bends occur across the grain, not with it. This hidden rule prevents field failures that damage customer relationships.

Rule 6: Avoid Narrow Cutouts

Laser cutting generates intense heat. Very narrow slots or thin finger-like projections can warp or twist from thermal stress. Keep any narrow cutouts at least 1.5 times wider than the material thickness. This maintains flatness and dimensional accuracy throughout your parts.

Avoiding Costly Design Mistakes

Even experienced engineers sometimes overlook these common pitfalls. Review your designs against this checklist before submitting for quotes:

- Insufficient Bend Relief: Without proper relief cuts, material tears at corners and bends deform. Always provide relief proportional to material thickness—typically 1 to 1.5 times the thickness.

- Holes Too Close to Bends: Placing holes closer than two times material thickness from a bend causes distortion. The metal stretches during bending, pulling holes out of shape or specification.

- Ignoring Grain Direction: Failing to orient bends perpendicular to the grain creates hidden weaknesses. Parts may pass initial inspection but crack under service loads.

- Specifying Unnecessarily Tight Tolerances: Calling out tolerances below ±0.005 inches (0.13mm) drives up costs dramatically. Standard sheet metal processes typically achieve ±0.010 to ±0.030 inches economically. Reserve tight tolerances only for features where they genuinely add functional value.

- Overlooking Material Thickness Effects: Thicker materials require larger bend radii, greater hole-to-bend distances, and more forming force. Don't assume rules that work for 1mm steel apply equally to 3mm aluminum.

- Using Non-Standard Hole Sizes: Specifying odd dimensions like 5.123mm requires custom tooling. Standard sizes—5mm, 6mm, or 1/4 inch—punch instantly with existing tools, accelerating turnaround.

Material Selection Considerations

Choosing the right material involves balancing function and manufacturability. Standard gauges cost less and have better availability than custom thicknesses. Material properties directly affect minimum bend radii—aluminum typically requires larger radii than steel of the same thickness.

For custom metal parts manufacturing projects involving surface treatments, specify coatings early. Powder coating adds thickness that affects final dimensions, so account for this in your tolerance calculations. Similarly, if corrosion resistance matters, select appropriate stainless steel grades or specify protective finishes during the design phase rather than as afterthoughts.

When Tighter Tolerances Actually Add Value

Not all tolerances are created equal. Tighter specifications make sense for:

- Mating surfaces where components must align precisely

- Assembly interfaces with fastener patterns requiring accurate hole positioning

- Visible edges on aesthetic enclosures

- Critical functional dimensions affecting product performance

Conversely, internal features hidden from view, non-critical bend angles, and dimensions with generous clearances rarely justify premium tolerance costs. As one industry axiom puts it: "As tight as necessary, as loose as possible."

Understanding these DFM principles positions you to create designs that fabricators can produce efficiently—translating directly into lower costs, faster delivery, and higher quality. With design fundamentals covered, the next logical question becomes: what actually drives the price of a sheet metal project?

Cost Factors and Pricing Considerations for Your Project

So you've designed a manufacturable part—but what will it actually cost? Whether you're sourcing sheet metal Los Angeles providers or working with fabricators across the country, understanding pricing drivers helps you budget accurately and identify opportunities to reduce costs without compromising quality.

Here's the truth: sheet metal pricing isn't arbitrary. Every quote reflects a combination of material expenses, labor hours, equipment time, and overhead. When you understand these components, you can make informed trade-offs and avoid sticker shock when quotes arrive.

What Drives Sheet Metal Fabrication Costs

Several interconnected factors determine your project's final price. Let's examine each one and explore how your decisions influence the bottom line.

Material Costs

Raw material represents a significant portion of any fabrication quote. According to Komacut's cost guide, material type dramatically affects pricing. Mild steel offers affordability and versatility, making it popular for cost-conscious projects. Aluminum costs more per kilogram but delivers weight savings critical for aerospace and automotive applications. Stainless steel commands premium pricing due to its corrosion resistance and durability.

Material grades within each category also impact cost. Standard grades like 304 stainless steel or 5052 aluminum remain readily available at competitive prices. Specialty alloys—think 316L stainless for marine environments or 7075 aluminum for aerospace—cost considerably more and may require longer lead times.

Thickness matters too. As industry research confirms, thickness impacts cost, weight, and structural integrity simultaneously. Thicker materials cost more per square foot and require additional processing time, while thinner gauges may need reinforcement features that add complexity.

Design Complexity

Intricate designs demand more labor, time, and specialized equipment. According to MAH Steel's fabrication analysis, projects with complex geometries, tight tolerances, or custom finishes require significantly more effort than simpler designs involving basic cutting and welding.

Every additional bend, hole pattern, or contour adds setup time and processing steps. A simple bracket with two bends costs far less than an enclosure requiring twelve bends, numerous cutouts, and hardware insertion. The math is straightforward: more operations equal more machine time and labor hours.

Labor and Expertise

Skilled welders, machine operators, and quality inspectors represent substantial cost components. Complex projects demanding specialized expertise—like certified aerospace welding or precision medical device fabrication—carry higher labor rates. Sheet metal fabrication Los Angeles CA shops and fabricators nationwide factor these skill premiums into quotes.

Secondary Operations

Beyond basic cutting and bending, many projects require additional processing. Hardware insertion (PEM nuts, studs, standoffs), deburring, tapping, and countersinking all add cost. As Protolabs advises, sticking with readily available fasteners from standard catalogs avoids premium pricing and extended lead times associated with specialty hardware.

Finishing Requirements

Surface treatments protect parts and enhance appearance—but they add cost. Powder coating, painting, galvanizing, anodizing, and plating each carry different price points. According to industry analysis, finish type depends on environmental exposure conditions and aesthetic preferences, with certain finishes requiring multiple layers or specialized applications that increase expenses.

Volume Pricing and Economies of Scale

Quantity dramatically influences per-part pricing. Here's why: setup time remains relatively constant whether you're making one part or one hundred. Programming CNC machines, loading tooling, and configuring press brakes takes similar effort regardless of batch size. Spread that fixed setup cost across more units, and your per-piece price drops substantially.

As fabrication experts note, larger projects or bulk orders typically enjoy economies of scale. The more steel components required, the more efficiently a fabrication shop can work, spreading out costs of setup, labor, and equipment use. Smaller or custom orders may not benefit from these efficiencies and could prove more expensive per unit.

Consider this practical example: a prototype order of five brackets might cost $50 each. Order 500 of the same bracket, and pricing might drop to $8-12 per unit. The design hasn't changed—only the quantity justifying more efficient production methods.

For high-volume production, progressive die stamping offers even greater savings. While tooling investment runs higher upfront, per-part costs plummet when quantities reach thousands or tens of thousands. Aluminum fabrication Los Angeles projects and similar high-volume work often transition from job-shop fabrication to stamping once demand justifies the tooling expense.

Cost Factor Summary and Optimization Strategies

Use this table to identify where your project's costs originate and how to optimize each factor:

| Factor | Impact Level | How to Optimize |

|---|---|---|

| Material Type | High | Choose mild steel when corrosion resistance isn't critical; use aluminum only when weight savings justify premium pricing |

| Material Grade | Medium | Specify standard grades (304 SS, 5052 AL) unless application genuinely requires specialty alloys |

| Material Thickness | Medium | Use minimum thickness that meets structural requirements; avoid over-engineering |

| Design Complexity | High | Simplify geometries where possible; consolidate features; use standard bend radii throughout |

| Tolerances | High | Specify tight tolerances only on critical features; use standard tolerances (±0.010"-0.030") elsewhere |

| Order Quantity | High | Batch orders when possible; consider blanket orders for recurring needs to lock in volume pricing |

| Hardware Selection | Medium | Use standard PEM hardware from readily available inventory; avoid specialty fasteners |

| Surface Finishing | Medium | Delay aesthetic finishes during prototyping; choose powder coating over more expensive alternatives when appropriate |

| Lead Time | Medium | Avoid rush orders when possible; tight deadlines incur overtime and expedited shipping fees |

| Transportation | Low-Medium | Design for efficient packaging; consider regional suppliers to reduce shipping distances |

Practical Tips for Cost Optimization

Beyond the table above, these strategies help reduce expenses without sacrificing quality:

- Simplify Your Models: As Protolabs recommends, suppress any CAD details unrelated to the part being manufactured. Extraneous data slows quoting and can cause confusion.

- Use Standard Off-the-Shelf Components: Building custom card guides or brackets into sheet metal costs significantly more than designing features that accept standard purchased components.

- Include Complete BOMs: Providing precise hardware specifications eliminates back-and-forth emails and prevents costly assumptions.

- Accept Manufacturer Suggestions: Quote responses often include process improvement recommendations (PPRs) that identify cost-saving design modifications. These suggestions reflect real manufacturing experience worth considering.

- Plan for Realistic Timelines: According to fabrication cost research, projects requiring faster turnaround incur additional fees for rush orders, overtime labor, or expedited shipping. Longer lead times allow fabricators to schedule work efficiently, potentially reducing costs.

Understanding these cost drivers empowers you to make strategic decisions throughout your project. You'll recognize which specifications genuinely add value versus those that merely inflate pricing. With this foundation, the next step involves matching your specific requirements to the right fabrication process—a decision that further influences both cost and quality outcomes.

Choosing the Right Sheet Metal Process for Your Application

You understand the processes. You've optimized your design for manufacturability. You know what drives costs. Now comes the pivotal decision: which fabrication method actually fits your project? Whether you're working with a west coast custom sheet metal provider or evaluating options from socal sheet metal shops, the right process selection separates successful projects from frustrating mismatches.

Here's the challenge: there's no universal "best" method. The optimal choice depends on your specific combination of volume requirements, geometric complexity, material specifications, and budget constraints. Let's walk through the decision framework that helps you match your project to the right manufacturing approach.

Matching Your Project to the Right Process

Think of process selection as solving a puzzle where multiple pieces must align simultaneously. Each factor influences the others, and the goal is finding the sweet spot where your requirements meet manufacturing capabilities efficiently.

Production Volume: The Primary Driver

Quantity requirements often dictate your starting point. According to Approved Sheet Metal's fabrication analysis, precision sheet metal fabrication leverages standard tooling and equipment to create parts, making it ideal for prototypes, one-off parts, and low-volume productions that don't require custom tooling. Metal stamping, conversely, employs custom tooling and specialized equipment, making stamping houses best for high-volume productions.

Why does this matter financially? Custom stamping dies can cost tens of thousands of dollars each. That investment makes sense when spread across 50,000 parts—but proves prohibitive for a 50-piece order. Traditional fabrication avoids this tooling expense, keeping small-batch projects economically viable.

Geometric Complexity and Feature Depth

Your part's geometry directly influences process compatibility. Traditional sheet metal fabrication handles formed features like embossments and louvers effectively—but with limitations. As industry experts note, the feature's depth can't significantly exceed the sheet metal's thickness when using standard fabrication methods.

Need deeper draws or complex three-dimensional shapes? Stamping operations using deep draw presses can bypass the depth maximums that limit fabricators. These specialized machines apply extreme pressure to draw metal blanks into dies, forming components impossible to achieve through conventional bending alone.

Tolerance Requirements

How precise must your parts be? This question significantly narrows your process options. According to tolerance comparison research:

- Sheet metal fabrication typically achieves tolerances ranging from ±0.005" to ±0.015", depending on cutting, bending, and welding processes used. CNC laser cutting and punching offer high precision, but bending can introduce slight variances due to material springback.

- Metal stamping can achieve much tighter tolerances, often as precise as ±0.001" to ±0.005", particularly for complex geometries. Since stamping tools are custom-made, every feature forms with extreme repeatability and minimal deviation.

For parts requiring tight tolerances, high repeatability, and minimal post-processing, stamping often emerges as the better option. If your design allows for slight variations, requires small batches, or undergoes frequent revisions, fabrication provides the necessary flexibility.

Material Specifications

Different processes handle materials differently. Fabrication shops work with diverse material types and thicknesses using laser cutters, punch presses, and press brakes. This versatility accommodates project-specific material requirements without tooling modifications.

Stamping operations optimize for specific material characteristics during die design. Once tooling exists, changing materials becomes complicated—the die geometry accounts for springback and material flow properties of the original specification. This inflexibility matters less for high-volume production runs using consistent materials but limits adaptability for evolving projects.

When to Choose Stamping Over Fabrication

The fabrication-versus-stamping decision ultimately comes down to matching your priorities with each process's strengths. Here's a framework for making this choice confidently:

Choose Traditional Fabrication When:

- Prototype vs. production quantities: You need prototypes, single units, or low-volume runs (typically under 1,000 pieces) where custom tooling costs can't be justified

- Geometric complexity: Your design uses standard formed features without extreme depth requirements—channels, flanges, brackets, and enclosures with moderate complexity

- Material specifications: You're experimenting with materials or expect material changes during the product lifecycle

- Surface finish requirements: Standard finishes meet your needs, and minor variations between parts are acceptable

- Budget constraints: Upfront capital for custom tooling isn't available, or the tooling investment timeline doesn't align with project schedules

Choose Stamping When:

- High-volume production: Quantities reach thousands or tens of thousands, allowing tooling costs to amortize across many units

- Complex three-dimensional geometries: Your design requires deep draws, precise formed features, or tiny parts under 1" that demand custom tooling precision

- Tight tolerance requirements: Critical dimensions require ±0.001" to ±0.005" consistency across every part

- High repeatability: Near-identical parts are essential, with minimal variation between the first unit and the ten-thousandth

- Cost-per-part optimization: Lowest possible per-unit cost matters more than initial investment

Progressive Die Stamping: The High-Volume Advantage

For truly high-volume applications, progressive die stamping offers compelling economics. Metal feeds from coils through a series of stations, with each press stroke performing multiple operations simultaneously. According to industry specifications, mechanical presses quickly and efficiently produce high volumes of simple, shallow-formed parts from sheet metal coils.

Progressive dies allow for high precision even in high-volume runs, reducing the need for secondary operations. Once the tooling investment is made, per-part costs drop dramatically compared to discrete fabrication operations.

However, progressive stamping requires stable designs. Tooling modifications are expensive and time-consuming. Projects with evolving specifications or frequent engineering changes fare better with fabrication's inherent flexibility.

The Hybrid Approach

Many successful projects combine both methods strategically. Prototypes and initial production runs use traditional fabrication—og sheet metal techniques that allow rapid iteration without tooling investment. Once designs stabilize and volumes justify the expense, production transitions to stamping for cost optimization.

This phased approach, sometimes called "prototype with production intent" as noted by All Metals Fab, builds prototypes using the material, thickness, and tooling assumptions expected in production. When that's not possible, documenting where prototypes differ from production intent enables smoother transitions later.

Experienced modern precision sheet metal fabricators understand this lifecycle and can advise on design decisions that simplify eventual production scaling. They'll identify features that work well in prototype fabrication but would require modification for efficient stamping—insights that save significant redesign costs down the road.

With process selection clarified, the next critical consideration involves ensuring your chosen fabrication partner maintains the quality standards your application demands—a topic where certifications and inspection protocols become essential evaluation criteria.

Quality Standards and Certifications in Metal Fabrication

You've selected the right process for your project—but how do you know the fabricator will deliver parts that actually meet your specifications? This is where quality standards and certifications become your safety net. Whether you're sourcing from able sheet metal inc or evaluating any fabrication partner, understanding these credentials helps you separate reliable suppliers from risky ones.

Here's the reality: a beautifully designed part means nothing if manufacturing inconsistencies cause assembly failures or field returns. According to Qualityze's quality management research, quality covers a broader spectrum including safety, efficiency, and reliability—and organizations that consistently exceed customer expectations rely on documented systems to achieve this.

Industry Certifications That Ensure Quality

Not all certifications carry equal weight, and the right credentials depend heavily on your application. Let's examine the major certifications you'll encounter when evaluating fabrication partners.

ISO 9001: The Universal Foundation

ISO 9001 is a set of international standards defining requirements for an effective quality management system (QMS). As industry documentation explains, ISO 9001 certified organizations demonstrate their ability to deliver high-quality products and services consistently while meeting customer and applicable regulatory requirements.

Think of ISO 9001 as the baseline credential every reputable fabricator should hold. It ensures documented procedures exist for everything from order processing to final inspection. When you see this certification, you know the shop has undergone third-party audits verifying their quality systems actually function as described.

IATF 16949: The Automotive Standard

If your parts are destined for automotive applications, IATF 16949 becomes essential. Specified by The International Automotive Task Force, this certification defines QMS standards specifically for the automotive industry. Here's the key distinction: automotive companies must comply with both IATF 16949 and ISO 9001 manuals for achieving certification.

Why does automotive demand additional rigor? Vehicle components face extreme safety and reliability requirements. A failed bracket in a consumer electronics enclosure causes inconvenience; a failed bracket in a vehicle suspension system can cause injuries. IATF 16949 addresses this heightened responsibility with stricter controls.

AS9100D: Aerospace Excellence

Aerospace applications operate under perhaps the most demanding quality requirements of any industry. According to AAA Air Support's aerospace guide, AS9100D is a globally recognized quality management system standard specifically designed for the aerospace industry, covering design, development, production, installation, and servicing processes.

AS9100D 2016 certification benefits include enhanced focus on risk management, improved supply chain oversight, and rigorous documentation requirements that create complete traceability from raw material to finished component. Companies like challenger sheet metal and macias sheet metal serving aerospace customers invest significantly in maintaining these certifications.

Matching Certifications to Your Industry

Different sectors demand different credentials:

- General industrial: ISO 9001:2015 provides adequate assurance for most commercial applications

- Automotive: Require IATF 16949 certification for Tier 1 and Tier 2 supplier qualification

- Aerospace: AS9100D certification is typically mandatory for any flight-critical components

- Medical devices: ISO 13485:2016 certification, as noted by Tempco Manufacturing, allows medical device manufacturers to display their quality management practices while protecting consumers

- Defense: Federal firearms licenses and ITAR compliance may apply depending on component function

Inspection and Quality Control Methods

Certifications establish systems—but what actually happens on the shop floor? Effective quality control involves multiple checkpoints throughout the manufacturing process, not just a final pass/fail inspection.

According to industry quality specialists, comprehensive quality assurance programs include dimensional checks, visual inspections, and material certifications that verify compliance at every stage. Here are the key quality checkpoints your fabrication partner should maintain:

- Incoming Material Inspection: Verification that raw materials match specifications before production begins. This includes checking material certifications, measuring thickness, and confirming alloy composition. Catching material problems here prevents wasted labor on non-conforming stock.

- In-Process Dimensional Checks: First-article inspections verify the initial parts meet specifications before full production runs. Operators perform periodic checks throughout runs using calibrated measuring instruments—calipers, micrometers, CMMs—to catch drift before it creates scrap.

- Final Inspection Protocols: Comprehensive verification that finished parts meet all drawing requirements. This includes dimensional verification, visual inspection for surface defects, and functional checks where applicable. Statistical sampling plans determine inspection frequency based on lot sizes and risk levels.

- Documentation Requirements: Complete records linking finished parts back to source materials, operators, machines, and inspection results. This traceability proves critical when investigating quality issues or demonstrating regulatory compliance. Material certifications, inspection reports, and certificates of conformance should accompany shipments.

Material Traceability: Following the Paper Trail

For regulated industries, knowing exactly where your metal came from isn't optional—it's mandatory. Material traceability requirements ensure every component can be traced back to specific heat lots, mill certifications, and processing records. If a quality issue surfaces months or years later, this documentation enables targeted investigations rather than blind recalls.

Fabricators serving aerospace and automotive customers like dave whipple sheet metal inc maintain heat lot traceability systems that track material from receiving dock through every processing step to final shipment. This chain of custody provides the evidence needed to demonstrate compliance during customer audits or regulatory reviews.

When evaluating potential fabrication partners, ask about their quality systems, request copies of current certifications, and inquire about their inspection capabilities. A quality-focused shop welcomes these questions—they've invested significantly in their systems and take pride in demonstrating their capabilities.

With quality assurance fundamentals covered, the next step involves actually engaging with fabrication partners—from preparing effective quote requests to evaluating proposals and managing projects through completion.

Working with Sheet Metal Service Providers Effectively

You've evaluated quality credentials and selected a process that fits your project. Now comes the practical work: actually engaging with fabrication partners to get your parts made. Whether you're a first-time buyer or a seasoned procurement professional, the way you structure your quote request directly impacts the speed, accuracy, and value of the responses you receive.

Here's what many buyers overlook: fabricators can only quote what you tell them. According to AMG Industries' procurement guide, requesting a quote for metal fabrication is like planning a road trip—you can't just start driving without a plan, or you'll end up lost, frustrated, or paying too much. The upfront effort you invest in preparing a complete request for quote (RFQ) pays dividends throughout your project.

Preparing an Effective Quote Request

A well-structured RFQ eliminates the back-and-forth emails that delay projects and frustrate everyone involved. As manufacturing specialists note, properly defined inquiry packages optimize system use and avoid lengthy communication loops—your waiting time drops significantly when documentation is complete from the start.

Think of your RFQ as telling the fabricator exactly who you are and what you need. Missing information forces estimators to make assumptions—and those assumptions may not match your expectations. Here's the essential checklist for preparing a complete quote request:

- Complete CAD Files: Supply drawings in standard formats such as DXF, DWG, STEP, or IGES. Drawings should be fully dimensioned, including tolerances, technical details, and cross-section views as needed. The more detailed your data, the more accurate the quote. If you only have 2D drawings, ensure critical dimensions are clearly marked.

- Material Specifications: Specify your material type preference (SPCC, SUS304, 5052 aluminum, etc.) and exact thickness. If you have special requirements for strength, corrosion resistance, or conductivity, note these clearly. This information directly impacts pricing and allows fabricators to suggest alternatives if appropriate.

- Quantity Requirements: State your estimated order size—whether it's a pilot run of 50 units, initial production of 500 pieces, or ongoing monthly volumes of 5,000. Per-unit pricing varies dramatically based on quantity due to setup cost amortization and economies of scale. Providing quantity tiers (50/500/5,000) helps you understand volume pricing breakpoints.

- Tolerance Callouts: Identify which dimensions require tight tolerances and which can accept standard fabrication tolerances. Calling out every dimension as critical inflates costs unnecessarily. Focus precision requirements on mating surfaces, assembly interfaces, and functional features.

- Finish Requirements: Specify your final surface treatment—powder coat color and thickness, electroplating type (zinc, nickel, chrome), anodizing color, or raw finish. This directly affects outsourcing costs and production scheduling. If multiple finish options work for your application, ask for pricing on each.

- Delivery Timeline: Communicate your preferred delivery date and any flexibility around it. Expedited timelines incur premium charges, while reasonable lead times allow fabricators to schedule efficiently. If you have a hard deadline, state it clearly so shops can confirm feasibility before quoting.

Including this complete information demonstrates professionalism and enables accurate, apples-to-apples quote comparisons. As Atscott MFG advises, a detailed project scope allows you to compare fabricators based on relevant experience and capabilities—not just price.

Evaluating Fabrication Partners

Once quotes arrive, the real evaluation begins. Resist the temptation to simply choose the lowest price—that approach often backfires when quality issues or delivery failures create far greater costs than the initial savings.

Quote Transparency Matters

Professional quotes should clearly itemize cost components rather than providing a single lump-sum figure. According to industry best practices, transparent pricing means seeing separate breakdowns for materials, processing fees, and surface finishing. This "black box" elimination builds trust and helps you identify where cost optimization opportunities exist.

Watch for these red flags in quotes:

- Vague line items that don't explain what's included

- Missing information about material grades or sources

- No mention of inspection or quality documentation

- Unusually short or long quoted lead times without explanation

Capability Alignment

Does the fabricator actually have the equipment and expertise your project requires? As selection guides emphasize, ensure the shop has the necessary equipment—such as CNC machinery, press brakes, automated welders, or laser cutters—and staff trained to operate them.

Verify material specialization too. Not every shop works with all metals. Whether your project uses sheet metal, stainless steel, aluminum, or heavy plate, confirm the fabricator handles those materials routinely, not occasionally.

Track Record Verification

Before committing, investigate the fabricator's history:

- Request references from similar projects or industries

- Review online testimonials and case studies

- Ask about experience with your specific part type or application

- Confirm certifications are current and audit-verified

A skilled project manager should walk you through the fabrication process with confidence and clarity. If questions leave them stumbling, that's a warning sign about organizational capabilities.

Streamlining the Quote-to-Production Process

The best fabrication partners do more than just manufacture parts—they actively help optimize your project from the initial quote forward. This is where Design for Manufacturability (DFM) support becomes invaluable.

When you submit drawings for quotation, experienced fabricators review them for potential manufacturing challenges. As one case study demonstrates, a manufacturer helped a customer reduce bending steps from seven to four by tweaking a design detail—without reducing functionality. This single optimization reduced the per-part cost by 18%.

For automotive applications specifically, manufacturers like Shaoyi (Ningbo) Metal Technology exemplify this streamlined approach. Their 12-hour quote turnaround eliminates the days-long waits common with traditional quoting processes, while comprehensive DFM support identifies optimization opportunities before production begins. With IATF 16949 certification, they meet the rigorous quality requirements automotive Tier 1 and Tier 2 suppliers demand.

Rapid prototyping capabilities—like Shaoyi's 5-day turnaround—allow you to validate designs physically before committing to production tooling or large-volume orders. This iterative approach catches issues early when changes remain inexpensive, rather than discovering problems after thousands of parts are manufactured.

What to Expect During Manufacturing

Once you've approved a quote and placed an order, understanding the production timeline helps you plan downstream activities. Typical fabrication projects progress through these phases:

Order Confirmation and Material Procurement: The fabricator confirms specifications, orders raw materials (if not in stock), and schedules production. Material lead times vary—standard grades ship quickly, while specialty alloys may require weeks.

Production Scheduling: Your order enters the production queue based on capacity and committed delivery dates. Fabricators balance multiple customer orders simultaneously, optimizing machine utilization across their shop.

Manufacturing and In-Process Inspection: Parts move through cutting, bending, welding, and finishing operations. Quality checks occur throughout—not just at the end. First-article inspection verifies initial parts meet specifications before full production proceeds.

Final Inspection and Documentation: Completed parts undergo comprehensive dimensional verification, visual inspection, and any required testing. Documentation packages—including inspection reports, material certifications, and certificates of conformance—prepare for shipment.

Shipping and Delivery: Finished parts are packaged to prevent transit damage and shipped via your specified carrier. Tracking information lets you monitor progress and prepare for receiving.

Throughout this process, communication matters. Responsive fabricators provide status updates proactively and alert you immediately if issues arise. Delayed communication about problems only compounds their impact on your project timeline.

With these practical guidelines for working with fabrication partners, you're equipped to manage projects from initial inquiry through delivery. The final step involves translating all this knowledge into concrete action based on where you currently stand in your sheet metal project journey.

Taking Action on Your Sheet Metal Project

You've journeyed through cutting methods, bending operations, DFM guidelines, cost factors, process selection, quality standards, and partner evaluation strategies. That's substantial ground to cover—but knowledge without action remains just information. Now it's time to translate everything you've learned into concrete next steps tailored to where you actually stand in your project.

Here's the good news: you don't need to master every detail before moving forward. The key is identifying your current stage and taking the appropriate action for that moment. Whether you're sketching initial concepts or finalizing production contracts, a clear path exists.

Your Next Steps Based on Project Stage

Early Design Phase

If you're still defining requirements or creating initial designs, focus on building manufacturability into your parts from the start. Review the DFM guidelines covered earlier—minimum bend radii, hole-to-bend distances, bend relief cuts, and grain direction considerations. These aren't restrictions to work around; they're design tools that prevent costly surprises later.

Consider reaching out to potential fabrication partners even at this stage. As Superior Manufacturing recommends, involving the fabricator early ensures you have enough time to make adjustments without missing deadlines. Early engagement often reveals cost-saving modifications that would be expensive to implement after designs are finalized.

Ready to Request Quotes

When your designs are stable enough for pricing, prepare comprehensive RFQ packages using the checklist from the previous section: complete CAD files, material specifications, quantity requirements, tolerance callouts, finish requirements, and delivery timelines. The more complete your documentation, the faster and more accurate your quotes will be.

Request quotes from multiple qualified fabricators—typically three to five—to understand market pricing and identify partners whose capabilities align with your needs. Remember that the lowest price isn't always the best value. Evaluate transparency, communication responsiveness, and relevant experience alongside cost.

Evaluating Production Partners

If you're comparing finalists, dig deeper into their quality systems, certifications, and track records. Request references from similar projects. Verify that their equipment matches your requirements—laser cutting versus plasma, CNC press brakes versus manual forming, in-house finishing versus outsourced operations.

Pay attention to how potential partners respond to questions. As industry guidance notes, your fabricator should be able to see your vision and offer services that align with your goals, ideally leveraging industry expertise to provide useful suggestions that may save time or money.

Moving Forward with Confidence

Regardless of your current stage, one principle stands above all others when working with sheet metal services:

Proper DFM review before production saves significant time and cost. Design changes become exponentially more expensive as projects progress—catching issues during engineering costs a fraction of fixing them on the production floor.

This single insight, consistently applied, separates smooth projects from troubled ones. Budget time for DFM review. Welcome fabricator feedback on your designs. Treat manufacturability as a design requirement, not an afterthought.

Key Takeaways to Carry Forward

- Match your fabrication process to your volume requirements—traditional fabrication for prototypes and low volumes, stamping for high-volume production

- Design with standard radii, adequate hole spacing, and proper bend relief to avoid manufacturing complications

- Specify tight tolerances only where they genuinely add functional value—over-tolerance costs money without benefit

- Verify fabricator certifications match your industry requirements—ISO 9001 for general industrial, IATF 16949 for automotive, AS9100D for aerospace

- Prepare complete RFQ packages to enable accurate quotes and minimize back-and-forth delays

For Automotive Applications

If your project involves chassis components, suspension parts, or structural assemblies requiring automotive-grade quality, specialized partners can significantly accelerate your timeline. Shaoyi (Ningbo) Metal Technology offers 5-day rapid prototyping that lets you validate designs quickly, followed by automated mass production when volumes scale. Their IATF 16949 certification ensures the quality documentation and traceability automotive supply chains demand, while comprehensive DFM support helps optimize your designs before tooling investments begin.

The path from concept to finished part doesn't have to be mysterious or frustrating. Armed with the knowledge from this guide—and clear next steps matched to your current stage—you're positioned to navigate sheet metal services with confidence. Your next move? Take it.

Frequently Asked Questions About Sheet Metal Services

1. What is sheet metal service?

Sheet metal services encompass industrial processes that transform flat metal sheets into functional parts through cutting, bending, forming, welding, and finishing operations. These services include laser cutting for precision work, waterjet cutting for heat-sensitive materials, press brake bending for creating angles, and various assembly and finishing operations. The global sheet metal fabrication market is projected to exceed £15 billion by 2030, serving industries from automotive to aerospace and electronics.

2. How much does sheet metal work cost?

Sheet metal fabrication costs range from $4 to $48 per square foot depending on material type, design complexity, order quantity, and finishing requirements. Key cost drivers include material selection (mild steel being most economical, stainless steel commanding premium pricing), tolerance specifications, secondary operations like hardware insertion, and surface treatments. Volume orders significantly reduce per-unit costs through economies of scale, with setup costs amortized across larger quantities.

3. What is the difference between sheet metal fabrication and stamping?

Sheet metal fabrication uses standard tooling for prototypes and low-volume production (typically under 1,000 pieces) without custom tooling investment. Metal stamping employs custom dies for high-volume production, achieving tighter tolerances of ±0.001" to ±0.005" compared to fabrication's ±0.005" to ±0.015". Stamping offers lower per-part costs for quantities reaching thousands, while fabrication provides flexibility for design changes and material variations.

4. What certifications should I look for in a sheet metal fabricator?

ISO 9001 serves as the baseline quality certification for reputable fabricators. Automotive applications require IATF 16949 certification, which ensures stricter quality controls for vehicle component safety. Aerospace projects demand AS9100D certification covering design, production, and servicing processes. Medical device components need ISO 13485:2016 certification. Always verify certifications are current and audit-verified before selecting a fabrication partner.

5. How do I prepare an effective quote request for sheet metal parts?

Include complete CAD files in standard formats (DXF, DWG, STEP), material specifications with exact thickness and grade, quantity requirements with multiple tiers for volume pricing, tolerance callouts identifying critical dimensions, finish requirements specifying coatings or treatments, and delivery timeline with flexibility notes. Complete documentation eliminates back-and-forth delays and enables accurate quote comparisons. Partners like Shaoyi Metal Technology offer 12-hour quote turnaround with comprehensive DFM support to optimize designs before production.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —