Precision Sheet Metal Fabrication: From Prototype To Production Mastery

What Makes Sheet Metal Fabrication Truly Precision

Ever wondered what separates a standard metal part from one that fits perfectly every single time? The answer lies in precision sheet metal fabrication—a specialized manufacturing approach where tolerances, equipment, and quality control operate at an entirely different level than conventional metalworking.

So, what is a sheet metal fabrication process considered "precision"? Simply put, metal fabrication means transforming flat metal sheets into finished components through cutting, bending, and forming operations. But when we add "precision" to the equation, we're talking about achieving dimensional accuracy that standard methods simply cannot deliver.

Defining Precision in Metal Fabrication

Precision sheet metal work distinguishes itself through three critical elements:

- Tighter tolerances: While standard sheet metal fabrication tolerances typically range from ±0.02" to ±0.03", precision fabrication can achieve tolerances of ±0.005" or tighter—sometimes reaching ±0.001" for critical applications.

- Advanced equipment requirements: CNC-controlled laser cutters, precision press brakes with real-time angle monitoring, and coordinate measuring machines (CMMs) replace manual equipment.

- Rigorous quality control protocols: Every dimension gets verified against specifications, often with statistical process control documenting consistency across production runs.

The fabrication of sheet metal at this level demands more than just better machines. It requires skilled operators who understand how material properties, thermal effects, and tooling conditions influence final dimensions.

How Tight Tolerances Transform Manufacturing Outcomes

When does precision sheet metal become necessary rather than optional? Consider this: a component that's just 0.015" off specification might seem acceptable—until you're assembling hundreds of parts together. Those small deviations compound, creating misalignment, assembly failures, or reduced product performance.

Industries like aerospace, medical devices, and automotive demand metal precision because:

- Safety-critical assemblies require perfect fit and structural integrity

- Complex multi-component systems depend on consistent dimensional accuracy

- Regulatory compliance often mandates documented precision standards

International standards frameworks like ISO 2768 provide tolerance guidelines that help manufacturers and designers communicate requirements clearly. These standards establish common expectations for linear dimensions, angular tolerances, and geometric characteristics—ensuring everyone speaks the same language when specifying precision requirements.

Tighter tolerances don't automatically mean higher quality—they mean higher costs. The key is specifying precision only where function or safety truly demands it.

Understanding when to invest in precision fabrication versus standard approaches comes down to application requirements. A decorative enclosure might tolerate ±0.03" variations without issue, while a chassis component interfacing with electronic assemblies could fail at half that deviation. Smart engineering balances these requirements, applying tight tolerances selectively to critical features while allowing looser specifications elsewhere to control costs.

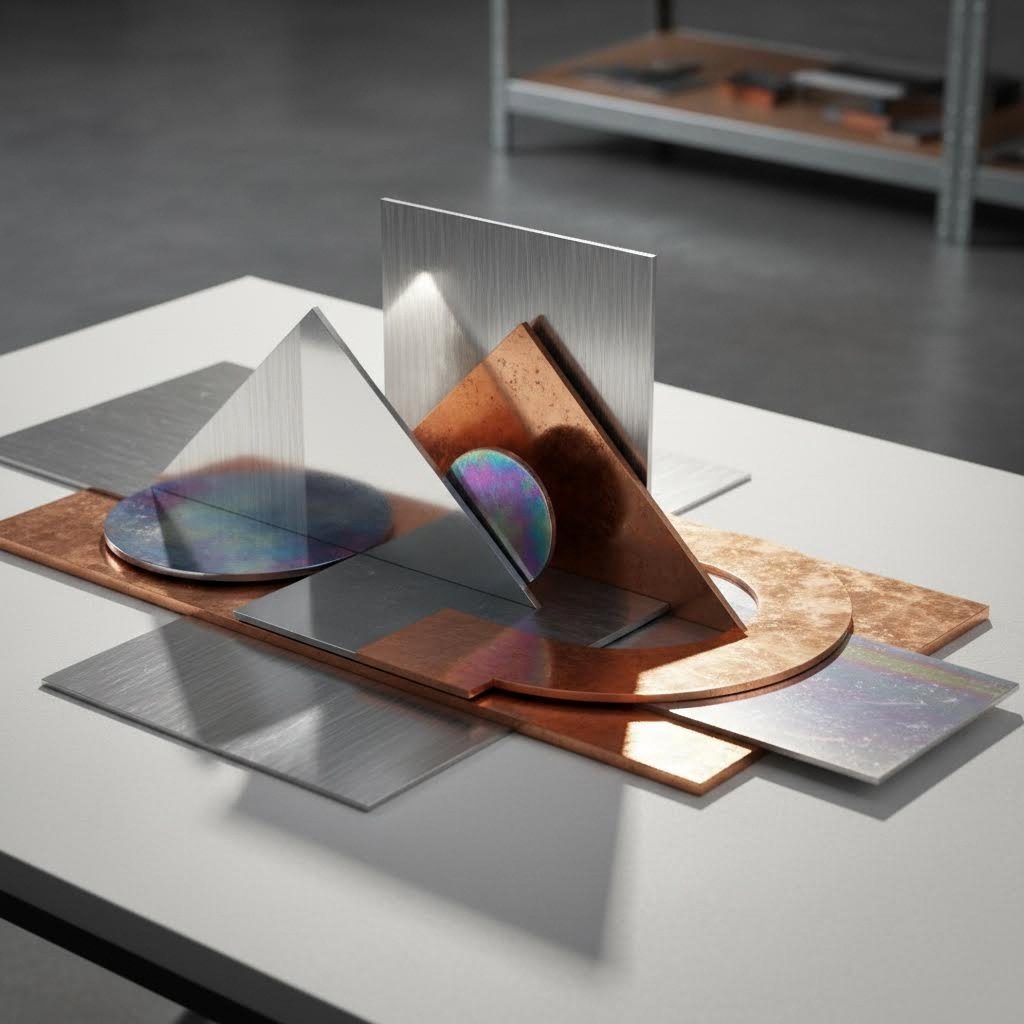

Material Selection for Optimal Precision Outcomes

You've defined your tolerance requirements—now what? Choosing the right material becomes your next critical decision. Why? Because different metals behave dramatically differently during cutting, forming, and finishing operations. The wrong material choice can make achieving your precision targets nearly impossible, while the right selection streamlines the entire manufacturing process.

In sheet metal engineering, material properties directly influence achievable tolerances, processing speeds, and final part quality. Understanding these relationships helps you balance performance requirements against budget constraints while ensuring your components meet specification every time.

Metal Properties That Impact Precision Results

Every metal brings unique characteristics to metal sheet processing operations. Some materials cut cleanly with minimal thermal distortion. Others bend predictably without excessive springback. The key is matching material behavior to your specific precision requirements.

Consider these core properties when evaluating materials for precision sheet metal forming applications:

- Formability: How easily the material bends, stretches, or draws without cracking. Highly formable materials like aluminum and mild steel allow intricate geometries without specialized tooling.

- Thermal conductivity: Materials that dissipate heat quickly (like aluminum) experience less thermal distortion during laser cutting. Lower conductivity metals (like titanium) require careful process control to maintain dimensional accuracy.

- Springback tendency: After bending, some materials partially return toward their original shape. High-strength alloys exhibit more springback, requiring compensation in tooling design.

- Work hardening behavior: Certain metals strengthen during forming operations, affecting subsequent processing steps and final part properties.

| Material | Formability | Thermal Behavior | Typical Precision Applications | Relative Cost |

|---|---|---|---|---|

| Mild Steel | Excellent | Moderate heat dissipation; minimal distortion with proper parameters | Structural components, enclosures, brackets | Low |

| Stainless Steel (304/316) | Good | Lower conductivity; requires controlled cutting speeds | Medical devices, food equipment, aerospace components | Moderate-High |

| Aluminum (5052/6061) | Excellent | High conductivity; excellent for thermal-sensitive precision work | Electronics housings, lightweight assemblies, heat exchangers | Moderate |

| Copper/Brass | Good-Excellent | Very high conductivity; clean cuts with minimal heat-affected zones | Electrical components, RF shielding, decorative parts | Moderate-High |

| Titanium | Moderate | Low conductivity; prone to work hardening; requires specialized processing | Aerospace, medical implants, high-performance applications | High |

Matching Materials to Tolerance Requirements

Here's something many engineers overlook: material thickness and hardness directly constrain your achievable tolerances. Thinner gauges tend toward distortion during cutting and handling, while thicker materials present challenges in maintaining consistent bend angles.

For precise metal production, consider these material-tolerance relationships:

- Thin-gauge metals (under 0.030"): Prone to warping and require careful fixturing. Select materials with good elongation properties—like 5052 aluminum—to improve manufacturability while maintaining tight tolerances.

- Medium-gauge (0.030" to 0.125"): The sweet spot for most precision applications. Materials remain stable during processing while still allowing complex forming operations.

- Heavy-gauge (over 0.125"): Plate metal fabrication at this thickness demands higher forming forces and may require pre-heating for certain alloys to achieve precise bends.

Material hardness adds another layer of complexity. Softer metals like aluminum and mild steel bend predictably with minimal springback. High-carbon steels and 400-series stainless steels resist deformation—excellent for wear resistance but requiring specialized tooling or heat treatment to achieve precision outcomes.

The most expensive material isn't always the most precise. Sometimes a well-understood, readily available alloy outperforms exotic alternatives simply because your fabricator has optimized their processes around it.

When evaluating metal parts fabrication suppliers, ask what materials they process most frequently. Experienced fabricators develop deep knowledge of specific alloys—understanding exactly how each material responds to their equipment and environment. This expertise often matters more than material specification alone when targeting tight tolerances.

The relationship between material cost and precision capability isn't always linear. Stainless steel costs more than mild steel but eliminates post-fabrication plating—which can add 3-5 days to lead time and introduce coating thickness variables. Aluminum's excellent machinability often reduces processing time enough to offset its higher material cost compared to steel.

With your material selection locked in, the next crucial decision becomes which cutting technology best achieves your precision requirements while respecting material properties.

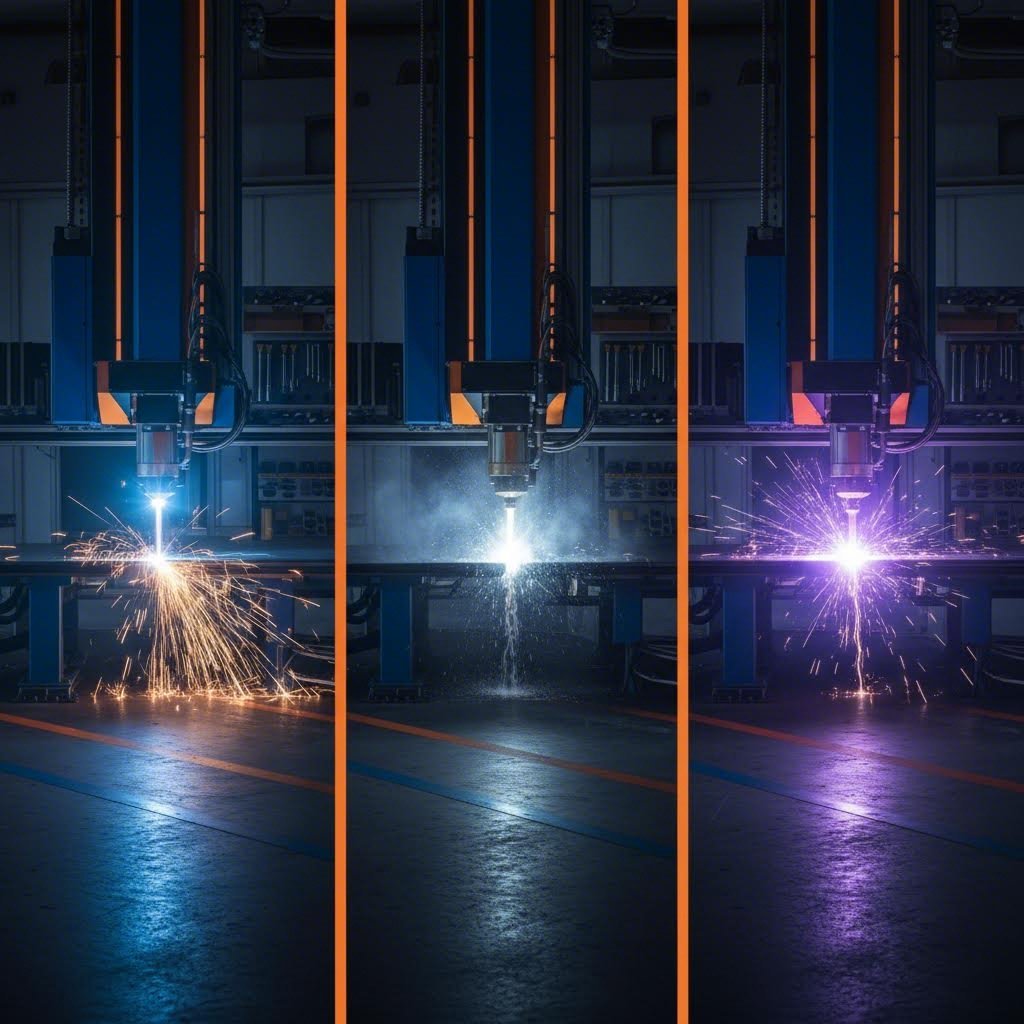

Cutting Technologies and Their Precision Capabilities

You've selected your material—now comes the question that can make or break your dimensional accuracy: which cutting method delivers the precision your application demands? The answer isn't always straightforward. Each cutting technology excels in specific scenarios, and understanding these distinctions helps you avoid costly rework while achieving tolerances that meet your exact specifications.

Whether you're working with a precision sheet metal fabricator on prototypes or scaling to production volumes, the right cutting method balances tolerance capability, material compatibility, and cost-effectiveness. Let's break down the three dominant technologies in precision sheet metal cutting: laser, waterjet, and plasma.

Laser Cutting for Ultra-Fine Precision Work

When ultra-tight tolerances matter most, laser cutting typically leads the conversation. Modern fiber laser systems deliver exceptional accuracy for thin to medium-gauge materials, making them the workhorse technology for most cnc sheet metal fabrication operations.

What makes laser cutting so precise? The focused beam creates an extremely narrow kerf—typically just 0.006 to 0.020 inches depending on material thickness. This minimal material removal translates directly to tighter dimensional control. According to industry data, laser cutting achieves tolerances of ±0.05-0.1 mm (approximately ±0.002-0.004") for thin-gauge materials, with tolerances widening as thickness approaches 25 mm.

Laser cutting excels with:

- Thin-gauge materials: Aluminum, stainless steel, and mild steel under 1/4" thick process rapidly with minimal distortion

- Complex geometries: Intricate patterns and tight internal radii cut cleanly without tooling changes

- High-volume consistency: CNC automation delivers identical results across thousands of parts

- Clean edges: Minimal dross or slag means reduced secondary finishing requirements

However, laser cutting does generate heat-affected zones (HAZ) along cut edges. For most sheet metal forming services, this HAZ remains minimal—typically 0.004 to 0.008 inches in depth. But on thicker materials or heat-sensitive alloys, this thermal impact can affect material properties near the cut edge.

When Waterjet Outperforms Thermal Methods

Need absolute maximum precision without any thermal effects? Waterjet cutting eliminates heat from the equation entirely. This cold-cutting process uses high-pressure water (typically 30,000-90,000 PSI) mixed with abrasive particles to cut through virtually any material.

The precision advantage is significant. Waterjet systems routinely achieve ±0.03-0.08 mm tolerances—often tighter than what laser cutting can deliver, especially on thicker sections. Because there's no thermal distortion, waterjet maintains consistent accuracy regardless of material thickness.

Waterjet becomes the preferred choice when:

- Material properties must remain unchanged: No heat-affected zones means original hardness and metallurgical structure stay intact

- Thick materials require precision: Waterjet maintains tolerances up to 200 mm thickness—far beyond laser capabilities

- Heat-sensitive alloys are involved: Titanium, hardened tool steels, and exotic alloys cut without affecting heat treatment

- Mixed material assemblies: The same machine handles metals, plastics, composites, and glass without parameter changes

The trade-off? Speed and cost. Waterjet cutting runs significantly slower than laser processing, and operating costs run higher due to abrasive consumption. For metal fabrication sheet metal applications where maximum precision justifies extended processing time, waterjet delivers unmatched results.

Comparing Cutting Technologies for Automated Sheet Metal Fabrication

The following table summarizes key performance characteristics across all three major cutting methods. Use this comparison when evaluating which technology best serves your specific precision sheet metal cutting requirements:

| Characteristic | Laser Cutting | Waterjet Cutting | Plasma Cutting |

|---|---|---|---|

| Tolerance Capability | ±0.05-0.1 mm (±0.002-0.004") | ±0.03-0.08 mm (±0.001-0.003") | ±0.5-1.5 mm (±0.020-0.060") |

| Kerf Width | 0.15-0.5 mm (0.006-0.020") | 0.6-1.0 mm (0.024-0.040") | 3.0-8.6 mm (0.120-0.340") |

| Maximum Precision Thickness | 25 mm (1") | 200+ mm (8"+) | 50 mm (2") for quality cuts |

| Heat-Affected Zone | 0.1-0.2 mm | None | Moderate to significant |

| Edge Quality | Excellent—minimal dross | Very good—slight taper possible | Good—may require grinding |

| Material Range | All metals; best on thin-medium | Any material including non-metals | Conductive metals only |

| Cutting Speed (Thin) | Very fast | Moderate | Fast |

| Cutting Speed (Thick) | Moderate | Slow | Fast |

| Operating Cost | Moderate | High (abrasive consumption) | Low |

| Equipment Cost | High | High | Low-Moderate |

How Kerf Width Impacts Dimensional Accuracy

Here's a detail many engineers overlook: kerf width directly affects your final part dimensions and nesting efficiency. The kerf—the material removed during cutting—must be compensated for in programming, or parts will consistently measure undersized.

Consider the practical implications:

- Laser's narrow kerf (0.4 mm typical) allows closer nesting of parts, maximizing material utilization while maintaining predictable dimensional offsets

- Waterjet's slightly wider kerf (0.6 mm typical) still permits precise compensation but reduces nesting density slightly

- Plasma's substantial kerf (3.8 mm typical) requires significant material allowance between parts and produces less precise edge positioning

For precision applications, kerf consistency matters as much as kerf width. Laser systems maintain highly repeatable kerf dimensions across production runs, enabling reliable CNC compensation. Plasma kerf varies more significantly with thickness changes and consumable wear, making tight tolerance work challenging.

CNC Integration and Automation Consistency

Modern precision sheet metal fabricator operations rely heavily on CNC-controlled cutting systems. This automation transforms cutting consistency from operator-dependent to process-dependent—a critical distinction for achieving repeatable precision.

Automated sheet metal fabrication systems deliver several precision advantages:

- Programmed compensation: Software automatically adjusts toolpaths for kerf width, eliminating manual calculation errors

- Consistent parameters: Speed, power, and gas settings remain identical across every cut, reducing part-to-part variation

- Reduced pierce delays: Automated height sensing and pierce sequencing minimize cycle time while protecting cut quality

- Real-time monitoring: Advanced systems detect parameter drift and compensate automatically

For high-volume production, laser cutting's speed advantage compounds significantly. Industry data shows that laser systems can produce 200+ parts per hour on thin materials—compared to roughly 25 parts per hour for oxyfuel and 70+ for standard plasma on equivalent geometries.

The most precise cutting technology isn't automatically the best choice. Match cutting method to your tolerance requirements, material type, and production volume—then optimize process parameters for your specific application.

Understanding cutting technology capabilities sets the foundation for successful precision fabrication. But cutting is just one step in the journey. The real challenge often emerges when scaling from a single validated prototype to consistent production volumes—where maintaining precision across hundreds or thousands of parts demands systematic process control.

The Prototype to Production Precision Journey

You've cut your first prototype—it looks perfect, measures within spec, and functions exactly as designed. But here's where many precision sheet metal fab projects stumble: what works beautifully as a one-off often fails spectacularly at scale. The transition from single prototype to volume production is where tolerances drift, costs multiply, and timelines collapse—unless you approach scaling with the same rigor you applied to that first sample.

Moving from custom sheet metal fab to contract fabrication volumes isn't simply about running the same program more times. It requires fundamentally rethinking tooling strategies, fixture designs, and documentation practices. The decisions you make during this transition phase determine whether your production runs deliver consistent precision—or frustrating variability that eats into margins and damages customer relationships.

Scaling from Single Prototype to Production Runs

Prototypes are optimized for speed and validation. Quick laser cuts, hand-bent flanges, and looser fixture requirements work fine when you're proving out a concept. But production demands something entirely different: repeatability, throughput, and cost-per-unit efficiency. Understanding where these goals conflict helps you anticipate scaling challenges before they become expensive problems.

According to manufacturing experts at All Metals Fab, the typical mismatch areas between prototype and production include tolerance assumptions, material handling procedures, and secondary operation sequences. A prototype might tolerate manual deburring that adds 15 minutes per part—acceptable for five pieces, catastrophic for five thousand.

The most effective approach? Adopt a "prototype with production intent" mindset from day one. Build prototypes using the same material grade, thickness, and tooling assumptions you'll employ in production. When that's not possible, document every deviation and require a delta review with manufacturing before finalizing production specifications.

Key Checkpoints in the Scaling Process

- Design freeze verification: Confirm all critical dimensions, material specifications, and tolerance requirements before tooling investment begins

- DFM review completion: Validate that bend radii, hole locations, and feature spacing meet production equipment capabilities

- Tooling qualification: Test production fixtures against prototype dimensions to confirm repeatability

- First Article Inspection (FAI): Verify that production processes replicate prototype accuracy across all critical features

- Process capability study: Measure variation across multiple production samples to confirm Cpk meets requirements

- Documentation lockdown: Finalize work instructions, inspection procedures, and revision control before volume release

Maintaining Precision Across Manufacturing Volumes

Here's something many engineers underestimate: fixtures convert flexible sheet metal into repeatable, locatable geometry for machining, welding, and inspection. A poor fixture makes otherwise capable machines produce out-of-spec parts. Investing in proper fixturing during the transition phase pays dividends across every subsequent production run.

For sheet metal custom fabrication at scale, fixture strategy typically falls into two categories. Dedicated fixtures offer maximum precision for high-volume, stable designs—but require significant upfront investment. Modular fixturing systems provide flexibility for product variations and shorter runs, typically amortizing cost quickly through reduced rework and increased throughput.

Modern fixture design incorporates several precision-enabling features:

- One-handed operation: Enables hands-free secondary actions, reducing operator fatigue and positioning variability

- Go/no-go indicators: Visual confirmation of correct part positioning before processing begins

- Lightweight, high-strength materials: 3D-printed fixtures eliminate bulky excess while maintaining rigidity

- Internal channels for vacuum management: Secure part holding without clamp marks on finished surfaces

Every extra deburr, welding sub-assembly, or finishing step is a takt multiplier. Design to reduce operations or combine them—your production costs depend on it.

How DFM Support Prevents Production Precision Issues

Design for Manufacturability isn't just a checkbox—it's your primary defense against precision failures during volume production. Engaging DFM support early in development catches issues that seem minor in prototype but become major at scale.

Consider these DFM principles that directly impact precision maintenance:

- Design for process capability, not perfection: Identify the operation that will be your bottleneck—whether laser cutting, brake forming, or welding—and design to its capabilities

- Standardize bend radii: Using consistent radii throughout the part prevents multiple setups, reducing cumulative positioning errors

- Locate holes away from bend lines: Features too close to bends can pull or distort, affecting both dimensional accuracy and hardware insertion

- Specify functional tolerances: Tight geometric tolerances drive cost exponentially—reserve them for features where precision genuinely matters

The relationship between batch size and per-unit precision costs follows a predictable curve. Initial batches carry higher per-unit costs due to setup time, fixture qualification, and first-article verification. As volume increases, these fixed costs amortize across more parts—but only if your process remains stable. Uncontrolled variation forces repeated setup adjustments, erasing the economies of scale you expected.

Custom Metal Assemblies and Large Fabrication Considerations

Scaling becomes even more complex when your project involves custom metal assemblies with multiple components or large fabrication requiring specialized handling equipment. Multi-part assemblies introduce tolerance stack-up concerns where individual part variations combine—sometimes constructively, sometimes destructively.

Revision control discipline becomes essential at this stage. Core rules include maintaining a master part number and revision on every print, using ECO templates with impact matrices covering cost, delivery, tooling, and supply chain effects, and archiving all revisions with release notes for traceability.

For precision sheet metal fab operations, First Article Inspection serves as your gated verification that process and documentation produce parts meeting design intent. FAI isn't just dimensional measurement—it encompasses material evidence, process steps, markings, and compliance documentation. Skipping or rushing FAI virtually guarantees precision problems surfacing later, when correction costs far exceed prevention investment.

The bottom line? Going from prototype to production doesn't require luck—it requires process. Apply DFM principles consistently, implement fixture strategies appropriate to your volumes, enforce revision control discipline, and treat FAI as a non-negotiable gate. Master these elements and you'll scale precision sheet metal parts with predictable outcomes rather than unpleasant surprises.

With your production processes validated and running consistently, one often-overlooked challenge remains: how finishing operations interact with the precision tolerances you've worked so hard to maintain.

Finishing Processes and Tolerance Preservation

Your parts measure perfectly after fabrication—but will they still meet spec after finishing? This question catches many engineers off guard. Almost all surface finishes cause some dimensional change to the part being finished, and for precision sheet metal products, even small additions can push critical features out of tolerance. Understanding how coatings interact with your dimensional requirements prevents costly surprises and rework downstream.

The challenge is straightforward: finishing operations add material. Powder coating builds up thickness. Plating deposits metal onto surfaces. Even anodizing—which many assume only affects surface appearance—changes dimensions measurably. When you're fabricating sheet metal to tolerances of ±0.005" or tighter, a coating that adds 0.006" per side can immediately create interference fits or assembly problems.

Surface Finishing Without Sacrificing Tolerances

Different finishing methods add vastly different thicknesses to your parts. Selecting the right finish requires balancing corrosion protection, appearance requirements, and dimensional constraints. Here's where precision metal processing demands careful planning rather than afterthought decisions.

According to Protocase's tolerance specifications, common finishing methods add the following thickness to each surface:

- Type II Anodizing: +0.0004" (0.01mm) per side—minimal buildup, ideal for tight-tolerance aluminum parts

- Type III Hard Anodizing: +0.001" (0.03mm) per side—thicker but provides superior wear resistance

- Powder Coating: +0.003" (0.08mm) per side—significant buildup requiring design compensation

- Electroless Nickel Plating: +0.0002" to 0.001" per side—variable based on specification

- Zinc Plating: +0.0002" to 0.0005" per side—common for corrosion protection on steel

- Chrome Plating: +0.0001" to 0.002" per side—highly variable based on decorative vs. hard chrome

Notice something important? Powder coating adds nearly eight times the thickness of Type II anodizing. For a 1" diameter hole that needs to accept a 1" component after finishing, you'd need to specify a 1.006" hole diameter before powder coating—but only 1.0008" before anodizing. This difference fundamentally changes your design approach.

Coating Thickness Considerations for Precision Parts

Here's what makes plating particularly challenging for precision fabrication services: thickness distribution isn't uniform across your part. As metal finishing experts at Anoplate explain, electricity travels the path of least resistance during electroplating. Current density concentrates at protrusions, sharp edges, and corners—depositing thicker coatings in these "high current-density areas."

The practical implications are significant:

- Exterior edges and corners: Receive the thickest deposits—sometimes ten times greater than recessed areas

- Interior surfaces and blind holes: May receive minimal or inconsistent coverage due to low current density

- Threaded holes: Through-holes plate more uniformly than blind holes, which can trap solution

- Protruding features: Studs and pins build up heavily at tips while their bases may be under-plated

What looks like a simple plating job can entail complicated considerations involving electricity, chemistry, and physics—often requiring special processing steps to maintain dimensional control.

Experienced finishers use several techniques to control uneven buildup. Shielding (sometimes called robbers, dummies, or thieves) blocks excess current from high-density areas. Additional anodes placed inside recessed features boost current flow to hard-to-reach surfaces. For parts with both through-holes and blind holes at the same diameter, fabricators may need to plate in multiple stages with selective masking—transforming that "simple" finishing operation into a multi-step process.

Masking Critical Tolerance Surfaces

When certain features absolutely cannot accept any dimensional change, masking becomes your primary defense. Masking involves covering specific areas to prevent coating deposition—but it introduces its own precision considerations.

According to industry specifications, masking placement typically carries a tolerance of ±0.080" (2.03mm). This means masked areas may have coating overlap or gaps at their boundaries. For precision metal fab products, this masking tolerance often exceeds the part tolerance—requiring careful feature placement to prevent conflicts.

Effective masking strategies include:

- Relocating critical features: Position tight-tolerance surfaces away from areas requiring coating when possible

- Specifying masking boundaries clearly: Call out exact masking zones on drawings rather than leaving interpretation to the finisher

- Post-finishing machining: For highest precision, machine critical features after coating application

- Selective finishing processes: Apply different finishes to different areas using multiple masking operations

Quality Control After Finishing Operations

Verifying precision after finishing requires different inspection approaches than raw fabrication verification. Coating thickness measurements, dimensional re-verification, and surface quality checks all play essential roles.

For precision fabrication services maintaining tight tolerances through finishing, implement these quality measures:

- Pre-finish dimensional documentation: Record critical dimensions before coating to establish baseline measurements

- Coating thickness verification: Use magnetic induction, eddy current, or cross-section microscopy to confirm actual buildup matches specifications

- Post-finish dimensional inspection: Re-measure critical features after coating, comparing against both pre-finish dimensions and final tolerance requirements

- Surface quality assessment: Verify coating uniformity, adhesion, and appearance meet requirements—particularly important since minor blemishes may occur that aren't visible from arm's length

The choice between anodizing and powder coating often comes down to tolerance sensitivity. Protolabs notes that anodizing adds very little buildup—making it ideal for tight fits or detailed parts—while powder coating's thicker layer may need extra clearance and can obscure fine details. Anodizing also becomes part of the metal itself and won't peel if scratched, while powder coating's external shell offers better impact resistance but can chip, exposing base metal.

Understanding these finishing-tolerance interactions transforms surface treatment from an afterthought into an integrated design decision. Specify your finish requirements alongside dimensional tolerances, communicate clearly with your finishing partners about critical features, and build coating allowances into your design from the start. This proactive approach ensures your precision sheet metal products maintain their accuracy through every manufacturing step—from raw material to finished assembly.

With finishing processes properly accounted for in your design, the next critical consideration becomes understanding how different industries define acceptable precision—and what certifications demonstrate your fabrication partner's capability to meet those demanding requirements.

Industry-Specific Precision Requirements Explained

Ever notice how a tolerance that's perfectly acceptable for one industry gets rejected outright in another? That's because different sectors define "precision" based on their unique safety requirements, regulatory frameworks, and functional demands. A chassis bracket for automotive applications operates under entirely different constraints than an enclosure for medical imaging equipment—even when both require industrial sheet metal fabrication from the same base materials.

Understanding these industry-specific requirements helps you specify the right precision level for your application and select metal fab services capable of meeting those standards. More importantly, it prevents over-engineering parts that don't need ultra-tight tolerances while ensuring you don't under-specify components where precision genuinely matters for safety or function.

Automotive Precision Standards and Certification Requirements

The automotive sector operates under one of the most structured quality frameworks in manufacturing: IATF 16949. This standard goes far beyond simply achieving tight tolerances—it mandates comprehensive quality management systems covering everything from supplier management to continuous improvement protocols.

What makes IATF 16949 different from generic quality certifications? The standard specifically addresses automotive manufacturing realities:

- Process-focused quality: Rather than just inspecting finished parts, IATF 16949 requires documenting and controlling every manufacturing process that affects quality outcomes

- Risk management integration: Manufacturers must identify potential failure modes and implement preventive measures before problems occur

- Supply chain accountability: Certified suppliers must demonstrate their sub-tier suppliers also meet quality requirements

- Continuous improvement mandates: Statistical process control, failure mode analysis (FMEA), and regular audits ensure ongoing performance rather than one-time compliance

For precision sheet metal in automotive applications, typical tolerances range from ±0.010" to ±0.030" depending on the component function. Structural chassis components often require tighter specifications than interior trim brackets—but both demand full documentation traceability and material certification that IATF 16949 ensures.

Medical Device Fabrication Tolerance Demands

Medical device manufacturing introduces an entirely different precision calculus: patient safety. When components interface with surgical equipment, diagnostic instruments, or implantable devices, tolerance failures can have life-threatening consequences. This reality drives both tighter specifications and more rigorous documentation requirements than most industrial metal fabrication services typically encounter.

The sheet metal manufacturing industry serving medical applications typically works within FDA 21 CFR Part 820 quality system regulations and ISO 13485 certification frameworks. These standards emphasize:

- Design controls: Formal verification that fabricated components meet design intent before production release

- Traceability: Complete material and process history for every component—often requiring lot-level tracking rather than batch-level documentation

- Validation protocols: Demonstrated evidence that manufacturing processes consistently produce conforming product

- Biocompatibility considerations: Material selection and finishing processes that ensure patient safety when devices contact tissue

Medical precision requirements often push into the ±0.002" to ±0.005" range for critical features—significantly tighter than automotive specifications. Surface finish requirements add another layer of complexity, as rough surfaces can harbor bacteria or create tissue irritation in patient-contact applications.

Comparing Industry Requirements

The following table summarizes key differences across major metal fabrication industries served by precision fabricators. Use this comparison when evaluating whether your fabrication partner's capabilities align with your sector's specific demands:

| Industry Sector | Typical Tolerances | Primary Certifications | Documentation Requirements | Special Considerations |

|---|---|---|---|---|

| Automotive | ±0.010" to ±0.030" | IATF 16949, ISO 9001 | PPAP, control plans, FMEA | High-volume consistency; supply chain integration |

| Medical Devices | ±0.002" to ±0.005" | ISO 13485, FDA 21 CFR 820 | Design history files, lot traceability, validation protocols | Biocompatibility; sterilization compatibility |

| Aerospace | ±0.001" to ±0.005" | AS9100, NADCAP (special processes) | First article inspection, material certs, process approval | Weight optimization; exotic materials; fatigue life |

| Electronics/Telecom | ±0.005" to ±0.015" | ISO 9001, IPC standards | RoHS compliance, material declarations | EMI/RFI shielding; thermal management; assembly fit |

| Industrial Equipment | ±0.015" to ±0.030" | ISO 9001 | Standard inspection reports, material certs | Durability; serviceability; cost optimization |

How Vertically Integrated Capabilities Affect Precision Outcomes

Here's something worth considering when selecting industrial metal fabrication services: supply chain complexity directly impacts precision consistency. Every handoff between suppliers introduces variability—different equipment calibrations, varying operator skills, and inconsistent environmental conditions all compound to affect final part accuracy.

Vertically integrated fabricators who control cutting, forming, welding, and finishing under one roof eliminate many of these variables. When the same quality system governs every operation—and the same engineering team can trace issues back to their source—precision problems get identified and corrected faster than when multiple vendors point fingers at each other.

For metal fab services industries where documentation traceability matters, vertical integration also simplifies compliance. A single quality record captures the complete manufacturing history rather than requiring coordination across multiple supplier systems.

Communicating Precision Requirements Effectively

Even the most capable fabrication partner can't meet requirements they don't understand. Effective communication of precision needs prevents costly misunderstandings and ensures quotes accurately reflect the work required. Consider these practices when engaging with fabrication partners:

- Specify tolerances on drawings, not just in conversations: Verbal agreements about "tight tolerances" mean different things to different people—GD&T callouts eliminate ambiguity

- Identify critical features explicitly: Not every dimension needs the same precision level; highlight which features drive assembly fit or function

- Provide assembly context: When fabricators understand how your part interfaces with mating components, they can flag potential issues before production

- Discuss inspection methods upfront: Confirm that your partner's measurement capabilities align with the tolerances you're specifying

- Share certification requirements early: Quality system certifications affect pricing and lead time—surprises at quote acceptance waste everyone's time

The best precision outcomes come from partnerships, not transactions. Fabricators who understand your industry's requirements become extensions of your engineering team rather than just vendors filling orders.

Whether you're operating in aerospace, medical, automotive, or general industrial applications, matching your precision requirements to your fabrication partner's capabilities prevents misaligned expectations. The certifications they hold, the quality systems they operate, and their experience in your specific industry all influence whether those tight tolerances you specified actually show up on finished parts.

Of course, even with perfectly matched capabilities, precision challenges still emerge during production. Understanding how to troubleshoot common issues—from warping to tolerance stack-up—helps you collaborate effectively with your fabrication partner when problems arise.

Troubleshooting Common Precision Fabrication Challenges

Even with perfect designs, ideal materials, and capable equipment, precision challenges still emerge on the shop floor. The difference between experienced precision metal fabricators and everyone else? They anticipate these issues before they become costly problems—and when surprises happen, they know exactly where to look. Understanding the root causes behind warping, tolerance stack-up, and material inconsistencies transforms reactive firefighting into proactive prevention.

Whether you're managing all precision sheet metal works in-house or partnering with a contract fabricator, recognizing these common failure modes helps you ask the right questions and implement effective solutions. Let's break down the most frequent precision killers and how metal fabrication engineering principles address each one.

Preventing Warping in Precision Sheet Metal Parts

Warping frustrates engineers because it often appears after the part looks complete. You've cut perfectly, formed accurately—then thermal stresses from welding or uneven cooling twist your component out of specification. The physics are straightforward: when heat is applied to metal, it causes thermal expansion, and as the metal cools, it contracts unevenly, leading to warping or distortion.

The severity depends on material type, heat input, and cooling rate. Thin-gauge materials suffer most because they can't absorb and dissipate heat as effectively as thicker sections. Here's what works to prevent warping:

- Intermittent welding: Instead of continuous welds, weld in short sections with gaps between them. This allows the metal to cool between passes, reducing overall heat buildup.

- Staggered heat distribution: When welding along edges of large plates, distribute heat evenly using staggered patterns. This balances expansion and contraction forces across the workpiece.

- Proper fixturing: Clamps and fixtures hold metal in position during welding, preventing movement as thermal stresses develop. Rigid fixturing is particularly critical for thin materials.

- Controlled preheating: Preheating reduces the temperature differential between the weld zone and surrounding material, promoting more even cooling. Use carefully on thin materials to avoid introducing excess heat.

- Balanced welding sequences: Weld on both sides of joints rather than concentrating heat on one side. This counterbalancing technique—sometimes called backstepping—distributes thermal effects symmetrically.

For precise metal fabrication requiring minimal distortion, parameter control becomes essential. Lowering amperage or increasing travel speed reduces heat input. Pulse welding alternates between high and low currents, providing better control over heat accumulation—especially valuable when working with distortion-prone materials.

Preventing warping is all about controlling heat input and managing cooling. By applying techniques such as intermittent welding, using heat sinks, or adjusting amperage and travel speed, you can minimize distortion and improve overall weld quality.

Managing Tolerance Stack-Up in Complex Assemblies

Here's an engineering nightmare that happens more often than anyone admits: every individual component measures perfectly within specification, but during assembly, parts don't fit. A critical gap is too small, or alignment is off. This frustrating scenario almost always results from tolerance stack-up—the cumulative effect of individual part tolerances combining along an assembly path.

Think of stacking coins. Each coin has a small thickness tolerance—individually acceptable variations. Stack ten coins together, and those small variations accumulate. The total height varies far more than any single coin. The same principle applies to mechanical assemblies where multiple dimensioned features contribute to a final critical dimension.

Two primary analysis methods address tolerance stack-up:

- Worst-Case (Linear) Analysis: Assumes all parts are simultaneously at their worst possible limits. Simple to calculate—just sum all individual tolerances. Guarantees 100% assembly success but often results in unnecessarily tight (and expensive) component tolerances.

- Root Sum Squared (RSS) Analysis: Uses statistical principles recognizing that all parts reaching worst-case limits simultaneously is extremely unlikely. Calculates total variation as the square root of the sum of squared individual tolerances. Allows more generous component tolerances but accepts approximately 0.27% theoretical rejection rate.

For precision sheet metal inc applications where assembly fit is critical, performing stack-up analysis during design prevents costly discoveries at assembly. The five-step process involves identifying the critical dimension, tracing the dimensional chain through contributing features, listing each dimension with its tolerance, calculating total variation using your chosen method, and comparing results against functional requirements.

When analysis reveals excessive variation, strategic tolerance tightening on high-impact features provides the most cost-effective solution. Not every dimension in the chain contributes equally—identify which components drive the largest variation and focus precision investment there.

Addressing Thermal Distortion During Cutting and Welding

Thermal distortion differs from warping in its timing—it occurs during the cutting or welding operation itself, affecting dimensional accuracy as the process proceeds. Laser cutting, plasma cutting, and welding all introduce localized heating that can shift material position during processing.

Effective thermal distortion management includes:

- Heat sinks: Copper bars or aluminum plates placed near the work zone pull heat away from the weld area, dissipating it more evenly and preventing localized overheating.

- Optimized cutting sequences: Programming cut paths to distribute heat across the sheet rather than concentrating it in one area reduces cumulative thermal buildup.

- Proper cooling protocols: Allow metal to cool naturally in air or use controlled cooling methods. Avoid quenching or rapid cooling, which can cause cracking or introduce new stresses that manifest as distortion.

- Material support: Adequate support across the workpiece prevents gravity from amplifying thermal-induced movement during processing.

Inspection Methods That Catch Precision Issues Early

The earlier you detect precision problems, the cheaper they are to fix. Waiting until final assembly to discover dimensional issues multiplies correction costs dramatically. Effective precision metal fabricators build inspection checkpoints throughout their process—not just at the end.

Essential measurement protocols for precision fabrication include:

- First-piece inspection: Verify the initial part from each setup meets specifications before running volume. Catches setup errors before they propagate through production.

- In-process monitoring: Periodic dimensional checks during production runs detect drift before it creates significant scrap quantities.

- Coordinate Measuring Machines (CMMs): Provide high-accuracy verification of complex geometries and multiple features in a single setup.

- Statistical Process Control (SPC): Tracks dimensional trends over time, identifying process drift before parts exceed tolerance limits.

- Go/No-Go gauging: Provides rapid pass/fail verification for critical features without requiring skilled measurement interpretation.

For assemblies where tolerance stack-up concerns exist, measuring mating features together—rather than just individual components—confirms actual fit performance matches theoretical analysis. This assembly-level verification catches interaction effects that component-level inspection might miss.

Precision challenges are inevitable in complex fabrication—but they don't have to be unpredictable. Understanding root causes, implementing prevention strategies, and catching issues early through systematic inspection transforms precision problems from project-threatening crises into manageable process variations. The investment in troubleshooting capability pays dividends across every production run.

With precision challenges understood and addressed, one question remains for most projects: how do these quality requirements translate into costs, and where does precision investment deliver the best return?

Cost Factors and Value Optimization Strategies

Here's the question every project manager eventually faces: how much does precision actually cost—and more importantly, when is that investment worth it? Understanding the economics behind precision sheet metal fabrication companies' pricing helps you make informed decisions that balance quality requirements against budget realities. The relationship between tolerance specifications and manufacturing costs isn't linear—it's exponential, and knowing where that curve steepens can save you thousands without sacrificing the precision your application genuinely requires.

Whether you're sourcing from local precision sheet metal fabrication near me suppliers or evaluating global metal fabrication suppliers, the same cost drivers apply. Let's break down what actually influences your project pricing and where strategic decisions can optimize value without compromising outcomes.

Balancing Precision Requirements with Budget Realities

The most expensive tolerance is often the one that provides no functional benefit. According to manufacturing experts at Modus Advanced, moving from standard machining tolerances (0.76 mm/0.030") to precision tolerances (0.025 mm/0.001") increases costs by approximately 4x. Push further to ultra-precision tolerances (0.0025 mm/0.0001"), and costs can escalate to 24 times standard pricing.

Why such dramatic increases? Tighter tolerances fundamentally change how parts must be manufactured, inspected, and validated. That seemingly simple 0.001" specification might require temperature-controlled environments, thermal stabilization of machine tools, and specialized inspection routines that transform a straightforward job into precision fabrication inc.-level work.

Key cost drivers in precision sheet metal fabrication include:

- Material type and thickness: Stainless steel costs more per pound than carbon steel and often demands specialized finishing. Thicker materials take longer to cut, bend, and weld—directly impacting production time.

- Design complexity: Components with multiple bends, intricate cutouts, or tight tolerances require more programming, setup, and inspection time. Every additional operation multiplies labor costs.

- Tolerance specifications: The tighter the tolerances, the higher the cost. Meeting stringent dimensional requirements involves more frequent inspections, slower machining speeds, and advanced measuring tools like CMMs.

- Production volume: A single prototype or small batch carries higher per-unit costs because setup and programming time spread across fewer parts. Volume production amortizes these fixed costs.

- Finishing requirements: Powder coating, anodizing, plating, or polishing each add time and cost depending on coating type, surface area, and durability requirements.

- Secondary operations: Post-fabrication assembly—welding sub-assemblies, inserting fasteners, or integrating machined parts—adds labor hours and inspection points.

- Lead time demands: Rush orders requiring accelerated delivery often involve overtime or production schedule adjustments that increase premium charges.

When Tighter Tolerances Pay for Themselves

Not all precision investment is wasted money. Some applications genuinely require tight tolerances, and recognizing these situations prevents both over-engineering and under-specification. The key is distinguishing between functional requirements and aesthetic preferences.

Precision investment typically delivers positive ROI when:

- Assembly efficiency matters at scale: High-volume production sometimes justifies tight tolerances for automated assembly. Parts that must assemble automatically or with minimal adjustment benefit from precise dimensional control, even if slightly looser tolerances would function adequately in hand assembly.

- Sealing performance is critical: Housings designed for environmental sealing need flatness control to ensure even gasket compression across the entire sealing perimeter.

- Safety-critical interfaces exist: When component failure could cause injury or system failure, precision becomes insurance rather than expense.

- Tolerance stack-up affects function: Complex assemblies where multiple parts interface benefit from selective precision on high-impact features.

According to TMCO's manufacturing analysis, the most cost-effective fabrication partner isn't necessarily the one with the lowest quote—it's the one who delivers value through accuracy, reliability, and long-term partnership. A vertically integrated manufacturer that handles fabrication, machining, finishing, and assembly in-house minimizes handoffs, reduces waste, and ensures every component meets performance expectations.

Understanding the variables that influence precision sheet metal fabrication costs empowers you to make informed decisions—from design optimization to material selection and scheduling.

Quote Turnaround and Project Timeline Acceleration

Time is money in manufacturing—and nowhere is this more evident than in quote turnaround expectations. Traditional quoting processes can stretch for days or weeks, delaying project launches and extending development cycles. This is where general metal fabrication service providers differ dramatically from precision-focused partners.

Modern precision sheet metal shops increasingly offer rapid quoting capabilities that compress timelines without sacrificing accuracy. A 12-hour quote turnaround, for example, enables engineering teams to evaluate multiple design iterations in days rather than weeks. This acceleration compounds throughout the project lifecycle—faster quotes mean faster design decisions, earlier production starts, and shorter time-to-market.

For automotive supply chain applications, manufacturers like Shaoyi (Ningbo) Metal Technology combine 12-hour quote turnaround with 5-day rapid prototyping capabilities. This compressed timeline enables design validation that would otherwise consume weeks of development schedule. When you're iterating on chassis, suspension, or structural components, that speed advantage translates directly to competitive positioning.

How DFM Support Reduces Overall Project Costs

Here's a cost reality that often surprises first-time buyers: the cheapest precision fabrication happens before manufacturing begins. Comprehensive Design for Manufacturability (DFM) support catches expensive problems when they're still just lines on a screen—not defective parts on the shop floor.

Effective DFM review identifies issues that inflate production costs:

- Unnecessarily tight tolerances: DFM engineers question specifications that drive cost without functional benefit, suggesting alternatives that achieve the same performance at lower cost.

- Bend sequence conflicts: Complex parts may have bend sequences that interfere with tooling access. Catching these issues early prevents costly redesigns after tooling investment.

- Material utilization inefficiencies: Nesting optimization and design modifications can dramatically improve material yield—savings that compound across production volumes.

- Secondary operation reduction: Consolidating operations or redesigning features to eliminate separate processes reduces both cost and lead time.

Online sheet metal fabrication platforms have expanded access to DFM feedback, but the depth of analysis varies significantly. The most valuable DFM support comes from fabricators with deep process expertise who can suggest alternatives—not just flag problems. IATF 16949-certified manufacturers bring systematic quality thinking to DFM review, identifying not just what might fail but what could drift during production runs.

For precision projects targeting automotive applications, partnering with fabricators offering comprehensive DFM support—combined with rapid prototyping and automated mass production capabilities—represents the optimal balance of quality, speed, and cost. The upfront investment in collaborative design review typically returns multiples through reduced rework, fewer engineering change orders, and smoother production launches.

Understanding these cost dynamics prepares you for the final critical decision: selecting a precision fabrication partner whose capabilities, certifications, and communication style align with your project's specific requirements.

Selecting Your Precision Fabrication Partner

You've mastered the technical requirements—tolerances, materials, cutting methods, and finishing processes. Now comes the decision that determines whether all that knowledge translates into successful parts: choosing the right precision sheet metal fabricators to execute your project. This selection isn't just about finding someone with the right equipment. It's about identifying a partner whose capabilities, certifications, and communication style align with your specific requirements.

The gap between an average supplier and a true strategic partner shows up in every metric that matters: on-time delivery, first-pass quality rates, and responsiveness when problems arise. According to industry analysis, the best fabricators achieve greater than 99.8% on-time delivery rates—a performance level that only comes from systematic process control and genuine manufacturing expertise.

Essential Questions When Evaluating Fabrication Partners

Before requesting quotes, develop a clear picture of what your project genuinely requires. Not every job needs aerospace-level precision, and paying for capabilities you won't use wastes budget that could improve other project elements. Start your evaluation by honestly assessing these factors:

- What tolerance levels does your application actually require? Distinguish between functional requirements and nice-to-have specifications.

- What certifications does your industry mandate? Automotive applications typically require IATF 16949; medical devices need ISO 13485; aerospace demands AS9100.

- What production volumes do you anticipate? Prototype quantities, low-volume production, and high-volume runs each favor different partner profiles.

- How critical is lead time to your project success? Rush requirements narrow your partner options significantly.

- Do you need comprehensive services or specialized expertise? Some projects benefit from vertically integrated one-stop-shop capabilities; others need deep specialization in specific processes.

When searching for precision metal fabrication near me or evaluating sheet metal manufacturers near me, resist the temptation to choose based solely on proximity or lowest quoted price. As manufacturing experts note, when it comes to quality, the most cost-effective method is not the best method—a fair price always beats a cheap product that requires rework or causes assembly failures.

Starting Your Precision Project on the Right Foundation

Once you've clarified your requirements, evaluate potential partners systematically. The following prioritized checklist helps you compare metal fabrication experts objectively, focusing on the factors that most directly impact precision outcomes:

- Certifications and quality systems: Verify current certifications match your industry requirements. IATF 16949 certification signals elite-level process control—if a supplier holds this automotive standard, they operate at a precision level that benefits projects in any industry. Also confirm ISO 9001 as a baseline quality management foundation.

- Rapid prototyping capabilities: Partners offering 5-day rapid prototyping compress development cycles dramatically. This capability enables design validation and iteration that would otherwise consume weeks, accelerating your time-to-market while reducing development risk.

- Comprehensive DFM support: The best precision metal fabricators inc. don't just manufacture your design—they improve it. Look for partners who provide proactive Design for Manufacturability feedback, identifying cost reduction opportunities and potential precision issues before production begins.

- Quote responsiveness: A 12-hour quote turnaround capability indicates both operational efficiency and customer focus. Slow quotes signal slow everything else.

- Equipment and technology: Modern CNC machinery, laser cutting systems, and automated production capabilities ensure consistency across volumes. Ask specifically about equipment brands (Trumpf, Amada, Yaskawa) and maintenance practices.

- Vertical integration: Fabricators handling cutting, forming, welding, and finishing in-house eliminate handoff variability and simplify accountability. A self-owned facility of significant scale (30,000+ square meters) indicates capacity for demanding projects.

- Industry experience: Request references from customers in your specific sector. A fabricator experienced with top metal fabrication companies in USA or certified as a partner for industry leaders like ABB or Schneider Electric has already passed rigorous quality audits.

- Scalability: Confirm the partner can grow with your needs—from prototype through automated mass production—without compromising quality or lead times.

Picking a fabricator with IATF 16949 certification helps ensure your project meets the highest possible quality standards, regardless of your industry.

Validating Partner Capabilities

Don't rely solely on marketing claims. Before committing to a precision fabrication partnership, take these verification steps:

- Facility visits: Walk the shop floor. Look for cleanliness, organization, and well-maintained equipment. Ask to see the quality control lab and inspection processes in action.

- Reference checks: Talk directly with past customers. Ask specifically about on-time delivery performance, quality consistency, and how problems were resolved when they occurred.

- Sample production: For critical projects, request sample parts before committing to production volumes. This validates actual capability rather than theoretical specifications.

- Documentation review: Request examples of inspection reports, material certifications, and process documentation. The depth and organization of these documents reveals operational maturity.

For automotive supply chain applications specifically, manufacturers like Shaoyi (Ningbo) Metal Technology exemplify the ideal partner profile: IATF 16949-certified quality systems, 5-day rapid prototyping for chassis, suspension, and structural components, comprehensive DFM support, and 12-hour quote turnaround. This combination of speed, quality certification, and engineering collaboration represents exactly what precision projects require—whether you're developing new products or optimizing existing supply chains.

The right precision fabrication partner becomes an extension of your engineering team rather than just a vendor filling orders. Invest the time upfront to evaluate candidates thoroughly, and you'll build a manufacturing relationship that delivers consistent precision across every project—from first prototype through production mastery.

Frequently Asked Questions About Precision Sheet Metal Fabrication

1. What is precision sheet metal fabrication?

Precision sheet metal fabrication is a specialized manufacturing process that shapes raw metal sheets into finished components meeting extremely tight tolerances—often ±0.005 inch or tighter. Unlike standard sheet metal work, precision fabrication requires advanced CNC-controlled equipment, rigorous quality control protocols, and skilled operators who understand how material properties and thermal effects influence final dimensions. Industries like aerospace, medical devices, and automotive rely on this process when safety-critical assemblies demand perfect fit and structural integrity.

2. How much does precision sheet metal fabrication cost?

Precision sheet metal fabrication costs vary significantly based on several factors: material type and thickness, design complexity, tolerance specifications, production volume, finishing requirements, and lead time demands. Moving from standard tolerances (±0.030 inch) to precision tolerances (±0.001 inch) can increase costs by approximately 4x. However, partnering with IATF 16949-certified manufacturers offering comprehensive DFM support and rapid prototyping can optimize costs by catching expensive design issues early and reducing rework throughout production.

3. What tolerances can precision sheet metal fabrication achieve?

Precision sheet metal fabrication achieves tolerances significantly tighter than standard methods. Laser cutting typically delivers ±0.002-0.004 inch accuracy, while waterjet cutting can reach ±0.001-0.003 inch tolerances. For bending and forming operations, precision fabricators using CNC press brakes with real-time angle monitoring can maintain ±0.005 inch or better. The achievable tolerance depends on material type, thickness, equipment capabilities, and the specific fabrication process being used.

4. What is the difference between laser cutting and waterjet cutting for precision work?

Laser cutting excels with thin to medium-gauge materials, offering fast processing speeds and narrow kerf widths (0.006-0.020 inch) with excellent edge quality. However, it creates heat-affected zones. Waterjet cutting eliminates thermal effects entirely, maintaining original material properties while achieving tighter tolerances (±0.001-0.003 inch) on thicker materials up to 8 inches. Choose laser for speed and thin materials; select waterjet when heat sensitivity or maximum precision on thick sections matters most.

5. How do I choose the right precision sheet metal fabrication partner?

Evaluate potential partners based on certifications matching your industry requirements (IATF 16949 for automotive, ISO 13485 for medical), rapid prototyping capabilities, comprehensive DFM support, quote responsiveness, equipment technology, and vertical integration. Request facility visits, check references, and consider sample production for critical projects. Manufacturers offering 5-day rapid prototyping, 12-hour quote turnaround, and automated mass production capabilities represent ideal partners for precision projects requiring both speed and consistent quality.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —