Precision Sheet Metal Fab Secrets: From Tolerances To Trusted Partners

Defining Precision Sheet Metal Fabrication and Why Tolerances Matter

When you hear the term "precision sheet metal fabrication," what exactly makes it different from standard metalwork? The answer lies in one critical factor: tolerances. These tiny measurements determine whether your components fit perfectly or fail catastrophically.

Precision sheet metal fabrication achieves tolerances of ±0.005 inches to ±0.010 inches, while standard fabrication typically operates within ±0.030 inches or wider—a difference that can mean success or failure in demanding applications.

Think about it this way. A tolerance of ±0.030 inches might seem negligible on paper. But when you're assembling aerospace components or medical devices, that variation becomes the difference between a part that works flawlessly and one that compromises safety.

What Separates Precision From Standard Fabrication

Standard metal fabrication handles general-purpose projects where dimensional variations are acceptable. According to EVS Metal's industry analysis, general fabrication typically maintains tolerances between ±1/16 inch to ±1/8 inch (±1.6mm to ±3.2mm). This works perfectly fine for construction frameworks, basic enclosures, and structural components.

Precision sheet metal shops operate on an entirely different level. They employ advanced equipment, sophisticated quality systems, and specialized material knowledge to achieve consistently tighter specifications. You'll notice several key differences:

- Equipment sophistication: Coordinate measuring machines (CMM), optical comparators, and laser measurement systems replace basic calipers and visual inspection

- Material expertise: Deep understanding of how different alloys behave during forming, including spring-back calculations and grain direction considerations

- Quality documentation: Complete traceability, statistical process control, and first article inspection protocols

- Tooling investment: Application-specific precision tooling that may cost 3-5 times more than standard tools but delivers repeatable accuracy

Tolerance Thresholds That Define Precision Work

So when does your project require precision metal fabrication versus standard approaches? The threshold becomes clear when examining specific tolerance requirements. According to industry specifications, edge-to-edge tolerances can reach ±0.005 inches, while bend-to-bend tolerances may extend to ±0.015 inches due to material flexibility.

Understanding tolerance stacking is equally important. When multiple tolerances accumulate across an assembly, small variations compound into significant dimensional shifts. Advanced metal components require manufacturers who anticipate these stack-up issues before they arise—sometimes recommending solutions like floating fasteners that allow ±0.03 inch radial adjustment.

Industries where component fit, function, and safety depend on exact specifications cannot afford to gamble with standard fabrication methods. Aerospace applications where a 0.020 inch deviation renders components unusable, medical devices requiring FDA-compliant dimensional accuracy, and electronics enclosures demanding precise EMI shielding gaps all demand precision metal cutting capabilities.

The bottom line? Precision sheet metal fabrication isn't simply about having better machines. It represents a comprehensive manufacturing approach encompassing advanced processes, rigorous quality systems, and engineering expertise that ensures your critical components perform exactly as designed.

Core Fabrication Processes That Achieve Tight Tolerances

Understanding tolerance thresholds is one thing. But how do precision manufacturers actually achieve those demanding specifications? The answer lies in four core processes—each contributing unique capabilities that work together to deliver components within ±0.005 inches or tighter.

Whether you're exploring sheet metal fabrication phoenix options or evaluating suppliers nationwide, knowing how these processes achieve precision outcomes helps you ask better questions and make smarter decisions.

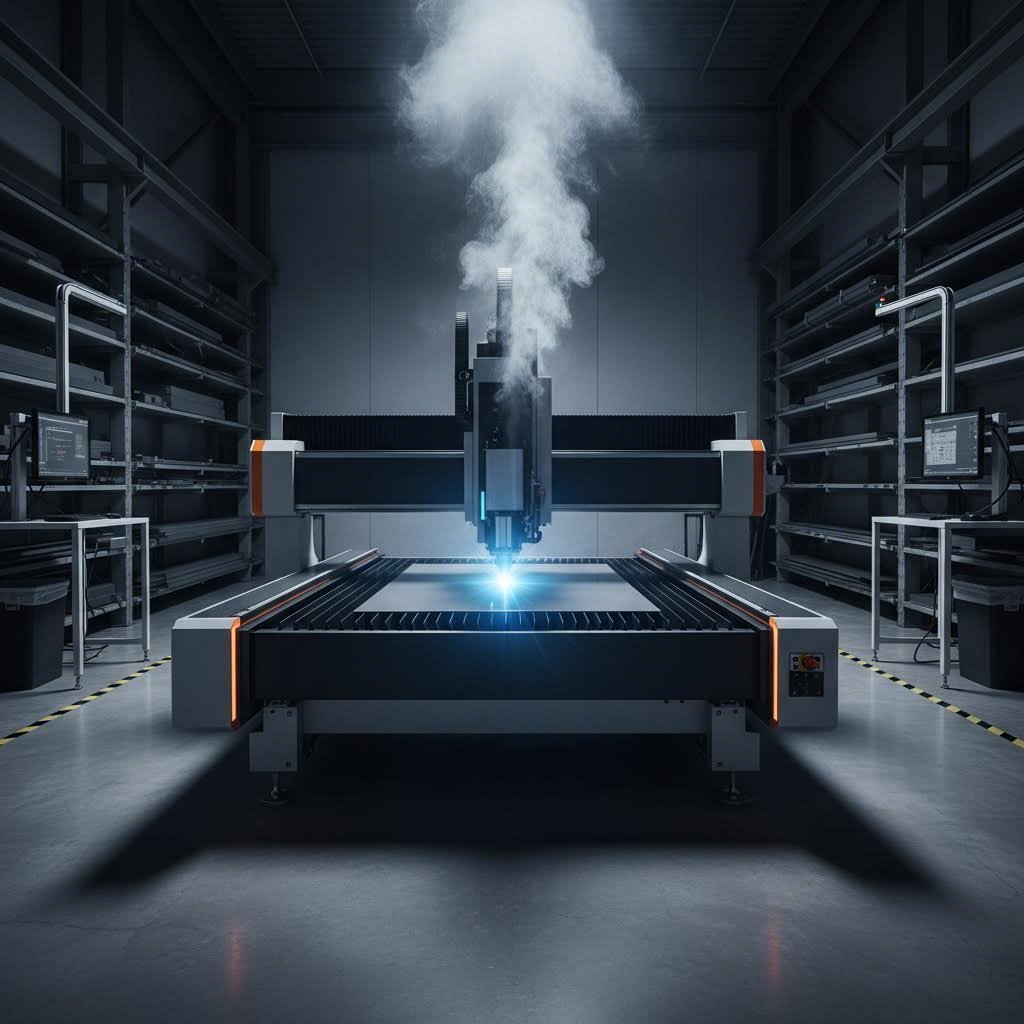

Laser Cutting for Micron-Level Accuracy

Laser cutting stands as the gold standard for precision sheet metal fab when intricate designs and tight tolerances are non-negotiable. A focused laser beam melts or vaporizes material along CNC-controlled paths, creating cuts without physical tool contact.

What makes laser cutting exceptionally precise? According to Greengate Metal Components, fiber lasers achieve tolerances as tight as ±0.1mm to ±0.15mm (approximately ±0.004 to ±0.006 inches). This non-contact process eliminates tool marks and produces smooth edges requiring minimal post-processing.

Key advantages for precision applications include:

- Material versatility: Fiber lasers cut mild steel up to 25mm thick while maintaining accuracy

- Complex geometries: Curved designs and intricate profiles that would challenge physical tooling

- No tooling costs: Design changes don't require new dies or punches

- Speed: Rapid positioning speeds reaching 300 meters per minute on appropriate materials

However, laser cutting does create minor heat-affected zones (HAZ) on thicker materials. For most precision applications, this rarely causes problems—but it's worth discussing with your phoenix metal fabricating partner when thermal sensitivity matters.

CNC Punching for High-Volume Repetitive Shapes

When your design features numerous holes, slots, or standardized cutouts, CNC punching machines deliver speed advantages that laser cutting can't match. A computer-guided punch presses through the material onto a die, creating precise shapes without thermal effects.

CNC punching achieves tolerances of approximately ±0.2mm (±0.008 inches)—slightly looser than laser cutting but perfectly suitable for many precision applications. The real advantage? According to Yijin Hardware's tolerance guide, this heat-free process avoids distortion entirely, preserving material flatness crucial for components requiring tight assembly fits.

Punching excels with thinner materials—mild steel up to 3mm and aluminum up to 6mm. For advance sheet metal projects featuring perforated panels, vented covers, or densely packed hole patterns, punching often completes work faster than laser alternatives.

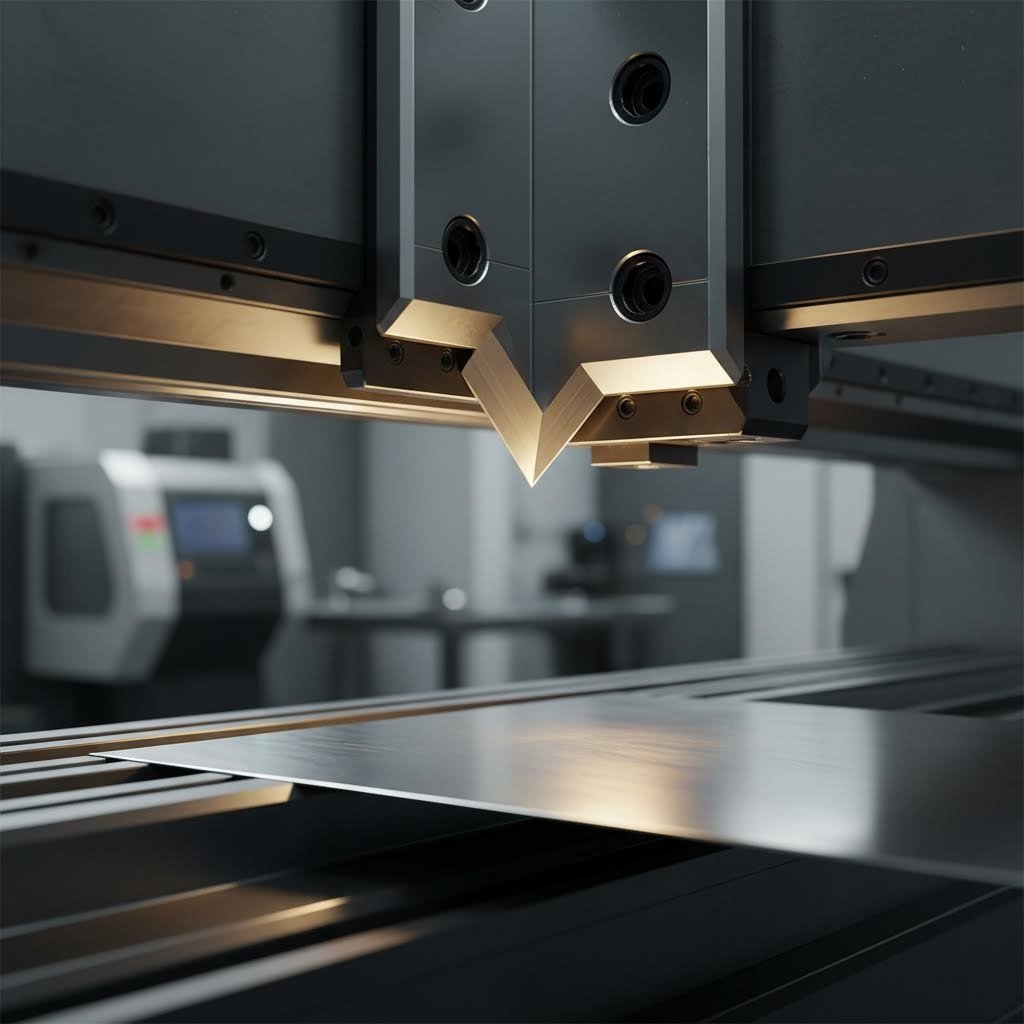

CNC Bending and Forming Techniques

Cutting creates flat profiles. Bending transforms them into three-dimensional components. This is where precision sheet metal fab becomes genuinely challenging—and where manufacturer expertise truly matters.

CNC press brakes form metal around straight axes to create V-shapes, U-channels, and complex multi-bend geometries. Advanced sheetmetal operations typically achieve:

- Angular tolerances: ±0.5° for most bend operations

- Linear tolerances: ±0.4mm to ±0.8mm for bent dimensions

Why do bending tolerances run looser than cutting tolerances? Every material exhibits springback—the tendency to partially return toward its original shape after bending. Experienced fabricators calculate springback compensation for each material type and thickness, adjusting bend angles to achieve target dimensions after relaxation.

Precision-ground dies and well-maintained tooling make significant differences here. High-end carbide dies maintain tolerances up to five times longer than standard steel tooling, according to industry data.

Precision Welding and Joining

Welding fuses components into assemblies—but it also introduces heat that can distort dimensions. Precision welding balances joint strength against dimensional stability through careful process control.

Common precision welding methods include:

- TIG welding: Superior control for thin materials and critical joints

- MIG welding: Faster deposition for larger assemblies

- Spot welding: Localized fusion minimizing heat spread

Welding tolerances typically range from ±0.5mm to ±2mm for linear dimensions and ±2° for angular dimensions. Skilled welders and proper fixturing reduce distortion, while post-weld stress relief or straightening operations recover dimensional accuracy when needed.

Process Comparison: Matching Methods to Precision Requirements

Choosing the right process depends on your specific tolerance requirements, material selection, and production volumes. This comparison helps clarify which approach fits your application:

| Process Type | Typical Tolerance Range | Best Material Applications | Ideal Use Cases |

|---|---|---|---|

| Laser Cutting | ±0.1mm to ±0.15mm (±0.004" to ±0.006") | Mild steel up to 25mm; stainless steel; aluminum | Complex profiles, prototypes, intricate designs, thick materials |

| CNC Punching | ±0.2mm (±0.008") | Mild steel up to 3mm; aluminum up to 6mm | High-volume hole patterns, perforated panels, repetitive shapes |

| CNC Bending | ±0.5° angular; ±0.4mm to ±0.8mm linear | All bendable sheet metals; varies by thickness and alloy | Enclosures, brackets, channels, formed components |

| Precision Welding | ±0.5mm to ±2mm linear; ±2° angular | Weldable steels, stainless, aluminum with proper filler | Assemblies, structural joints, multi-component fabrications |

| Stamping | ±0.1mm to ±0.5mm; critical features to ±0.05mm | Thinner gauge materials suited to die forming | High-volume production, consistent repeatability requirements |

Notice how tolerances compound when processes combine. A part requiring laser cutting followed by multiple bends and welding accumulates variations at each step. This tolerance stacking reality explains why experienced fabricators review complete manufacturing sequences—not just individual operations—when quoting precision work.

Understanding these process capabilities prepares you for the next critical decision: selecting materials that support your precision requirements while meeting performance demands.

Material Selection Criteria for Optimal Precision Outcomes

You've mastered the processes. Now comes a question that trips up even experienced engineers: which material actually delivers the precision your application demands?

Here's the reality most fabrication guides skip over. The same laser cutter achieving ±0.004 inches on aluminum might struggle to hold ±0.010 inches on certain stainless grades. Why? Material properties fundamentally shape what's achievable—and choosing wrong means compromising tolerances, increasing costs, or both.

How Material Properties Impact Precision Results

Every metal behaves differently under cutting, bending, and forming operations. Understanding these behaviors helps you anticipate challenges before they derail your project.

Aluminum alloys represent the precision fabricator's best friend for many applications. According to Okdor's material selection guide, 6061 aluminum can hold tight cutting tolerances approaching ±0.05 to ±0.1mm with stable setups—roughly ±0.0004 to ±0.0008 inches. This exceptional stability stems from aluminum's consistent grain structure and predictable springback characteristics.

What makes aluminum particularly forgiving? Consider these factors:

- Machinability: Cuts cleanly without excessive tool wear or burring

- Thermal conductivity: Dissipates heat quickly, minimizing heat-affected zones during laser cutting

- Bend radius tolerance: Accepts radii as tight as 1× material thickness without cracking

- Weight advantage: At approximately 2.7 g/cm³, it's one-third the density of steel

Stainless steel achieves similar precision to aluminum but demands more from your fabrication partner. Grades like 304 and 316 reach ±0.01 to ±0.02mm tolerances despite being significantly harder to cut. The tradeoff? Increased tool wear, slower processing speeds, and tighter minimum bend radii—typically 1.5 to 2× material thickness to prevent edge cracking.

Mild steel (carbon steel) offers excellent weldability and the lowest material costs. However, precision outcomes suffer compared to aluminum and stainless alternatives. Typical achievable tolerances run around ±0.05mm (±0.002 inches), with thin gauges particularly prone to warping during machining or welding operations.

Copper and brass present unique challenges. While these materials offer excellent ductility—accepting bend radii as tight as 0.5 to 1× thickness—they're rarely first choices for precision sheet metal fab. Copper's softness causes galling on tooling, and both materials tarnish without protective finishes. Reserve these for applications where electrical conductivity or specific aesthetic requirements justify the added complexity.

Matching Metals to Application Requirements

Selecting materials isn't just about what's achievable—it's about matching metal properties to your specific performance environment. A part destined for sterilization cycles faces entirely different demands than one operating in high-temperature aerospace applications.

Aerospace applications overwhelmingly favor aluminum alloys. According to Fry Steel's aerospace metals overview, approximately 80% of aircraft structures use aluminum, often alloyed with copper, manganese, and magnesium for enhanced durability and corrosion resistance. Common aerospace-grade options include 2024, 6061, and 7075 aluminum—each offering different strength-to-weight ratios for specific structural demands.

Medical device fabrication demands materials surviving repeated sterilization while meeting FDA compliance standards. Here, 304 and 316 stainless steel dominate. These grades withstand chemical exposure, cleaning cycles, and provide the hygienic surfaces healthcare environments require. The higher cost compared to carbon steel becomes irrelevant when patient safety depends on corrosion-free performance.

Electronics enclosures often leverage aluminum's combination of lightweight construction, thermal management, and excellent surface finish potential. Anodized aluminum achieves Ra 1.6 to 3.2 µm matte finishes ideal for consumer-facing products—something mild steel simply cannot match without extensive coating systems.

Structural and industrial applications frequently default to mild steel when corrosion exposure remains minimal. The material welds easily, costs less per pound, and provides adequate strength for frames, brackets, and support structures where ±0.05mm tolerances prove acceptable.

Material Specifications for Precision Applications

This comparison consolidates key specifications helping you match materials to your precision requirements:

| Material Type | Recommended Gauge Range | Achievable Tolerances | Thermal Considerations | Best Applications |

|---|---|---|---|---|

| Aluminum (6061, 5052) | 0.020" to 0.250" (22 ga to 1/4") | ±0.01 to ±0.02mm (±0.0004" to ±0.0008") | Excellent heat dissipation; retains toughness at low temperatures | Aerospace structures, electronics enclosures, lightweight housings |

| Stainless Steel (304, 316) | 0.018" to 0.187" (24 ga to 3/16") | ±0.01 to ±0.02mm (±0.0004" to ±0.0008") | Resists heat and fire; withstands sterilization temperatures | Medical devices, food processing, marine environments |

| Mild Steel (Cold Rolled) | 0.024" to 0.500" (22 ga to 1/2") | ±0.05mm (±0.002"); warping risk in thin gauges | Requires coatings in humid environments; can distort under heat | Structural frames, industrial brackets, cost-sensitive enclosures |

| Copper | 0.020" to 0.125" (24 ga to 1/8") | ±0.02 to ±0.05mm (±0.0008" to ±0.002") | Highest thermal conductivity; manages heat effectively | Electrical components, heat exchangers, bus bars |

| Brass | 0.020" to 0.125" (24 ga to 1/8") | ±0.02 to ±0.05mm (±0.0008" to ±0.002") | Good thermal properties; tarnishes without protective finish | Decorative applications, electronic connectors, aesthetic hardware |

Notice how gauge range affects precision outcomes? Thinner materials generally permit tighter tolerances during cutting but become more susceptible to distortion during forming and welding. Thicker stock resists warping but requires more powerful equipment and longer processing times.

Avoiding Common Material Selection Mistakes

The most expensive errors happen when engineers overspecify or ignore manufacturability limits. A few critical pitfalls to avoid:

- Specifying exotic alloys unnecessarily: Choosing 317 stainless when 304 performs identically for your application increases costs and extends lead times

- Ignoring forming limits: Designing 90° bends in stainless without adequate radius causes edge cracking during production

- Overlooking environment: Mild steel deployed outdoors without proper coatings guarantees premature corrosion failure

- Failing stock availability checks: Specifying gauges or alloys suppliers don't carry forces last-minute redesigns under deadline pressure

The takeaway? Start with your performance requirements—strength, corrosion resistance, weight, and thermal behavior—then verify that your chosen material actually delivers the precision tolerances your design demands. This foundational decision shapes every subsequent manufacturing step.

With materials selected, your next consideration becomes equally critical: designing parts that manufacturers can actually produce efficiently and accurately.

Design for Manufacturability Best Practices in Precision Work

You've selected your material and understand the processes. Now comes the step that separates smooth production runs from costly nightmares: designing parts that machines can actually build efficiently.

Design for Manufacturability—commonly called DFM—sounds technical. But here's what it really means: creating designs that work with fabrication equipment rather than against it. When DFM principles get ignored, you're looking at higher prices, longer wait times, and elevated risk of errors.

The payoff for getting this right? According to Norck's fabrication guide, proper DFM eliminates what manufacturers call "manufacturing friction"—those hidden inefficiencies that inflate quotes and delay shipments.

DFM Principles That Reduce Fabrication Errors

Imagine folding a piece of cardboard too sharply. The outer edge cracks or creases unevenly. Metal behaves similarly—and understanding these physical limits prevents expensive rework.

Here are the critical DFM considerations every custom precision sheet metal design should address:

- Minimum bend radii by material: The inside curve of your bend should at least match the material thickness. According to Approved Sheet Metal's 2025 guidelines, the industry standard bend radius of 0.030" works for all material thicknesses up to 0.125" (⅛"). Thicker materials require proportionally larger radii—use 0.060" or more for stock between 0.125" and 0.250".

- Hole-to-edge distances: Position holes at minimum two times the material thickness from any bend location. Place them closer and the hole stretches into an oval during forming—making screws and pins impossible to fit properly.

- Relief cuts for complex bends: When bending metal alongside a flat edge, the material tries to separate at corners. Small rectangular or circular cut-outs at bend line ends—called bend reliefs—prevent tearing and ensure clean, professional finishes.

- Minimum flange lengths: Press brake tooling needs sufficient surface area to grip the metal. Design flanges at least four times the material thickness. Shorter "illegal" flanges require custom, expensive molds that can double production costs.

- Grain direction awareness: Metal sheets have a "grain" from the rolling process at the mill. Bending along the grain dramatically increases cracking risk. Orient your folds to cross the grain whenever possible.

- Narrow cutout limitations: Laser cutters use intense heat. Very thin fingers or narrow slots can warp like potato chips. Keep cutouts at least 1.5 times wider than material thickness to maintain flatness.

Why does this matter for special fab & machine operations? Every violated principle creates inspection points, potential rejects, and production delays. Following these rules means your parts pass quality checks the first time.

Designing for Bend Radii and Material Flow

Bend radius mistakes cause more fabrication headaches than almost any other design error. Two common pitfalls trip up even experienced engineers.

The first mistake? Listing 0.100" as the bend radius—the default measurement in SOLIDWORKS. Standard tooling cannot create this radius. Your fabricator would need custom tooling costing thousands of dollars, extending lead times significantly.

The second mistake? Making the inside bend radius exactly match material thickness. Sounds logical, right? But if you're using 0.100" aluminum or 0.104" stainless steel, you're back to that custom tooling problem.

The solution is straightforward: specify 0.030" for bend radii on materials up to ⅛" thick. This measurement ensures consistent, high-quality parts with solid structural integrity—and it matches the tooling every competent fabricator already owns.

What about springback? Metal is slightly elastic. When bent to 90 degrees and released, it naturally returns partway—maybe to 88 or 89 degrees. Your options here:

- Accept standard tolerances: If your design doesn't require exactly 90.00 degrees, allow ±1° to ±2° wiggle room in specifications

- Communicate critical angles: Flag dimensions where angular precision matters so fabricators can compensate during programming

- Avoid over-specifying: Being unnecessarily strict on tolerances increases inspection time and cost without functional benefit

Tolerance Stacking: The Hidden Precision Killer

Here's where precision sheet metal fab gets genuinely tricky. Every cut, bend, and hole introduces small variations. Individually, these stay within tolerance. But stack multiple operations together, and those variations accumulate.

According to Protolabs' tolerance analysis, crossing four bends while measuring hole-to-hole gives you a linear tolerance of ±0.030 inches and a stacking angular tolerance of 1° per bend. That's significantly looser than single-surface tolerances.

How do you overcome this? Consider these strategies from scriven precision fabricating approaches:

- Open mating holes: Enlarge holes in one component to allow for misalignment in corresponding parts

- Use floating hardware: Specify fasteners allowing ±0.03" radial adjustment between assembled components

- Minimize bend crossings: Design critical hole patterns on single surfaces whenever possible

- Specify datum references: Identify which dimensions are critical versus which can absorb variation

Combining these approaches trivializes stacking tolerances. You end up with functional assemblies that mate reliably—without requiring machining-like tolerances your special fab and machine partner cannot economically deliver.

Standard Hole Sizes: A Simple Cost Saver

One often-overlooked DFM principle involves hole sizing. Design a hole at exactly 5.123mm diameter, and your fabricator may need to procure custom tooling just for your order.

The fix? Use standard sizes: 5mm, 6mm, ¼ inch, or other off-the-shelf dimensions. This allows high-speed punching with existing tools, often enabling same-day turnaround versus days of delay waiting for custom drill bits.

This principle extends beyond holes to slots, notches, and cutouts. Standard dimensions leverage standard tooling. Custom dimensions require custom solutions—and custom invoices.

What Happens When DFM Gets Ignored

Skip these principles and you'll encounter predictable consequences:

- Cracked edges: Bend radii too tight for the material cause visible fractures or hidden stress concentrations

- Distorted holes: Positioning too close to bends stretches circular holes into unusable ovals

- Warped profiles: Narrow cutouts and inadequate relief cuts twist flat surfaces into wavy, non-conforming shapes

- Assembly failures: Tolerance stacking across multiple bends makes mating parts impossible to align

- Custom tooling charges: Non-standard specifications trigger expensive one-off tool procurement

The bottom line? A designer cannot expect to hold machining-like tolerances in sheet metal parts. Understanding physical limits and working thoughtfully within fabrication guidelines separates designs that ship on budget from projects that hemorrhage money.

With DFM fundamentals covered, you're ready to explore how different industries apply these principles—each with unique precision requirements shaped by their specific safety and performance demands.

Industry Applications and Their Unique Precision Requirements

You understand materials, processes, and DFM principles. But here's the question that ultimately determines everything: does your specific application actually require precision sheet metal fab?

The answer depends entirely on your industry. A decorative enclosure tolerates variations that would ground an aircraft. A consumer electronics bracket accepts dimensional flexibility that would fail a medical implant inspection. Understanding these distinctions helps you specify appropriately—avoiding both under-engineering that risks failure and over-engineering that wastes budget.

Aerospace and Defense Tolerance Standards

When lives depend on components performing flawlessly at 35,000 feet, tolerance requirements become non-negotiable. According to Buell Automatics' inspection standards, aerospace parts often require tolerances within ±0.0001 inches—ten times tighter than general precision fabrication.

Why such extreme precision? Consider what happens when specifications slip:

- Turbine blade imbalances: Even microscopic dimensional variations create vibration, fuel inefficiency, or catastrophic engine failure

- Control surface misalignment: Flight control components must move precisely as designed—binding or excessive play endangers aircraft stability

- Fatigue stress concentrations: Imprecise edges or radii create weak points where cracks initiate during repeated pressure cycling

- Assembly interference: Components that won't fit during production delay aircraft delivery and inflate costs

Aerospace fabrication also demands rigorous certification. ITAR (International Traffic in Arms Regulations) compliance becomes mandatory for defense-related applications. According to Approved Sheet Metal's certification guide, ITAR registration signals manufacturers are approved to handle sensitive defense technologies—with violations carrying massive civil and criminal penalties.

Additional aerospace requirements include:

- AS9100 certification: The aerospace-specific quality management standard building on ISO 9001

- Complete material traceability: Every component traced from raw mill certificate through final inspection

- First Article Inspection (FAI) reports: Comprehensive documentation verifying initial parts match exact design specifications

Medical Device Fabrication Requirements

Medical applications present a different precision challenge: components must perform reliably while surviving repeated sterilization cycles and meeting FDA compliance standards.

According to industry inspection benchmarks, medical implants require exact dimensional fits for patient safety. Surface finish becomes equally critical—roughness values (Ra and Rz measurements) must fall within tight bands to prevent bacterial colonization on implantable devices.

Medical fabrication demands include:

- Biocompatibility: Materials must not trigger adverse biological responses—typically requiring 316L stainless steel or titanium alloys

- Sterilization resistance: Components must withstand autoclave temperatures, chemical exposure, and repeated cleaning without degradation

- FDA documentation: Manufacturing processes require validation demonstrating consistent, reproducible outcomes

- ISO 13485 certification: The medical device-specific quality management system standard

- Surface integrity verification: Visual inspection under magnification catches micro-burrs or inconsistencies affecting performance

The consequences of insufficient precision in medical applications extend beyond product failure. Patient harm, regulatory action, and liability exposure create stakes far exceeding component costs. If your application involves patient contact or implantation, precision fabrication isn't optional—it's the baseline requirement.

Electronics Industry Precision Demands

Miniaturization drives electronics fabrication requirements. According to Hartford Technologies' tolerance analysis, components like printed circuit boards and connectors require manufacturing tolerances measured in microns.

This precision ensures:

- Reliable electrical connections: Connector housings must align precisely with PCB mounting points

- Effective EMI shielding: Enclosure gaps exceeding specifications allow electromagnetic interference leakage

- Thermal management: Heat sink mounting surfaces require flatness tolerances ensuring complete contact with components

- High-density packaging: Compact consumer devices leave no room for dimensional variation

For sheet metal phoenix fabricators serving electronics manufacturers, these requirements translate to laser cutting for intricate patterns, tight bend tolerances for enclosure fit, and surface finishes supporting anodizing or powder coating without visible defects.

Automotive Sector Requirements

Automotive precision requirements occupy a middle ground—demanding enough to ensure safety and assembly fit, yet practical enough for high-volume production economics.

According to Hartford Technologies' industry analysis, engine components rely on all parts working harmoniously. Even slight piston dimensional deviations result in decreased efficiency, increased emissions, or complete engine failure.

Automotive fabrication priorities include:

- IATF 16949 certification: The automotive-specific quality standard exceeding general ISO 9001 requirements

- Statistical Process Control (SPC): Real-time data tracking catches trends like tool wear before they impact quality

- High-volume repeatability: Tolerances must hold across thousands or millions of parts

- Assembly integration: Components must mate perfectly with parts from multiple suppliers

Chassis, suspension, and structural components particularly demand precision. These safety-critical parts protect occupants during crashes—dimensional variations that compromise energy absorption pathways create unacceptable risks.

Determining If You Need Precision Fabrication

How do you know whether your application requires precision sheet metal fab versus standard approaches? Ask yourself these questions:

- What happens if dimensions vary by ±0.030 inches? If the answer involves safety risks, assembly failures, or functional degradation—you need precision

- Does your industry require specific certifications? Aerospace, medical, automotive, and defense applications typically mandate certified suppliers

- Will components undergo regulatory inspection? FDA, FAA, or DOT oversight demands documented precision and traceability

- Do parts mate with precision-manufactured components? Mixing precision and standard fabrication often creates assembly problems

- What are the consequences of failure? Safety-critical applications justify precision costs; decorative components rarely do

Whether you're sourcing metal fabrication phoenix az suppliers or evaluating partners nationwide, matching fabrication capabilities to your actual requirements prevents both quality failures and unnecessary expense. The goal isn't maximum precision—it's appropriate precision for your specific application.

Understanding industry requirements naturally leads to the next critical question: how do fabricators actually verify they're meeting these demanding specifications?

Quality Control Methods and Industry Certifications Explained

Your fabricator claims ±0.005 inch tolerances. But how do you know they actually deliver? The answer lies in inspection methods and certifications—yet most manufacturers mention these briefly without explaining what they mean for your project.

Here's the reality: claiming precision and proving precision are entirely different things. According to IPQC's comprehensive inspection guide, modern quality control combines multiple verification technologies, each addressing specific dimensional requirements. Understanding these methods helps you evaluate supplier capabilities—and spot red flags before they become expensive problems.

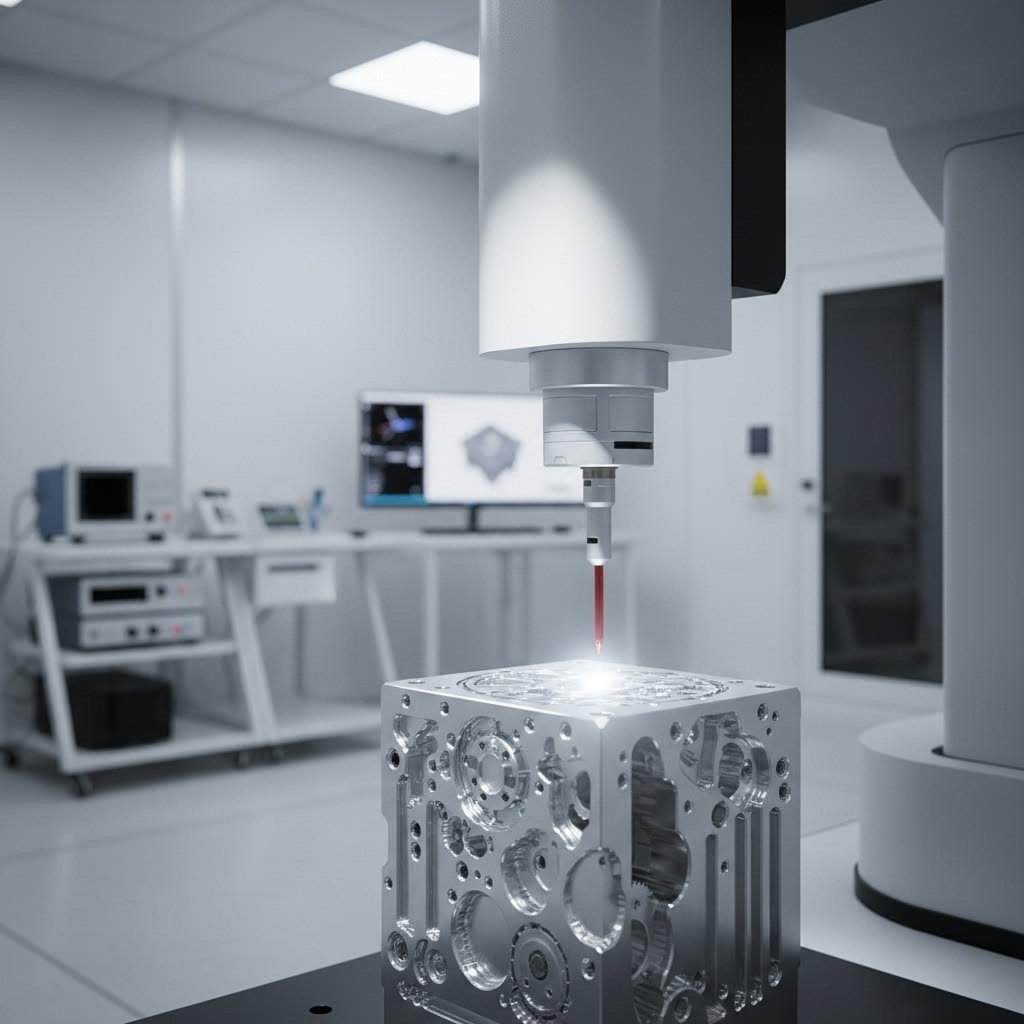

Inspection Technologies That Verify Precision

Traditional calipers and micrometers still have their place. But precision sheet metal fab demands far more sophisticated verification. Let's examine the technologies separating capable fabricators from those merely claiming precision capabilities.

Coordinate Measuring Machines (CMMs) represent the gold standard for dimensional verification. These precision instruments use touch probes to collect 3D coordinate data, measuring complex geometries with micron-level accuracy. When your part features multiple critical dimensions across curved or angled surfaces, CMM inspection provides definitive verification that specifications are met.

What makes CMMs particularly valuable? They eliminate operator influence. The machine follows programmed inspection routines, collecting hundreds of data points automatically. Results get compared directly against CAD models, generating comprehensive deviation reports showing exactly where dimensions fall within—or outside—specified tolerances.

Optical comparators project magnified part profiles onto screens with overlay templates for rapid visual comparison. These systems excel at checking 2D contours, hole patterns, and edge conditions. While less sophisticated than CMMs, they provide fast verification during production runs without removing parts from the manufacturing flow.

Laser scanners capture complete surface data using non-contact measurement. By projecting laser lines onto parts, these devices create point clouds representing entire component geometries. This approach proves ideal for free-form surfaces, flexible materials, or situations where physical contact might damage delicate features.

Automated vision systems use camera-based inspection comparing parts against digital templates. These high-speed solutions integrate directly into production lines, checking every part rather than relying on sampling. When you're ordering thousands of components, this 100% inspection capability catches defects that statistical sampling might miss.

Beyond dimensional checks, surface quality analysis evaluates finish characteristics. Surface roughness testers quantify texture using parameters like Ra (average roughness) and Rz (maximum height). For applications requiring specific surface finishes—medical devices, aerospace components, or consumer electronics enclosures—these measurements verify compliance with finish specifications.

Statistical Process Control: Catching Problems Before They Happen

Inspection after manufacturing catches defects. But what if you could prevent defects from occurring in the first place?

That's exactly what Statistical Process Control (SPC) accomplishes. According to EOXS's manufacturing analysis, SPC systematically monitors processes through real-time statistical analysis. By collecting data during production, manufacturers identify variations before they lead to out-of-spec parts.

Imagine a CNC press brake gradually drifting as tooling wears. Without SPC, you might not discover the problem until finished parts fail final inspection. With SPC monitoring bend angles continuously, operators see the drift developing and adjust before tolerances get violated.

Key SPC benefits for precision fabrication include:

- Early defect detection: Identifying variations before they produce scrap

- Cost reduction: Minimizing rework and rejected parts

- Process optimization: Data-driven adjustments improving efficiency

- Trend identification: Spotting tool wear, material variations, or environmental factors affecting quality

When evaluating phoenix sheet metal suppliers or fabricators anywhere, ask about their SPC implementation. Shops running SPC demonstrate commitment to proactive quality management—not just reactive inspection.

Understanding Quality Certifications

Certifications appear on every fabricator's website. But what do those acronyms actually mean for your project? According to Hartford Technologies' certification guide, different certifications address different industries and quality requirements.

Here's what each major certification signals about a fabricator's capabilities:

- ISO 9001: The foundational quality management certification applicable across all industries. It confirms the organization maintains documented processes, customer focus, and continuous improvement systems. Consider this the baseline—any serious precision fabricator should hold current ISO 9001 certification.

- AS9100: The aerospace-specific standard building on ISO 9001 with additional requirements for product design, production processes, and traceability. If your components fly, your fabricator needs AS9100. This certification addresses the unique safety and reliability demands of aviation applications.

- IATF 16949: Developed by the International Automotive Task Force specifically for automotive manufacturing. It encompasses ISO 9001 requirements plus automotive-specific standards for production processes, improvement methodologies, and customer requirements. Automotive OEMs typically require IATF 16949 certification from their supply chain.

- ISO 13485: The medical device-specific quality standard emphasizing safety-focused design and manufacturing. This certification ensures components meet the rigorous requirements protecting patient health. Any sheet metal phoenix az fabricator serving medical customers should maintain this certification.

- ITAR (International Traffic in Arms Regulations): Not a quality certification but a regulatory registration indicating approval to handle defense-related technologies. ITAR-registered manufacturers can work on military and defense projects—violations carry severe civil and criminal penalties.

- ISO 14001: Environmental management certification demonstrating commitment to sustainable practices. While not directly quality-related, it signals organizational maturity and responsibility increasingly important to corporate customers with sustainability mandates.

What should you look for? Match certifications to your industry. Aerospace projects require AS9100. Automotive applications demand IATF 16949. Medical devices need ISO 13485. General industrial work requires at minimum ISO 9001.

But don't stop at checking boxes. Ask fabricators to explain their certification scope and recent audit results. Certifications require ongoing surveillance audits—a company certified five years ago without recent verification may have let systems slip. Current certifications with clean audit histories demonstrate sustained commitment to quality.

These verification systems and certifications provide the foundation for consistent precision. But how do fabricators apply these capabilities across different production scenarios—from single prototypes to mass production runs?

Prototyping to Production and Scaling Precision Manufacturing

You've validated quality systems and certifications. Now comes a practical question every product developer faces: should you invest in production tooling immediately, or start with prototypes to validate your design first?

This decision carries significant cost implications. According to Eabel's manufacturing analysis, the biggest cost factor in sheet metal manufacturing is tooling amortization. Mass production requires expensive dies—and those investments only pay off when spread across large quantities.

Getting this balance wrong means either overspending on tooling before your design is finalized, or relying on slow, costly prototyping methods for mid-volume runs that should have transitioned to production tooling weeks earlier.

Prototyping Speed vs. Production Scale Tradeoffs

Rapid prototyping and mass production serve fundamentally different purposes. Understanding these tradeoffs helps you allocate budget and timeline appropriately.

Rapid prototyping delivers speed and flexibility. Engineers can test, adjust, and re-cut metal parts within days. This agility proves invaluable during early-stage development when designs evolve rapidly based on functional testing and stakeholder feedback. According to UPTIVE's production guide, even the first iPhone went through dozens of iterations before its 2007 launch—prototyping enabled that refinement process.

What makes prototyping cost-effective for low volumes? It avoids tooling expenses entirely. Laser cutting and CNC bending create parts directly from CAD files without requiring dies or custom fixtures. Design changes cost virtually nothing—just update the file and cut again.

Mass production inverts this equation. Hardened tooling and automated processes deliver extremely consistent tolerances across thousands or millions of identical parts. The per-unit cost drops dramatically once tooling investments get absorbed. But design changes become expensive—any modification may require die rework or completely new tooling.

Here's the critical insight: the crossover point typically occurs between a few dozen to a few hundred parts, depending on material and part complexity. Miscalculating this threshold leads to avoidable expenses:

- Moving to production too early: Investing in tooling before design stabilization wastes money when modifications require expensive die rework

- Staying in prototyping too long: Using laser cutting for 500+ part runs when stamping would deliver lower per-unit costs

- Ignoring bridge tooling options: Some manufacturers offer soft tooling for mid-volume runs—testing designs before committing to hardened production dies

When to Choose Rapid Prototyping Services

Rapid prototyping makes sense in specific scenarios. If any of these apply to your project, prioritize prototyping before production commitment:

- Early design stages: When concepts require validation and feedback loops drive frequent changes

- Proof-of-concept parts: Demonstrating functionality to stakeholders before significant investment

- Small batches: Quantities below the tooling cost crossover point

- Complex geometries: Shapes requiring validation before committing to production-level tooling

- Timeline pressure: When you need functional parts in days rather than weeks

Modern manufacturers bridge the prototype-to-production gap efficiently. For example, Shaoyi offers 5-day rapid prototyping alongside automated mass production capabilities—enabling seamless transitions as designs mature and volumes increase. Their IATF 16949 certification ensures automotive-grade precision throughout both phases.

What about quality differences between prototyping and production? According to Eabel's analysis, rapid prototyping delivers strong functional quality, but tolerances can vary depending on machine setup, bending complexity, and manual assembly involvement. Mass production's hardened tooling produces extremely consistent tolerances—essential when thousands of identical parts must meet strict quality standards.

The Vertical Integration Advantage

How do manufacturing capabilities affect your prototype-to-production journey? According to Komaspec's industry analysis, vertically integrated fabricators control multiple stages of the supply chain—from raw materials through finished assemblies.

This integration creates tangible benefits for precision sheet metal fab projects:

- Quality consistency: Single-source accountability eliminates finger-pointing between separate cutting, forming, and finishing vendors

- Reduced lead times: Parts move between processes without shipping delays or communication gaps between companies

- Cost efficiency: Eliminating middlemen and consolidating operations reduces overhead built into pricing

- Design flexibility: In-house capabilities enable rapid adjustments when prototyping reveals needed changes

Smart factories take integration further. According to Komaspec, intelligent factory systems connect processes, information streams, and stakeholders in streamlined fashion. Automated sheet metal machines work in succession with minimal human intervention—enabling production of unique, complex designs that traditional facilities find challenging.

For phoenix fabrication projects or az metal fabrication requirements, vertical integration particularly benefits automotive applications. Chassis, suspension, and structural components demand both prototyping agility during development and production-scale consistency for volume manufacturing. Finding sheet metal fabrication phoenix az partners offering both capabilities under one roof simplifies qualification and maintains quality continuity.

Making the Transition Successfully

The path from prototype to production isn't automatic. According to UPTIVE's manufacturing guide, several critical steps ensure smooth transitions:

- Complete DFM review: Finalize Design for Manufacturability checks before investing in production tooling—catching issues earlier costs far less than die modifications

- Low-volume validation runs: Manufacture small batches using production methods to verify processes, identify bottlenecks, and assess quality before full-scale commitment

- Documentation handoff: Maintain detailed records of changes made during prototyping so production teams understand design evolution

- Supply chain verification: Confirm material availability and supplier reliability before production dependencies lock in

Many metal fabricators phoenix az serve follow hybrid paths: starting with rapid prototyping, moving to soft tooling for mid-volume runs, and scaling into full production as demand and design stability increase. This staged approach minimizes risk while maintaining flexibility.

The bottom line? Prototyping validates designs before expensive tooling investments. Production delivers economies of scale once designs stabilize. Choosing partners capable of supporting both phases—with certifications matching your industry requirements—positions your project for success from first prototype through volume manufacturing.

Understanding these production considerations prepares you for the final critical step: evaluating potential fabrication partners to find the right fit for your specific requirements.

How to Evaluate and Select a Precision Fabrication Partner

You've done the homework. You understand tolerances, materials, DFM principles, and quality systems. Now comes the decision that determines whether all that knowledge translates into successful projects: choosing the right fabrication partner.

This selection matters more than most procurement decisions. According to JR Metal Works' supplier evaluation guide, a business's reputation depends largely on the value of products and services it provides—and the quality of work delivered by your metal fabricating partner becomes a direct reflection of your company.

Getting this wrong sets back timelines and pushes budgets to breaking points. Getting it right creates partnerships that simplify meeting customer expectations and ultimately lead to better products.

Key Questions to Ask Potential Fabrication Partners

Before requesting quotes, develop a structured evaluation approach. According to Southern Metalcraft's buyer guide, a supplier's process matters more than their equipment list. Here are the questions that reveal genuine capabilities versus marketing claims.

Certification and quality verification:

- Which quality certifications do you currently hold, and when were they last audited?

- Can you provide copies of current certification documents?

- What inspection equipment do you use for dimensional verification?

- Do you implement Statistical Process Control during production runs?

Tolerance and capability documentation:

- What tolerances can you consistently achieve for laser cutting, bending, and welding?

- Can you provide capability studies or Cpk data demonstrating process stability?

- How do you handle tolerance stacking across multi-operation parts?

- What gauge ranges and materials does your equipment accommodate?

Engineering and DFM support:

- Do you provide Design for Manufacturability feedback before quoting?

- Will your engineers identify cost-saving design modifications?

- How quickly can you review designs and provide recommendations?

- Do you offer prototyping services to validate designs before production?

According to the Southern Metalcraft analysis, great suppliers don't just deliver parts—they collaborate to make products better and more cost-effective. Look for partners willing to engage in value-added engineering that benefits both parties.

Communication and responsiveness:

- What is your typical quote turnaround time?

- How will you communicate project status and progress updates?

- Who will be my primary contact, and what are their response time expectations?

- Are you flexible about communication methods—email, phone, messaging platforms?

Responsiveness during the quoting phase predicts responsiveness during production. Some manufacturers, like Shaoyi, offer 12-hour quote turnaround times with comprehensive DFM support—setting benchmarks for what responsive service looks like. Their expertise in chassis, suspension, and structural components makes them particularly relevant for automotive buyers seeking IATF 16949-certified precision.

Red Flags When Evaluating Manufacturers

Not every fabricator claiming precision capabilities actually delivers. According to JR Metal Works' evaluation framework, certain warning signs should trigger deeper investigation—or elimination from consideration entirely.

Avoid fabricators who:

- Cannot provide references: Steer clear of companies that won't—or can't—connect you with current or past customers. Legitimate partners welcome verification of their track record.

- Offer vague tolerance specifications: "We're very precise" means nothing without documented capabilities. Demand specific numbers: ±0.005" cutting tolerance, ±0.5° bend accuracy, supported by process data.

- Lack relevant certifications: Missing ISO 9001 suggests inadequate quality systems. Missing industry-specific certifications (AS9100 for aerospace, IATF 16949 for automotive) disqualifies suppliers from those sectors entirely.

- Show poor financial stability: According to JR Metal Works, financially-stable organizations attract and retain top talent while maintaining equipment investments. Companies struggling financially may cut corners affecting your quality.

- Resist facility visits: Reputable fabricators welcome tours. According to Southern Metalcraft's buyer guide, regular in-person engagement keeps relationships strong and uncovers opportunities for improvement.

- Overpromise without evidence: Claims of "fastest turnaround" or "lowest prices" without supporting documentation often signal problems. Sustainable partnerships balance competitive pricing with realistic capabilities.

Your Evaluation Checklist

Use this structured checklist when comparing potential metal phoenix az fabricators or suppliers anywhere in your supply chain:

| Evaluation Criteria | What to Verify | Acceptable Evidence |

|---|---|---|

| Certification Status | Current ISO 9001 plus industry-specific standards | Certificate copies with recent audit dates |

| Tolerance Capabilities | Documented precision for each process type | Capability studies, Cpk data, sample inspection reports |

| DFM Support | Engineering review availability and depth | Sample DFM feedback reports, engineer credentials |

| Quote Turnaround | Response time for standard quote requests | Documented SLA or demonstrated performance |

| Communication | Responsiveness and clarity during evaluation | Your direct experience during selection process |

| References | Verifiable customer relationships | Contact information for current customers willing to discuss |

| Financial Stability | Capacity for investment and talent retention | Years in business, facility investments, employee tenure |

Building Long-Term Partnerships

Finding a capable fabricator is just the beginning. According to the Southern Metalcraft buyer perspective, the most successful supplier relationships are built on trust, communication, and shared goals.

What separates transactional vendors from true partners?

- Mutual investment: Partners invest in understanding your business, not just filling orders

- Proactive communication: They surface potential problems before they become crises

- Continuous improvement: They suggest process refinements that reduce your costs over time

- Flexibility: They accommodate rush orders and design changes when circumstances demand

As Southern Metalcraft's buyer guide emphasizes: "My success depends on my supplier's success, and vice versa." When you find a supplier who treats your success as their own—investing in people, processes, and technology to support your goals—you've found a partner worth keeping.

The effort required to properly evaluate prospective metal phoenix az fabricators pays dividends throughout your product lifecycle. A reliable partnership makes meeting customer expectations easier and ultimately leads to better products reaching your market.

Frequently Asked Questions About Precision Sheet Metal Fabrication

1. What is precision sheet metal fabrication?

Precision sheet metal fabrication is a manufacturing process that achieves extremely tight tolerances, typically within ±0.005 to ±0.010 inches, compared to standard fabrication's ±0.030 inches or more. This level of accuracy requires advanced equipment like laser cutters, CNC press brakes, and coordinate measuring machines (CMMs) for verification. Industries such as aerospace, medical devices, and automotive rely on precision fabrication where component fit, function, and safety depend on exact specifications. Manufacturers like Shaoyi deliver IATF 16949-certified precision for critical automotive components including chassis and suspension parts.

2. How do I choose the right metal fabrication company for my product?

Selecting the right precision fabrication partner requires evaluating several key factors: verify current quality certifications (ISO 9001, AS9100 for aerospace, IATF 16949 for automotive), request documented tolerance capabilities with supporting process data, assess DFM support availability, and check quote turnaround times. Look for partners offering comprehensive engineering support—some manufacturers provide 12-hour quote turnaround with detailed DFM feedback. Avoid fabricators who cannot provide customer references, offer vague specifications, or resist facility visits. Building long-term partnerships with suppliers who invest in understanding your business leads to better products and streamlined manufacturing.

3. What tolerances can precision sheet metal fabrication achieve?

Precision sheet metal fabrication achieves different tolerances depending on the process: laser cutting delivers ±0.1mm to ±0.15mm (±0.004" to ±0.006"), CNC punching achieves ±0.2mm (±0.008"), CNC bending holds ±0.5° angular and ±0.4mm to ±0.8mm linear tolerances, while precision welding maintains ±0.5mm to ±2mm linear accuracy. Material selection significantly impacts achievable tolerances—aluminum alloys can hold ±0.01 to ±0.02mm under stable conditions. Understanding tolerance stacking across multiple operations is critical, as variations accumulate when parts undergo cutting, bending, and welding sequences.

4. What is the difference between rapid prototyping and mass production in sheet metal?

Rapid prototyping prioritizes speed and flexibility, delivering functional parts within days using laser cutting and CNC bending directly from CAD files without tooling investment. This approach excels during design validation when frequent changes occur. Mass production requires hardened tooling investment but delivers consistent tolerances across thousands of parts at significantly lower per-unit costs. The crossover point typically occurs between a few dozen to a few hundred parts. Modern manufacturers like Shaoyi bridge this gap with 5-day rapid prototyping alongside automated mass production capabilities, enabling seamless transitions as designs stabilize.

5. What quality certifications should a precision sheet metal fabricator have?

Required certifications depend on your industry: ISO 9001 serves as the foundational quality management standard all precision fabricators should hold. Aerospace applications require AS9100, automotive projects demand IATF 16949, and medical device fabrication needs ISO 13485. Defense-related work requires ITAR registration. Beyond checking certification status, verify recent audit dates and ask about certification scope. Fabricators should also implement Statistical Process Control (SPC) for real-time quality monitoring and use inspection technologies like CMMs and optical comparators to verify stated tolerances.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —