Essential Sheet Metal Formability Analysis for Preventing Defects

TL;DR

Sheet metal formability analysis is a critical engineering process used to evaluate a metal's ability to be shaped into a component without defects like necking or cracking. It combines physical tests and advanced computer simulations to predict how the material will behave during the stamping process. This predictive insight is essential for optimizing tool design, reducing manufacturing costs, and ensuring the final part meets strict quality standards.

Understanding Sheet Metal Formability: Core Concepts and Importance

In manufacturing, formability refers to the ability of a sheet of metal to undergo plastic deformation and be shaped into a desired component without failing. The process of evaluating this capability is known as sheet metal formability analysis. It is a cornerstone of modern metal stamping, providing engineers with the data needed to bridge the gap between a digital design and a successfully manufactured physical part. The primary goal is to anticipate and prevent common forming defects before they occur, saving significant time and resources.

The importance of this analysis cannot be overstated. Without it, manufacturers risk a trial-and-error approach that leads to high scrap rates, expensive tool modifications, and production delays. Key defects that formability analysis helps prevent include necking, which is the localized thinning of the material that precedes failure, and cracking, where the material fractures completely. By understanding a material's limits, engineers can design more efficient processes and select the right alloy for the job, balancing strength requirements with manufacturing feasibility.

A thorough analysis provides numerous benefits that directly impact a company's bottom line and product quality. By predicting material flow and stress concentrations, the analysis ensures a robust and repeatable manufacturing process. This is especially vital with the increasing use of advanced high-strength steels (AHSS) and aluminum alloys, which offer significant weight savings but have more complex forming behaviors.

The core benefits include:

- Cost Reduction: Minimizes the need for expensive and time-consuming rework of stamping dies and reduces material waste from failed parts.

- Improved Quality: Ensures components are manufactured consistently and meet all geometric and structural specifications.

- Faster Time-to-Market: Shortens the tool try-out phase by resolving potential issues in the virtual design stage.

- Material Optimization: Allows for the confident selection and use of lightweight, high-performance materials without sacrificing manufacturability.

- Enhanced Design Freedom: Enables the creation of more complex and ambitious component shapes by providing a clear understanding of material limitations.

Key Methods and Tests for Evaluating Formability

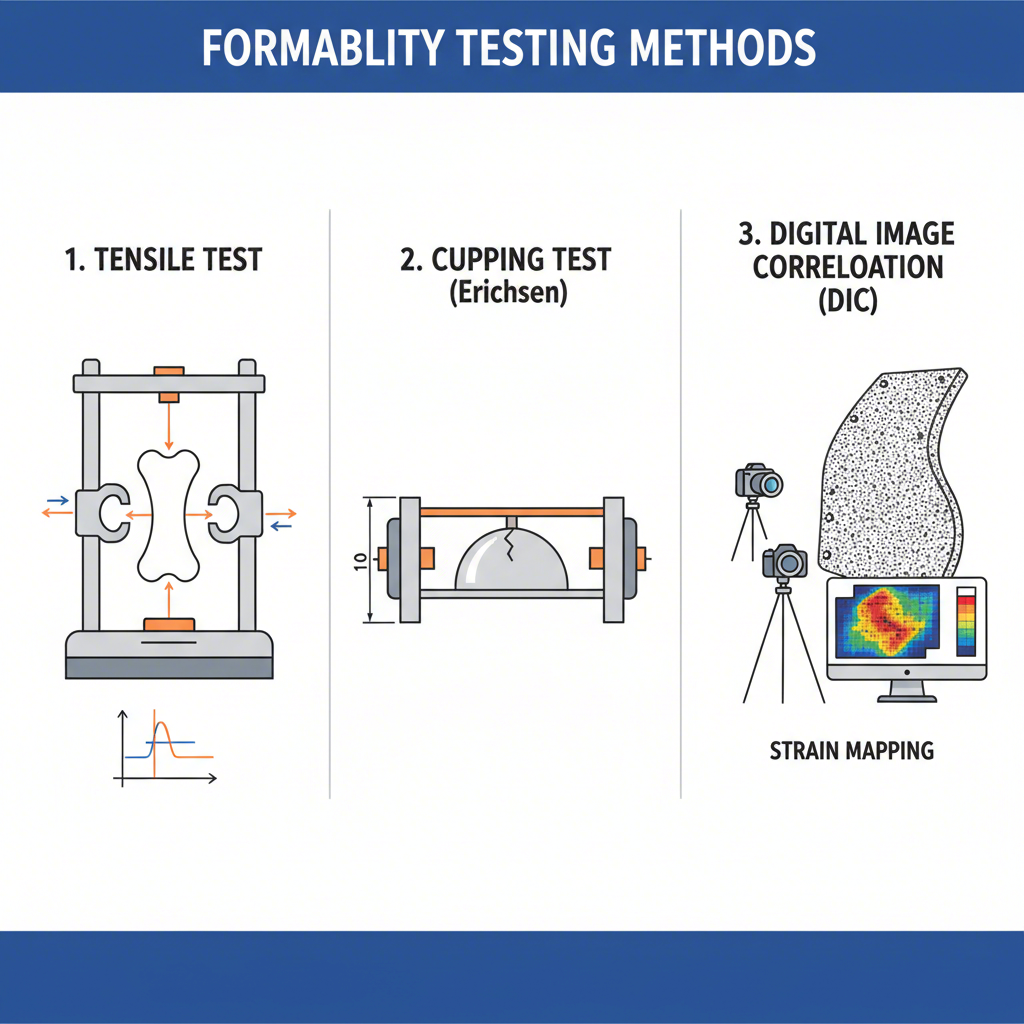

Evaluating sheet metal formability involves a range of tests, from traditional mechanical methods to sophisticated, non-contact optical systems. Each method provides different insights into how a material will behave under the stresses of a forming operation. The choice of test often depends on the material, the complexity of the part, and the level of precision required.

Traditional methods often begin with the uniaxial tensile test. This foundational test pulls a sample of material until it breaks, measuring properties like total elongation and the strain-hardening coefficient (n-value). While simple and inexpensive, its main limitation is that it only measures stress in one direction, whereas most real-world stamping operations involve complex, biaxial (two-direction) stresses. To better simulate these conditions, engineers use tests like the Erichsen cupping test or the Nakajima test. In these procedures, a punch deforms a clamped sheet into a dome shape, providing a more realistic assessment of formability under biaxial stretching.

More recently, advanced optical 3D measurement systems have revolutionized formability analysis. Techniques like Digital Image Correlation (DIC) provide a full-field view of deformation. In this method, a grid or dot pattern is applied to the metal blank before forming. During the stamping process, high-resolution cameras capture images from multiple angles. Specialized software then analyzes how the pattern has deformed, calculating the precise major and minor strain across the entire surface of the part. This non-contact approach delivers vastly more data than traditional tests, allowing for the precise identification of critical strain areas.

The following table compares these common methods:

| Test Method | What It Measures | Advantages | Limitations |

|---|---|---|---|

| Tensile Test | Elongation, strength, n-value | Simple, inexpensive, standardized | Uniaxial stress state is not representative of most forming operations |

| Cupping / Bulge Test | Dome height at fracture, biaxial strain limits | Simulates biaxial stretching conditions | Time-consuming, provides limited data points, can be influenced by friction |

| Optical 3D Analysis (DIC) | Full-field 3D strain and deformation | Highly accurate, comprehensive data, non-contact | Requires specialized equipment and software |

Advanced Analysis: Modeling, Simulation, and Failure Prediction

Beyond physical testing, the most powerful tools in modern formability analysis are computational modeling and simulation. Using Finite Element Analysis (FEA) software, engineers can create a virtual representation of the entire stamping process. This includes the geometry of the tools, the properties of the sheet metal, and process parameters like friction and blank holder force. The simulation then predicts how the sheet metal will flow, stretch, and thin as it is formed into the final part shape.

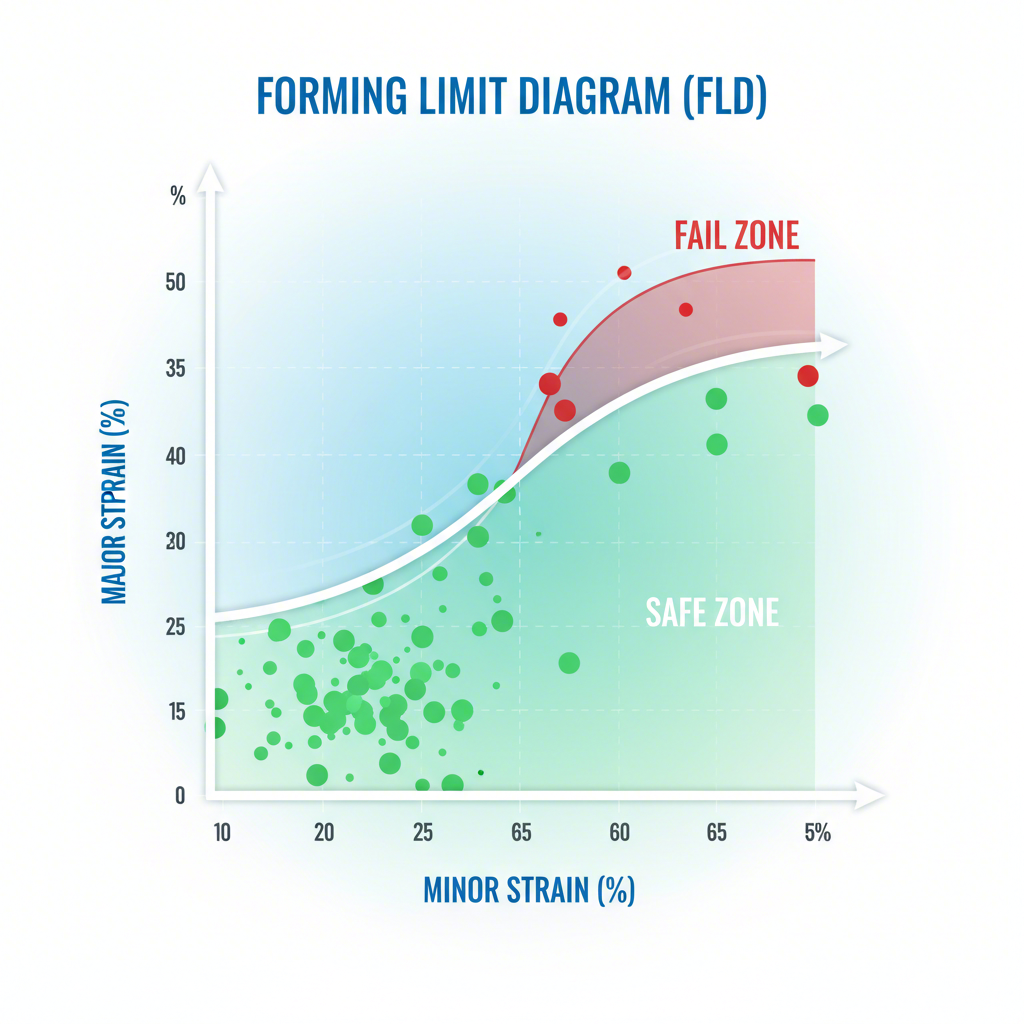

A central element of this simulation is the Forming Limit Diagram (FLD). The FLD is a chart that defines the safe manufacturing window for a specific material. It plots major strain against minor strain, with a boundary line known as the Forming Limit Curve (FLC) separating acceptable deformation from the onset of necking and failure. During a simulation, the software calculates the strain state for thousands of points on the part and plots them on the FLD. If points fall above the FLC, it signals a high risk of failure in that area, prompting a design change.

However, the traditional FLD has limitations, particularly for multi-stage forming processes or when dealing with advanced materials. As explained by industry experts, factors like non-proportional loading (where the strain path changes during the process) and the stabilizing effects of bending over small radii can alter a material's true forming limit. Advanced formability analysis frameworks now account for these effects to provide more accurate failure predictions for complex parts. Leading manufacturers of complex components, such as the experts at Shaoyi (Ningbo) Metal Technology Co., Ltd., leverage advanced CAE simulations to ensure the precision of automotive stamping dies, significantly reducing lead times and improving outcomes for OEMs and Tier 1 suppliers.

The benefits of incorporating simulation into the design process are substantial:

- Virtual Prototyping: Reduces the need for costly and slow physical tool try-outs by solving problems on the computer first.

- Design Optimization: Allows engineers to quickly test different part geometries, tool designs, or material choices to find the most robust solution.

- Defect Prediction: Accurately forecasts not only splits and necking but also issues like wrinkling, springback, and surface distortions.

- Process Efficiency: Helps optimize parameters like blank shape and press tonnage to minimize material usage and energy consumption.

Interpreting Results and Applying Design Best Practices

The true value of sheet metal formability analysis lies in its ability to generate actionable insights that guide engineering decisions. The output from simulations is typically a color-coded map of the part, where different colors represent varying levels of strain or thinning. Green areas are generally safe, yellow indicates a marginal condition close to the forming limit, and red highlights critical zones with a high probability of failure. These visual aids allow engineers to immediately pinpoint problem areas.

When a simulation flags a potential issue, the analysis provides the data needed to solve it. For example, if a high strain concentration is predicted near a sharp corner, the design recommendation would be to increase the radius of that feature. This distributes the strain over a larger area, bringing it back into the safe zone. Similarly, if wrinkling is predicted in a flat panel, the solution might involve adjusting the blank holder force or adding drawbeads to better control material flow.

This data-driven approach is a core tenet of Design for Manufacturability (DFM). By considering formability principles early in the design phase, engineers can create parts that are not only functional but also efficient to produce. This proactive approach avoids late-stage design changes that can derail project timelines and budgets.

Here are some key design best practices informed by formability analysis:

- Use Generous Radii: Avoid sharp internal and external corners whenever possible. Larger radii are one of the most effective ways to prevent localized thinning and cracking.

- Keep Features Away from Bends: As a general guideline, keep holes at least 2.5 times the material's thickness plus the bend radius away from a bend line. This helps prevent the feature from distorting during the bending process.

- Incorporate Draft Angles: For deep-drawn parts, slight angles on vertical walls reduce friction and the force required for forming, decreasing the risk of splits.

- Specify Appropriate Tolerances: Use Geometric Dimensioning and Tolerancing (GD&T) to define acceptable limits for flatness, straightness, and other features, recognizing that the forming process will introduce some variation.

- Consult Material Data: Always base designs and simulations on accurate material property data, as formability can vary significantly even between different grades of the same metal.

Frequently Asked Questions

1. What is the formability of a metal?

Formability is the ability of a sheet metal to be plastically deformed and shaped into a component without developing defects like cracks or necking. It is primarily influenced by the metal's ductility (its ability to stretch) and its strain-hardening properties, which affect how uniformly it thins during forming.

2. What are common formability tests for sheet metal?

Common tests include the uniaxial tensile test, which measures basic elongation and strength; cupping tests (e.g., Erichsen, Olsen) and bulge tests that simulate biaxial stretching; and modern non-contact optical 3D analysis systems (DIC) that provide a full-field map of surface strain.

3. What is the 4T rule in sheet metal design?

A common design guideline states that to prevent distortion, a feature like a hole should be located at a distance of at least 2.5 times the material's thickness plus the bend radius away from a bend line. A '4T' value is sometimes applied to slots, but the full guideline is typically 4 times the thickness plus the bend radius.

4. What is GD&T for sheet metal?

Geometric Dimensioning and Tolerancing (GD&T) is a symbolic language used on engineering drawings to define the allowable variation in a part's geometry. For sheet metal, GD&T specifies critical tolerances for form features like flatness, straightness, and profile to ensure the final, formed part functions correctly and fits within its assembly.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —