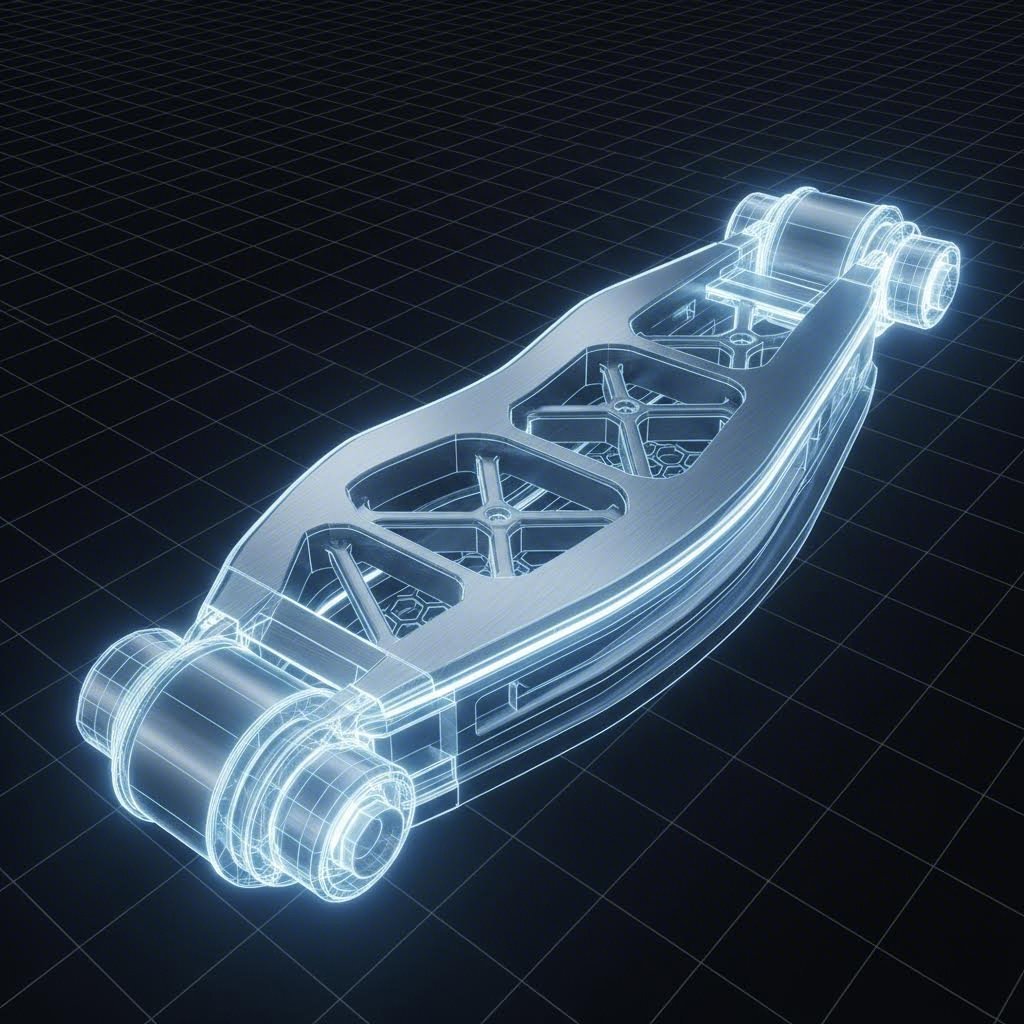

Stamping Automotive Suspension Control Arms: Process, Materials & Costs

TL;DR

Stamping automotive suspension control arms is the industry-standard manufacturing process for balancing structural integrity with cost-efficiency in mass-market vehicles. By cold-forming high-strength low-alloy (HSLA) or boron steel sheets using progressive die technology, manufacturers achieve a component that is typically 20–35% cheaper than forged alternatives and 15–30% lighter than cast iron. This method allows for high-volume scalability with OE-level precision, utilizing boxed or open-shell designs to meet the rigorous demands of modern vehicle dynamics, including the reduced unsprung mass required for electric vehicles (EVs).

The Engineering Behind Stamped Control Arms

The manufacturing of stamped control arms is a study in precision engineering, moving far beyond simple metal bending. It involves a sophisticated workflow designed to transform flat steel sheets into complex, load-bearing suspension components that define a vehicle's handling characteristics. The process begins with material selection and blanking, where high-grade steel coils are laser-cut or mechanically blanked into precise shapes, minimizing scrap and preparing the grain structure for deformation.

At the core of production is progressive die stamping. In this phase, the steel blank is fed through a series of stations within a single die set. Each station performs a specific operation—bending, punching, or coining—incrementally shaping the part. For B2B procurement and engineering teams, the critical metric here is the "production beat," which advanced facilities can reduce to approximately 15 seconds per part. This speed, combined with automated transfer systems, ensures consistent geometry with tolerances often held within ≤0.05mm, a benchmark cited by leading suppliers like MIVO Parts.

Design complexity often dictates the final assembly steps. While "open shell" designs consist of a single stamped sheet, higher-load applications require "boxed" or "clamshell" designs. Here, two stamped halves are welded together via robotic arms to create a hollow, rigid structure. This technique maximizes torsional stiffness without adding significant weight. For OEMs and Tier 1 suppliers bridging the gap from rapid prototyping to mass production, partnering with facilities that offer versatile press capabilities is essential. Shaoyi Metal Technology’s comprehensive stamping solutions, for instance, leverage press capacities up to 600 tons and IATF 16949-certified protocols to deliver both prototype batches and high-volume runs that meet strict global standards.

Material Science: Advanced Steels and Durability

The outdated perception of stamped steel as "flimsy" has been dismantled by the adoption of Advanced High-Strength Steels (AHSS). Modern control arms utilize Dual-Phase (DP) and Boron steels with tensile strengths ranging from 800 to 1200 MPa (Megapascals). This metallurgical advancement allows engineers to use thinner gauges of steel to reduce weight while maintaining or exceeding the structural strength of thicker, older steel grades. As noted in technical comparisons by SH Autoparts, this high strength-to-weight ratio is crucial for meeting fuel economy standards and offsetting battery weight in EVs.

Corrosion resistance is the final critical layer of the material science equation. Since stamped parts are susceptible to oxidation, the industry standard involves a multi-stage protection process. Components undergo E-coating (electrophoretic deposition), where they are submerged in an electrically charged paint bath to ensure even coverage of every crevice. This is often followed by powder coating for impact resistance. Reliable manufacturers validate this protection through rigorous testing, such as the 720-hour salt spray test, ensuring the control arm can withstand years of exposure to road salts and moisture without structural compromise.

Comparative Analysis: Stamped vs. Cast vs. Aluminum

Selecting the right manufacturing method is a trade-off between cost, weight, and performance. For commercial investigation, the following comparison highlights why stamping remains dominant for high-volume applications.

| Feature | Stamped Steel | Cast Iron | Forged Aluminum |

|---|---|---|---|

| Weight | Moderate (Lighter than Cast) | Heavy | Lightest |

| Cost Efficiency | High (Best for Volume) | High | Low (Expensive Material) |

| Tensile Strength | High (500–1200 MPa) | Moderate | Very High |

| Fatigue Life | Good (High Elasticity) | Moderate (Brittle) | Excellent |

| Volume Suitability | Mass Production (>500k) | Mass Production | Premium/Low Volume |

Stamped Steel vs. Cast Iron: Stamped arms offer a clear advantage in weight reduction, typically saving 15–30% compared to cast iron. While cast iron is durable and cheap, its weight negatively impacts fuel efficiency and handling dynamics. Stamping also offers better NVH (Noise, Vibration, and Harshness) absorption due to the natural elasticity of steel sheets compared to the brittle nature of cast iron.

Stamped Steel vs. Forged Aluminum: Aluminum is the winner for pure performance, offering the lowest weight and high rigidity. However, it costs 20–35% more than stamped steel. For most passenger vehicles, the marginal performance gain of aluminum does not justify the steep cost increase. Furthermore, modern HSLA stamped arms are narrowing the weight gap, making them a "cost-effective, OE-style solution" as described by GSW Autoparts.

Applications and Future Trends

The trajectory of automotive manufacturing is heavily influenced by the electrification of the powertrain. In this landscape, stamped control arms are playing a pivotal role. Electric Vehicles (EVs) require components that can handle increased vehicle weight (due to battery packs) while simultaneously reducing unsprung mass to preserve range. Stamped steel’s ability to be formed into optimized, hollow geometries allows engineers to shave off critical kilograms without sacrificing the load-bearing capacity required for heavier EV platforms.

In the aftermarket sector, stamped control arms are the preferred choice for "OE-fit" restoration. Because they mimic the exact geometry and material properties of the original equipment, they ensure consistent alignment and handling. Quality assurance in this sector is governed by certifications like IATF 16949, and reputable suppliers conduct "million-cycle fatigue testing" to guarantee longevity. As vehicle platforms become more modular, the flexibility of progressive die stamping will continue to make it the go-to fabrication method for next-generation suspension systems.

Summary of Engineering Value

Stamping automotive suspension control arms represents the intersection of economic necessity and engineering innovation. By leveraging advanced materials and automated processing, manufacturers deliver components that sustain the global automotive supply chain. For procurement leaders, the focus remains on selecting suppliers who combine high-tonnage press capabilities with rigorous metallurgical quality control.

Frequently Asked Questions

1. How do I tell if I have stamped steel control arms?

You can identify stamped steel control arms by their appearance and a simple magnet test. Stamped arms typically look like a folded sheet of metal, often with a "sandwich" or welded seam construction, and they have a smooth, painted texture. Unlike aluminum arms, a magnet will stick strongly to stamped steel. Cast iron arms also attract magnets but usually have a rougher, sand-cast surface texture and a solid, blocky shape without seams.

2. What is the main advantage of stamping over casting for control arms?

The primary advantage is the strength-to-weight ratio. Stamped steel arms are significantly lighter than cast iron equivalents, which reduces the vehicle's unsprung weight. This reduction improves suspension response, ride comfort, and fuel efficiency. Additionally, the elasticity of rolled steel offers better shock absorption properties compared to the more brittle nature of cast iron.

3. Are aftermarket stamped control arms safe to use?

Yes, aftermarket stamped control arms are safe provided they meet OE specifications. Reputable aftermarket parts are manufactured using the same HSLA steel grades and protective coatings as the original parts. However, it is critical to verify that the manufacturer adheres to quality standards like IATF 16949 to ensure the welding quality and steel grade meet the necessary safety requirements for suspension components.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —