Quality Sheet Metal Secrets: 8 Factors Suppliers Won't Tell You

Understanding What Defines Quality Sheet Metal

Ever wondered why two sheets of metal that look identical can perform so differently in real-world applications? The answer lies in understanding what truly separates premium materials from standard stock. When you're evaluating quality sheet metal, you need more than a supplier's word—you need concrete criteria to assess it yourself.

Quality in sheet metal isn't just marketing speak. It's a measurable combination of material properties, manufacturing precision, and performance characteristics that directly impact your project's success. Whether you're sourcing for automotive components, HVAC systems, or architectural applications, knowing these fundamentals empowers you to make informed decisions.

What Separates Premium Sheet Metal from Standard Stock

Think about it this way: standard stock gets the job done, but premium sheet metal anticipates the challenges your application will face. The difference shows up in three critical areas.

First, there's tensile strength—the amount of force required to pull the material to its breaking point. According to industry standards, this property determines how well your finished product handles stress without failing. Second, malleability affects how the metal responds during fabrication processes like bending and forming. Premium materials maintain their integrity through complex shaping operations. Third, corrosion resistance dictates longevity, especially in demanding environments where moisture or chemicals are present.

Standard stock might meet minimum specifications, but quality sheet metal fabrication starts with materials that exceed baseline requirements. This distinction becomes apparent when parts must fit together precisely or withstand years of operational stress.

The Four Pillars of Sheet Metal Quality Assessment

How do you evaluate whether sheet metal meets your quality standards? Focus on these four essential indicators:

- Material Composition: The specific alloy grade and elemental makeup determine mechanical properties. Certifications from organizations like ASTM or ISO verify that materials meet documented specifications for strength, ductility, and chemical resistance.

- Gauge Accuracy: Thickness consistency across the entire sheet matters. Dimensional accuracy ensures parts fit together correctly during assembly—even slight deviations can cause functional defects or assembly issues.

- Finish Uniformity: Surface quality affects both aesthetics and functionality. Look for freedom from defects like inclusions, porosity, corrosion spots, or discoloration that could compromise performance.

- Structural Integrity: This encompasses freedom from warping, internal stresses, and manufacturing defects. Quality sheet metal maintains its intended shape and resists distortion during processing and end-use.

Understanding these pillars gives you a framework for evaluating any supplier's offerings. Rather than relying solely on price comparisons, you can assess whether materials genuinely meet your project requirements. This knowledge proves especially valuable when working with quality sheet metal inc providers or any fabrication partner—you'll speak their language and recognize when shortcuts might compromise your results.

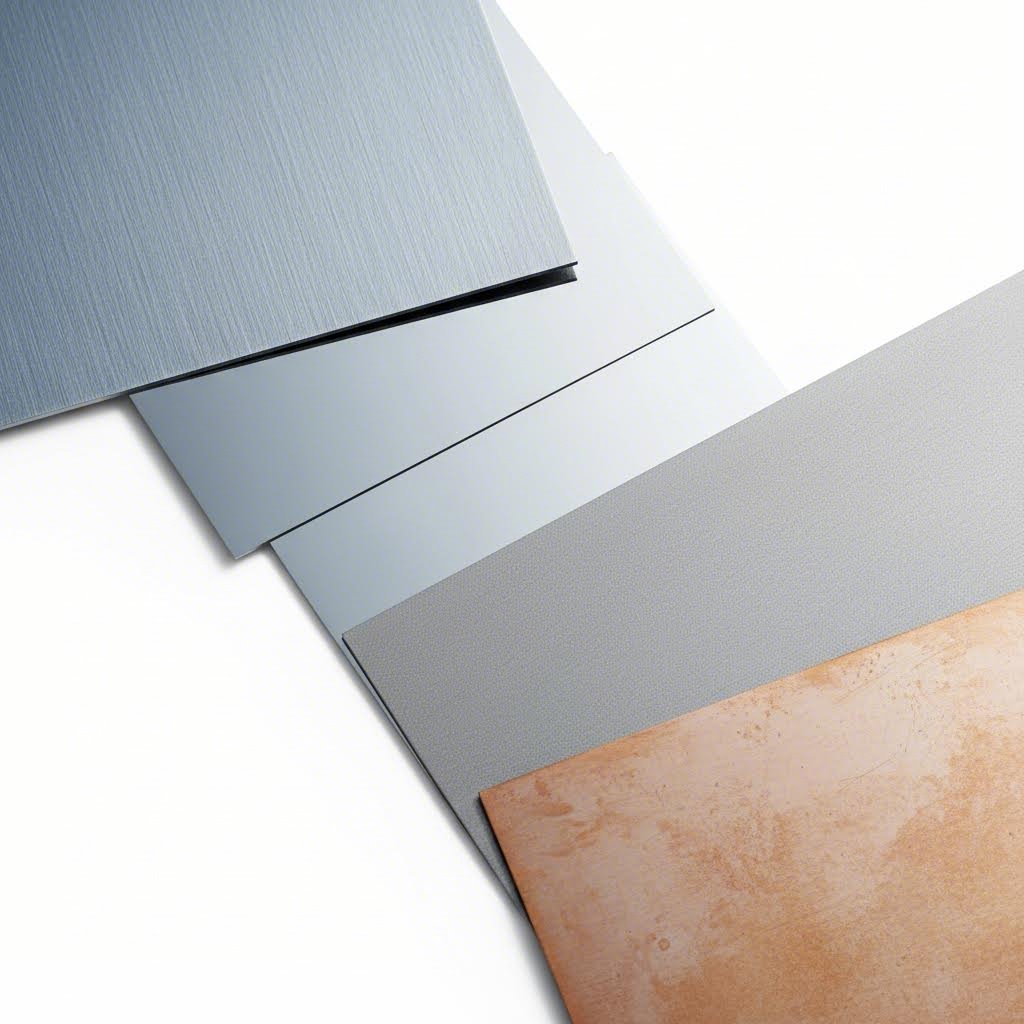

Material Types and Their Quality Characteristics

Now that you understand how to assess quality, let's explore the materials themselves. Here's what most sheet metal shops won't explain upfront: each material type has distinct quality indicators that affect performance in specific applications. Knowing these differences helps you select the right material—not just the cheapest option.

The most common sheet metals include steel (in various grades), aluminum, stainless steel, and copper. Each brings unique properties to the table, and understanding their characteristics prevents costly mismatches between material selection and application demands.

Steel Grades and Their Quality Implications

Steel dominates the sheet metal market, but not all steel is created equal. According to the World Steel Association, there are more than 3,500 grades of steel available. The grade you choose directly impacts strength, workability, and longevity.

Steel grades follow a standardized numbering system developed by the Society of Automotive Engineers (SAE). Here's how to decode these numbers:

- First digit: Identifies the primary alloy element (1XXX indicates carbon steel)

- Second digit: Refers to secondary alloying elements

- Final two digits: Display carbon content in hundredths of a percent by weight

For example, 1020 steel tells you it's carbon steel with no secondary alloys and 0.20% carbon content—making it mild carbon steel with good formability. Higher carbon content increases strength but reduces ductility, which is the metal's ability to be stretched or formed without cracking.

Carbon steel categories break down by carbon content:

- Low carbon steel (mild steel): Up to 0.3% carbon—excellent for forming and welding

- Medium carbon steel: 0.3% to 0.6% carbon—balances strength with workability

- High carbon steel: Greater than 0.6% carbon—maximum strength but limited formability

When working with domestic custom metals suppliers, understanding these grades helps you verify you're getting exactly what your application requires.

Aluminum vs Stainless Steel Performance Characteristics

Choosing between aluminum and stainless steel? This decision often comes down to weight, corrosion resistance, and cost trade-offs.

Aluminum weighs nearly one-third the density of steel. For two parts with identical geometry, a steel part weighs almost three times as much. This weight advantage makes aluminum essential for automotive, aerospace, and applications where reducing mass improves efficiency. According to material specialists, aluminum's tensile strength ranges from 40 to 690+ MPa, depending on the alloy and temper.

Aluminum also has a built-in corrosion defense. When exposed to oxygen, it forms an aluminum oxide layer that acts like armor over the exposed surface—unlike iron oxide (rust), which is weak and flakes away. This makes aluminum ideal for Florida metal fabrication projects and other humid or coastal environments.

Stainless steel, composed of at least 10.5% chromium, offers superior corrosion resistance compared to regular steel. The three main types include:

- Austenitic stainless steel: Non-magnetic, contains around 18% chromium with 8% nickel—common in commercial kitchens and food processing

- Ferritic stainless steel: Lower nickel content, 12-17% chromium—good for automotive trim and appliances

- Martensitic stainless steel: Magnetic and heat-treatable, 11-17% chromium—used for cutting tools and surgical instruments

Copper deserves mention for specialized applications. Its excellent electrical conductivity makes it ideal for wiring and electronics. Copper sheets resist rust because they lack sufficient iron content, and the material becomes stronger when alloyed with other elements.

Material Comparison at a Glance

Use this table to quickly compare material options for your next project:

| Material Type | Quality Indicators | Best Applications | Durability Rating | Cost Tier |

|---|---|---|---|---|

| Mild Carbon Steel (1008, A36) | Excellent formability, consistent thickness, good weld quality | Structural components, machine parts, construction | Moderate (requires coating for corrosion protection) | Low |

| High-Strength Steel (4130) | Superior tensile strength, heat-treatable, uniform grain structure | Aerospace frames, automotive chassis, high-stress components | High | High |

| Stainless Steel (304, 316) | Corrosion resistance, surface finish quality, chromium content verification | Food processing, medical equipment, marine applications | Excellent | Medium-High |

| Aluminum (5052, 6061) | Weight-to-strength ratio, oxide layer integrity, alloy certification | Automotive panels, cookware, electronics enclosures | Good (self-protecting oxide layer) | Medium |

| High-Strength Aluminum (7075) | Tensile strength verification, temper designation, fatigue resistance | Aerospace components, high-performance automotive parts | Good | Medium-High |

| Copper | Conductivity ratings, purity percentage, surface finish uniformity | Electrical wiring, plumbing, decorative architecture | Excellent (no rust) | High |

| Galvanized Steel | Zinc coating thickness, adhesion quality, coverage uniformity | HVAC ductwork, outdoor construction, automotive underbody | Very Good | Low-Medium |

Notice how quality indicators vary by material type. A quality assessment for aluminum focuses on weight-to-strength ratios and temper designations, while stainless steel evaluation prioritizes chromium content and surface finish. Understanding these distinctions prevents you from applying the wrong criteria to your material selection process.

With material types clarified, the next critical factor is thickness—and the gauge numbering system that defines it creates confusion for many buyers.

Gauge and Thickness Selection for Optimal Results

Here's something most suppliers won't explain: the gauge numbering system runs backward from what you'd expect. A higher gauge number actually means thinner metal. Sounds confusing? You're not alone. This counterintuitive system trips up even experienced buyers—and understanding it is essential for selecting quality sheet metal that matches your project requirements.

According to industry specialists, gauge thickness dates back to the 1800s, before universal measurement standards existed. The system originated from wire drawing operations, where each successive draw through a die reduced the wire's diameter. More draws meant thinner wire—and a higher gauge number. This historical quirk persists today, creating a measurement system where 10-gauge steel is substantially thicker than 20-gauge steel.

Decoding Sheet Metal Gauge Numbers

The gauge system presents two challenges that can derail your material selection. First, the increments between gauge numbers aren't equal. Moving from 3-gauge to 4-gauge stainless steel reduces thickness by 0.016 inches, while moving from 24-gauge to 25-gauge only changes thickness by 0.003 inches. Second—and this catches many buyers off guard—gauge numbers mean different thicknesses for different materials.

Consider this example from Ryerson's metal resources:

- 14-gauge stainless steel = 0.0751 inches

- 14-gauge carbon steel = 0.0747 inches

- 14-gauge aluminum = 0.0641 inches

That's a 0.011-inch difference between stainless and aluminum at the same gauge—well outside acceptable tolerances for precision applications. Using the wrong gauge chart can mean ordering material that doesn't fit your design specifications.

Why does this variation exist? As Xometry explains, gauge sizes were developed based on the weight of the sheet for a given material, not the actual dimensional thickness. Since different metals have different densities, the same gauge number translates to different physical measurements.

Matching Thickness to Project Requirements

Selecting the right thickness involves balancing several factors: structural requirements, weight constraints, fabrication processes, and cost. Here's how to think through each consideration:

Structural demands dictate minimum thickness. A 10-gauge metal sheet (approximately 3.4 mm or 0.1345 inches for steel) handles heavy-duty applications like structural components and load-bearing assemblies. Thinner gauges work for enclosures, panels, and decorative elements where strength requirements are lower.

Fabrication processes influence selection too. Quality custom metal fabrication often involves bending, forming, or welding operations. Thicker materials resist deformation better during handling but require more force to form. Thinner gauges bend more easily but risk warping or tearing during aggressive forming operations.

Weight considerations matter for applications where mass affects performance. Automotive and aerospace projects often specify the thinnest gauge that meets structural requirements to minimize weight.

Use this reference table to match common gauge numbers with their actual measurements and typical applications:

| Gauge Number | Steel Thickness (inches) | Steel Thickness (mm) | Stainless Thickness (inches) | Aluminum Thickness (inches) | Recommended Applications |

|---|---|---|---|---|---|

| 10 | 0.1345 | 3.42 | 0.1406 | 0.1019 | Heavy structural components, industrial equipment, chassis parts |

| 12 | 0.1046 | 2.66 | 0.1094 | 0.0808 | Structural brackets, machine guards, heavy enclosures |

| 14 | 0.0747 | 1.90 | 0.0781 | 0.0641 | Automotive panels, equipment housings, moderate-stress components |

| 16 | 0.0598 | 1.52 | 0.0625 | 0.0508 | HVAC ductwork, appliance panels, light structural applications |

| 18 | 0.0478 | 1.21 | 0.0500 | 0.0403 | General sheet metal work, cabinets, decorative trim |

| 20 | 0.0359 | 0.91 | 0.0375 | 0.0320 | Light enclosures, electronics housings, non-structural panels |

| 22 | 0.0299 | 0.76 | 0.0313 | 0.0253 | Flashing, light ductwork, decorative applications |

| 24 | 0.0239 | 0.61 | 0.0250 | 0.0201 | Thin-wall enclosures, prototypes, low-stress applications |

Notice how the same gauge number yields different thicknesses across materials. This is why specifying dimensional thickness in inches or millimeters—rather than gauge alone—reduces ordering errors and ensures you receive material that meets your design requirements.

There's also a practical boundary to keep in mind: most sheet metals have a lower limit around 0.5 mm and an upper limit of 6 mm. According to industry standards, any metal thicker than 6 mm is classified as plate rather than sheet metal.

Making an informed decision regarding sheet metal thickness reduces waste and production costs. Before deciding on the gauge, consider the application, material type, environmental factors, industry standards, weight, and budget.

When working with suppliers—whether you're searching for sheet metal folding near me or evaluating a specialty fabricator—always confirm both the gauge number and the actual dimensional thickness in your specifications. This double-check prevents miscommunication and ensures your quality sheet metal arrives ready for your specific application.

With material types and thickness fundamentals covered, the next consideration is how quality requirements shift across different industries and applications.

Quality Requirements Across Different Industries

Here's what makes evaluating sheet metal tricky: the same material that excels in one application might fail completely in another. A 16-gauge galvanized steel panel perfect for HVAC ductwork could be entirely wrong for precision automotive components. Understanding how quality requirements shift across industries helps you specify materials that actually perform—not just materials that look good on paper.

Most suppliers specialize in one or two sectors, which means their quality benchmarks reflect those specific needs. When you're sourcing across multiple applications—or moving into unfamiliar territory—you need a broader perspective on what "quality" truly means in each context.

Automotive and Precision Component Requirements

The automotive industry demands some of the tightest tolerances in sheet metal fabrication. Why? Because components must fit together precisely across thousands of assemblies, withstand continuous vibration, and perform reliably for years under harsh conditions.

When evaluating sheet metal for automotive applications, focus on these critical quality criteria:

- Dimensional accuracy: Tolerances often fall within ±0.1 mm for stamped components—anything beyond that creates fit issues during assembly

- Surface finish consistency: Visible body panels require uniform finishes free from scratches, dents, or tool marks that show through paint

- Formability without springback: High-strength steels must bend predictably without excessive elastic recovery that distorts final dimensions

- Fatigue resistance: Suspension and chassis components endure millions of stress cycles over a vehicle's lifetime

- Weldability: Materials must join cleanly without porosity or cracking that compromises structural integrity

Precision component manufacturing—whether for automotive, aerospace, or industrial machinery—shares similar demands. Machine shops in Naples, Florida and fabrication facilities nationwide apply these standards when producing parts where failure isn't an option. The key difference from other industries? Every specification gets documented, verified, and traced back to material certifications.

HVAC and Industrial Equipment Standards

HVAC applications prioritize different properties than precision components. Ductwork and equipment housings must resist corrosion, maintain structural rigidity across temperature swings, and often meet fire safety codes.

Quality indicators for HVAC sheet metal include:

- Galvanization quality: Zinc coating thickness and adhesion prevent rust in humid environments—minimum G90 coating (0.90 oz/sq ft) is standard for most ductwork

- Seam integrity: Properly formed seams prevent air leakage that reduces system efficiency

- Gauge consistency: Uniform thickness ensures predictable airflow characteristics and noise performance

- Thermal expansion tolerance: Materials must handle repeated heating and cooling cycles without warping or separating at joints

Industrial equipment adds durability requirements. Enclosures for machinery, control panels, and processing equipment face impacts, chemical exposure, and demanding cleaning protocols. Stainless steel grades like 304 or 316 become essential when corrosive substances are present.

Construction and Architectural Quality Standards

Roofing, flashing, and architectural metalwork face unique challenges: decades of weather exposure, thermal movement, and aesthetic expectations that other industries don't consider.

According to Heather & Little, with over 90 years of experience in architectural sheet metal work, quality construction-grade materials should demonstrate:

- Corrosion resistance appropriate to the environment: Coastal installations require different protection than inland applications—copper and stainless steel perform well in marine environments where galvanized steel struggles

- Finish durability: Painted, powder-coated, or anodized surfaces must resist UV degradation, chalking, and fading over 20+ year lifecycles

- Thermal expansion management: Roofing panels can experience 100°F+ temperature swings—expansion joints and fastening systems must accommodate movement without buckling

- Aesthetic consistency: Visible architectural elements require color matching across production lots and resistance to "oil canning" (wavy surface distortion)

- Code compliance: Fire ratings, wind uplift resistance, and impact ratings vary by jurisdiction and building type

Welding Naples FL contractors and machine shop Naples facilities working on architectural projects understand that these installations become permanent building features. Quality compromises show up as premature failures, leaks, or visible deterioration that reflects poorly on everyone involved.

Industry-Specific Quality at a Glance

Consider how the same quality factor carries different weight across industries:

| Quality Factor | Automotive Priority | HVAC Priority | Architectural Priority | Industrial Priority |

|---|---|---|---|---|

| Dimensional Tolerance | Critical (±0.1 mm) | Moderate (±0.5 mm) | Moderate | Varies by application |

| Surface Finish | Critical for visible parts | Low priority | Critical | Low to moderate |

| Corrosion Resistance | High (underbody parts) | High | Critical | Varies by environment |

| Fatigue Resistance | Critical | Low priority | Moderate | High for moving parts |

| Aesthetic Consistency | Critical for body panels | Not applicable | Critical | Low priority |

| Certification Requirements | Extensive (IATF 16949) | Moderate (UL, SMACNA) | Code-dependent | Application-specific |

This cross-industry perspective reveals why a single supplier's definition of "quality" might not match your specific needs. A fabricator focused primarily on HVAC work applies different standards than one serving the automotive sector—even when using the same base materials.

Understanding these industry-specific requirements prepares you to ask better questions when evaluating suppliers. But quality isn't just about raw materials—it's equally about how those materials get transformed during fabrication.

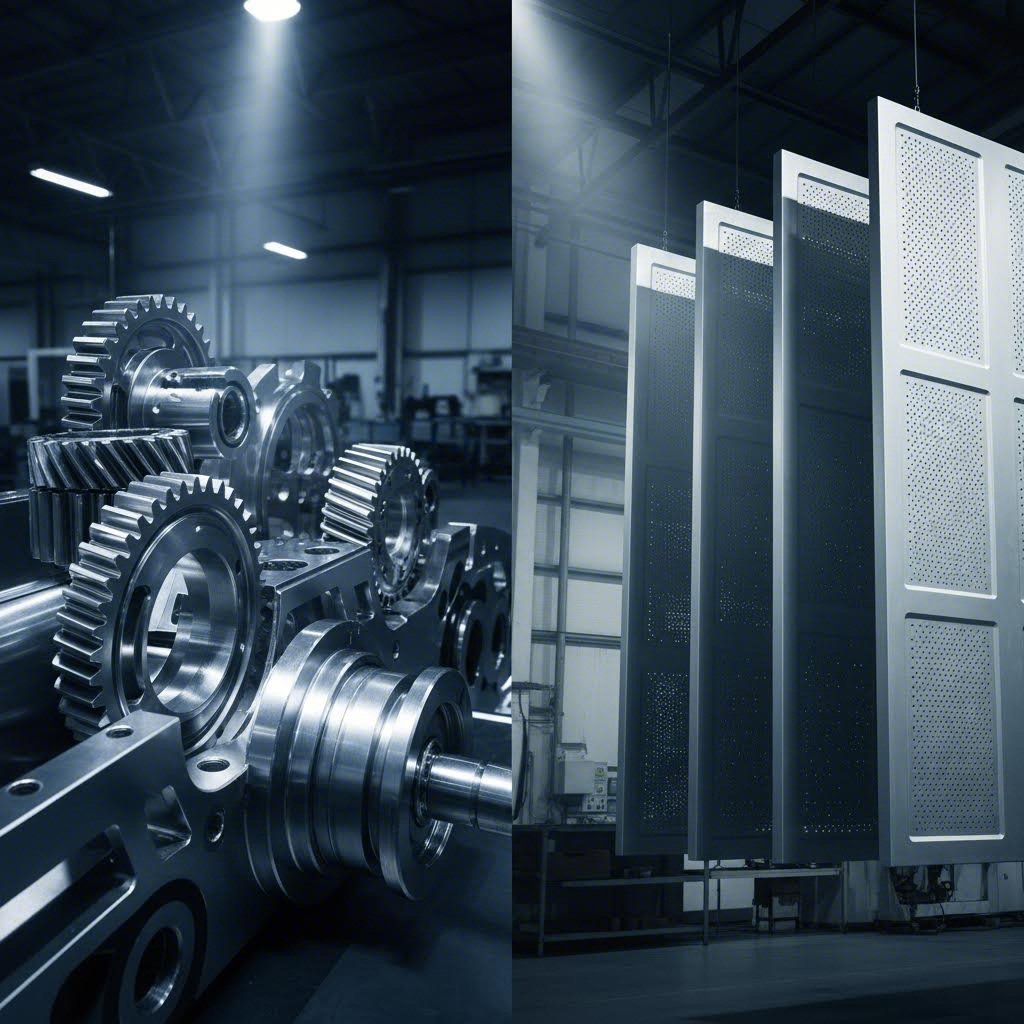

Fabrication Processes That Determine Final Quality

You've selected the right material and specified the correct thickness. Now comes the critical question most suppliers sidestep: how does the fabrication process itself affect your final product? The truth is, even premium sheet metal can become scrap if cutting, bending, forming, or welding processes introduce defects. Understanding the sheet metal fabrication process empowers you to evaluate whether a supplier's methods preserve—or compromise—material quality.

According to Prime Fabrication, quality control in metal fabrication involves monitoring every step to minimize defects, ensure consistency, and produce high-quality finished products. Each fabrication stage presents opportunities for quality enhancement—or quality degradation. Let's break down what happens at each step and what to look for when evaluating finished components.

Precision Cutting and Its Impact on Edge Quality

Cutting is where fabrication begins, and the method used directly affects edge quality, dimensional accuracy, and downstream processing. Modern precision metal cutting services use several technologies, each with distinct quality implications:

- Laser cutting: Delivers unequaled accuracy for intricate shapes with minimal heat-affected zones—ideal for parts requiring tight tolerances

- Plasma cutting: Faster for thicker materials but produces rougher edges that may require secondary finishing

- Waterjet cutting: Eliminates heat distortion entirely, preserving material properties for heat-sensitive applications

- Mechanical shearing: Cost-effective for straight cuts but can cause edge deformation on thicker gauges

Why does cutting method matter so much? As Minifaber explains, laser cutting and bending are consecutive processes—errors during cutting could result in the cancellation of subsequent operations, causing significant waste of time and material. An accurate laser cut results in smooth bending, reducing warping and enhancing finished product quality.

When evaluating cut quality, inspect for these indicators:

- Edge straightness: Clean, burr-free edges indicate proper cutting parameters

- Heat discoloration: Excessive oxidation or bluing suggests improper speeds or power settings

- Dimensional accuracy: Measure multiple points against specifications—variation indicates equipment calibration issues

- Surface contamination: Slag, dross, or residue affects subsequent processes like welding and finishing

Forming Techniques That Preserve Material Integrity

Once cut to shape, sheet metal typically undergoes forming operations—bending, rolling, stamping, or drawing—to achieve three-dimensional geometry. These metal forming techniques apply controlled force to reshape material without removing any of it. The challenge? Maintaining material integrity while achieving precise angles and curves.

According to New Mexico Metals LLC, different sheet metal processing techniques help achieve desired shapes, and a skilled workforce knows when each method would be most effective. Here's how common forming processes impact quality:

- Bending: A die and punch bend metal into V-shapes, U-shapes, or custom angles. Quality depends on proper tooling selection, accurate bend allowance calculations, and consistent material properties. Springback—the tendency of metal to partially return to its original shape—must be anticipated and compensated for.

- Hemming/Curling: Rough or uneven edges get folded onto themselves (open, closed, or teardrop-shaped hems). This strengthens edges and eliminates sharp surfaces that could cause injury or material damage.

- Ironing: Achieves uniform thickness throughout the sheet metal. When material is too thick for an application, ironing attains suitable consistency for further processing.

- Deep drawing: Transforms flat sheets into cup-shaped or box-shaped components. Material stretches significantly, making ductility and grain orientation critical to preventing tears or wrinkles.

Quality checkpoints for formed components include:

- Angle accuracy: Verify bend angles against specifications using precision measuring tools

- Surface cracking: Inspect outer bend surfaces for micro-cracks indicating excessive strain

- Dimensional consistency: Check that formed dimensions match across multiple parts in a production run

- Springback compensation: Confirm that final angles account for elastic recovery

Welding Quality and Joint Integrity

Welding joins separate metal pieces into unified assemblies. According to industry quality standards, welding is a critical process that ensures the robustness of all joints. Evaluating weld quality requires examining penetration depth, weld bead quality, and alignment.

The sequential steps for ensuring weld quality include:

- Pre-weld preparation: Surfaces must be clean, properly fitted, and free from contaminants that cause porosity

- Welding parameter control: Correct amperage, voltage, travel speed, and shielding gas ensure consistent results

- Visual inspection: Identifies surface anomalies like undercut, overlap, spatter, or incomplete fusion

- Non-destructive testing (NDT): Ultrasonic testing and radiographic testing provide comprehensive evaluation of internal weld integrity

- Post-weld treatment: Stress relief, grinding, or finishing operations address residual stresses and surface imperfections

Visual inspection serves as the critical first mechanism to identify potential anomalies, but supplementary NDT techniques offer more thorough analysis for structural applications where failure isn't acceptable.

Finishing Processes and Final Quality

Surface finishing completes the fabrication cycle. Whether the goal is corrosion protection, aesthetic appeal, or functional performance, finishing treatments significantly impact how products perform in service.

Common finishing options include:

- Powder coating: Durable, uniform finish with excellent corrosion resistance

- Painting: Versatile color options with varying durability levels

- Anodizing: Electrochemical process that creates protective oxide layers on aluminum

- Plating: Applies thin metallic coatings (zinc, chrome, nickel) for protection or appearance

- Passivation: Chemical treatment that enhances corrosion resistance on stainless steel

How to Evaluate Fabrication Quality Yourself

Imagine receiving parts from a new supplier. How do you assess whether fabrication quality meets your standards? Follow this evaluation sequence:

- Visual inspection: Examine surfaces for scratches, dents, discoloration, or contamination—defects visible to the naked eye indicate process control issues

- Dimensional verification: Measure critical dimensions against specifications using calipers, micrometers, or CMM equipment

- Edge quality assessment: Check cut edges for burrs, roughness, or heat damage

- Bend inspection: Verify angles, check for cracking, and confirm consistency across multiple parts

- Weld examination: Look for uniform bead appearance, proper penetration, and absence of defects

- Finish evaluation: Assess coating adhesion, uniformity, and thickness compliance

Quality control is crucial in sheet metal processing to ensure products meet specified standards and customer requirements. It includes detecting defects, correcting them, and manufacturing only quality products.

The shift toward automation has transformed fabrication quality. As industry sources note, robotic systems and CNC controls reduce human intervention, minimize fatigue-related errors, and boost overall workplace safety. Components produced through automated systems increasingly meet design specifications and tolerances, satisfying customers who demand precision and consistency.

When working with a Pomper Sheet Metal Inc supplier or any fabrication partner, understanding these processes helps you ask informed questions about equipment, capabilities, and quality control procedures. But how do these quality investments translate to pricing—and what hidden costs come with cutting corners?

Cost Factors That Influence Sheet Metal Quality

Here's a question suppliers rarely answer directly: why does premium sheet metal cost more—and is it actually worth the investment? The relationship between quality and pricing isn't as straightforward as "you get what you pay for." Understanding the specific factors that drive costs helps you make smarter purchasing decisions and avoid the expensive trap of false economy.

According to Sunlink Metal, choosing the lowest quote may result in rework, delays, or structural issues, while overpaying unnecessarily reduces project profitability. The key is finding the right balance—and that starts with understanding what you're actually paying for.

Why Premium Materials Command Higher Prices

When you compare quotes from different suppliers, the price gap between standard and premium sheet metal can seem puzzling. What justifies the difference? Several interconnected factors determine sheet metal pricing:

- Material grade and composition: Higher-grade alloys contain more refined elements and undergo stricter manufacturing controls. For example, 304 stainless steel costs more upfront compared to mild steel or aluminum because it offers superior durability, particularly in outdoor or corrosive environments.

- Thickness and gauge consistency: According to industry specialists, thicker materials take longer to cut, bend, and weld, directly impacting production time and cost. Tighter thickness tolerances also require more precise manufacturing processes.

- Finish type and treatment: A raw aluminum part might cost significantly less than the same part with a powder coat finish. While this may seem like a steep jump, powder coating offers better long-term durability and a cleaner finish—making it worthwhile for customer-facing products.

- Certification requirements: Materials carrying ASTM, ISO, or industry-specific certifications undergo additional testing and documentation. This verification adds cost but provides traceability and quality assurance that generic materials lack.

- Fabrication complexity: According to TMCO, a part's geometry significantly affects how long it takes to fabricate. Components with multiple bends, intricate cutouts, or tight tolerances require more programming, setup, and inspection time.

- Production volume: A single prototype or small batch run costs more per unit than a large-volume order because setup and programming time are spread across fewer parts.

There's also a factor many buyers overlook: supplier purchasing power. Companies buying thousands of tons of material at a time can pass on savings to customers. Your local shop might price aluminum higher simply because they lack the volume to negotiate bulk rates.

Hidden Costs of Choosing Low-Quality Sheet Metal

The cheapest quote often becomes the most expensive decision. How? Low-quality materials and fabrication create downstream costs that don't appear on the initial invoice.

According to metal fabrication specialists, a fabricator offering very low pricing may be compensating through less experienced labor, poor dimensional control, minimal QA checks, weak welding practices, or inadequate finishing. These shortcuts lead to:

- Rework and rejection costs: Parts that don't meet specifications require correction or replacement—doubling your material and labor investment

- Installation delays: Components that don't fit properly cause on-site problems, extending project timelines and labor hours

- Premature replacement: Materials without adequate corrosion resistance or structural integrity fail earlier than expected, requiring complete replacement rather than the expected service life

- Coating and treatment expenses: Choosing mild steel over stainless to save money may require protective coatings that eliminate the initial savings—and those coatings need periodic maintenance

- Reputation damage: Failed components reflect poorly on your project or product, affecting customer confidence and future business

Consider the material selection question this way: the right question isn't "Which is cheapest?" but "Which material is suitable for the environment and lifespan?" Choosing incorrectly leads to corrosion, structural degradation, and early replacement.

The most cost-effective fabrication partner isn't necessarily the one with the lowest quote—it's the one who delivers value through accuracy, reliability, and long-term partnership.

Making Smart Cost-Quality Tradeoffs

So how do you balance budget constraints with quality requirements? Start by identifying where quality matters most for your specific application:

- Visible surfaces: Customer-facing components justify investment in better finishes and surface quality

- Structural elements: Load-bearing or safety-critical parts demand premium material grades and tighter tolerances

- Environmental exposure: Outdoor or corrosive environments require appropriate corrosion protection—stainless steel's rust-resistant properties can save you from annual maintenance hassles

- Fit-critical dimensions: Parts that must interface precisely with other components need consistent gauge accuracy

For non-critical applications, standard materials with adequate quality may deliver the best value. The goal is matching investment to actual requirements—neither over-specifying nor cutting corners where performance matters.

Understanding these cost factors positions you to evaluate quotes more effectively. But how do you verify that a supplier actually delivers the quality they claim? That's where certifications and standards come into play.

Certifications and Standards That Validate Quality

How do you know a supplier's quality claims aren't just marketing speak? The answer lies in third-party certifications—independent verification that a manufacturer's processes, materials, and outputs meet established standards. When you understand what these certifications actually mean, you can separate genuinely quality-focused fabricators from those making empty promises.

According to Pacific Certifications, sheet metal product manufacturers support critical industries including automotive, aerospace, industrial machinery, consumer appliances, electronics, renewable energy, HVAC, and construction. With precision, durability, corrosion resistance, safety standards, and compliance requirements rising across global supply chains, ISO certifications provide manufacturers with operational discipline, documented quality processes, and competitive trust.

Industry Certifications That Guarantee Quality Standards

Not all certifications carry equal weight for every application. Understanding which standards apply to your industry helps you evaluate whether a supplier's credentials match your requirements. Here are the key metal fabrication certifications you'll encounter:

- ISO 9001: The foundational quality management system (QMS) standard recognized globally. It ensures products meet customer and regulatory requirements consistently. For sheet metal manufacturers, this certification demonstrates commitment to documented processes, continuous improvement, and customer satisfaction.

- ISO 14001: Addresses environmental management systems. Manufacturers holding this certification demonstrate efficient resource use, waste reduction, and adherence to environmental regulations—increasingly important for companies with sustainability requirements.

- ISO 45001: Focuses on occupational health and safety management. This standard ensures safe working conditions through proactive risk management—particularly relevant in sheet metal facilities where cutting, welding, and forming operations present inherent hazards.

- ISO 3834: Specifically addresses quality requirements for welding processes. According to industry sources, welding is integral to sheet metal fabrication, and this standard ensures high-quality welding processes critical for maintaining structural integrity.

- ISO 1090: Applies specifically to steel and aluminum structural fabrication, ensuring compliance with safety and performance requirements for construction applications.

- AWS D1.1: The American Welding Society's standard for structural welding. According to AZ Metals, it outlines requirements for welding processes, materials, and welder qualifications for structural steel components used in bridges, buildings, and infrastructure.

- ASME Section IX: Covers welding and brazing standards for vessels, pipes, and components facing high pressure—essential for fabricators working on boilers, pressure vessels, and related equipment.

Beyond process certifications, look for material certifications from organizations like ASTM (American Society for Testing and Materials) that verify specific material properties meet documented specifications.

What IATF 16949 Means for Precision Components

If you're sourcing quality sheet metal for automotive applications, one certification stands above others: IATF 16949. This isn't just another quality badge—it's the automotive industry's definitive quality assurance sheet metal standard.

According to Xometry, the International Automotive Task Force (IATF) maintains this framework using the ISO 9001 quality management system as its foundation, but tailored specifically for automotive manufacturers and suppliers. The IATF 16949 certification spans an impressive range of topics and doubles down on creating consistency, safety, and quality across automotive products.

What makes IATF 16949 different from general ISO standards?

- Automotive-specific focus: While ISO 9001 applies broadly across industries, IATF 16949 distills requirements specifically relevant to automotive manufacturing challenges

- Binary certification: A company either meets the standard or doesn't—there are no partial certifications or variations

- Defect prevention emphasis: The standard prioritizes limiting defects in products, which also reduces waste and wasted effort throughout the supply chain

- Supply chain requirements: While not legally mandated, suppliers and OEMs often won't collaborate with manufacturers lacking this certification

For precision automotive components like chassis parts, suspension systems, and structural assemblies, IATF 16949 certification signals that a manufacturer maintains the rigorous quality controls these applications demand. Companies like Shaoyi (Ningbo) Metal Technology demonstrate this commitment through their IATF 16949-certified operations, delivering custom metal stamping parts and precision assemblies for automotive manufacturers who cannot compromise on quality.

How Certifications Translate to Real-World Quality

Certifications aren't just paperwork—they represent documented systems that directly impact the products you receive. According to industry experts, the most important aspect in metal fabrication is maintaining quality. Compromising is never a choice, as millions of future projects depend upon it.

When a manufacturer holds relevant ISO sheet metal standards, you can expect:

- Documented processes: Every production step follows established procedures that can be audited and verified

- Traceability: Materials and processes can be traced back through the supply chain

- Continuous improvement: Certified organizations must demonstrate ongoing efforts to enhance quality

- Regular audits: Third-party assessments verify ongoing compliance—not just initial certification

- Corrective action systems: When issues arise, formal processes ensure root causes are identified and addressed

The global sheet metal fabrication market reflects this certification trend. According to industry data, over 60 percent of leading fabrication suppliers worldwide hold at least ISO 9001 certification, while adoption of ISO 3834 welding certification has surged in automotive and renewable-energy fabrication segments.

Metal fabricators have a huge responsibility for their work, maintaining quality, and employees. Certifications and standards aim to ensure that metal fabricators maintain safety and quality while remaining competitive in the market.

Understanding these certifications gives you a powerful tool for supplier evaluation. But certifications alone don't tell the complete story—you also need practical methods for assessing whether a supplier truly delivers on their quality promises.

How to Evaluate and Select Quality Sheet Metal Suppliers

Certifications tell you what a supplier claims to deliver. But how do you verify those claims before committing to a partnership? The sheet metal supplier evaluation process separates buyers who get consistent results from those who learn expensive lessons through trial and error. Most suppliers won't walk you through this vetting process—because thorough evaluation exposes the gaps between marketing promises and actual capabilities.

According to York Sheet Metal, satisfying your customers' needs should be at the top of your list—but does your sheet metal supplier think the same way? If your supplier doesn't share your priorities, it's time to re-evaluate who you're getting your materials from. Let's build a systematic approach to choosing a metal fabrication company that actually delivers.

Key Questions to Ask Potential Suppliers

Before placing your first order, the right questions reveal whether a fabricator can meet your requirements. According to Ryerson Advanced Processing, many suppliers present themselves well during initial evaluation—but it's only when you delve deeper that you discover whether they're truly the right fit.

Here are the essential questions that separate quality-focused suppliers from the rest:

- Are you viable long-term? How long has the company been in business? Do they invest in modern equipment and technology? A fabricator that stays ahead of industry developments signals ongoing commitment to quality.

- Can you handle my specific requirements? Anyone can claim capability—but can they demonstrate experience with your material types, tolerances, and applications? Ask for examples of similar projects.

- What's your quoting turnaround? Responsiveness during the quote phase predicts responsiveness during production. Quality-focused suppliers like Shaoyi Metal Technology offer 12-hour quote turnaround times, demonstrating systems designed for efficiency rather than delays.

- Do you offer DFM support? Design for manufacturability consultation helps optimize your designs before production begins—reducing costs and preventing quality issues. Comprehensive DFM support indicates a partner invested in your success, not just order fulfillment.

- What are your prototyping capabilities? Can they produce samples quickly for validation? Rapid prototyping—some suppliers deliver in as few as 5 days—allows you to verify quality before committing to production volumes.

- How do you handle the supply chain? According to industry sources, the ability to pivot at a moment's notice demonstrates the extra value quality fabricators bring. Ask about material sourcing, inventory management, and contingency planning.

- What quality control measures do you employ? According to Ryerson, poor quality can manifest in imprecise specs, sloppy workmanship, or careless logistics. Ask specifically about inspection points, testing methods, and documentation.

The answers to these questions reveal more than capability—they expose priorities. A supplier who struggles to answer or provides vague responses likely lacks the systems that quality metal supplier criteria demand.

A Step-by-Step Supplier Evaluation Process

Structured evaluation prevents emotional decisions and ensures consistent comparison across potential partners. Follow this sequence for thorough sheet metal vendor selection:

- Define your requirements clearly: Document material specifications, tolerances, volume expectations, and delivery schedules before contacting suppliers. Ambiguous requirements invite mismatched quotes.

- Request detailed quotes from multiple suppliers: Compare not just pricing but what's included—setup costs, tooling, finishing, inspection, and shipping. According to Fab Metal, a vague RFQ process leaves room for hidden costs and confusion.

- Verify certifications independently: Don't take claims at face value. Request current certification documents and verify their validity with issuing organizations.

- Assess communication quality: Track response times and clarity during the quoting process. According to York Sheet Metal, when you call or email your supplier, how long does it take for them to get back to you? Communication lines should go both ways.

- Request sample parts or facility tours: Physical evidence beats promises. Inspect sample quality against your specifications, or visit the facility to assess equipment, organization, and workforce competency.

- Check references from similar customers: Ask for contacts in your industry segment. According to industry experts, you can find out a lot about supplier quality by what other customers say.

- Start with a small order: Test the relationship with a limited initial project before committing to large volumes. Evaluate delivery accuracy, part quality, and problem resolution.

- Establish clear expectations and metrics: Document quality standards, acceptable defect rates, and escalation procedures before scaling up production.

Red Flags That Indicate Quality Compromises

Knowing what to avoid proves just as valuable as knowing what to seek. According to Fab Metal, choosing the right metal fabrication vendor is not just about price or proximity—it's about finding a partner you can trust to deliver consistent, high-quality results at scale. Watch for these warning signs:

- Poor communication or delayed responses: If a vendor takes days to respond or gives vague answers, that's your first clue something is amiss. A reliable partner should be transparent, provide fast turnaround on RFQs, and speak clearly about timelines, tolerances, and capabilities.

- No investment in equipment or technology: Outdated equipment or lack of automation often means slower lead times, inconsistent output, and limited scalability. You want a shop that evolves with the industry.

- One-off mindset instead of scalable support: A good vendor isn't just there for your prototype. They should be able to scale with you, growing from one-off needs into repeat, high-volume production.

- Disorganized facilities: A chaotic shop floor often reflects chaotic processes. According to industry experts, disorganization creates risk—not just for safety, but for timelines and final quality.

- Unclear pricing or hidden costs: When money and materials are on the line, clarity is non-negotiable. Suppliers who can't break down costs clearly may be hiding quality shortcuts.

- Reluctance to take on challenges: According to York Sheet Metal, a true partnership requires both trust and the ability to take risks. Find a supplier willing to tackle new materials or technologies alongside you.

- No accountability for mistakes: Accountability is the foundation of trust. When things don't go as planned, does your supplier take responsibility and work to improve? If not, quality will never be consistent.

The certainty that a stronger supplier provides to your supply chain beats aggressive promises and missed deliveries. Look for partners who commit to realistic dates and deliver what they promise.

What Quality-Focused Capabilities Look Like

Understanding red flags is essential—but recognizing genuinely quality-focused operations matters equally. Here's what distinguishes excellent suppliers:

| Capability Area | Standard Supplier | Quality-Focused Supplier |

|---|---|---|

| Quote Turnaround | 3-5 business days | Same day to 12 hours |

| Prototyping Speed | 2-4 weeks | 5-day rapid prototyping available |

| DFM Support | Limited or extra cost | Comprehensive and integrated |

| Production Scalability | Fixed capacity | Automated systems for volume flexibility |

| Communication | Reactive, delayed | Proactive updates, rapid response |

| Quality Documentation | Available on request | Standard with every shipment |

Manufacturers demonstrating these capabilities signal investment in systems that produce consistent results. For automotive applications specifically, suppliers offering rapid prototyping, comprehensive DFM consultation, and IATF 16949 certification—like those focused on chassis, suspension, and structural components—represent the quality standard other industries can benchmark against.

The goal isn't finding the cheapest option—it's finding a partner whose capabilities match your requirements and whose priorities align with yours. According to industry veterans, your customers don't tolerate poor quality, and you can't either from your sheet metal supplier. Find a supplier that takes quality just as seriously as you do, and you won't have to worry about substandard parts disrupting your operations.

Armed with this evaluation framework, you're now equipped to assess any supplier's claims against objective criteria—transforming the sheet metal sourcing process from guesswork into informed decision-making.

Frequently Asked Questions About Quality Sheet Metal

1. What defines quality in sheet metal fabrication?

Quality sheet metal is defined by four key pillars: material composition verified through ASTM or ISO certifications, gauge accuracy ensuring consistent thickness across the entire sheet, finish uniformity free from defects like porosity or corrosion spots, and structural integrity that resists warping during processing. Premium materials exceed baseline specifications for tensile strength, malleability, and corrosion resistance—properties that directly impact how well finished products handle stress and environmental challenges over time.

2. How do I choose the right sheet metal gauge for my project?

Selecting the correct gauge requires balancing structural demands, weight constraints, and fabrication processes. Remember that gauge numbers run counterintuitively—higher numbers mean thinner metal. Additionally, the same gauge number represents different thicknesses across materials: 14-gauge stainless steel measures 0.0781 inches while 14-gauge aluminum is only 0.0641 inches. Always specify both gauge number and actual dimensional thickness in your orders to prevent costly errors.

3. What certifications should I look for in a sheet metal supplier?

Key certifications include ISO 9001 for quality management systems, ISO 3834 for welding quality, and AWS D1.1 for structural welding standards. For automotive applications, IATF 16949 certification is essential—it represents the industry's definitive quality standard with emphasis on defect prevention and supply chain requirements. Manufacturers like Shaoyi Metal Technology demonstrate this commitment through IATF 16949-certified operations for precision automotive components.

4. Why does quality sheet metal cost more than standard stock?

Premium sheet metal pricing reflects several factors: higher-grade alloys with refined elements, tighter thickness tolerances requiring precise manufacturing, specialized finishes like powder coating for durability, and certification requirements involving additional testing and documentation. However, choosing cheaper materials often leads to hidden costs including rework expenses, installation delays, premature replacement, and reputation damage that far exceed initial savings.

5. How can I evaluate a sheet metal supplier before placing an order?

Start by assessing quote turnaround times—quality-focused suppliers like Shaoyi offer 12-hour responses. Ask about DFM support, prototyping capabilities (some deliver in 5 days), and production scalability. Verify certifications independently, inspect sample parts against specifications, and check references from similar customers. Watch for red flags like delayed communication, outdated equipment, unclear pricing, or reluctance to take accountability for quality issues.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —