Sheet Metal Manufacturing Companies: 8 Essential Points To Vet Your Next Partner

Understanding Sheet Metal Manufacturing Companies and Their Industrial Role

Ever wondered what separates a reliable metal partner from one that leaves you scrambling mid-project? When you're sourcing components for automotive assemblies, HVAC systems, or industrial equipment, understanding what sheet metal manufacturing companies actually do becomes essential knowledge—not just industry jargon.

These specialized operations transform raw materials into precision components that power virtually every industry you can imagine. From the brackets holding your car's engine in place to the enclosures protecting sensitive electronics, their work surrounds us daily. Yet many buyers struggle to distinguish between different types of metal service providers, leading to costly miscommunications and project delays.

What Sheet Metal Manufacturing Companies Actually Do

At its core, the sheet metal manufacturing industry focuses on creating metal sheets from raw materials through large-scale production processes. This involves metal selection, rolling to achieve specific thicknesses, cutting into standard sizes, and applying protective coatings for durability. Think of these operations as the foundation—they produce the base materials that other processes will transform into finished products.

Metal sheets manufacturers typically handle materials like steel, aluminum, copper, and various alloys. Their operations include embossing to create surface patterns, precision rolling through industrial rollers, and finishing treatments that protect against corrosion and environmental wear.

From Raw Steel to Precision Parts

Here's where terminology confusion often trips up buyers. While manufacturing creates the raw sheets, sheet metal fabrication takes those materials and shapes them into custom components for specific applications. Fabrication involves cutting, bending, notching, welding, and assembly—transforming flat sheets into three-dimensional parts.

Consider the difference this way:

- Metal fabrication creates custom components tailored to your exact specifications

- Steel fabrication specifically handles steel-based projects requiring structural integrity

- Metal fab shops focus on precision work—laser cutting, CNC bending, and welding assemblies

- General metalworking encompasses broader machining and forming operations beyond sheet materials

Why does this distinction matter? When you contact a supplier asking for "manufacturing" but actually need "fabrication," you'll likely experience delays, incorrect quotes, or procurement headaches. According to AZ Metals, using these terms interchangeably can cause significant miscommunication when sourcing materials.

Over the past 70+ years, this industry has evolved dramatically. What once required manual labor and basic machinery now involves computerized precision, laser technology, and automated quality control. Modern operations blend both manufacturing and fabrication capabilities, offering end-to-end solutions from raw material sourcing through finished component delivery.

This guide walks you through eight essential evaluation points—giving you the knowledge to identify partners who'll deliver quality results rather than costly headaches.

Core Equipment and Technology Behind Modern Metal Manufacturing

Imagine walking into a metal fabrication facility for the first time. Rows of sophisticated machinery hum with precision, transforming flat sheets into complex components within minutes. But here's the question that separates informed buyers from those who get burned: do you know what each machine actually does—and why it matters for your project?

Understanding the equipment behind sheet metal operations helps you evaluate whether a potential partner can genuinely deliver on their promises. Let's break down the core technologies that define capable manufacturing operations.

CNC and Laser Cutting Technology Explained

When you hear "CNC," what comes to mind? The CNC meaning—Computer Numerical Control—refers to automated machinery guided by programmed instructions rather than manual operation. This technology revolutionized metal fabrication by enabling repeatable precision that human hands simply cannot match.

CNC machines and CNC router CNC systems execute cutting, drilling, and text milling operations with tolerances measured in thousandths of an inch. When a manufacturer enters specifications into the controller, the equipment handles complex geometries consistently across hundreds or thousands of parts. This automation eliminates human error while dramatically accelerating production timelines.

Now, consider the laser cutter—perhaps the most versatile cutting technology in modern fabrication. Laser cutting cutting operations use focused light beams to slice through metal with exceptional edge quality and minimal material waste. Here's what makes this technology stand out:

- Precision: Cuts as fine as 0.1mm width, enabling intricate designs impossible with mechanical methods

- Speed: Processes thin materials at rates exceeding 20+ meters per minute

- Versatility: Handles stainless steel, aluminum, copper, and specialty alloys without tool changes

- Clean edges: Produces smooth cuts requiring minimal secondary finishing

When evaluating manufacturers, ask about their laser capabilities—specifically wattage, bed size, and material thickness limits. A 6kW fiber laser handles vastly different work than a 2kW CO2 system.

Press Brakes and Forming Equipment Essentials

Cutting creates flat profiles, but bending transforms those profiles into three-dimensional components. This is where press brakes become essential. According to Boyd Metals, press brakes work by using a punch and die set at predetermined angles to bend metal into various shapes and forms.

The basic principle relies on tonnage—the total pressure applied during bending. Higher tonnage handles thicker materials, while bending length determines the maximum sheet size a machine can process. Modern press brakes fall into three categories:

- Manual press brakes: Best for mass production of consistent angles and dimensions

- Hydraulic press brakes: Utilize dual cylinders for controlled, consistent strokes

- CNC press brakes: Offer highest precision through computerized control of angle, thickness, and positioning

Beyond press brakes, stamping equipment enables high-volume production of identical parts through die-based forming. Stamping operations punch, emboss, or draw metal at speeds reaching hundreds of parts per minute—ideal for automotive brackets, electronic enclosures, and appliance components.

Understanding these equipment categories helps you ask the right questions during vendor evaluation:

- Cutting systems: Laser cutters, plasma tables, waterjet machines, and mechanical shears

- Forming equipment: Press brakes, stamping presses, roll forming lines, and tube benders

- Joining technologies: MIG/TIG welders, spot welders, robotic welding cells, and hardware insertion equipment

- Finishing stations: Deburring machines, grinding equipment, powder coating lines, and inspection systems

A manufacturer's equipment directly impacts what they can produce. Limited press brake tonnage means they cannot handle thick materials. Outdated laser technology slows production and increases costs. When you understand these connections, you'll recognize whether a partner's capabilities truly match your project requirements—or whether they're overpromising to win your business.

Material Selection Guide for Sheet Metal Projects

You've identified a capable manufacturer with the right equipment. Now comes a decision that impacts everything from component performance to long-term costs: which metal should you actually use? This choice determines whether your parts resist corrosion for decades or deteriorate within months, whether assemblies meet weight targets or burden your designs with unnecessary mass.

Many buyers default to familiar materials without understanding the trade-offs involved. That approach works—until a stainless steel sheet corrodes unexpectedly in a marine environment, or an aluminum sheet metal component fails under loads it wasn't designed to handle. Let's explore the substantive guidance you need to make informed material decisions.

Stainless Steel vs Aluminum for Your Project

When comparing metals aluminium and stainless steel, you're weighing fundamentally different performance characteristics. According to Clickmetal, steel comes out on top for raw strength due to its high carbon content, making it stronger and more resilient than aluminum. However, strength alone doesn't determine the right choice.

Consider the strength-to-weight ratio: aluminum is 1/8 compared to stainless steel's 1/16. What does this mean practically? An aluminum structure supporting the same load as a steel structure will be larger but weigh roughly half as much. For automotive applications where every gram matters, or for aerospace components requiring maximum strength with minimum weight, this difference becomes critical.

Temperature performance creates another decision point:

- Stainless steel: Melting point around 1,400°C—ideal for high-temperature applications like furnaces and exhaust systems

- Aluminum sheet: Melting point around 660°C, but tensile strength actually increases as temperatures drop, making it superior for cold environments

- Steel plates: Become brittle in extreme cold, potentially compromising structural integrity

Corrosion resistance often tips the scales. Aluminum naturally forms a protective oxide layer that prevents rust without additional treatment. Standard steel rusts when exposed to moisture, though 316 stainless steel contains chromium and molybdenum that provide excellent protection—even in harsh marine environments. Galvanized sheet metal offers a cost-effective middle ground, using zinc coating to shield underlying steel from oxidation.

Choosing the Right Metal Grade

Beyond broad material categories, specific grades determine real-world performance. According to Ryerson, aluminum grade 6061 stands out for excellent strength-to-weight ratio, corrosion resistance, and machinability—ideal for structural applications and heavy-duty projects. Meanwhile, 6063 aluminum offers superior surface finish quality, making it the go-to choice for architectural applications like window frames and tubing.

Stainless steel grades follow similar logic. For applications exceeding 2,000°F, 310 stainless steel provides oxidation resistance and high-temperature strength—commonly used in furnaces and heat treatment equipment. Standard 304 stainless handles most general-purpose applications, while 316 stainless steel delivers superior corrosion resistance for chemical processing or coastal installations.

The following comparison helps you match material properties to application requirements:

| Property | Stainless Steel Sheet | Aluminum Sheet Metal | Galvanized Sheet Metal |

|---|---|---|---|

| Tensile Strength | High (505-860 MPa for 304 grade) | Moderate (125-310 MPa for 6061) | Moderate-High (varies by base steel) |

| Corrosion Resistance | Excellent (especially 316 grade) | Excellent (natural oxide layer) | Good (zinc coating protection) |

| Weight | Heavy (8.0 g/cm³) | Light (2.7 g/cm³) | Heavy (7.85 g/cm³) |

| Cost Consideration | Higher material cost | Moderate cost, lower fabrication expense | Lower cost than stainless |

| Formability | Moderate (work hardens quickly) | Excellent (highly ductile) | Good (coating may crack if over-bent) |

| Common Applications | Medical equipment, food processing, marine hardware | Aerospace, automotive panels, electronics enclosures | HVAC ductwork, outdoor structures, agricultural equipment |

Specialty alloys expand your options further. Copper alloys provide antimicrobial properties for healthcare applications. Titanium delivers exceptional strength-to-weight ratios for aerospace components where cost constraints are secondary. Nickel alloys handle extreme chemical exposure that would destroy conventional materials.

When selecting materials for automotive applications, weight reduction drives many decisions—aluminum panels reduce fuel consumption while maintaining crash performance. Architectural projects often prioritize aesthetics and longevity, making anodized aluminum or brushed stainless steel attractive options. Industrial equipment typically demands maximum durability at reasonable cost, pointing toward galvanized or painted steel.

The right material choice requires balancing these properties against your specific requirements. Don't accept vague recommendations—ask potential manufacturing partners to explain exactly why they suggest particular grades for your application. Their ability to articulate material trade-offs reveals their expertise level and commitment to your project's success.

How to Evaluate and Select the Right Manufacturing Partner

You've mastered material selection and understand core equipment capabilities. But here's the challenge that trips up even experienced procurement professionals: how do you actually evaluate whether a sheet metal partner can deliver consistent quality over months or years of production? The wrong choice doesn't just cost money—it derails timelines, compromises product quality, and damages relationships with your own customers.

When searching for "metal fabrication near me" or "fabrication shops near me," you'll find dozens of options. The real question isn't who's closest—it's who meets the criteria that actually matter for your specific projects. Let's break down the actionable evaluation framework you need.

Certification Standards That Matter

Certifications tell you more than compliance status—they reveal a manufacturer's commitment to systematic quality management. But not all certifications carry equal weight for every application. Understanding what each standard actually requires helps you separate marketing claims from genuine capability.

ISO 9001 establishes the foundation. This internationally recognized standard ensures a company maintains documented quality management systems, monitors customer satisfaction, and pursues continuous improvement. Think of it as the baseline requirement—necessary but not sufficient for demanding applications.

IATF 16949 raises the bar significantly for automotive supply chains. According to OGS Industries, while ISO 9001 centers on customer satisfaction, IATF 16949 goes further to ensure compliance with lean manufacturing, defect prevention, variance deterrence, waste reduction, and company-specific requirements. This certification means manufacturers have proven systems for:

- Consistent quality: Monitored and measured processes that maximize productivity and deliver predictable outcomes

- Reduced product variation: Reviewed manufacturing processes ensuring components consistently meet high-performance vehicle requirements

- Defect prevention: Tested fabrication, welding, and finishing procedures that minimize inefficiencies and diminish defects

- Reliable supply chain: Internationally recognized benchmarks for sourcing and supplier management

For automotive projects, IATF 16949 certification isn't optional—it's a requirement for participation in major OEM supply chains. Steel fabricators serving aerospace applications need AS9100 certification instead, which addresses the unique traceability and documentation requirements of that industry.

Evaluating Production Capabilities

Certifications confirm systems exist, but production capabilities determine what those systems can actually deliver. When vetting metal fabricators near me, use this checklist to assess whether their capabilities match your project requirements:

- Equipment capabilities: Do they have the right machinery for your material thickness, tolerance requirements, and volume needs? Ask about specific equipment models, bed sizes, and tonnage ratings—not just general categories.

- Material expertise: Can they demonstrate experience with your specific alloys and grades? Request examples of similar projects and ask about material sourcing relationships with reputable mills.

- Prototype-to-production scalability: Some shops excel at one-offs but struggle with volume. Others focus exclusively on high-volume runs. Confirm they can support your project through development phases into full production.

- Quality control infrastructure: Beyond certifications, what inspection equipment do they maintain? CMM machines, optical comparators, and documented inspection protocols separate professional operations from job shops.

- Communication standards: How quickly do they respond to RFQs? Do they assign dedicated project managers? Clear communication prevents the misunderstandings that derail projects.

When researching top metal fabrication companies in USA, you'll notice the largest metal fabrication companies share common characteristics: documented procedures, invested workforces, and transparent communication. Smaller regional shops can deliver excellent results for appropriate projects, but verify their systems match the complexity of your requirements.

When Geography Actually Matters

Does proximity matter when selecting a manufacturing partner? The answer depends entirely on your project characteristics.

Geography matters most when:

- Projects require frequent design iterations with in-person collaboration

- Shipping costs significantly impact total landed cost for heavy or bulky components

- Just-in-time delivery requirements demand short transit times

- Quality issues require rapid on-site resolution

Geography matters less when:

- Designs are finalized and production is standardized

- Components are small, lightweight, and ship economically

- Lead times accommodate standard shipping windows

- Digital communication and file sharing enable remote collaboration

Modern communication tools have reduced the friction of working with distant partners. Video calls, shared CAD platforms, and real-time project tracking make remote collaboration practical for many applications. However, nothing replaces walking a production floor when troubleshooting persistent quality issues or developing complex new products.

The evaluation criteria above give you a framework for assessing any potential partner objectively. But understanding capabilities is only half the equation—you also need to understand how manufacturing processes actually unfold from initial concept through volume production.

Manufacturing Processes from Prototyping to Mass Production

You've found a qualified partner with the right certifications and equipment. Now comes the practical question that determines whether your project stays on schedule and on budget: how long will this actually take? Understanding the journey from initial concept to finished components helps you set realistic expectations—and avoid the frustration of missed deadlines.

Whether you need a single prototype or thousands of production parts, the manufacturing process follows predictable phases. Each phase carries distinct timelines and cost implications that directly impact your project planning. Let's walk through what actually happens when sheet metal manufacturing companies turn your designs into reality.

From Prototype to Production Line

Think of manufacturing as a progression through increasingly refined stages. Rushing through early phases creates expensive problems later. Skipping validation steps leads to production parts that don't fit or function properly. Here's how capable manufacturers structure this progression:

- Design review and DFM analysis: Before any metal cutter touches material, engineers evaluate your drawings for manufacturability. This Design for Manufacturability (DFM) process identifies potential issues—sharp internal corners that stress tooling, tolerances tighter than necessary, or material choices that complicate fabrication. According to Protolis, the better your drawings are finalized, the faster the DFM stage moves forward to production. Optimized designs reduce costs by 15-30% compared to drawings that require extensive revision.

- Prototyping: Initial samples validate form, fit, and function before committing to production tooling. Rapid prototyping through CNC machining or laser cutting typically delivers parts within one week. This phase catches design errors when changes cost hundreds rather than thousands of dollars.

- Testing and validation: Prototypes undergo functional testing, dimensional inspection, and often customer review. This verification stage prevents costly surprises during volume production. Rushing through testing is where many projects go wrong.

- Tooling development: For stamping operations or high-volume runs, custom dies and fixtures require fabrication. This investment pays off through faster cycle times and lower per-part costs at scale—but adds upfront time and expense.

- Production scaling: With validated designs and prepared tooling, manufacturers ramp from small batch runs to full production volumes. This progression allows quality monitoring at each stage before committing to larger quantities.

Why does this phased approach matter? Each step builds confidence that final production parts will meet specifications. Manufacturers who skip phases to promise faster delivery often create more problems than they solve.

Understanding Manufacturing Lead Times

Realistic timeline expectations separate successful projects from frustrating delays. Setup time—the preparation before manufacturing begins—varies dramatically by technology.

For sheet metal forming operations, expect 5 to 10 working days for tooling and setup, according to industry benchmarks from Protolis. This includes programming machines, preparing fixtures, and validating first-article parts. Compare this to injection molding at 15 to 45 working days, and you'll understand why sheet metal fabrication often delivers faster results for appropriate applications.

Once setup completes, actual part production moves quickly. A die cut machine stamps components in seconds. Laser cutting and CNC bending typically complete parts within hours to one day, depending on complexity. The kerf—the width of material removed during cutting—affects both precision and speed, with finer cuts requiring slower processing.

Production cycle times range from minutes for stamped parts to several hours for complex fabricated assemblies requiring multiple operations.

Finishing operations add time that buyers often underestimate. Painting and powder coating require 1 to 3 days. Surface treatments like anodizing or zinc plating add 2 to 4 days. When reviewing a drill chart or gauge size chart for your project specifications, factor these finishing timelines into your overall schedule.

DFM support dramatically accelerates these timelines. When manufacturers review designs early and suggest modifications for easier fabrication, they eliminate revision cycles that otherwise consume weeks. Parts designed for manufacturability from the start move through production without the delays caused by mid-project engineering changes.

Understanding these realistic timelines helps you plan projects effectively—and recognize when quoted schedules seem unrealistically aggressive. With process knowledge established, you're ready to explore the diverse industry applications where these manufacturing capabilities deliver real-world results.

Industry Applications and Specialized Manufacturing Sectors

Now that you understand how manufacturing processes unfold, here's a question worth considering: what exactly are all these precision components being used for? The answer spans virtually every industry you encounter daily—from the vehicle you drove this morning to the building you're sitting in right now.

Sheet metal manufacturing companies serve remarkably diverse sectors, each with unique requirements for precision, finish quality, and regulatory compliance. Understanding these applications helps you communicate more effectively with potential partners and ensures they have relevant experience for your specific industry. Let's explore where fabricated metal sheets actually end up—and why each sector demands different capabilities.

Automotive and Transportation Applications

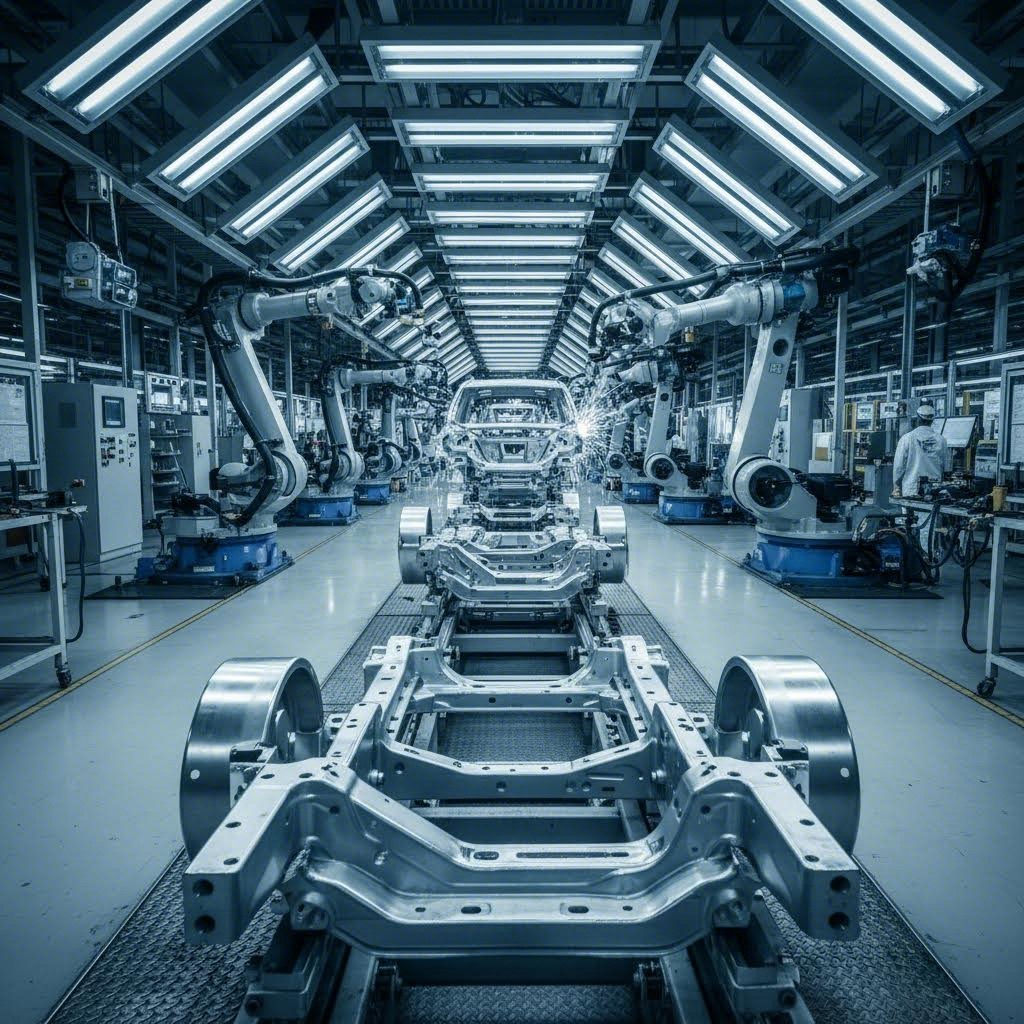

Few industries push manufacturing precision harder than automotive. According to Metal Supermarkets, before the 1980s, most cars used traditional body-on-frame designs. Today, monocoque construction—where metal panels form both the body and structure—dominates passenger vehicle manufacturing. This evolution was only possible through advancements in sheet metal forming and aluminum welding technologies.

What does this mean for component suppliers? Automotive applications demand:

- Body panels and structural components: Doors, hoods, fenders, and unibody sections requiring tight tolerances and consistent surface quality across thousands of units

- Chassis and suspension parts: Brackets, cross-members, and mounting plates that must withstand continuous stress and vibration

- Exhaust systems: Heat-resistant steel plate components formed to precise specifications for optimal flow and durability

- Interior brackets and reinforcements: Hidden structural elements that add safety without visible seams

With over 15 million vehicles sold annually in the US alone, the scale of automotive metal fabrication is immense. Robotic welding, automated assembly, and IATF 16949 quality systems have become standard requirements—not optional extras.

Transportation extends beyond passenger cars. According to Washington Metal Fabricators, the transportation industry relies on metal fabricators for robust components in rail, trucking, and shipping equipment. Suspension brackets, trailer frames, and cargo container reinforcements all demand precision fabrication combined with exceptional durability.

Architectural and Commercial Metal Solutions

Walk through any modern city and you're surrounded by fabricated metal. Architecture has evolved far beyond wood and ceramic—today's buildings showcase what precision metal forming can achieve. Consider the intricate detailing on New York's Chrysler Building: those iconic stainless steel eagles and sunburst patterns would be impossible without advanced sheet metal fabrication techniques.

Commercial and architectural applications include:

- Corrugated metal roofing and cladding: Durable exterior surfaces that withstand decades of weather exposure while delivering distinctive aesthetics

- Custom metal signs and decorative elements: Laser-cut logos, wayfinding signage, and artistic installations that define brand identity

- Structural supports and frameworks: Beams, columns, and reinforcements that architects and contractors depend on for safety and longevity

- Railings and balustrades: Code-compliant safety elements fabricated to exact specifications

The finishing requirements here differ dramatically from automotive. Architectural projects often prioritize visual appeal—brushed stainless surfaces, powder-coated colors, or anodized aluminum that maintains appearance for decades. Compliance standards focus on building codes and fire ratings rather than crash performance.

HVAC and Residential Systems

Your home's heating and cooling systems depend entirely on precision metal fabrication. HVAC ductwork, vents, and equipment enclosures require components that seal properly, resist corrosion, and meet energy efficiency standards. According to Washington Metal Fabricators, the HVAC industry demands precision and durability to ensure reliable performance in heating, ventilation, and air conditioning systems.

Residential and commercial HVAC applications include:

- Ductwork and plenums: Galvanized metal plate sections that distribute conditioned air throughout buildings

- Equipment enclosures: Protective housings for furnaces, air handlers, and condensing units

- Vents and registers: Finished components that combine function with aesthetics in living spaces

- Electrical panels and junction boxes: Laser-cut and formed enclosures meeting code requirements

Industrial Equipment and Specialized Sectors

Beyond consumer-facing applications, heavy industry consumes enormous quantities of fabricated metal. Manufacturing machinery, agricultural equipment, and energy infrastructure all require components built to withstand demanding operational environments.

- Agricultural equipment: Farming machinery, storage bins, silos, and irrigation systems built to endure rugged outdoor conditions year-round

- Energy sector: Transformer tanks protecting electrical equipment, solar panel frames, and wind turbine components meeting rigorous performance standards

- Food and beverage: Stainless steel storage tanks and production line machinery meeting strict health and safety regulations

- Healthcare: Medical equipment, hospital beds, and surgical instruments requiring precision fabrication and hygienic finishes

- Consumer electronics: Computer frames and chassis for devices requiring delicate, high-precision metal plate components

Each sector brings unique compliance requirements. Food processing demands FDA-approved materials and finishes. Medical applications require traceability documentation. Energy projects often involve third-party certification of structural integrity.

Understanding these application differences helps you evaluate whether a potential manufacturing partner has relevant experience for your industry. A shop excelling at architectural work may lack the quality systems automotive projects require—and vice versa. The next consideration? Ensuring any partner maintains the quality control standards your application demands.

Quality Control Standards and Industry Certifications

You've identified potential manufacturing partners with impressive equipment and relevant industry experience. But here's the question that separates reliable suppliers from those who create costly headaches: how do they actually verify that parts meet specifications—every single time? Quality control isn't just paperwork. It's the systematic approach that prevents defective components from reaching your assembly line.

Understanding quality systems helps you evaluate whether a manufacturer can deliver consistent results across production runs spanning months or years. Let's decode what certifications actually require and how inspection protocols catch problems before they become your problems.

Quality Certifications Decoded

Certifications represent more than wall plaques—they document proven systems for preventing defects and ensuring consistency. But what do these standards actually require from manufacturers?

According to Smithers, IATF 16949 outlines requirements for a quality management system that helps organizations improve overall efficiency while enhancing customer satisfaction. This automotive-specific standard builds upon ISO 9001 foundations but adds rigorous requirements that general fabricators rarely maintain.

The major IATF 16949 requirements include:

- Quality Management System: Documented procedures covering customer focus, leadership involvement, process approach, and evidence-based decision-making

- Planning and Risk Analysis: Identification and assessment of potential risks at every manufacturing stage, including supply chain considerations

- Process Management: Monitored and measured procedures ensuring consistent quality across all business activities

- Product Design and Development: Robust systems accounting for customer requirements, safety regulations, and legal obligations

- Monitoring and Measurement: Regular audits, inspections, and performance evaluations confirming the system functions as intended

| Certification | Primary Focus | Key Requirements | Typical Applications |

|---|---|---|---|

| ISO 9001 | General quality management | Documented procedures, customer satisfaction monitoring, continuous improvement | General manufacturing, commercial products |

| IATF 16949 | Automotive supply chain quality | Defect prevention, lean manufacturing, variance reduction, supplier management | Automotive components, OEM supply chains |

| AS9100 | Aerospace quality systems | Traceability, configuration management, counterfeit part prevention | Aircraft components, defense applications |

| ISO 13485 | Medical device manufacturing | Risk management, sterile processing, regulatory compliance | Medical equipment, surgical instruments |

When reviewing a sheet metal gauge chart for your project specifications, remember that tolerances mean nothing without inspection systems to verify them. Certifications ensure those verification systems exist and function consistently.

Inspection and Testing Protocols

Certifications establish systems, but inspection protocols execute quality control on every part. Understanding these protocols helps you ask informed questions when evaluating potential partners.

First Article Inspection (FAI) represents the critical bridge between design intent and production reality. According to ELO1, FAI is the detailed examination of an initial production part to confirm it conforms to engineering drawings, specifications, and customer requirements. This inspection catches problems before hundreds or thousands of parts are produced incorrectly.

A comprehensive FAI typically includes:

- Dimensional verification: Measuring critical dimensions using calipers, height gauges, CMMs, or laser scanners

- Material verification: Confirming correct material grade, thickness, and certifications

- Bend and form checks: Verifying bend angles, radii, and flat pattern accuracy

- Feature inspection: Checking hole sizes, locations, slots, and formed features

- Surface finish and appearance: Inspecting for scratches, burrs, sharp edges, or coating defects

- Functional fit: Ensuring parts fit properly with mating components

Beyond first articles, ongoing inspection stages maintain quality throughout production runs. In-process checks catch drift before it creates scrap. Final inspection verifies completed parts before shipping. Documentation standards ensure traceability—critical when troubleshooting issues months after production.

Surface Finishing as Quality Consideration

Finishing operations represent both aesthetic and functional quality factors. Powder coat applications provide durable, consistent color while protecting against corrosion and wear. Professional powder coating services deliver finishes that outlast traditional paint by years.

For aluminum components, anodizing creates a hard, anodized aluminum surface that resists scratching and corrosion far better than raw material. This electrochemical process builds the protective layer from the aluminum itself rather than adding a coating—meaning it won't chip or peel like paint. Anodized finishes range from clear protection to vibrant colors, expanding design possibilities while improving durability.

Quality manufacturers document finishing specifications alongside dimensional requirements. They verify coating thickness, adhesion, and appearance as rigorously as they verify part geometry. This attention to finishing separates professional operations from shops that treat surface treatment as an afterthought.

With quality systems understood, you're ready to prepare your own project for successful manufacturing engagement—starting with what information manufacturers actually need to provide accurate quotes.

Getting Started with Your Sheet Metal Manufacturing Project

You've evaluated capabilities, understood quality systems, and identified promising partners. Now comes the moment that determines whether your project launches smoothly or stalls in confusion: requesting a quote. This step seems straightforward—until you realize that incomplete information leads to inaccurate pricing, extended timelines, and frustrating back-and-forth communications.

Think of a quote request like planning a road trip. You can't just start driving without knowing your destination, route preferences, and timeline constraints. According to AMG Industries, a little preparation makes all the difference—it's not just about getting a price, it's about setting up a smooth project with a fabricator who understands your needs. Let's walk through exactly what sheet metal companies need from you to deliver accurate, actionable quotes.

Preparing Your Project for Quotation

Before reaching out to sheet metal contractors or searching for "sheet metal near me," take time to organize the technical details that manufacturers require. The more complete your initial request, the faster you'll receive accurate pricing—and the fewer revision cycles you'll endure.

According to Protolabs, ensuring that a supplier has all the necessary information to generate an accurate quote is the first and most important hurdle to cross. Here's what your Request for Quote (RFQ) should include:

- 3D CAD files: Submit .STEP, .STP, .SLDPRT, or .IGS files. These allow manufacturers to analyze geometry, identify manufacturing issues, and calculate accurate pricing. The CAD file determines the route your physical parts will take through the factory.

- Material specifications: Specify exact material grade (not just "stainless steel" but "304 stainless steel, 0.060" thickness"). Include any special requirements like grain direction or temper condition.

- Quantity requirements: Provide both initial order quantities and estimated annual volumes. Larger quantities typically reduce per-piece costs, and manufacturers need this information for tooling decisions.

- Tolerance needs: Call out critical dimensions that require tighter-than-standard tolerances. Standard fabrication tolerances work for most features—specifying tight tolerances everywhere increases costs unnecessarily.

- Timeline expectations: Share your target delivery date and any flexibility. Rush requirements affect pricing and manufacturing prioritization.

- Surface finish requirements: Specify powder coating colors, anodizing, plating, or other finishing needs. Include any masked areas requiring protection during finishing operations.

- Hardware and secondary operations: If your design requires PEM inserts, threaded holes, welding, or other operations, document these clearly with standard callouts.

For contractors sheet metal projects involving hardware inserts, Protolabs recommends including hardware as solid bodies independent from the sheet metal component body, packaged into a single 3D CAD file. Use standard naming conventions from Penn Engineering rather than internal part numbers—this accelerates quote processing and prevents confusion.

The fastest and most accurate quotes come from complete documentation. Vague requests generate vague pricing.

Working with Manufacturing Partners Effectively

Submitting complete documentation is just the beginning. How you engage with potential partners throughout the quoting process shapes your entire manufacturing relationship. Top metal manufacturing companies distinguish themselves through communication quality—not just equipment capabilities.

What should you expect from quality sheet metal contracting partners?

- DFM feedback: Experienced manufacturers review your designs and suggest modifications that reduce cost or improve manufacturability. This collaborative approach catches expensive design errors before production begins.

- Transparent pricing: Detailed quotes break down costs by operation—cutting, forming, hardware, finishing, and assembly. This transparency helps you identify cost reduction opportunities.

- Realistic timelines: Professional partners provide accurate lead times rather than overpromising to win business. Setup for sheet metal forming typically requires 5 to 10 working days before production begins.

- Clear communication channels: Dedicated project managers, responsive engineering support, and documented change order processes prevent the miscommunications that derail projects.

When evaluating stainless steel sheet metal fabricators or specialized automotive suppliers, quote turnaround time reveals operational efficiency. Some manufacturers require weeks to process complex RFQs. Others leverage digital systems and experienced teams to respond much faster.

For example, Shaoyi (Ningbo) Metal Technology demonstrates what efficient quoting looks like for automotive stamping projects—delivering quotes within 12 hours while providing comprehensive DFM support. Their IATF 16949 certification and 5-day rapid prototyping capabilities represent the benchmarks quality-focused buyers should expect from serious manufacturing partners. When chassis, suspension, or structural components require both speed and certified quality, these capabilities become essential rather than optional.

Avoiding Common Quote Request Mistakes

Even experienced procurement professionals make errors that slow down quoting and create downstream problems. Watch for these pitfalls:

- Submitting only 2D drawings: While drawings remain valuable for communicating surface finish needs and secondary operations, 3D CAD files are now essential for accurate quoting. Relying solely on drawings adds time and invites interpretation errors.

- Missing material certifications: For aerospace, medical, or automotive applications, specify required material certifications upfront. Adding certification requirements after quoting changes pricing and lead times.

- Unclear revision status: Ensure submitted files represent your current design intent. Outdated drawings create confusion when production begins on parts you've already revised.

- Overlooking finishing requirements: Surface treatments significantly impact cost and timeline. Specifying finishing needs in the initial RFQ prevents surprises during order placement.

Thorough preparation demonstrates professionalism—and fabricators notice. When your RFQ arrives complete and well-organized, it signals that you're a serious partner worth prioritizing. That reputation pays dividends through better service, more competitive pricing, and smoother production runs.

Whether you need precision prototypes or high-volume production, the principles remain consistent: complete documentation, clear communication, and realistic expectations create successful manufacturing partnerships. Armed with the evaluation criteria from this guide, you're ready to identify sheet metal manufacturing companies capable of delivering quality results—on time and on budget.

Frequently Asked Questions About Sheet Metal Manufacturing Companies

1. What are the 5 sheet metal operations?

The five primary sheet metal operations are shearing (cutting straight lines), blanking (cutting closed shapes), punching (creating holes), bending (forming angles using press brakes), and drawing (stretching metal into three-dimensional shapes). Additional operations include piercing, trimming, embossing, and squeezing. Each operation requires specific equipment—laser cutters handle precision cutting, while CNC press brakes manage complex bending sequences. Understanding these operations helps you evaluate whether a manufacturer has the capabilities your project requires.

2. How much does it cost to fabricate sheet metal?

Sheet metal fabrication costs average $1,581, with typical ranges between $418 and $3,018 depending on project complexity. Per-square-foot costs range from $4 to $48 based on material selection, customization level, and finishing requirements. Key cost factors include material grade (stainless steel costs more than galvanized), tolerance requirements (tighter tolerances increase machining time), quantity (higher volumes reduce per-piece costs), and secondary operations like powder coating or hardware insertion. Requesting detailed quotes with itemized breakdowns helps identify cost optimization opportunities.

3. Who is the largest steel fabricator in the US?

Nucor is North America's largest steel manufacturer and recycler, dominating the domestic market. However, when evaluating manufacturing partners, size alone shouldn't determine your choice. Large fabricators offer extensive capacity and diverse capabilities, while smaller regional shops may provide more personalized service, faster turnaround, and specialized expertise for niche applications. The right partner depends on your specific requirements—certifications like IATF 16949 for automotive work, equipment capabilities matching your material needs, and communication quality during the quoting process.

4. What certifications should I look for in a sheet metal manufacturer?

Essential certifications depend on your industry. ISO 9001 establishes baseline quality management systems. IATF 16949 is mandatory for automotive supply chains, requiring defect prevention, lean manufacturing, and supplier management protocols. AS9100 covers aerospace applications with strict traceability requirements. ISO 13485 applies to medical device manufacturing. Beyond certifications, evaluate inspection capabilities—CMM machines, documented first article inspection procedures, and quality control infrastructure. Manufacturers serving automotive OEMs, like Shaoyi with IATF 16949 certification, demonstrate the systematic quality approach demanding applications require.

5. How long does sheet metal manufacturing take from design to production?

Timeline varies by project phase. DFM review and prototyping typically complete within 5-10 working days for sheet metal forming operations. Rapid prototyping through CNC machining delivers initial samples within one week. Testing and validation add additional time depending on complexity. Production tooling development—required for stamping operations—may add several weeks. Once setup completes, actual production moves quickly, with laser cutting and CNC bending completing parts within hours. Some manufacturers offer accelerated timelines—Shaoyi provides 5-day rapid prototyping and 12-hour quote turnaround for automotive stamping projects.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —